Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-43-040-001 Angle Gearbox Driven Gearshaft Assembly - Disassemble The Gearshaft Assembly, Disassembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of the threaded parts and parts with an interference fit. Let the parts soak before removal.

Discard all rubber seal rings, cotter pins and seal washers removed in this procedure.

In this TASK it can be necessary to refer from one illustration to other illustrations. If this is necessary, the illustrations are identified by the 4th and 5th element numbers only - for example Fig 990-017.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard wrench | LOCAL | Standard wrench | ||

| Swivel vise | LOCAL | Swivel vise | ||

| IAE 1F10121 Puller | 0AM53 | IAE 1F10121 | 1 | |

| IAE 1F10119 Wrench | 0AM53 | IAE 1F10119 | 1 | |

| IAE 1F10115 Ring | 0AM53 | IAE 1F10115 | 1 | |

| IAE 1F10116 Base | 0AM53 | IAE 1F10116 | 1 | |

| IAE 1F10110 Stud | 0AM53 | IAE 1F10110 | 3 | |

| IAE 1F10114 Hydraulic cylinder | 0AM53 | IAE 1F10114 | 1 | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10117 Pusher | 0AM53 | IAE 1F10117 | 1 | |

| IAE 1F10259 Puller | 0AM53 | IAE 1F10259 | 1 | |

| IAE 1P16539 Fixture | 0AM53 | IAE 1P16539 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | X222X | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

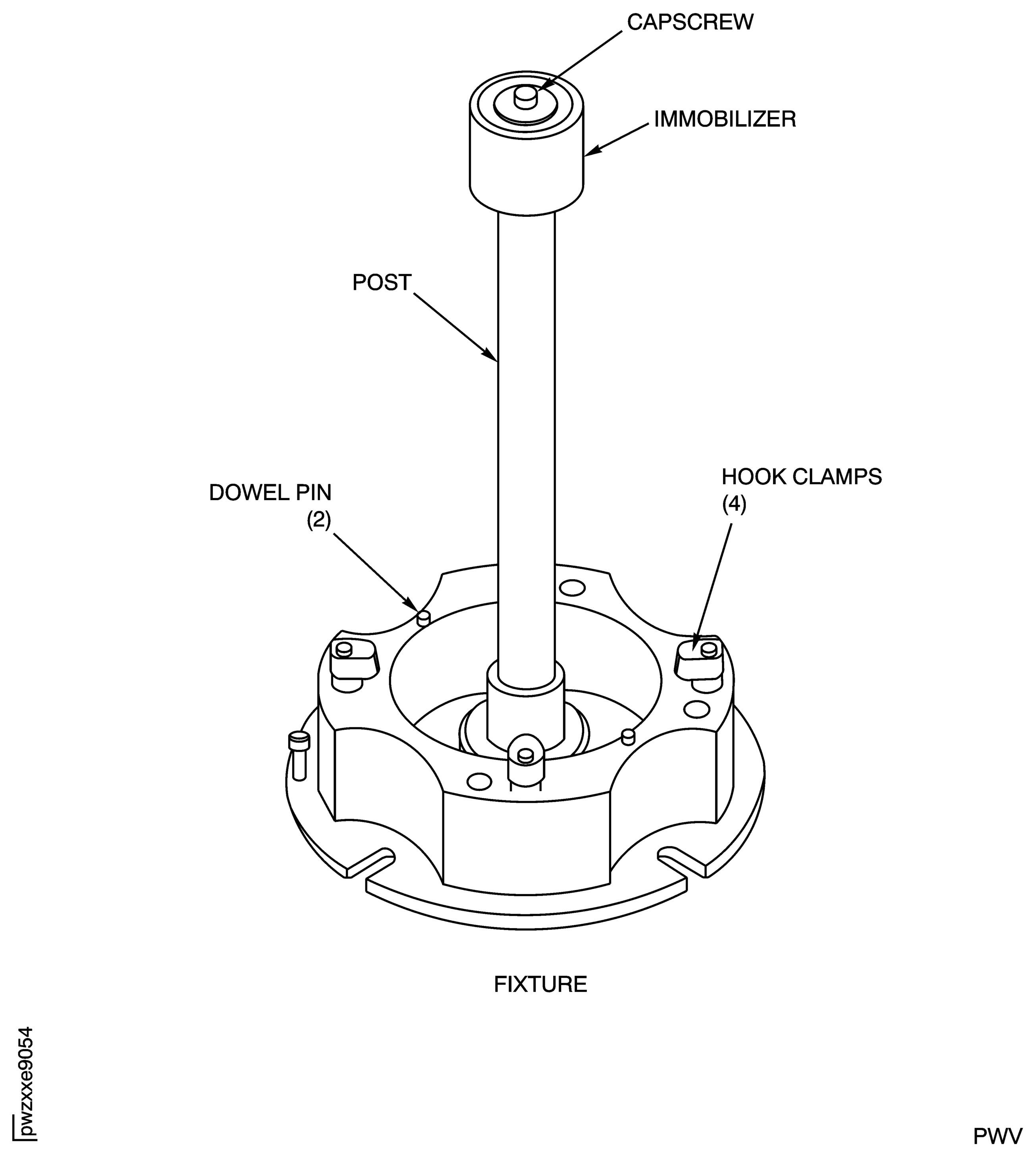

Install the angle gearbox driven gear and layshaft assembly on IAE 1P16539 Fixture 1 off with the hub to the top.

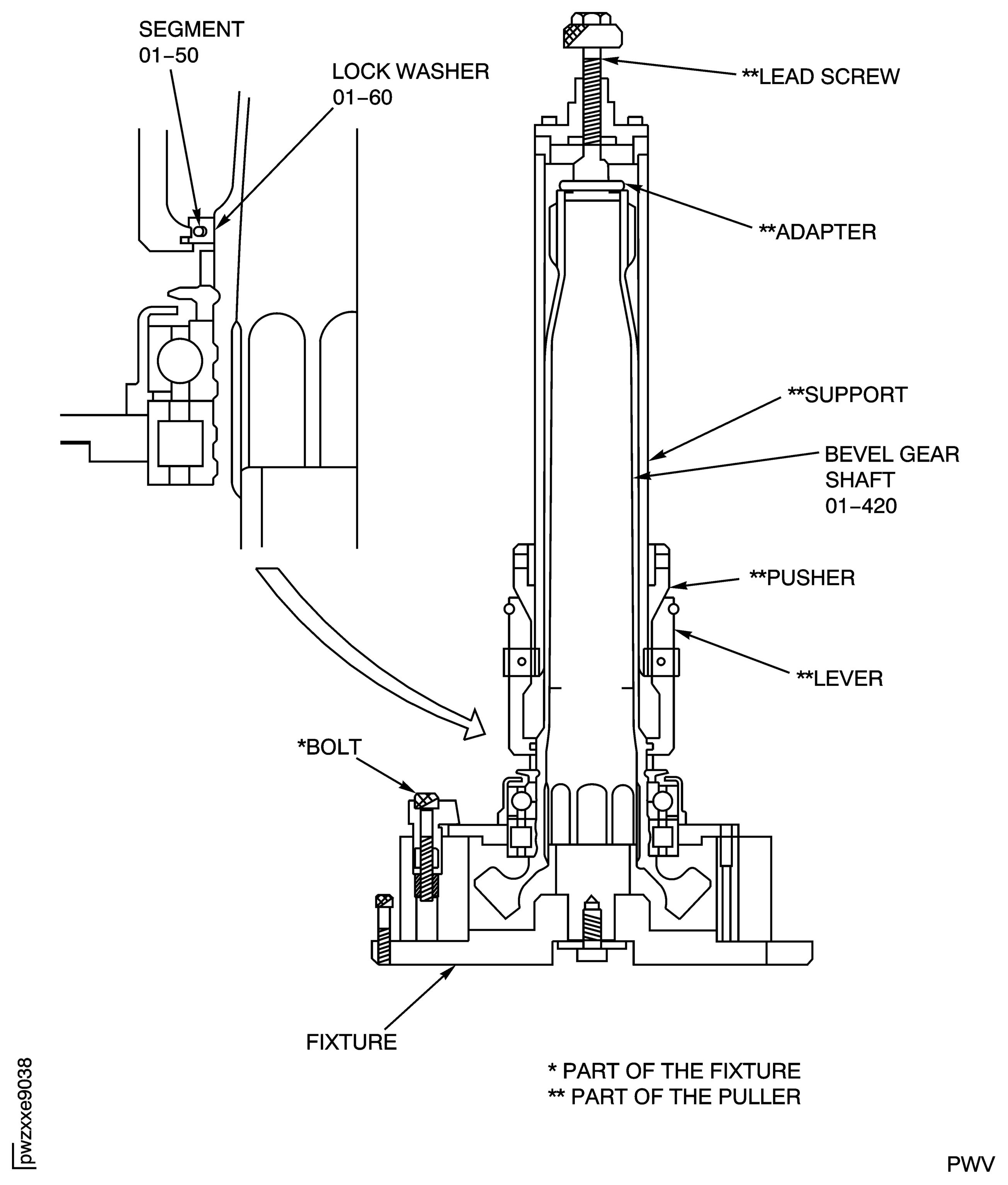

Install IAE 1F10121 Puller 1 off on the lock washer.

SUBTASK 72-60-43-040-051 Remove the Lock Washer and the Segment from the Retaining Nut

Install IAE 1F10119 Wrench 1 off over the bevel gearshaft.

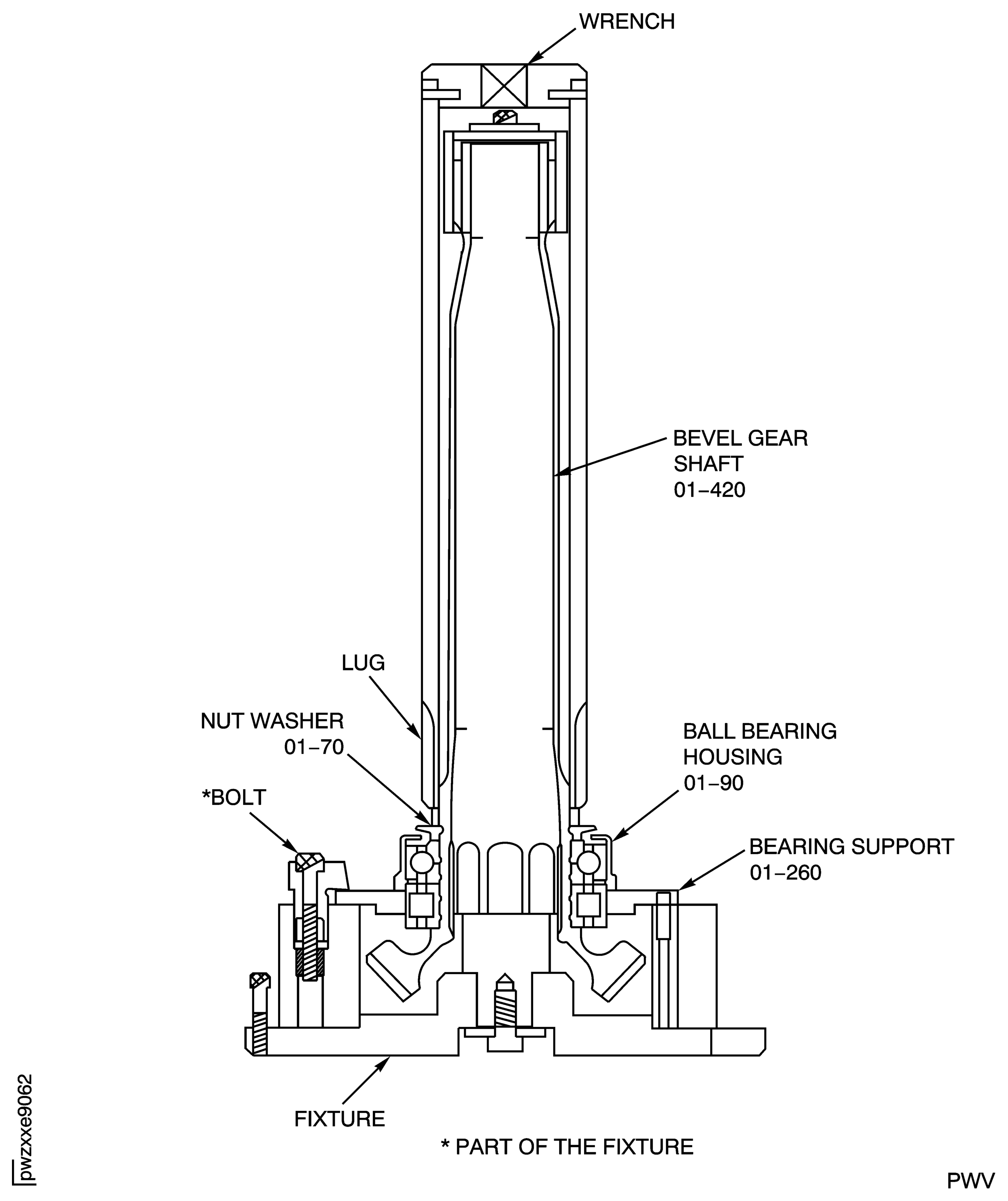

SUBTASK 72-60-43-040-052 Remove the Nut Washer from the Bevel Gearshaft

Refer to Figure.

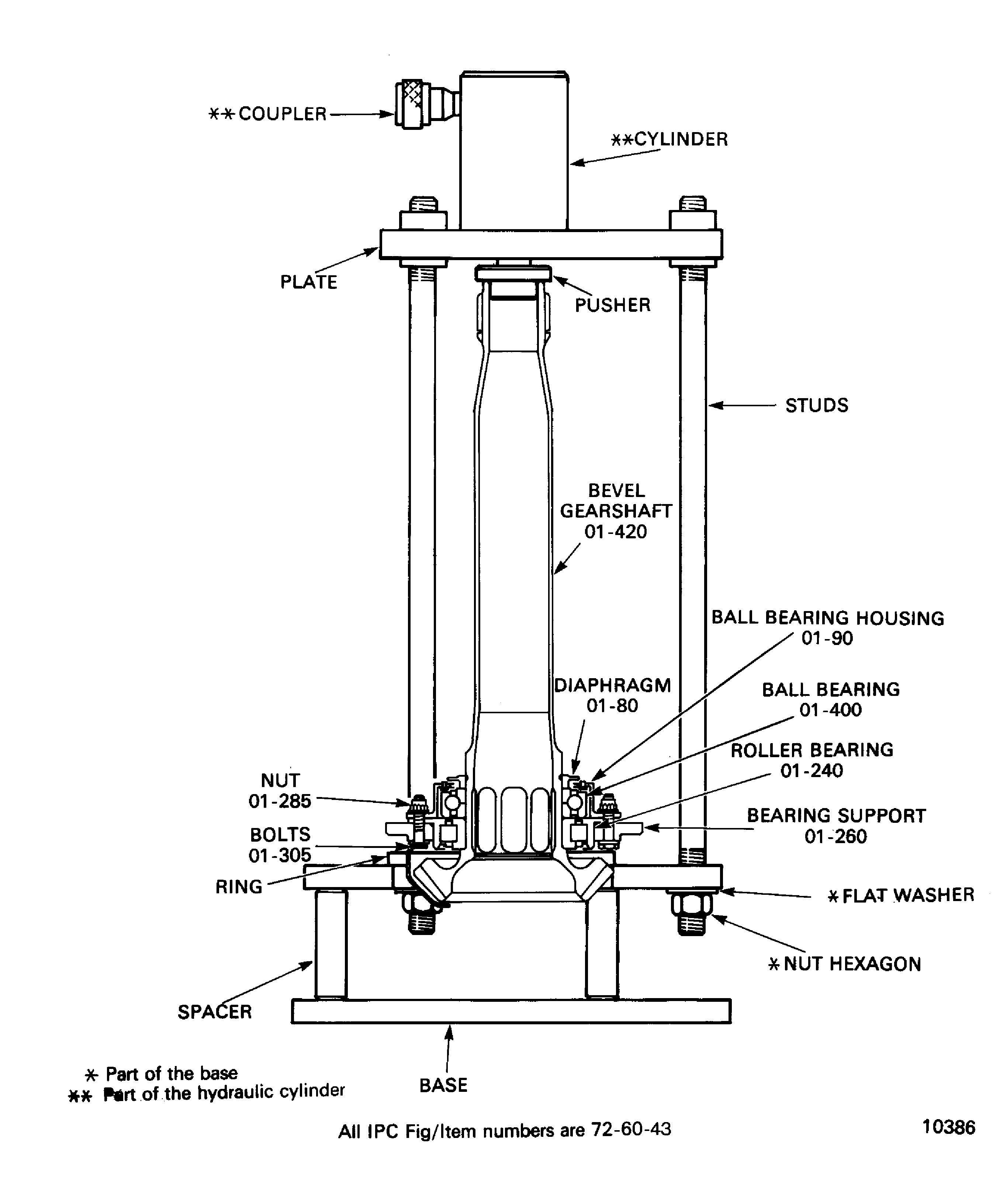

Put IAE 1F10115 Ring 1 off below the inner race of the roller bearing on the opposite side of the oil shroud. Make sure that the oil shroud is free from the ring.

Install the ring and the bevel gearshaft on IAE 1F10116 Base 1 off with the spiral bevel gear to the bottom.

Remove the four nuts which loosend in Step, from the bolts. Remove the free bolt and the flat washer from the bearing support.

Install IAE 1F10110 Stud 3 off on the base. Attach with the flat washers and the hexagon nuts.

Install IAE 1F10117 Pusher 1 off in to the ID of the bevel gearshaft.

Install the plate of IAE 1F10114 Hydraulic cylinder 1 off over the three studs. Make sure that the hydraulic cylinder is seated to push.

Attach IAE 1F10026 Hydraulic hand pump 1 off to the coupler of the hydraulic cylinder.

SUBTASK 72-60-43-040-054 Remove the Bearings from the Bevel Gearshaft

Refer to Figure.

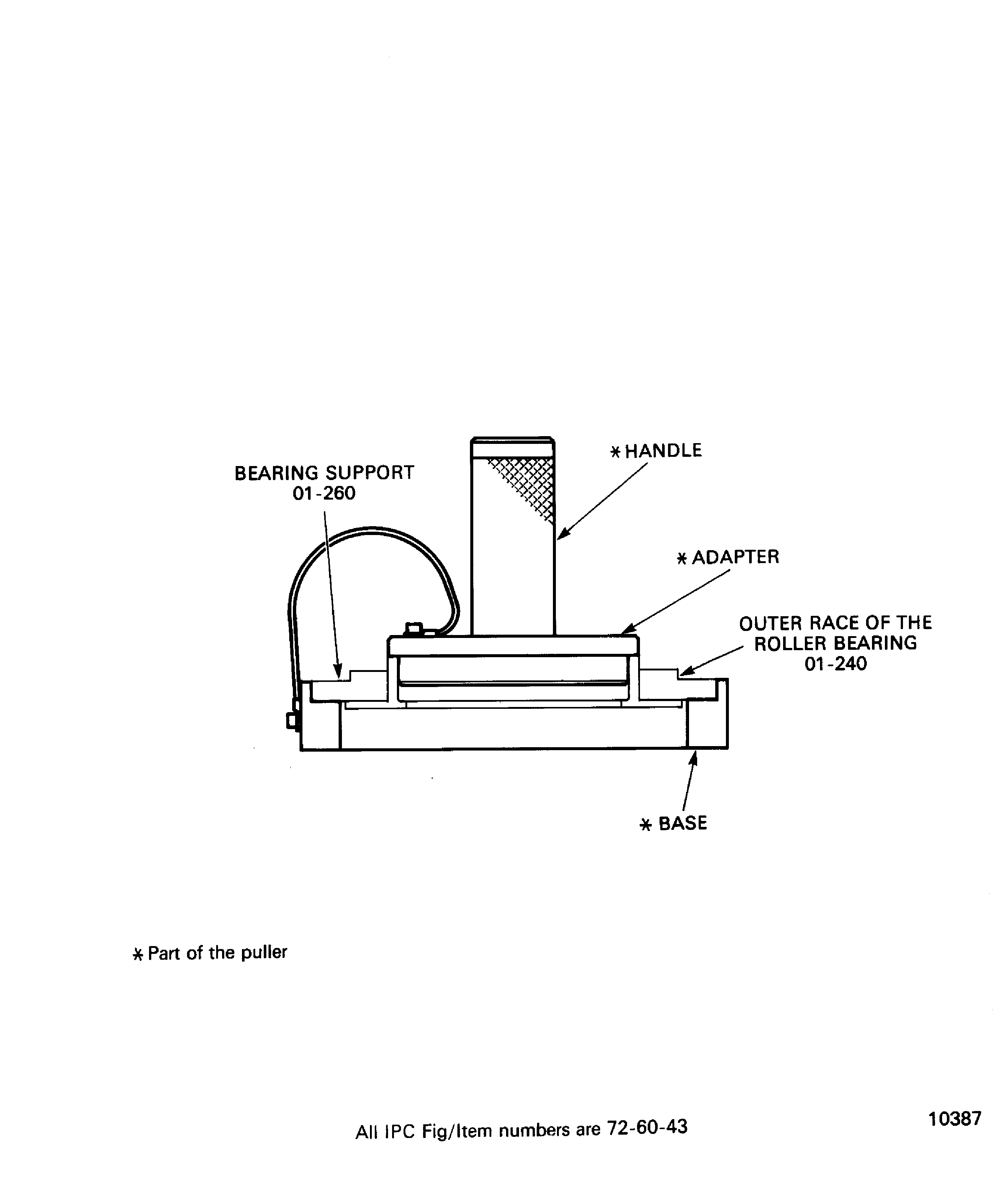

Install the bearing support on the base of IAE 1F10259 Puller 1 off with the mounting flange of the outer race of the roller bearing to the bottom.

SUBTASK 72-60-43-040-055 Remove the Outer Race of the Roller Bearing from the Bearing Support

Figure: Remove the Lock Washer and the Segment from the Nut Washer

Remove the Lock Washer and the Segment from the Nut Washer

Figure: Remove the Nut Washer from the Bevel Gearshaft

Remove the Nut Washer from the Bevel Gearshaft

Figure: Remove the Bearings from the Bevel Gearshaft

Remove the Bearings from the Bevel Gearshaft

Figure: Remove the Outer Race of the Roller Bearing from the Bearing Support

Remove the Outer Race of the Roller Bearing from the Bearing Support

Figure: Remove the Bevel Gearshaft from the Fixture

Remove the Bevel Gearshaft from the Fixture