Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-22-48-700-101 P2/T2 Sensor Air Tube - Do A Pressure Test, Testing-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha-variants refer to the IPC.

The P2/T2 tube must be cleaned and inspected before this pressure test, refer to Cleaning-000 TASK 73-22-48-100-100 and Inspection-000 TASK 73-22-48-200-100.

The Test Equipment Specification

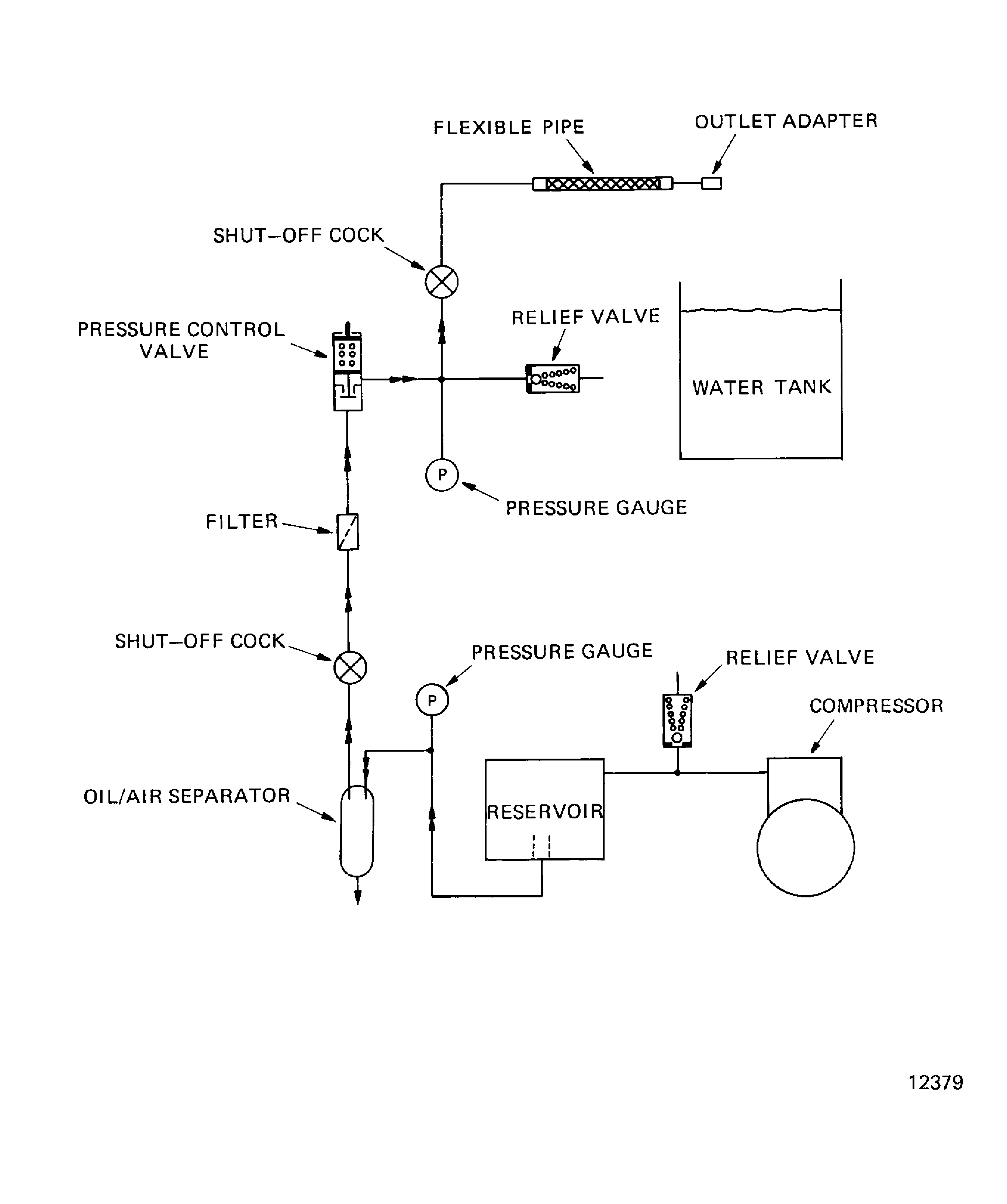

To do the test on the P2/T2 tube use equipment equivalent to that shown in Figure.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Pneumatic pressure testing rig | LOCAL | Pneumatic pressure testing rig | ||

| MS21913-4 Blanking plug | 0AM53 | MS21913-4 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Install the MS21913-4 Blanking plug to one end of the tube.

SUBTASK 73-22-48-780-051 Prepare the Tube (01-020) for the Pneumatic Pressure Test

Connect the tube to the outlet of the Pneumatic pressure testing rig.

Put a pressure of 50 psi (350 kPa) in the tube.

Put the tube in the water tank.

Let the pressure stay in the tube for 2 minutes.

Make sure that the tube has no leaks. If the tube has leaks, reject the tube. Refer to Inspection-000 TASK 73-22-48-200-100.

Decrease the pressure in the tube to zero.

Disconnect the tube from the outlet of the Pneumatic pressure testing rig.

Remove the blanking cap from the tube.

SUBTASK 73-22-48-780-052 Do the Pneumatic Pressure Test on the Tube (01-020)

Figure: Pneumatic Pressure Testing Rig

Pneumatic Pressure Testing Rig