Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-22-51-300-006 P4.9 Air Sensor Tubes and Manifolds - Repair the Manifolds in the Turbine Exhaust Case, Repair-006 (VRS5428)

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

The pressure control manifolds can be repaired by using one or both of the following methods depending on the damaged surface:

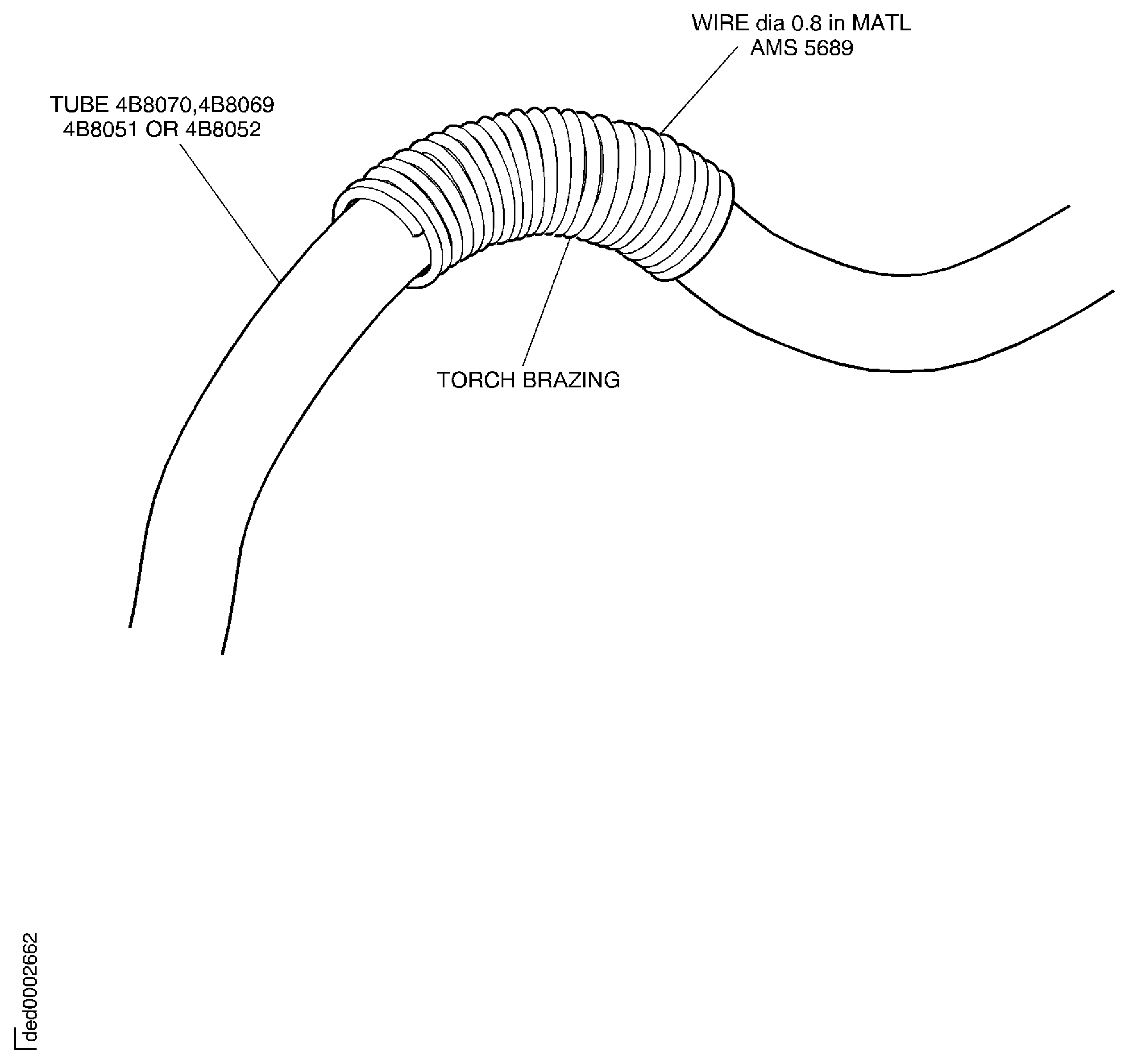

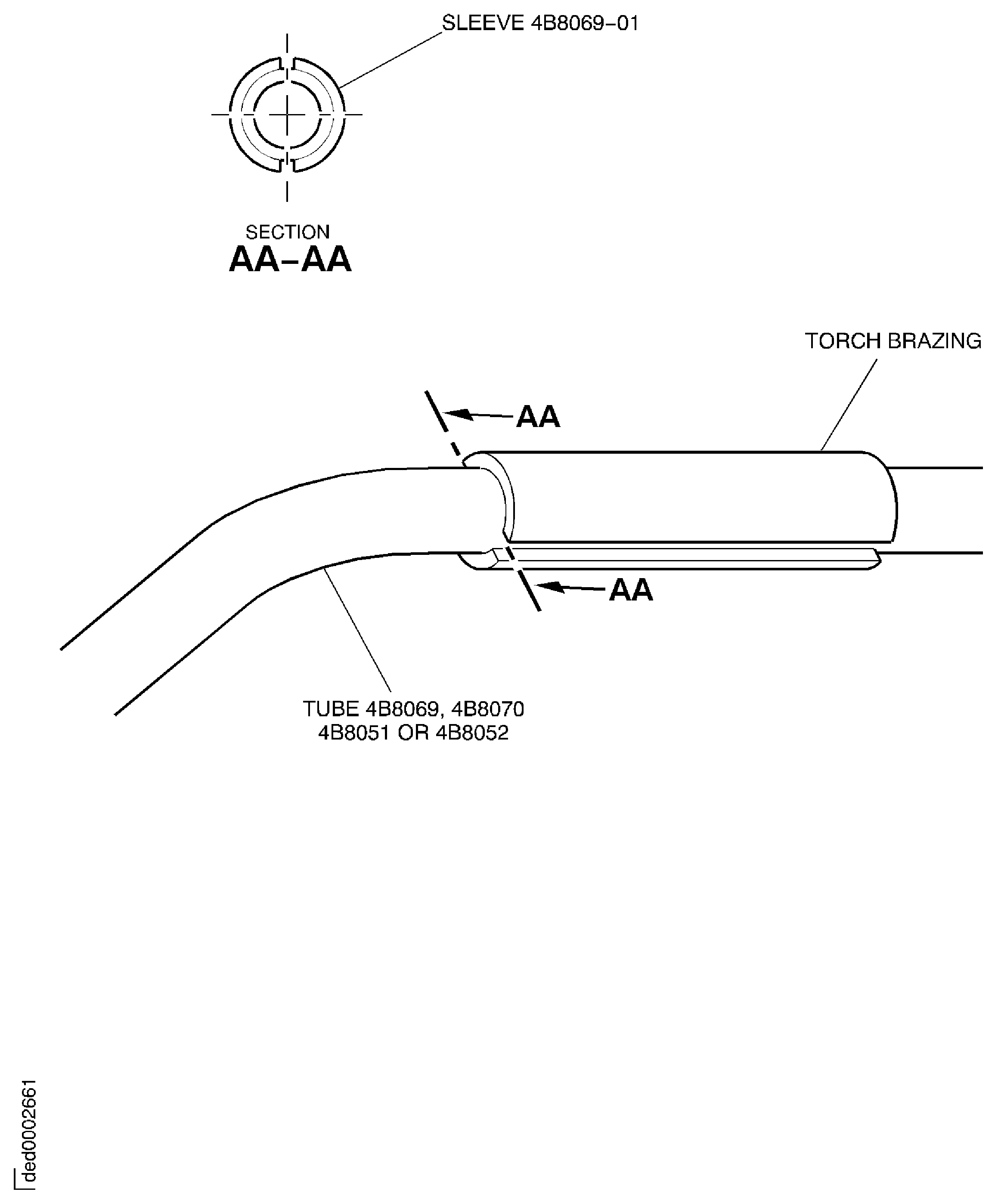

Non curved locations: Use the sleeve to repair the part.

Curved locations: Use the safety wire to repair the part.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop Inspection Equipment | LOCAL | Workshop Inspection Equipment | ||

| Torchbrazing equipment | LOCAL | Torch brazing equipment | ||

| FPI inspection station | LOCAL | FPI inspection station | ||

| Hydraulic test pump | LOCAL | Hydraulic test pump |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-001 SOLVENT, DELETED | 0AM53 | CoMat 01-001 | ||

| CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED) | LOCAL | CoMat 01-007 | ||

| CoMat 03-004 INTERM. TEMP. BRAZINGWIRE, 24% Ag | LOCAL | CoMat 03-004 | ||

| CoMat 03-005 BRAZING FLUX | LOCAL | CoMat 03-005 |

Spares

NONESafety Requirements

NONEProcedure

Use hand tools.

Polish the surfaces to be brazed to give a good finish.

Use a lint free cloth, made moist with CoMat 01-001 SOLVENT, DELETED.

Degrease the parts to be brazed.

Use a lint free cloth, made moist with CoMat 01-001 SOLVENT, DELETED.

Clean the parts to be brazed.

Refer to SPM TASK 70-31-01-310-501.

Torch braze the parts.

SUBTASK 73-22-51-310-052 Torch Braze the Pressure Control Manifolds

Inspect the brazing for a good continuity.

Braze again the areas where the brazing is not satisfactory.

Do an inspection all over the brazed parts.

SUBTASK 73-22-51-210-051 Examine the Brazed Parts

Refer to SPM TASK 70-23-05-230-501.

No cracks are permitted.

Do the fluorescent penetrant inspection for cracks.

SUBTASK 73-22-51-230-060 Examine the Brazed Parts

Use a pump.

Apply an air pressure of 120 psig. Hold the test pressure for at least 1 minute.

No leakages are permitted.

Do the pressure test.

SUBTASK 73-22-51-370-052 Pressure Test the Pressure Control Manifolds

Figure: Repair Details - Brazing on Curved Locations

Repair Details - Brazing on Curved Locations

Figure: Repair Details - Brazing on Curved Locations

Repair Details - Brazing on Curved Locations