DMC:V2500-A0-74-11-3800-02A-649A-CIssue No:002.00Issue Date:2014-05-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 74-11-38-300-005 Ignition Exciters - Related Parts - Repair The Tube By Blending, Repair-005 (VRS1625)

General

Price and availability

Refer to IAE for any of the following:

Tools

Engine parts

Repair of spares

The practice and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

To identify the consumable materials refer to the PCI.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Grinder, hand held pneumatic | LOCAL | Grinder, hand held pneumatic | ||

| Files, rotating (Silicon carbide) | LOCAL | Files, rotating (Silicon carbide) | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Use Grinder, hand held pneumatic and Files, rotating (Silicon carbide). Dress until all damage is removed.

Dress to remove damage.

Maximum blend limit is 0.005 in. (0.13 mm) in depth.

Refer to SPM TASK 70-35-03-300-501.

Blend dressed area and polish out scores.

SUBTASK 74-11-38-350-058 Dress to Remove Damage

CAUTION

TITANIUM COMPONENTSSILICON CARBIDE TYPE WHEELS, STONES AND ABRASIVE PAPERS ARE TO BE USED FOR THIS REPAIR.ALUMINUM OXIDE TYPES MUST NOT BE USED.THE MATERIAL WILL OXIDIZE AND CRACK IF MECHANICAL CUTTERS ARE USED HEAVILY. THIS HAS OCCURRED IF THE COMPONENT SHOWS DARK STRAW TO BLUE DISCOLORATION. IF AT ANY TIME THIS COLORATION OCCURS THE COMPONENT MUST BE REJECTED.Visually examine the repaired area for nicks, scratches and/or damage.

Do a visual inspection on the bracket.

SUBTASK 74-11-38-220-074 Examine the Tube

Refer to SPM TASK 70-23-01-230-501.

Make sure there are no cracks in the repaired area.

Penetrant crack test dressed area.

SUBTASK 74-11-38-230-058 Examine the Tube for Cracks

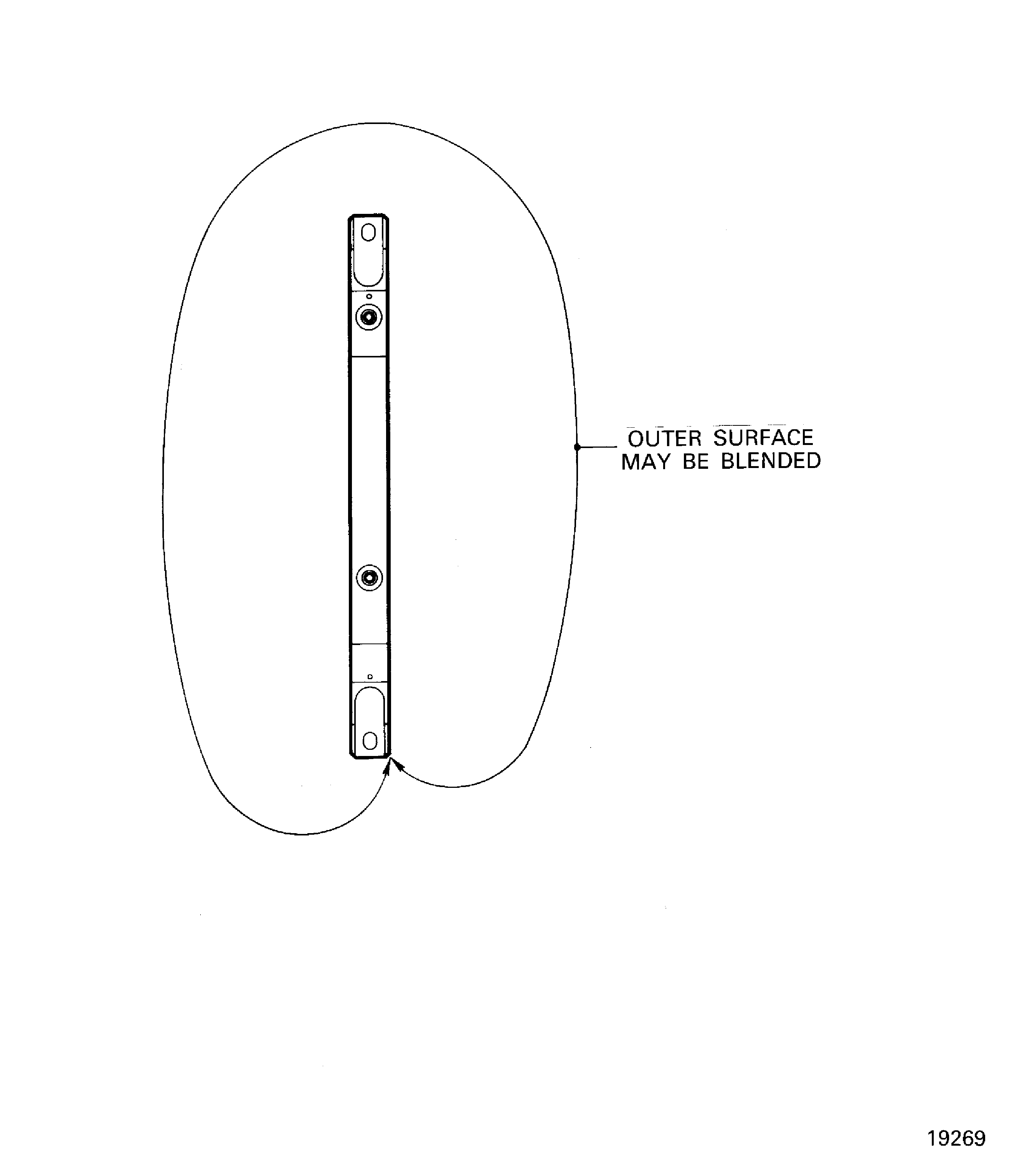

Figure: Support Tube

Support Tube