DMC:V2500-A0-75-23-4800-00A-649A-CIssue No:001.00Issue Date:2014-05-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-23-48-300-003 Turbine Cooling Controlled Air Tubes - Related Parts - Blend Damaged Surface Of The Brackets, Repair-003 (VRS1666)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

For the method to clean the parts, refer to Cleaning-000 TASK 75-23-48-100-400.

NOTE

To identify the consumable materials refer to the PCI.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Use portable grinding equipment.

Dress until all damage is removed.

Dress to remove damage

Refer to Figure.

Refer to SPM TASK 70-35-03-300-501.

Blend dressed area

SUBTASK 75-23-48-350-051 Blend the Damaged Surface of the Brackets (04-147 and 04-555)

Refer to Figure.

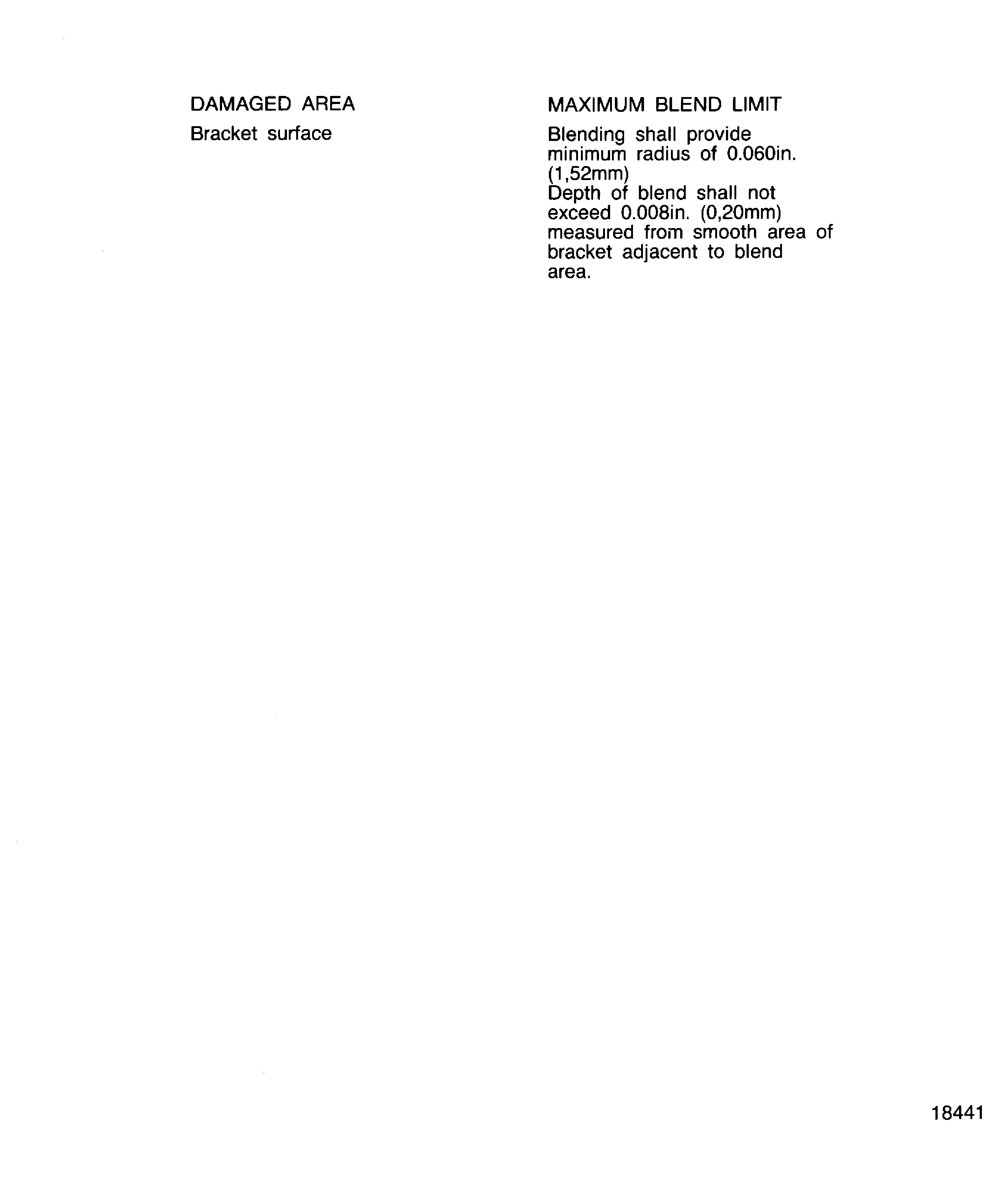

If the blended area exceeds the blend limit given in Figure, reject the brackets.

Examine the repaired area of brackets

Refer to Inspection-000 TASK 75-23-48-200-400.

Use 8X magnifying glass.

Visually examine the bracket

SUBTASK 75-23-48-220-067 Examine the Brackets (04-147 and 04-555)

Figure: Blend Limit of the Brackets

Blend Limit of the Brackets