Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

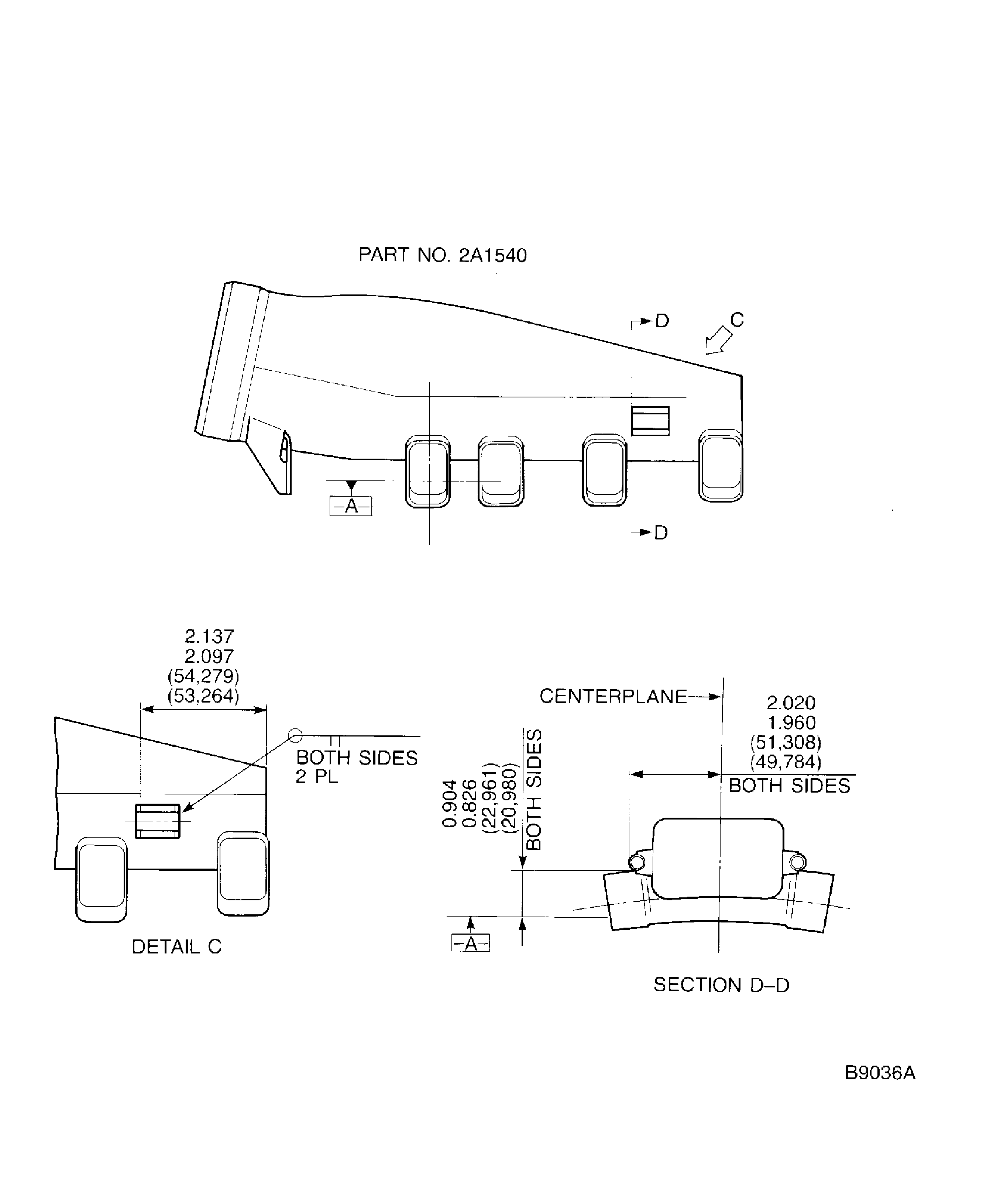

TASK 75-24-48-300-005 HPT ACC Air Manifold - Replace the Pin, Repair-005 (VRS1535)

Material of component

PART IDENT | SYMBOL | MATERIAL |

Turbine cooling manifold assembly | Fe-18.5Cr-11Ni-0.4Ti | |

Turbine cooling manifold (pin) assembly | Fe-18.5Cr-11Ni-0.4Ti |

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

For the method to clean the parts, refer to Cleaning-000 TASK 75-24-48-100-100.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| TIG welding equipment | LOCAL | TIG welding equipment | ||

| Grinder, Hand held pneumatic | LOCAL | Grinder, Hand held pneumatic | ||

| Magnifying glass | LOCAL | Magnifying glass | 8X |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| MANIFOLD - TURBINE COOLING, ASSEMBLY OF | 0AM53 | 2A0202 | ||

| MANIFOLD - TURBINE COOLING, ASSEMBLY OF | 0AM53 | 2A1540 | ||

| MANIFOLD - TURBINE COOLING, ASSEMBLY OF | 0AM53 | 2A3665 | ||

| PIN | 0AM53 | 2A0241 | 2 off | |

| PIN - HOLLOW | 0AM53 | 2A1564 | 2 off |

Safety Requirements

NONEProcedure

Refer to Cleaning-000 TASK 75-24-48-100-100.

Remove all the oxides, hydrocarbon, grit and scale from the surface to be welded and adjacent area by local cleaning.

SUBTASK 75-24-48-350-070 Remove All the Soil from the Surface

Refer to the SPM TASK 70-31-02-310-501.

Use a TIG welding equipment.

Weld the pin to the support by tungsten inert gas (TIG) weld.

Use a Grinder, Hand held pneumatic.

In contact area, remove excess weld and dress flush with adjacent area.

SUBTASK 75-24-48-350-071 Weld the Pin

Stress relieve at 1200 deg F - 25 deg F (649 deg C - 14 deg C) for one hour.

Heat treat the turbine cooling manifold assembly.

SUBTASK 75-24-48-310-057 Heat Treat the Turbine Cooling Manifold Assembly

Refer to the SPM TASK 70-23-05-230-501.

Penetrant examine the repaired area.

Use a 8X Magnifying glass.

Refer to Inspection-000 TASK 75-24-48-200-100.

Visually examine the repaired area.

SUBTASK 75-24-48-220-063 Examine the Welded Area for Cracks

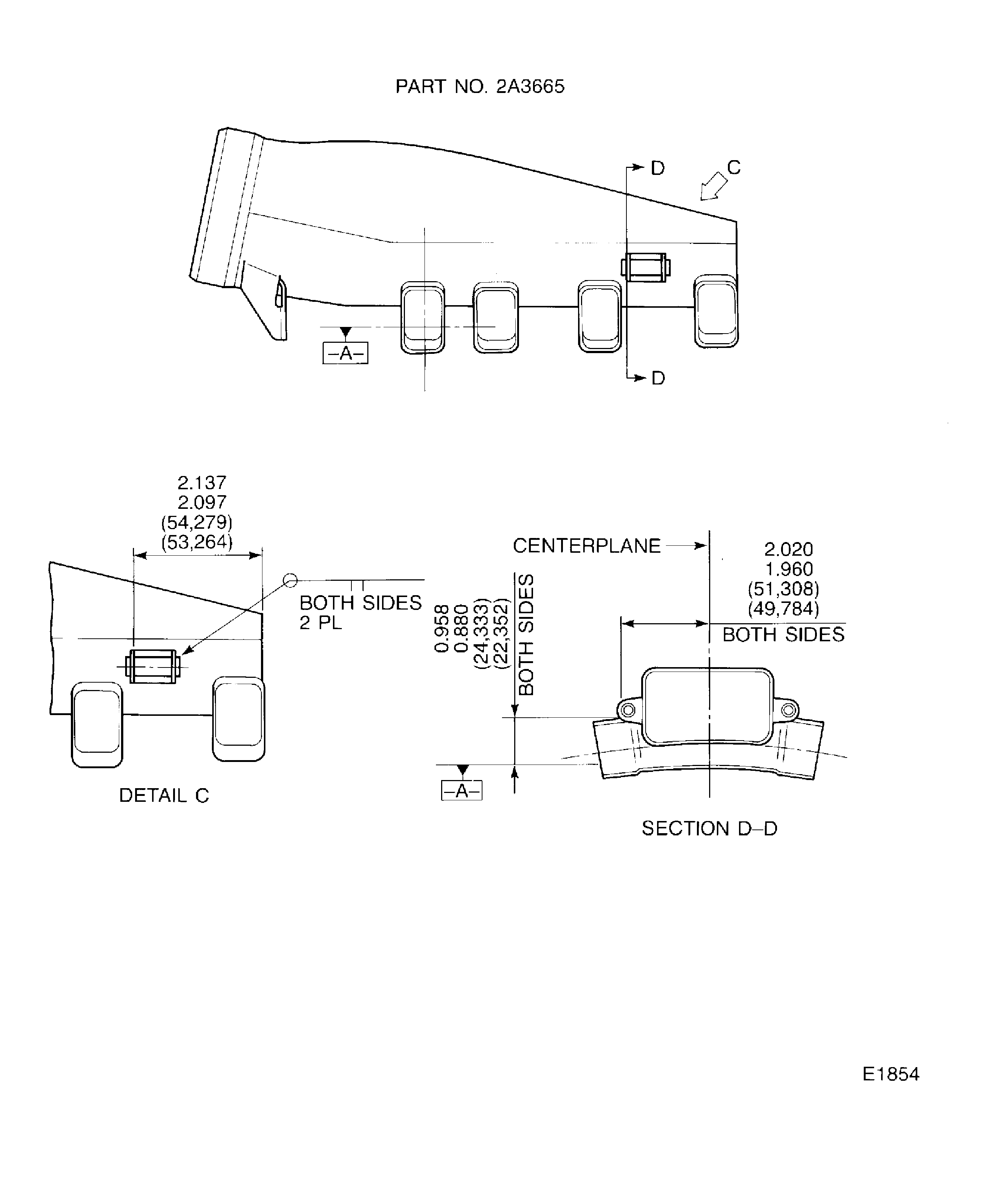

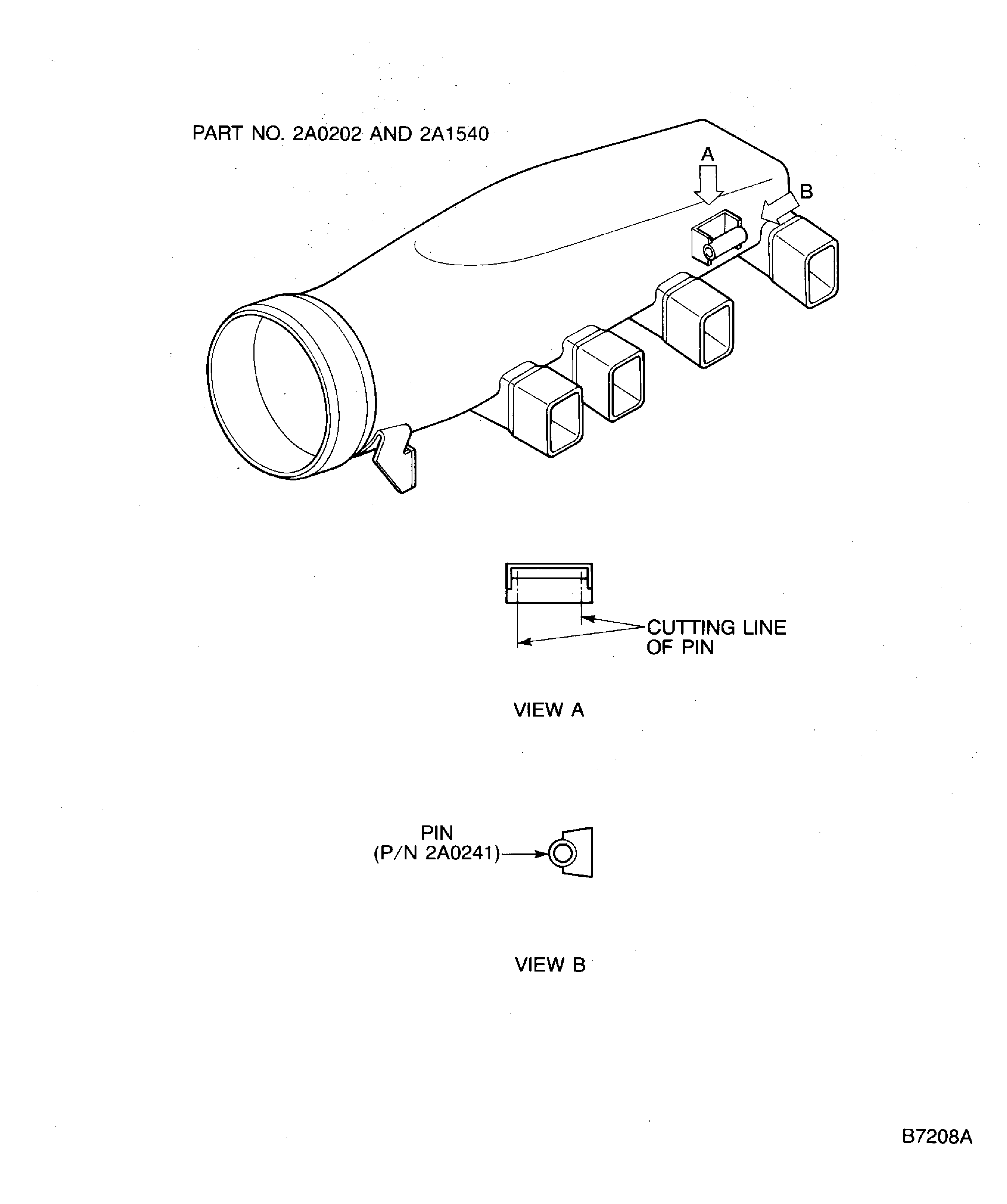

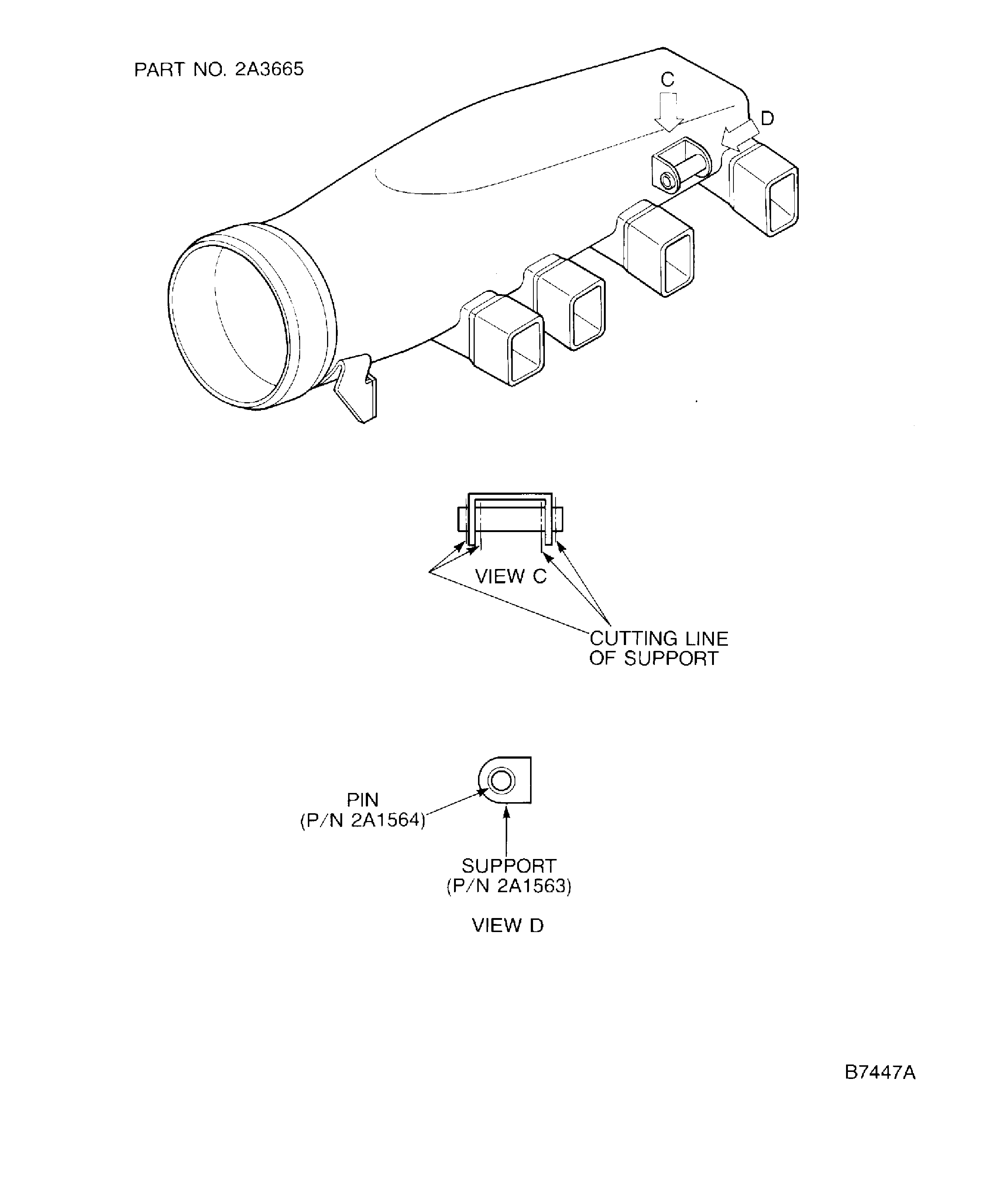

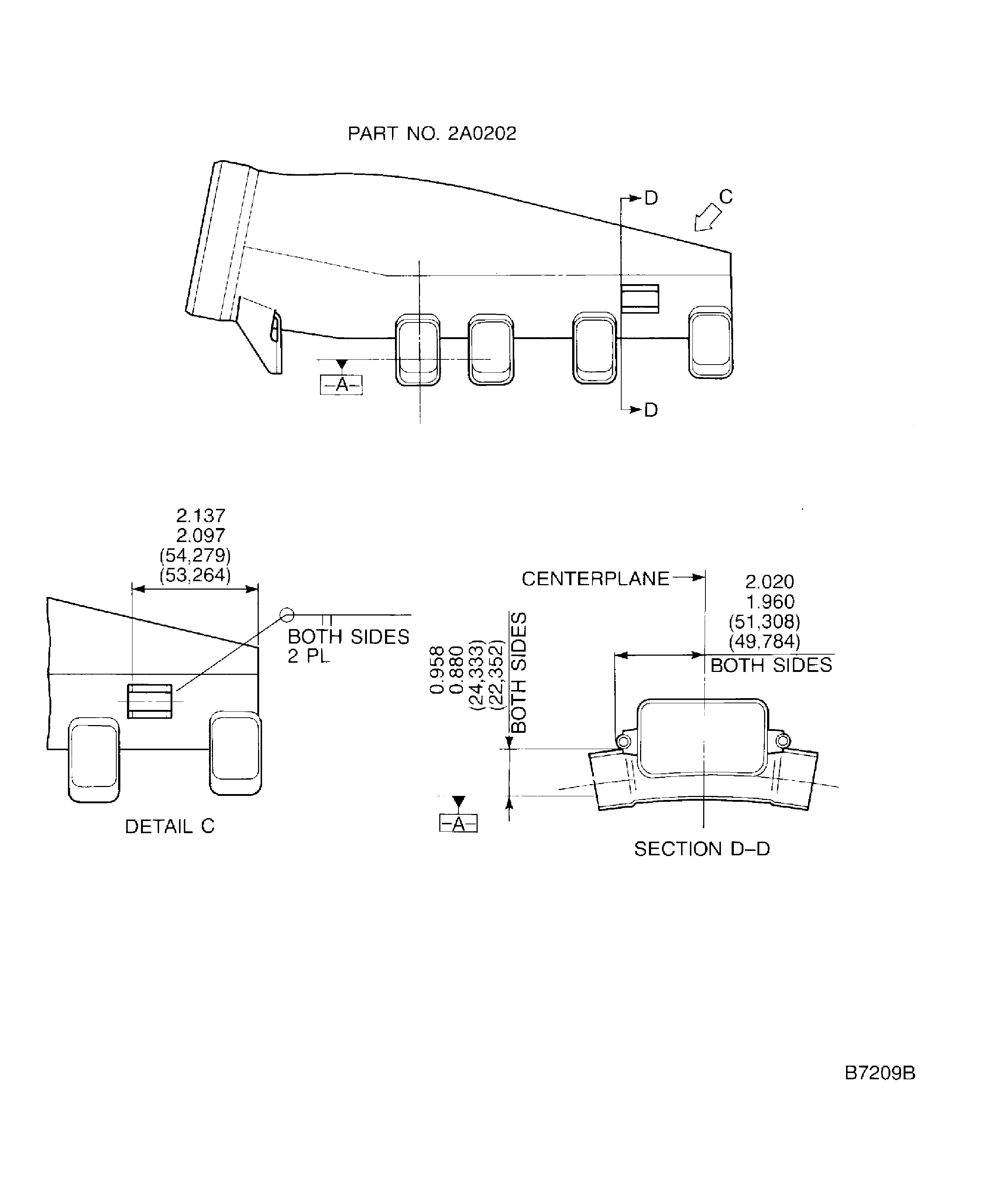

Figure: Replacement of the Pin

Replacement of the Pin

Replacement of the Pin

Replacement of the Pin

Replacement of the Pin

Replacement of the Pin