Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-48-300-001 HPT ACC Air Tubes - Weld Repair Cracks, Repair-001 (VRS1532)

Effectivity

FIG/ITEM | PART NO. |

02-200 | 2A0220 |

02-210 | 2A0225 |

02-220 | 2A0229 |

02-230 | 2A0233 |

02-400 | 2A0223 |

02-410 | 2A0227 |

02-420 | 2A0231 |

02-430 | 2A0235 |

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

For the method to clean the parts, refer to Cleaning-000 TASK 75-24-48-100-100.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| TIG welding equipment | LOCAL | TIG welding equipment | ||

| Grinder, hand held pneumatic | LOCAL | Grinder, hand held pneumatic | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-099 LINT-FREE CLOTH | X222X | CoMat 02-099 | ||

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-23-02-230-501.

Fluorescent penetrant examine TCC tube assemblies for crack indications

SUBTASK 75-24-48-230-054 Examine the TCC Tube Assemblies

Refer to Figure.

Use a Grinder, hand held pneumatic.

Dress out the crack.

Ensure that the crack is completely removed from the TCC tube assembly and/or turbine cooling manifold assembly.

SUBTASK 75-24-48-350-054 Dress Out the Crack to Weld Without Patches

Refer to Cleaning-000 TASK 75-24-48-100-100.

Remove the all oxides, hydrocarbon, grit and scale from the surface to be welded and adjacent area by local cleaning.

SUBTASK 75-24-48-110-057 Remove All the Soil from the Surface

Refer to Figure.

Refer to SPM TASK 70-31-02-310-501.

Use the TIG welding equipment with CoMat 03-204 WELDING FILLER WIRE.

Weld dressed cracks manually by tungsten inert gas (TIG) weld.

Use a Grinder, hand held pneumatic.

Remove excess weld and dress flush with adjacent area.

SUBTASK 75-24-48-310-051 Weld the Dressed Cracks on the TCC Tube Assembly

Re-establish airhole pattern with same size and spacing of other holes, in same hole system, where welds affect holes.

Produce airholes in repaired area of TCC tube assembly, (If applicable).

SUBTASK 75-24-48-350-055 Produce Airholes in the TCC Tube Assembly

Stress relieve at 1200 deg F plus or minus 25 deg F (649 deg C plus or minus 14 deg C) for one hour.

Heat treat the TCC tube assemblies.

SUBTASK 72-24-48-210-058 Heat Treat the TCC Tube Assemblies

Refer to Figure.

Refer to SPM TASK 70-23-05-230-501.

Penetrant examine the repaired area.

Use a 8X magnifying glass.

Refer to Inspection-000 TASK 75-24-48-200-100.

Visually examine the repaired area.

Refer to Figure.

Dimensionally check TCC tube assemblies for distortion (this does not include the patch welding repaired area).

SUBTASK 75-24-48-350-056 Examine the Repaired Area for Cracks

Use a Grinder, hand held pneumatic.

Use patch as a template to cut out damaged area. Bevel repair edges.

SUBTASK 75-24-48-350-058 Cut Out the Damaged Area

Refer to Cleaning-000 TASK 75-24-48-100-100.

Remove the all oxides, hydrocarbon, grit and scale from the surface to be welded and adjacent area by local cleaning.

SUBTASK 75-24-48-110-058 Remove the All Soil from the Surfaces

Refer to SPM TASK 70-31-02-310-501.

NOTE

Patch weld repair is not allowed tubes if total patch weld areas are greater than 20 per cent of surface.

Weld the patch.

Use a Grinder, hand held pneumatic.

Avoid undercutting parent metal.

In contact area, remove excess weld and dress flush with adjacent area.

SUBTASK 75-24-48-350-059 Weld the Patch to the TCC Tube Assemblies

Re-establish airhole pattern with same size and spacing of other holes, in same hole system, where welds or patches affect holes.

Make airholes through the patch, (if applicable).

SUBTASK 75-24-48-350-060 Make Airholes in the TCC Tube Assemblies

Stress relieve at 1200 deg F plus or minus 25 deg F (649 deg C plus or minus 14 deg C) for one hour.

Heat treat the TCC tube assemblies.

SUBTASK 75-24-48-310-059 Heat Treat the TCC Tube Assemblies

Refer to Figure.

Refer to SPM TASK 70-23-05-230-501.

Penetrant examine the repaired area.

Use a 8X magnifying glass.

Refer to Inspection-000 TASK 75-24-48-200-100.

Visually examine the edge of the patch.

Refer to Figure.

Dimensionally check TCC tube assemblies for distortion (Except the patch welding repaired area).

SUBTASK 75-24-48-350-061 Examine the Repaired Area for Cracks

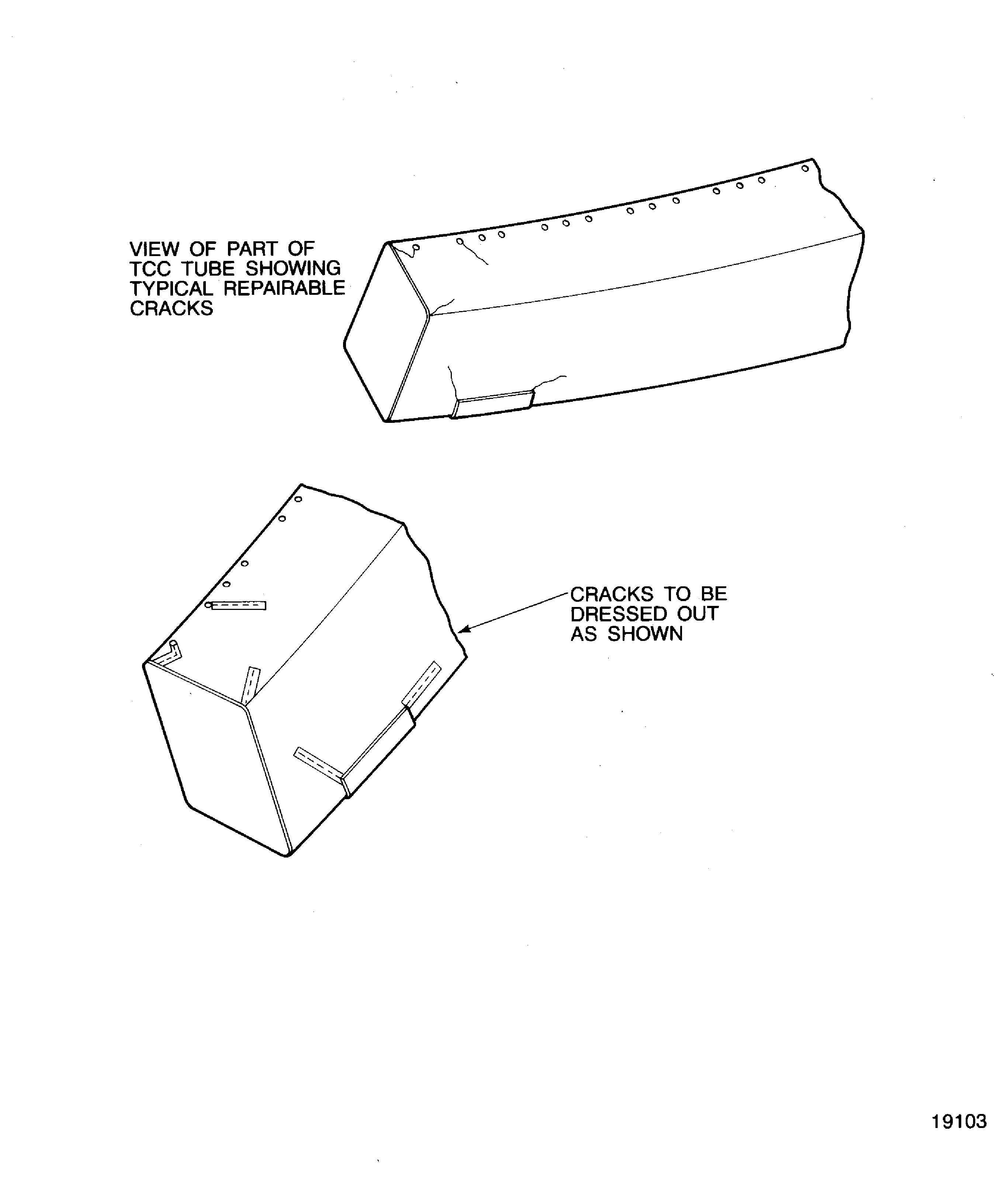

Figure: Weld of the TCC Tubes

Weld of the TCC Tubes

Weld of the TCC Tubes

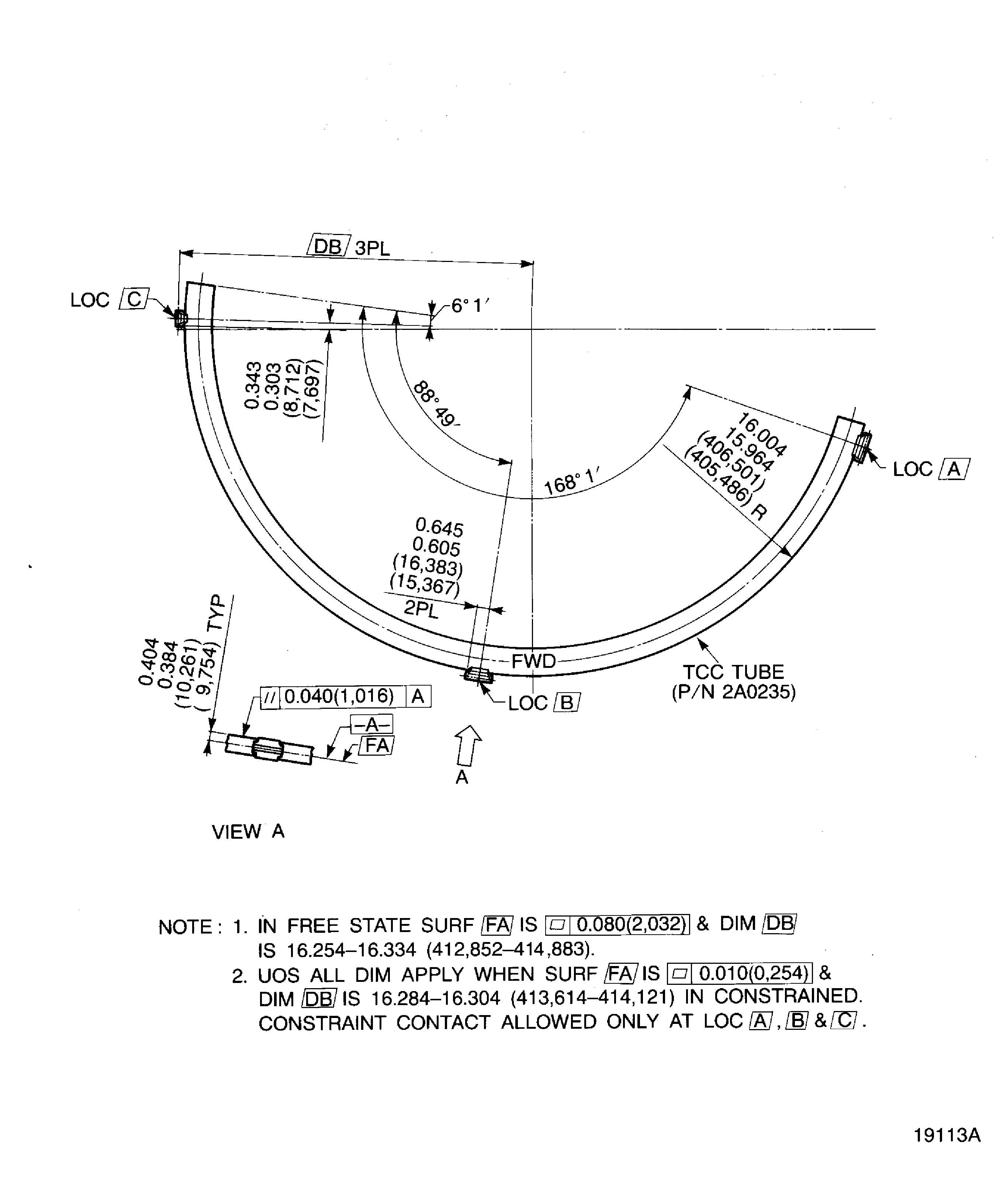

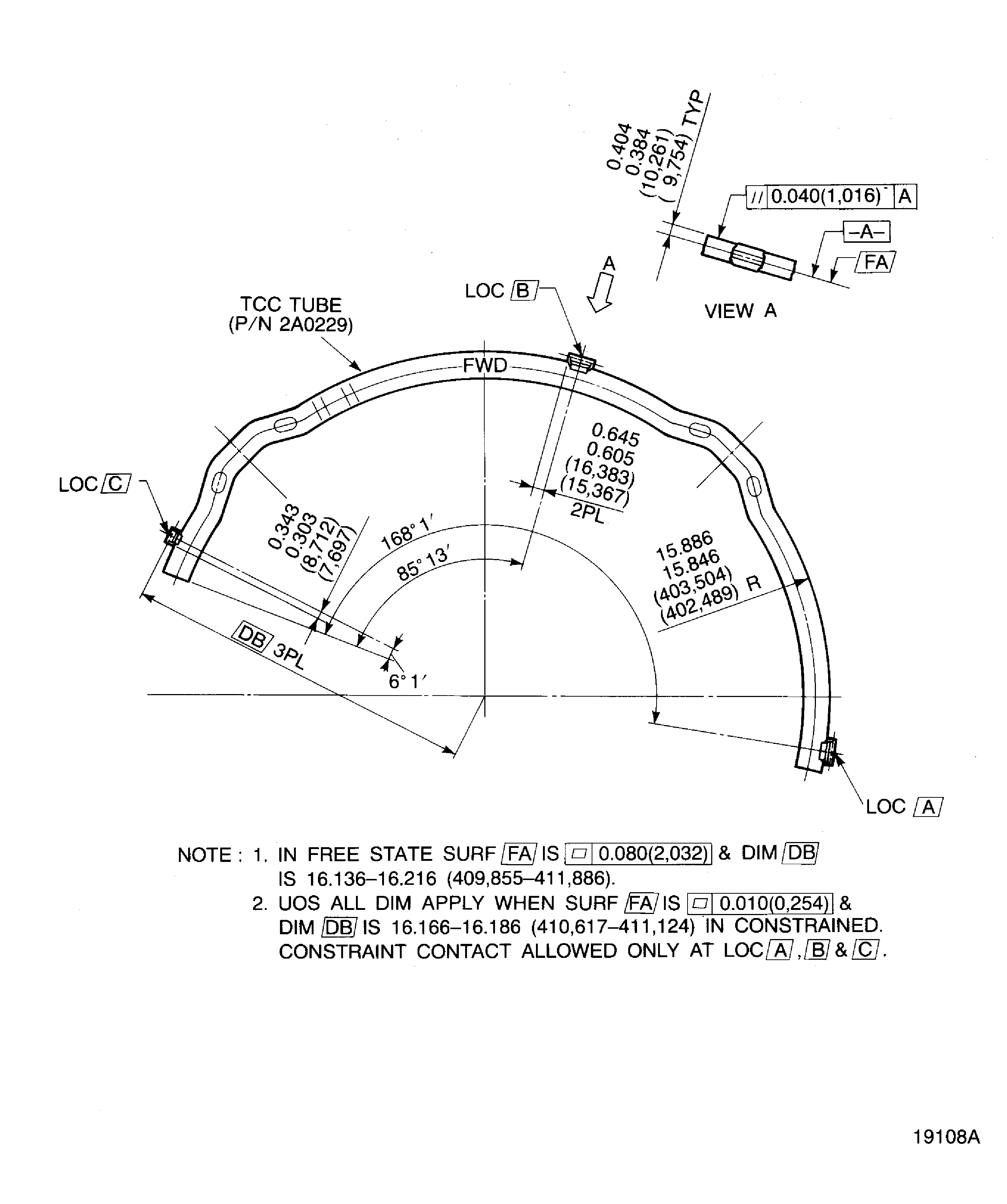

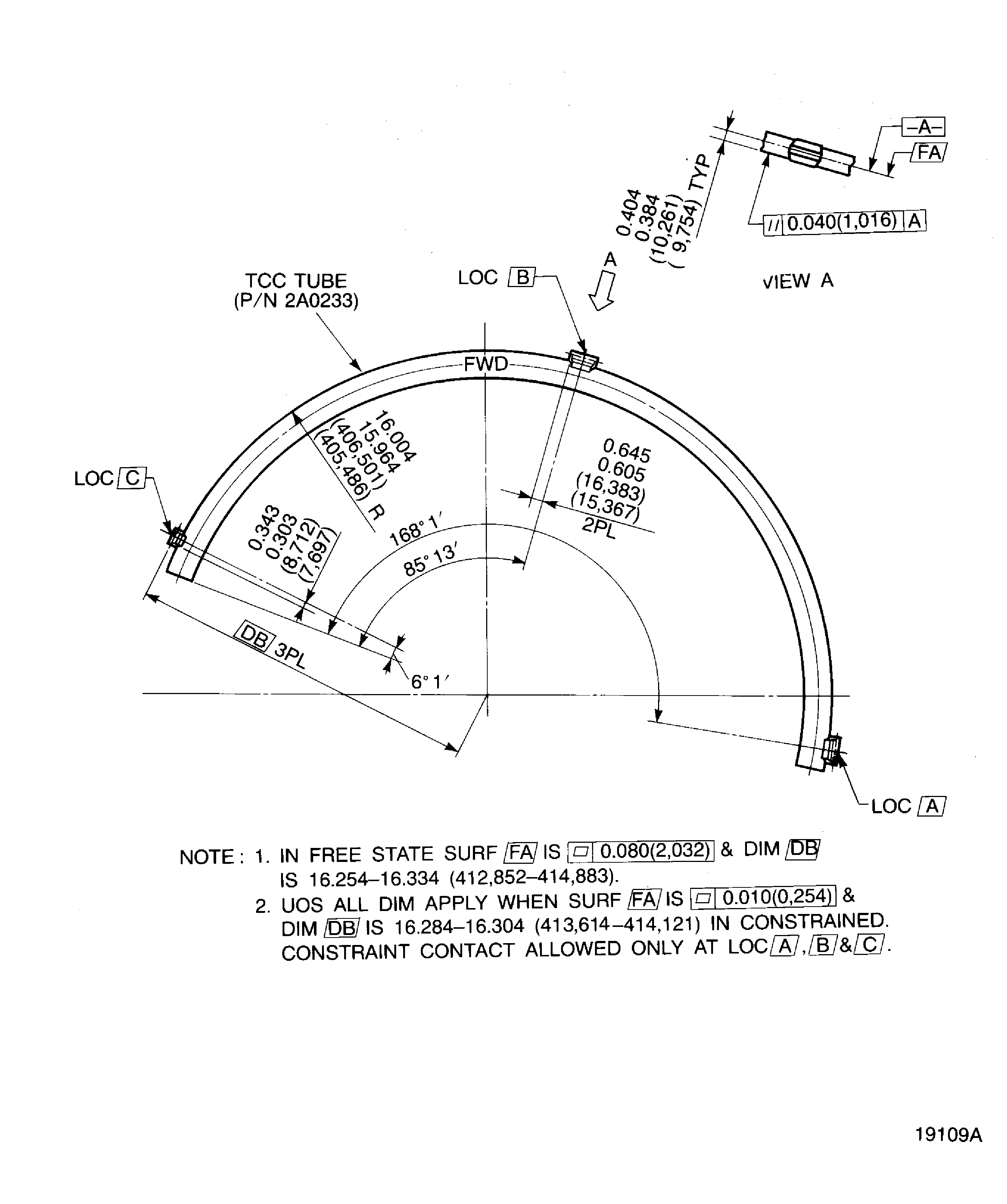

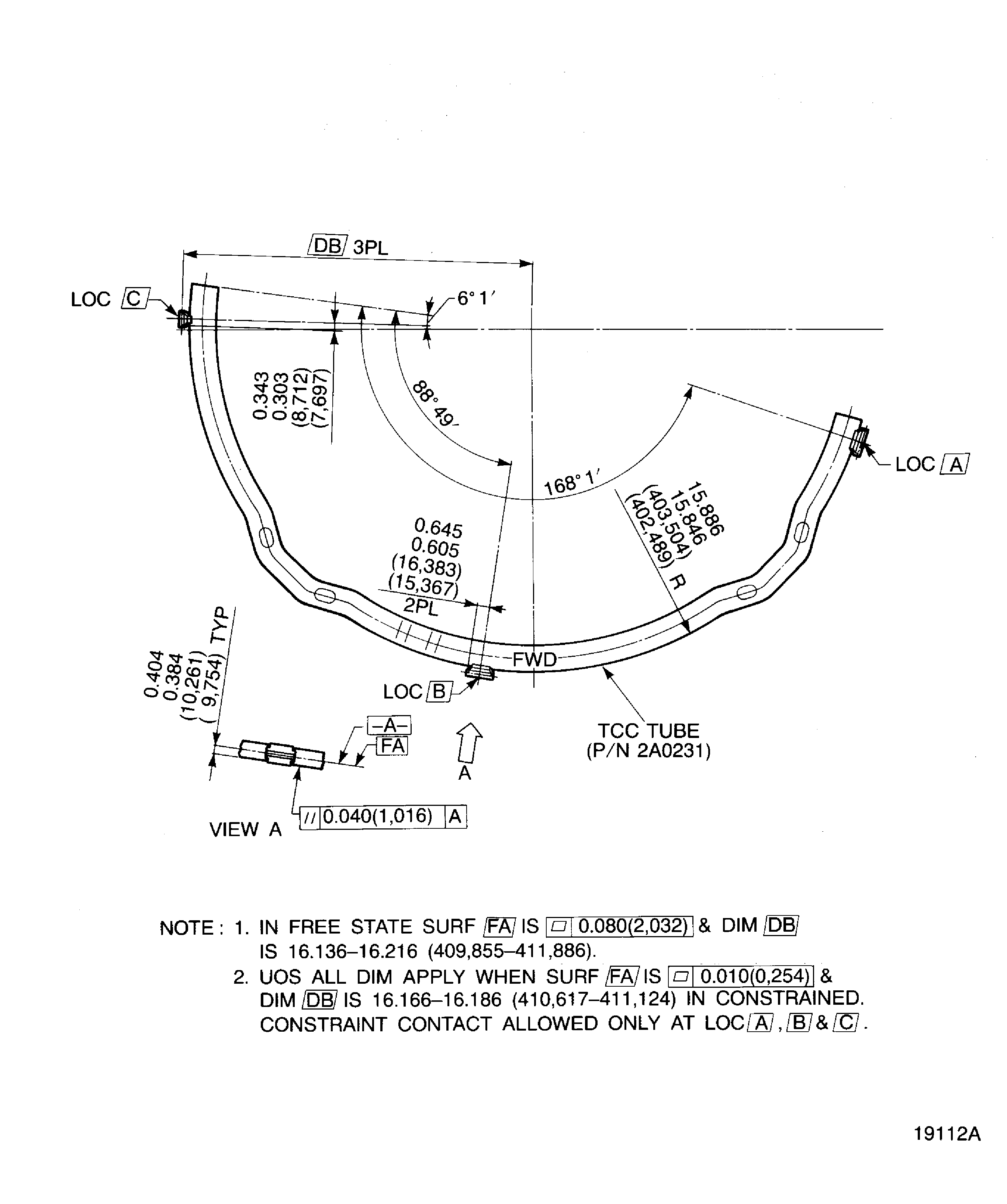

Figure: Dimension of the TCC tubes

Dimension of the TCC tubes

Dimension of the TCC tubes

Dimension of the TCC tubes

Dimension of the TCC tubes

Dimension of the TCC tubes

Dimension of the TCC tubes

Dimension of the TCC tubes

Dimension of the TCC tubes