Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 78-32-77-430-301 Right C-Duct Electrical Harness - Assemble The Harness, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in this procedure.

To identify the consumable materials refer to the PCI.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-176 LOCKWIRE | LOCAL | CoMat 02-176 | ||

| CoMat 02-177 MASKING TAPE (GLASS CLOTH) | LOCAL | CoMat 02-177 |

Spares

NONESafety Requirements

NONEProcedure

Get the contact insertion tool for the wire size to be installed. Refer to Figure.

CAUTION

THE INSERTION TOOL MUST BE PARALLEL TO THE AXIS OF THE CONNECTOR WHEN THE WIRES ARE INSTALLED TO PREVENT INTERNAL DAMAGE TO THE CONNECTOR.Put the contacts (01-250) in to the correct positions by hand. After the contacts are started in to the connector, fully install them with the insertion tool.

Push on the contact from the front of the connector to make sure that it has been correctly inserted. The contact is correctly inserted when there is no rearward movement of the contact within the connector.

Move the boot (01-300) along the wire bundle toward the connector until it touches the rear grommet.

Move the connector backshell along the wire bundle and turn it on to the connector shell. Tighten the backshell by hand plus 1/8 to 1/4 turn with the connector pliers.

Wrap the wire bundle at the strain relief clamp location with CoMat 02-177 MASKING TAPE (GLASS CLOTH) until there is enough tape to give a tight hold on the wire bundle when the strain relief clamp is installed on the backshell.

Install the strain relief clamp on the backshell with the screw. Torque the screws to between 12 and 15 lbfin (1 and 2 Nm). Safety the screws with CoMat 02-176 LOCKWIRE.

Do a continuity check of the wire harness to make sure that it has been assembled correctly. Refer to Testing-001 TASK 78-32-77-700-301.

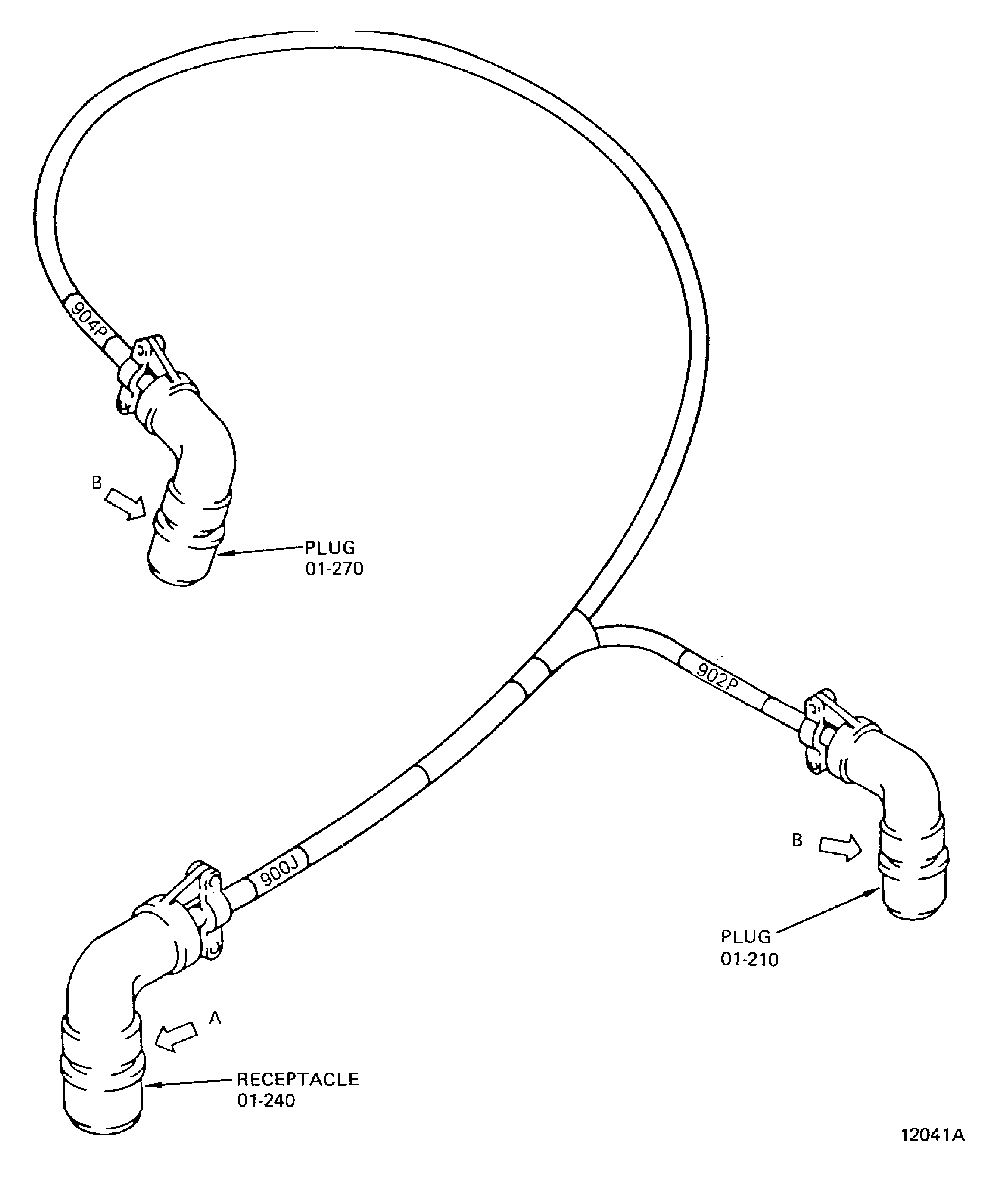

Assemble the 902P plug (01-210) on the wire.

Get the contact insertion tool for the wire size to be installed. Refer to Figure.

CAUTION

THE INSERTION TOOL MUST BE PARALLEL TO THE AXIS OF THE CONNECTOR WHEN THE WIRES ARE INSTALLED TO PREVENT INTERNAL DAMAGE TO THE CONNECTOR.Put the contacts (01-250) in to the correct positions by hand. After the contacts are started in to the connector, fully install them with the insertion tool.

Push on the contact from the front of the connector to make sure that it has been correctly inserted. The contact is correctly inserted when there is no rearward movement of the contact within the connector.

Move the boot (01-290) along the wire bundle toward the connector until it touches the rear grommet.

Move the connector backshell along the wire bundle and turn it on to the connector shell. Tighten the backshell by hand plus 1/8 to 1/4 turn with the connector pliers.

Wrap the wire bundle at the strain relief clamp location with the CoMat 02-177 MASKING TAPE (GLASS CLOTH) until there is enough tape to give a tight hold on the wire bundle when the strain relief clamp is installed on the backshell.

Install the strain relief clamp on to the backshell with the screws. Torque the screws to between 12 and 15 lbfin (1 and 2 Nm). Safety the screws with the CoMat 02-176 LOCKWIRE.

Do a continuity check of the wire harness to make sure that it has been assembled correctly. Refer to Testing-001 TASK 78-32-77-700-301.

Assemble the 904P plug (01-270) on the wire.

Get the contact insertion tool for the wire size to be installed. Refer to Figure.

CAUTION

THE INSERTION TOOL MUST BE PARALLEL TO THE AXIS OF THE CONNECTOR WHEN THE WIRES ARE INSTALLED TO PREVENT INTERNAL DAMAGE TO THE CONNECTOR.Put the contacts (01-220) in to the correct positions by hand. After the contacts are started in to the connector, fully install them with the insertion tool.

Push on the contact from the front of the connector to make sure that it has been correctly inserted. The contact is correctly inserted when there is no rearward movement of the contact within the connector.

Move the boot (01-300) along the wire bundle toward the connector until it touches the rear grommet.

Move the connector backshell along the wire bundle and turn it on to the connector shell. Tighten the backshell by hand plus 1/8 to 1/4 turn with the connector pliers.

Wrap the wire bundle at the strain relief clamp location with the CoMat 02-177 MASKING TAPE (GLASS CLOTH) until there is enough tape to give a tight hold on the wire bundle when the strain relief clamp is installed on the backshell.

Install the strain relief clamp on to the backshell with the screws. Torque the screws to between 12 and 15 lbfin (1 and 2 Nm). Safety the screws with the CoMat 02-176 LOCKWIRE.

Do a continuity check of the wire harness to make sure that it has been assembled correctly. Refer to Testing-001 TASK 78-32-77-700-301.

Assemble the 900J receptacle (01-240) on the wire.

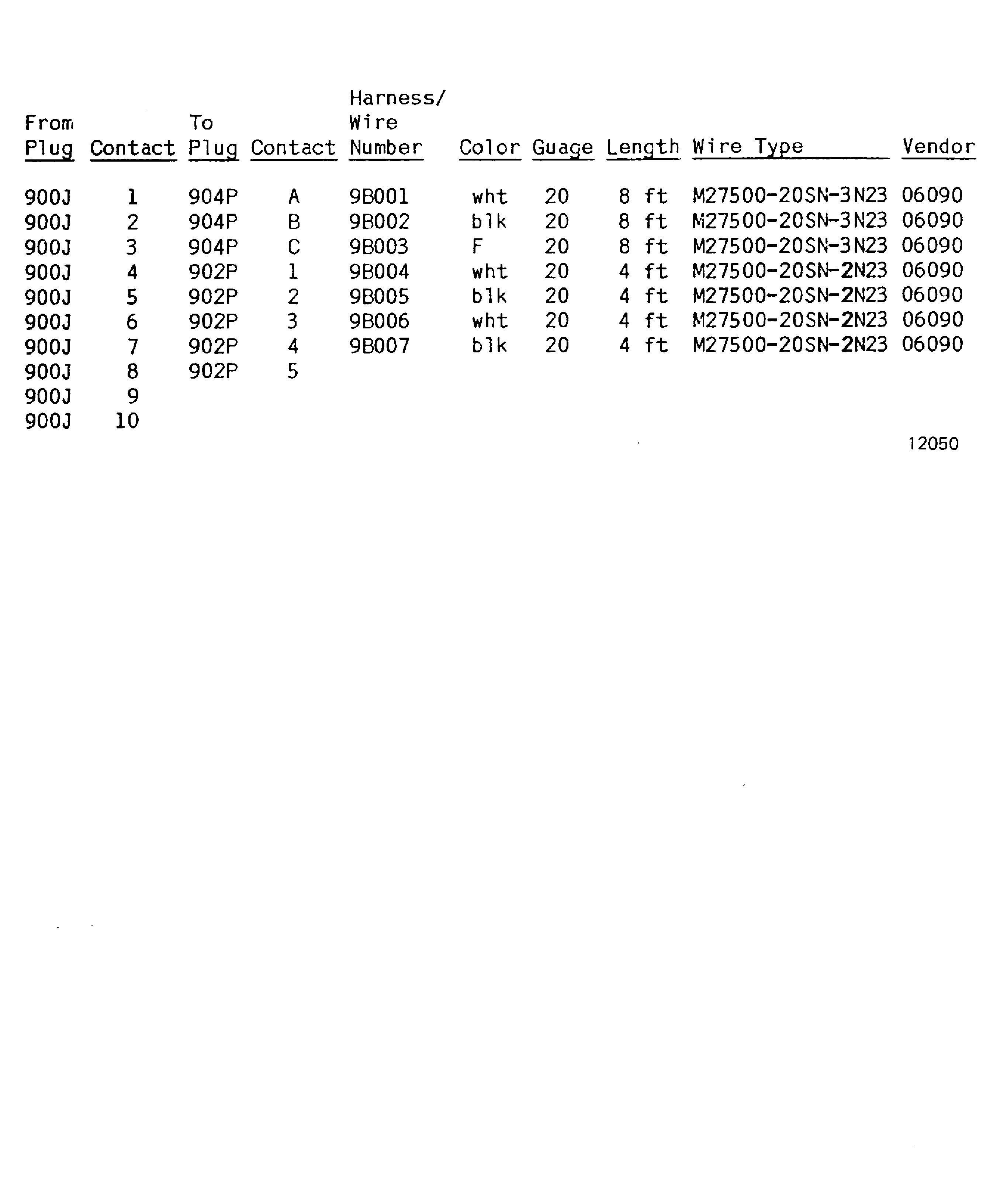

SUBTASK 78-32-77-430-051 Assemble the Right C-Duct Electrical Harness

Figure: Electrical harness

Electrical harness

Electrical harness

Electrical harness