Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

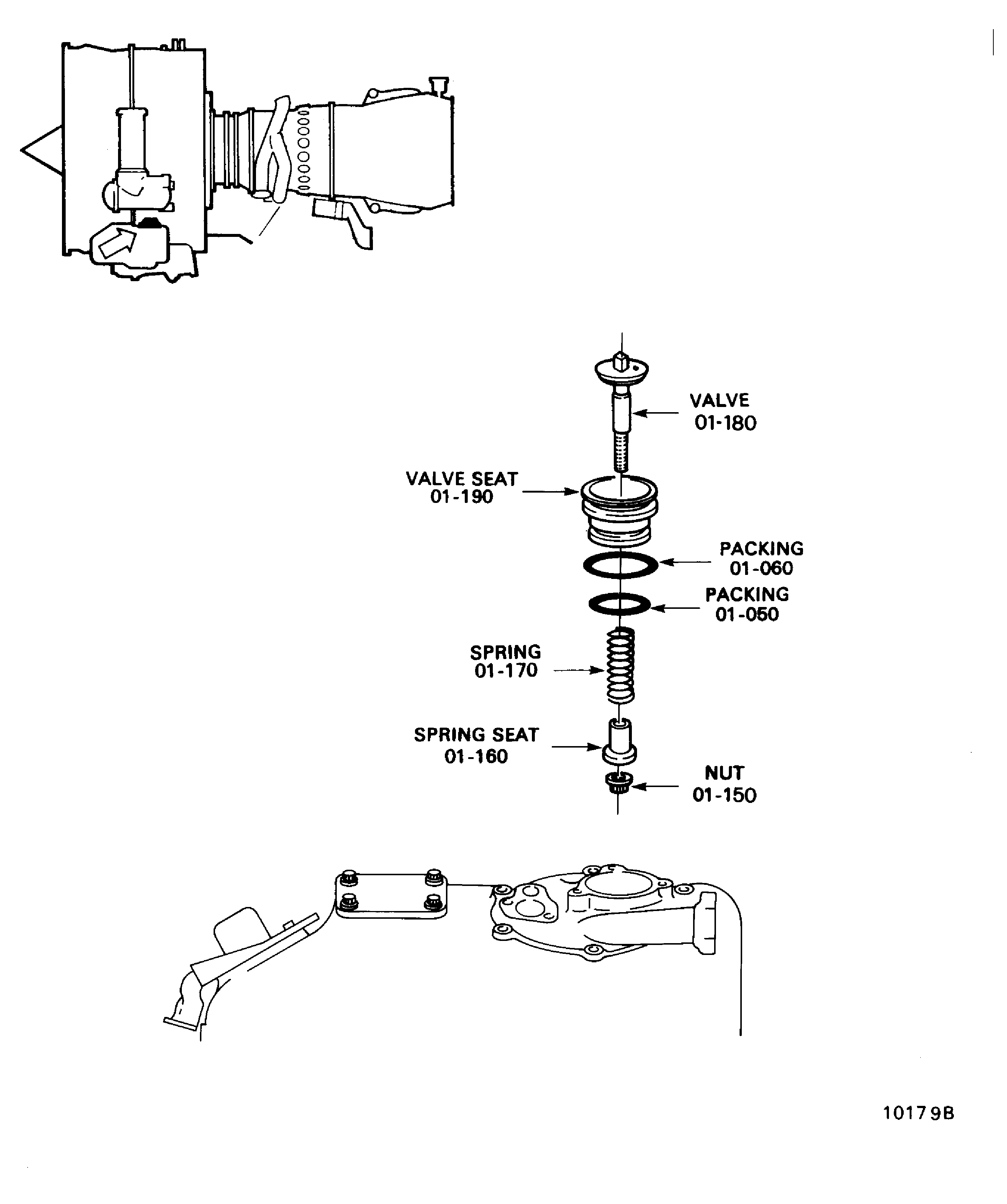

TASK 79-11-51-460-401 Oil Tank Valve - Related Parts - Assemble The Pressurization Valve Assembly, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

All parts to be assembled must be clean.

Lubricate all packings, all threads and slider surface with CoMat 10-077 APPROVED ENGINE OILS.

Inspect pressure relief hole in valve. It should be free from obstruction.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Introduce the valve in the valve seat.

Install the spring and the spring seat on the valve. Tighten the seat spring so that the length of the spring is 0.75 in. (19 mm).

Install the nut. Lightly tighten the nut.

Install the valve on a suitable test rig. Use compressed air. Adjust the spring seat and the nut to get a spring load so that the valve opens between 5.70 psi and 6.29 psi (39.273 Kpa to 43.407 Kpa).

Hold the seat spring and the valve. Torque the nut between 40.7 lbf-in. and 50.5 lbf-in. (4.6 N m to 5.7 N m).

Install (79-11-51,01-050) packing and (79-11-51,01-060) packing in to the grooves of the valve seat.

SUBTASK 79-11-51-460-051 Assemble the Oil Tank Valve

Figure: Assemble the Oil Tank Valve

Assemble the Oil Tank Valve