Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 79-21-41-300-033 Oil Pressure Pump/Filter Housing - Related Parts - Repair The Surfaces Of The Oil Pressure Pump Drive Gear Assembly, Repair-033 (VRS5652)

General

NOTE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-140 TRIANGULAR INDIA STONE, FINE GRIT | LOCAL | CoMat 02-140 |

Spares

NONESafety Requirements

NONEProcedure

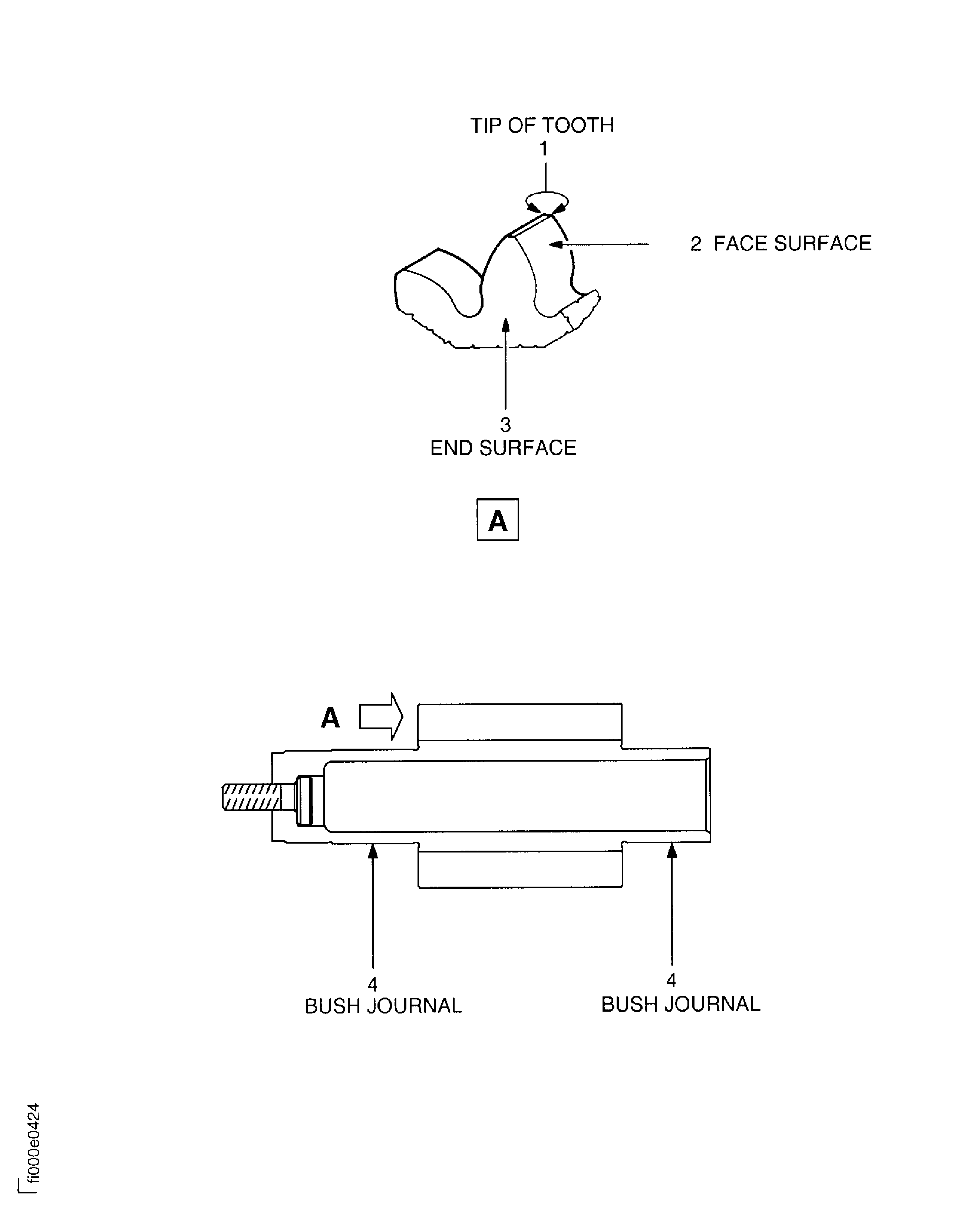

Refer to Figure.

Refer to SPM TASK 70-35-03-300-501.

The maximum permitted blend length is 0.060 in. (1.50 mm).

The maximum permitted blend depth is 0.012 in. (0.30 mm).

Do not blend more than 50 percent of each tooth tip.

Do not blend one tooth after the other tooth in the same circumferential area.

Blend the gear tip of the tooth at location 1.

Refer to SPM TASK 70-35-03-300-501.

The maximum permitted blend depth is 0.002 in. (0.05 mm).

The maximum permitted damaged area on each tooth is 10 percent of the face surface.

Blend the face surface of the gear tooth at location 2.

Refer to SPM.TASK 70-35-03-300-501.

A 40 micro inches (1 micrometer) is necessary.

Reject gear if chips or nicks cannot be fully removed.

Hand polish and blend the damage on the end surface at location 3.

Refer to SPM TASK 70-35-03-300-501.

A 4 micro inches (0.1 micrometer) is necessary.

Hand hone the damage on the bush journals at location 4.

SUBTASK 79-21-41-350-086 Blend Repair the Drive Gear Assembly Surfaces

Figure: Locations On The Drive Gear Assembly

Locations On The Drive Gear Assembly