Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 79-21-49-700-101 Engine Pressure Oil Tubes - Do A Pressure Test, Testing-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha-variants refer to the IPC.

The pressure oil tubes must be cleaned and inspected before this pressure test, refer to Cleaning-000 TASK 79-21-49-100-100 and Inspection-000 TASK 79-21-49-200-100.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hydraulic pressure testing rig | LOCAL | Hydraulic pressure testing rig | ||

| Pneumatic pressure testing rig | LOCAL | Pneumatic pressure testing rig | ||

| MS21913-4 Blanking plug | 0AM53 | MS21913-4 | ||

| MS21914-4 Blanking cap | 0AM53 | MS21914-4 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Install an applicable MS21914-4 Blanking cap to the 'T' connector on the tube (17- 500).

SUBTASK 79-21-49-780-051 Prepare the Tubes (17-100, 17-500 and 18-100) for the Hydraulic Pressure Test

Connect the tube to the outlet of the hydraulic pressure testing rig and the bleed valve adapter. Make sure that the bleed valve is open.

Make sure that the pressure control valve is set to zero.

Start the Hydraulic pressure testing rig.

Slowly turn the pressure control valve until the fluid comes out of the bleed valve.

Close the bleed valve.

CAUTION

DO NOT GO PAST THE TEST PRESSURE SHOWN BELOW. IT CAN CAUSE DAMAGE TO THE TUBE. IF THE PRESSURE IN THE TUBE GETS TO MORE THAN THAT SHOWN BELOW, REJECT THE TUBE.Increase the pressure in the tubes (17-100, 17-500 and 18-100) to 1000 psi (6895 kPa).

Let the pressure stay in the tube for 2 minutes.

Make sure that the tube has no leaks. If the tube has leaks, reject the tube. Refer to Inspection-000 TASK 79-21-49-200-100.

Decrease the pressure in the tube to zero.

Stop the Hydraulic pressure testing rig.

Open the bleed valve.

Disconnect the tube from the outlet of the hydraulic pressure testing rig and the bleed valve adapter.

Remove the pressure MS21914-4 Blanking cap from the tube.

WARNING

BE CAREFUL WHEN YOU USE COMPRESSED AIR. PUT ON PROTECTIVE CLOTHING AND GOGGLES.Remove unwanted fluid from the tube with clean, dry compressed air.

SUBTASK 79-21-49-780-052 Do the Hydraulic Pressure Test on the Tube (17-100, 17-500 and 18-100)

Install an applicable MS21914-4 Blanking cap to the tube (17-100).

Install an applicable MS21914-4 Blanking cap to the 'T' connector on the tube (17- 500).

Install an applicable MS21914-4 Blanking cap to the tubes (17-500 and 18-100).

SUBTASK 79-21-49-780-053 Prepare the Tubes (17-100, 17-500 and 18-100) for the Pneumatic Pressure Test

Connect the tube to the outlet of the Pneumatic pressure testing rig.

Put a pressure of 14.5 psi (100 kPa) in the tube.

Put the tube in the water tank.

Let the pressure stay in the tube for 1 minute.

Make sure that the tube has no leaks. If the tube has leaks, reject the tube, refer to Inspection-000 TASK 79-21-49-200-100.

Decrease the pressure in the tube to zero.

Disconnect the tube from the outlet of the pneumatic pressure testing rig.

Remove the MS21914-4 Blanking cap or MS21913-4 Blanking plug from the tube.

SUBTASK 79-21-49-780-054 Do the Pneumatic Pressure Test on the Tube (17-100, 17-500 and 18-100)

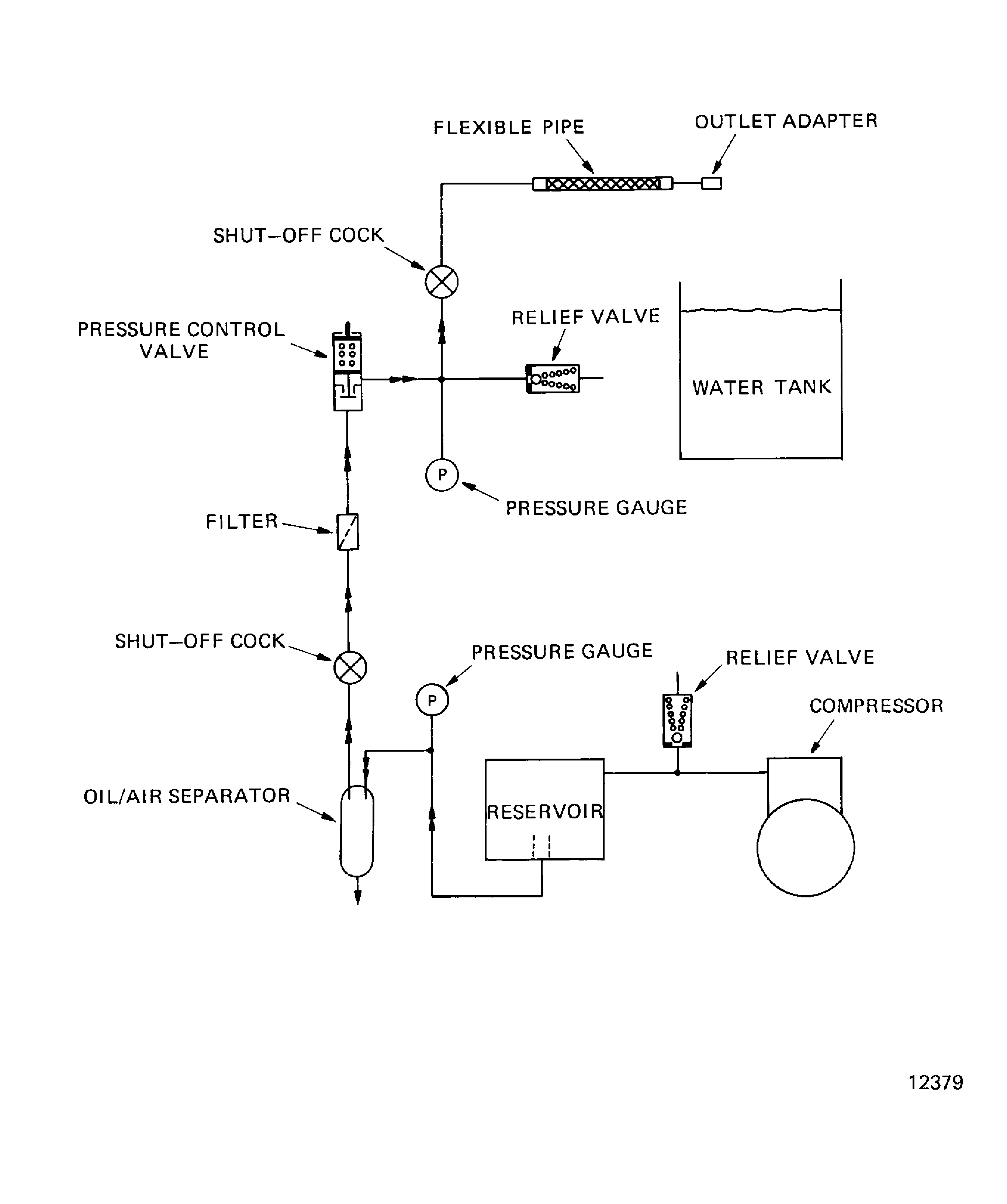

Figure: Hydraulic Pressure Testing Rig

Hydraulic Pressure Testing Rig

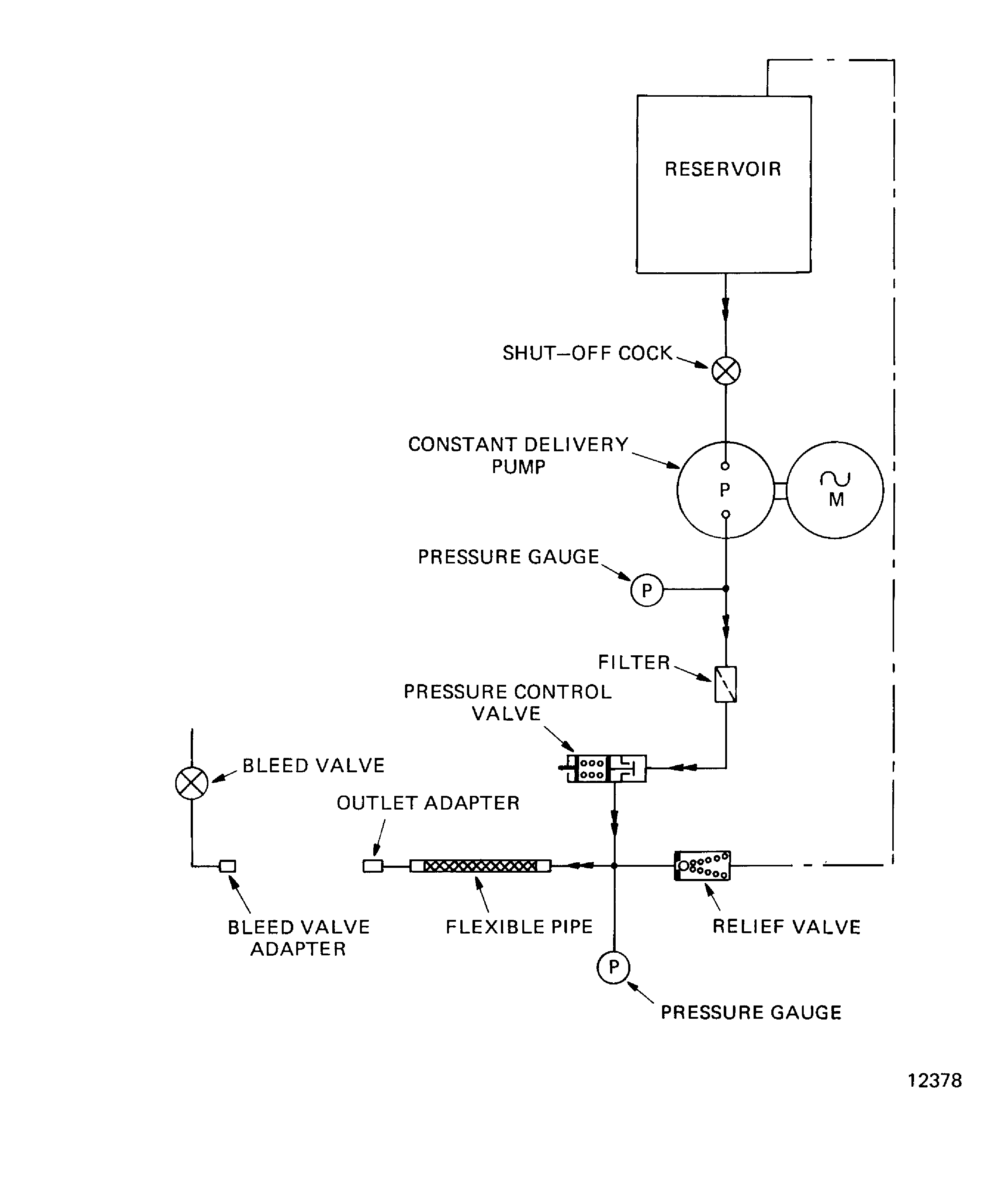

Figure: Pneumatic Pressure Testing Rig

Pneumatic Pressure Testing Rig