Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 79-22-41-700-401 Oil Scavenge Pump - Related Parts - Do A Test On The Oil Scavenge Pump, Testing-001

Effectivity

FIG/ITEM | PART NO. |

01-001 | 4A7013 |

01-001 | 4A7112 |

01-001 | 4A7114 |

01-001 | 4A7117 |

01-001 | 4A7118 |

01-001 | 4A7120 |

01-001 | 4A7121 |

01-001 | 4A7123 |

01-001 | 4A7123A |

01-001 | 4A7124 |

01-001 | 4A7124A |

General

NOTE

If installed remove storage parts from the oil scavenge pump.

Do not allow oil to become aerated.

Make sure that the drive oil pump turn free by hand.

Pump rotation must be anticlockwise (view the drive end).

Monitor the pump for unusual noises during the test.

For standard torque data and procedures, refer to SPM TASK 70-41-02-400-501 and SPM TASK 70-42-00-400-501.

WARNING

WARNING

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Motor drive unit | LOCAL | Motor drive unit | Variable speed 300 to 3000 rpm and 30 kW. | |

| Oil pump | LOCAL | Oil pump | 350 l/min and 6 kW. | |

| Adapter | LOCAL | Adapter | To connect the oil scavenge pump to the test bench. | |

| Heat exchanger | LOCAL | Heat exchanger | ||

| Filter | LOCAL | Filter | 5 micron. | |

| Flowmeter | LOCAL | Flowmeter | (4 off) | I 1 to 12.4 gal/min (4 to 47 l/min). |

| Flowmeter | LOCAL | Flowmeter | (2 off) | II-2.4 to 25 gal/min (9,4 to 94,6 l/min). |

| Flowmeter | LOCAL | Flowmeter | III-12.4 to 124 gal/min (47 to 473 l/min). | |

| Flowmeter | LOCAL | Flowmeter | (4 off) | I-1 to 12.4 gal/min (4 to 47 l/min). |

| Flowmeter | LOCAL | Flowmeter | (2 off) | II-2.4 to 25 gal/min (9.4 to 94.6 l/min). |

| Flowmeter | LOCAL | Flowmeter | III-12.4 to 124 gal/min (47 to 473 l/min). | |

| Pressure gauge | LOCAL | Pressure gauge | (2 off) | 0 to 100 psig (0 to 689 KPa). |

| Temperature gauge | LOCAL | Temperature gauge | (3 off) | 32 to 392 deg F (0 to 200 deg C). |

| Vacuum gauge | LOCAL | Vacuum gauge | (12 off) | 0 to -30 in.Hg. |

| Vacuum pump | LOCAL | Vacuum pump | 0 to -28 in.Hg. | |

| Oil reservoir | LOCAL | Oil reservoir | Minimum capacity 53 gal (200 l). | |

| Hoses | LOCAL | Hoses | Inner diameter 0.787 in. (20 mm). |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

The Source Demonstration requirements of this testing means that any facility not authorized to perform this testing either utilize the Authorized Testing Vendor listed below or contact IAE Technical Services to determine if qualification program can be initiated at their facility.

IAE - INTERNATIONAL AERO ENGINES

400 Main Street

East Hartford , CT 06108

U.S.A.

Authorized Vendors for this testing are listed below:

AVIO - Divisone AvioService

EF5Y829M

Viale Impero angolo Viale Alfa

80038 Pomigliano d'Arco (NA)

ITALY

IHI Corporation (IHI)

IHI Mizuho Plant

229 Tonogaya

Mizuho-Machi

Nishitama-Gun

Tokyo 190-1297

JAPAN

The designation by IAE of an authorized testing vendor indicates that the vendor has demonstrated the necessary capability to enable it to carry out the testing. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the vendor to carry out the testing, and accepts no responsibility what so ever for any work that may be carried out by a vendor, other than when IAE is listed as the vendor. Authorised vendors do not act as agents or representatives of IAE.

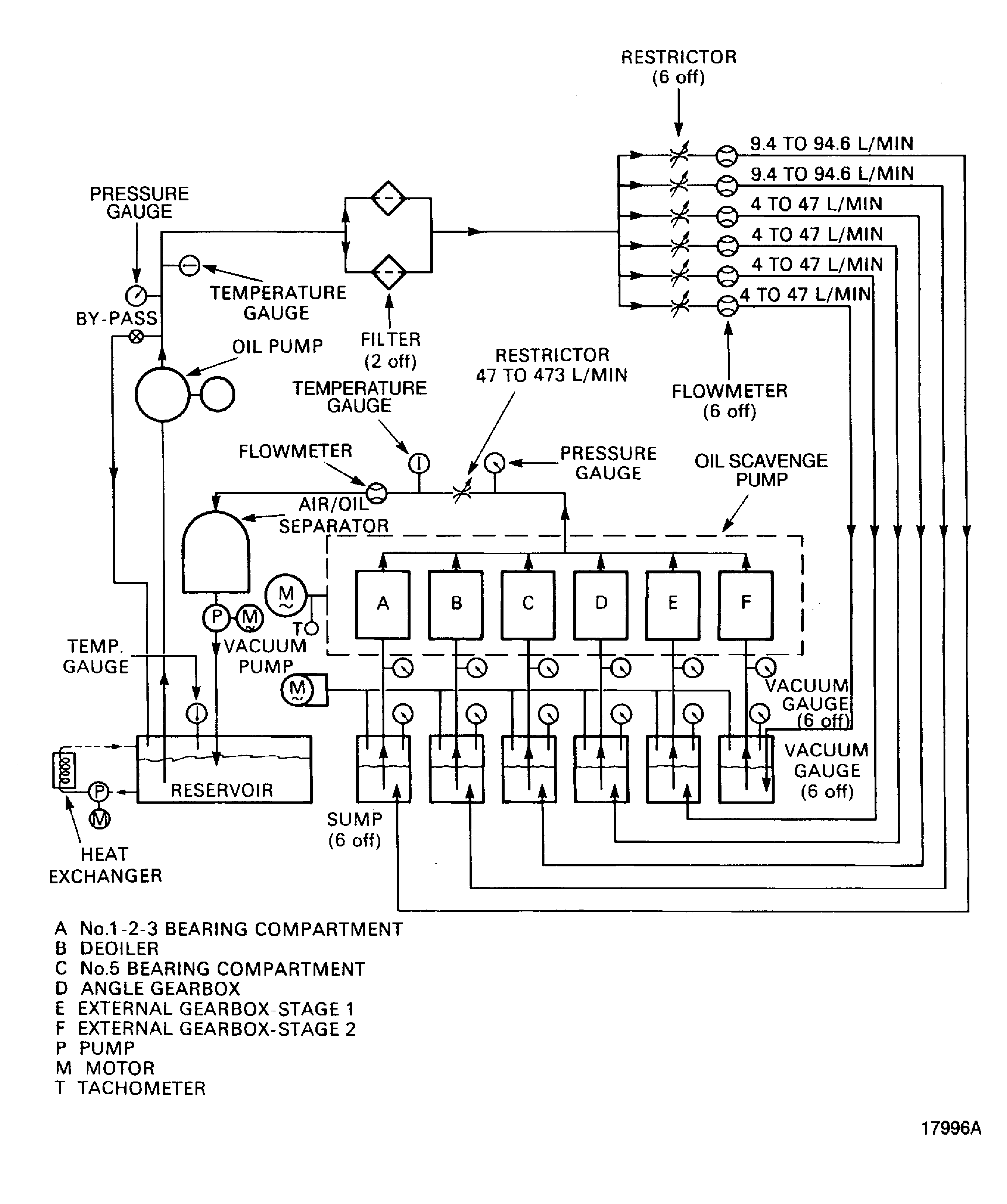

Set up the test bench. Refer to Figure.

Adjust the heater to maintain the oil supply at a temperature of 230~F (110 deg C).

Operate the oil scavenge pump, adjust the speed to 2860 rpm, the discharge pressure to 25 psi (172 KPa) and the vacuum inside sumps to 0 in.Hg.

Run-in the pump for 30 minutes.

Monitor the oil level in the sumps.

SUBTASK 79-22-41-790-052 Do the Running-in on the Oil Scavenge Pump

Operate the Vacuum pump and adjust the vacuum in the six sumps and the oil flow to the first value given in Figure.

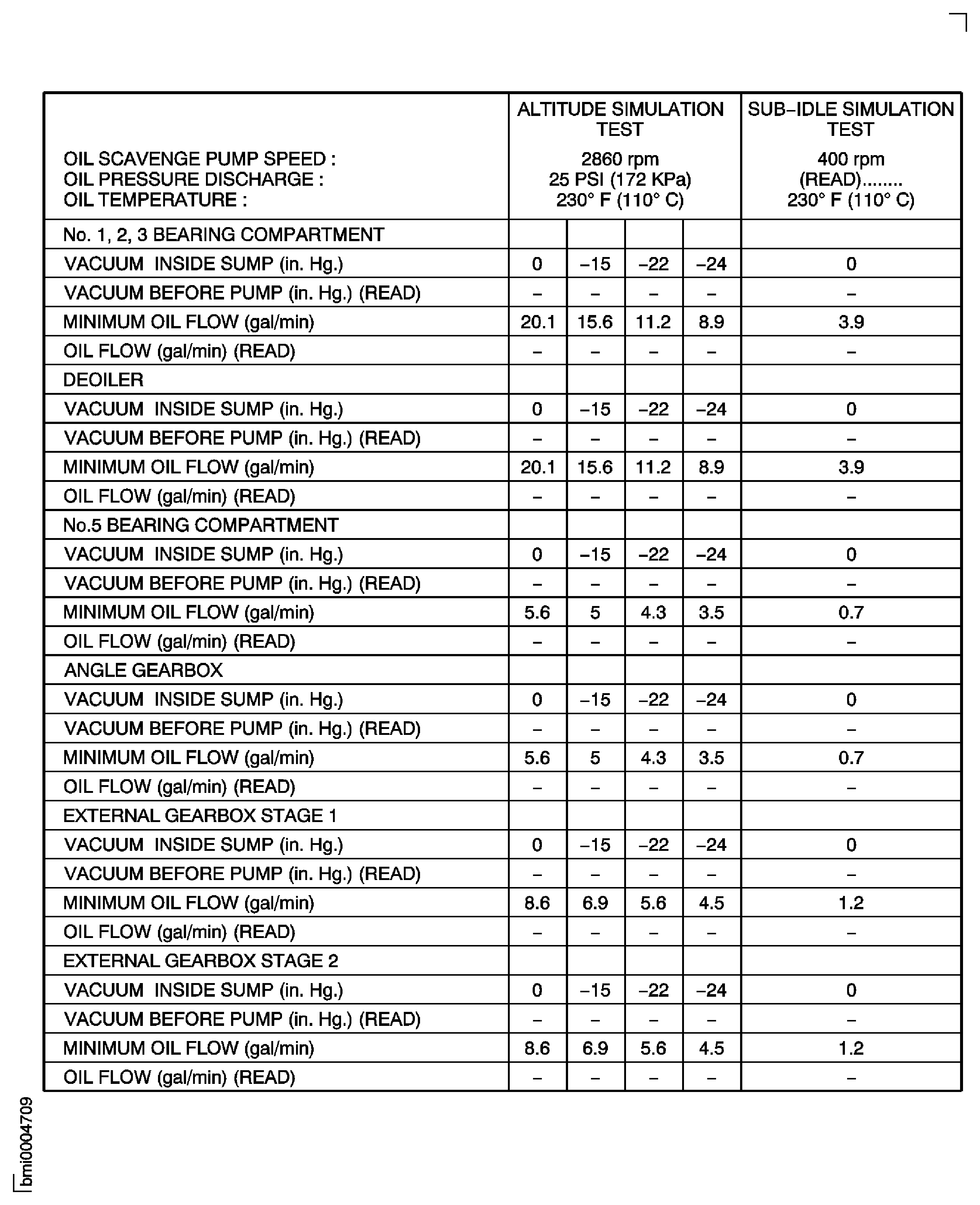

Read and record on the scavenge pump data sheet all the required values. Refer to Figure.

SUBTASK 79-22-41-790-053 Do the Altitude Simulation Test on the Oil Scavenge Pump

Adjust the flow in order to keep the oil level in the sumps constant.

Wait for five minutes and check again the oil level in the sumps.

The oil level in the sumps must remain constant.

Read and record on the scavenge pump data sheet all the required values. Refer to Figure.

SUBTASK 79-22-41-790-054 Do the Sub-Idle Simulation Test on the Oil Scavenge Pump

NOTE

Do not change the oil pressure discharge setting.

Figure: Oil Scavenge Pump Altitude Simulation Test Set-Up

Oil Scavenge Pump Altitude Simulation Test Set-Up

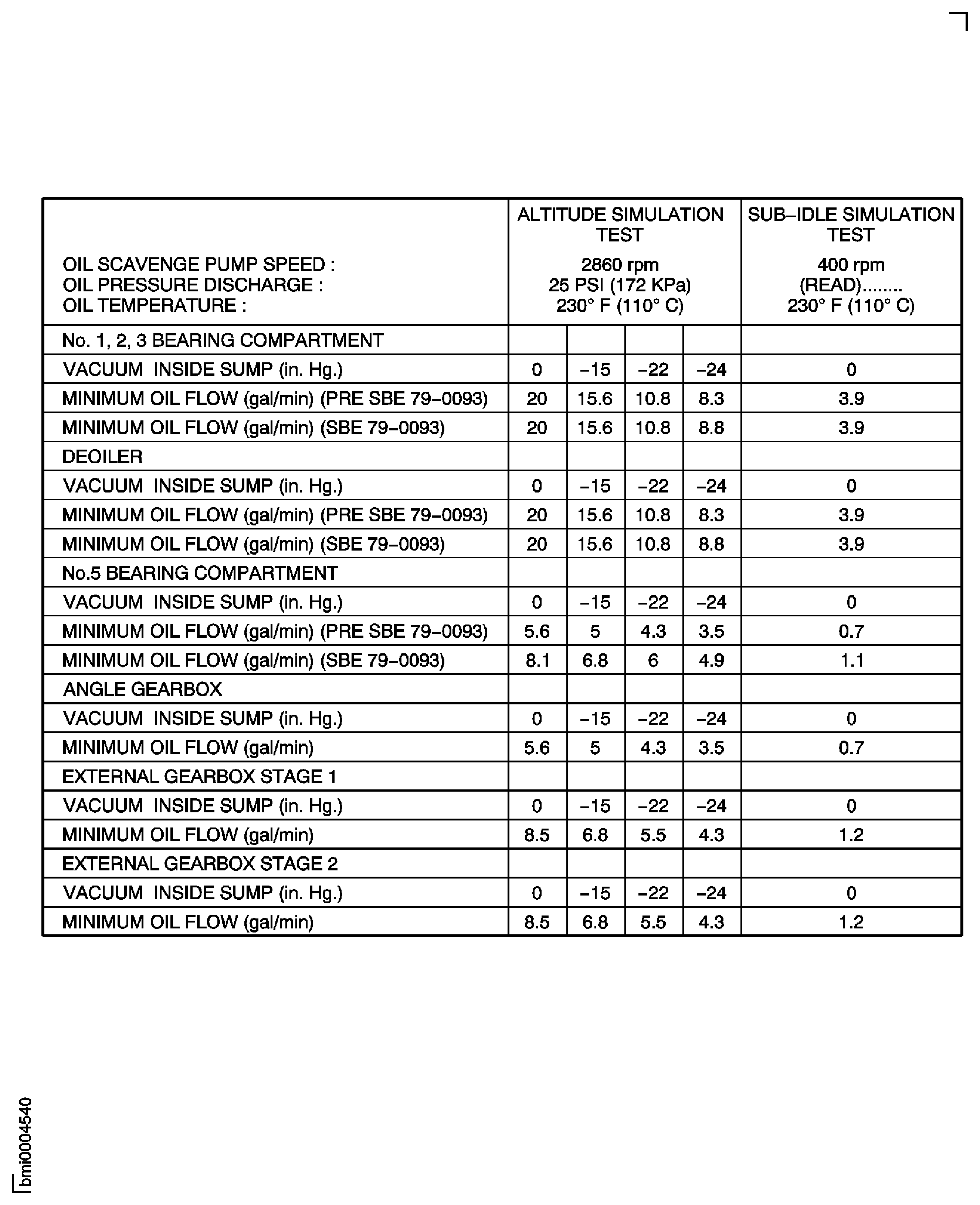

Figure: Oil Scavenge Pump Altitude Simulation Test Set Value

Oil Scavenge Pump Altitude Simulation Test Set Value

Figure: Oil Scavenge Pump Data Sheet

Oil Scavenge Pump Data Sheet