Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 79-22-41-300-030 Oil Scavenge Pump - Related Parts - Nickel Plate The Cover Seat In The Casing Assembly, Repair-030 (VRS5367)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop Inspection Equipment | LOCAL | Workshop Inspection Equipment | ||

| Grinding Machine | LOCAL | Grinding Machine | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| Oven | LOCAL | Oven | 4X | |

| Magnifying glass | LOCAL | Magnifying glass | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-067 STRIPPABLE COATING | 71410 | CoMat 02-067 |

Spares

NONESafety Requirements

NONEProcedure

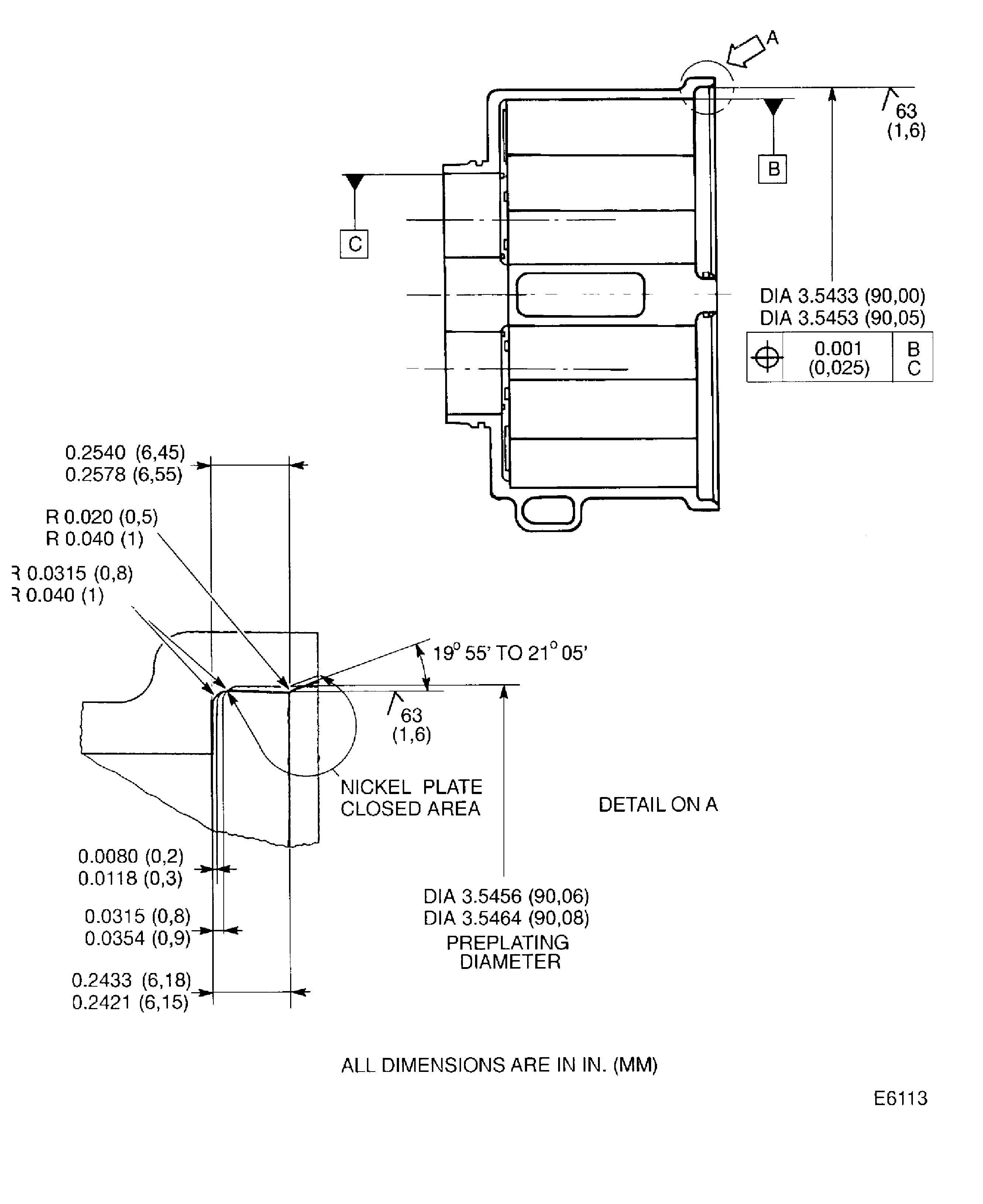

Refer to Figure.

Remove all damage and wear.

The cover seat must be between 3.5456 to 3.5464 in. (90.060 to 90.080 mm) after the removal of the damage.

Keep the removal of the material to the minimum necessary to remove the damage

Machine the cover seat

SUBTASK 79-22-41-320-055 Machine the Cover Seat in the Casing Assembly

No cracks are permitted.

Refer to SPM TASK 70-23-01-230-501.

Do the fluorescent penetrant inspection for cracks

SUBTASK 79-22-41-230-059 Examine the Casing Assembly

Refer to Figure.

Mask the areas of the casing assembly not to be plated

Refer to SPM TASK 70-33-08-300-503.

Plate to a sufficient thickness to permit machining to the last dimensions indicated in the reference figure.

Plating out of the piloting diameter area is permitted, but must be removed

Do the nickel plating

Remove the mask.

Flush with cold water.

Flush with hot water.

Dry with an air blast.

Clean and dry the drive gear

SUBTASK 79-22-41-330-067 Nickel Plate the Cover Seat in the Casing Assembly

Do this procedure as soon as possible, in less than 4 hours, after plating

Put the casing assembly into an Oven at 241 to 260 deg F (116 to 127 deg C) for 60 to 90 minutes

SUBTASK 79-22-41-370-053 De-embrittle the Casing Assembly

Plating must have a constant color. No circumferential cracks are permitted.

No roughness or blistering is permitted

Do a visual inspection of the plating for finish, cracks and adhesion

SUBTASK 79-22-41-220-160 Examine the Casing Assembly

Refer to Figure.

Use a grinding machine.

The dimension must be between 3.5433 to 3.5453 in. (90.000 to 90.050 mm).

Chamfer where necessary.

Machine the cover seat

SUBTASK 79-22-41-320-056 Machine the Cover Seat in the Casing Assembly

Refer to Figure.

Use a 4X Magnifying glass. The natural network crack, emphasized by grinding is permitted.

Do the visual inspection of the plated area for cracks and adhesion

Do not accept a thickness of less than 0.0006 in. (0.015 mm), after the last machining.

Measure the thickness of the plating

SUBTASK 79-22-41-220-161 Examine the Nickel Plated Area

Refer to Figure.

Remove the metal lifted by marking.

Vibro-engrave, VRS5367, adjacent to the part number

SUBTASK 79-22-41-350-071 Record the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions