Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 71-00-00-700-063-A00 Test Cell Requirements, Testing-000

General

The operator or the overhaul agency must make sure that their test facility is calibrated correctly. The operator or the overhaul agency must make sure that the standard of calibration always meets the requirement of the Local Airworthiness Authority. You can contact your IAE representative to get the test facility correlation procedure.

Applicable test data must be corrected by specific test cell correction before you use the curves and limits given in these test procedures.

Test Cell Correlation (or Re-Correlation) Requirements:

There are several conditions for which test cells require correlation or re-correlation. When there is doubt regarding the requirement for correlation/re-correlation, IAE Product Support Group should be contacted for advice and recommendations. Examples of conditions that require a test cell correlation or re-correlation:

Following construction of a new test cell.

Following modifications that have been made to the external testing environment, new building construction or the teardown of an existing structure close to the test cell's inlet or exhaust.

When major changes are made to cell inlet or exhaust areas.

When the location of the engine exhaust relative to the exhaust augmentor tube is changed.

When changes that affect the airflow are made in the test cell.

When either a new engine model or derivative model of higher (and sometimes lower) thrust is introduced.

When modifications have been made to existing data acquisition which impact the engine performance evaluation method. For example:

Scanning, averaging and editing rates

Modifications to the instrumentation type, quantity and location.

Changes in the testing configuration that affect engine performance will also require a re-correlation. Examples of configuration changes:

Engine test hardware:

New or revised inlet configuration

New or revised exhaust system components (primary nozzle, fan ducts, thrust reversers, etc.)

If none of the above occurs, re-correlation is recommended every seven years unless trending of the test data is accomplished for quality purposes. This trending must identify root cause of any unexplained performance shifts or trends.

Some conditions that do not require test cell correlation are as follows:

Test cell modifications that do not affect the aerodynamics of the test cell or the performance of the engine.

Operation of an engine model in the same test configuration at a lower thrust level.

EEC and Test Cell Interface Requirements

The test facility must be able to communicate with the EEC for input and output data. The Automatic Data Acquisition and Processing System (ADAPS) is recommended. ADAPS gives the necessary EEC interface connections and data processing to monitor the engine operation and performance. Most of the EEC inputs are engine parameters, but some are aircraft inputs and must be simulated.

Communication with the EEC is by ARINC Specification 429 format. The parameters which follow must be input from ADAPS equipment to the EEC to both Channel A and B for all operation.

ARINC Label 203 = Pressure/altitude - actual condition

ARINC Label 242 = Total air pressure - actual condition

ARINC Label 211 = Total air temperature - actual condition

The Engine Interface Unit (EIU) Discrete inputs that are necessary are 030, 031 and 034.

The EEC output parameters which follow must be monitored by the text facility for all engine tests. The ARINC outputs are available in the ARINC 429 format.

ARINC Label 130 = T2

ARINC Label 131 = P2

ARINC Label 346 = N1

ARINC Label 344 = N2

ARINC Label 257 = P12.5

ARINC Label 262 = P2.5

ARINC Label 264 = Pb

ARINC Label 132 = P4.9

ARINC Label 263 = T2.5

ARINC Label 265 = T3

ARINC Label 345 = T4.9

ARINC Label 325 = Stator vane actuator feedback

ARINC Label 335 = 2.5 bleed feedback

ARINC Label 330 = HPT ACC feedback

ARINC Label 137 = Reverser position

ARINC Label 133 = Thrust lever angle

ARINC Label 315 = IDG oil temperature

ARINC Label 332 = Heat exchanger air valve feedback

ARINC Label 245 = Back to tank valve feedback

ARINC Label 300 = N2 DOT

ARINC Label 336 = N2C26

ARINC Label 244 = Fuel flow

ARINC Label 340 = EPR actual

ARINC Label 341 = EPR command

ARINC Label 342 = EPR take-off

ARINC Label 252 = EPR idle

ARINC Label 203 = Selected altitude

ARINC Label 205 = Selected mach number

ARINC Label 337 = EPR limit

ARINC Label 166 = Throttle EPR reference

ARINC Label 343 = Target EPR (Echo)

ARINC Label 214 = Flex take-off temperature

ARINC Label 115 = Fuel temperature

ARINC Label 316 = Oil temperature

Discrete 270 = Status word 1

Discrete 271 = Status word 2

Discrete 272 = Status word 3

Discrete 273 = Status word 4

Discrete 274 = Status word 5

Discrete 275 = Status word 6

Discrete 276 = Status word 7

Discrete 145 = Status word 8

Discrete 146 = Status word 9

Discrete 350 = Maintenance word 1

Discrete 351 = Maintenance word 2

Discrete 352 = Maintenance word 3

Discrete 353 = Maintenance word 4

Discrete 354 = Maintenance word 5

Discrete 155 = Maintenance word 6

Discrete 156 = Maintenance word 7

Discrete 157 = Maintenance word 8

Test Facility Instrumentation Requirements (for Data Not Always Acquired from ARINC)

Temperature requirements

T2E - The T2 value for all of the engine parameters and calculations will be the ARINC output from the engine T2 probe.

TWF - Fuel temperature sensor at the test cell fuel flow meter.

MOT - Oil System temperature

Pressure requirements

P2E - The P2 value for all of the engine parameters and calculations will be the ARINC output from the engine P2 probe.

P25 - Station 2.5 probe. For engines with Engine Condition Monitoring (ECM), the EEC gives P2.5 over ARINC. For engines without ECM, the test facility must sense the P2.5 probe.

PBAR - Ambient pressure outside the test cell and in the environment of the test facility pressure transducers.

P125 - Station 12.5 probe. For engines with ECM, the EEC gives P12.5 over ARINC. For engines without ECM, the test facility must sense the P12.5 probe.

PCELL (inlet) - A minimum of one pressure sensor in the test cell near the plane of the intake flare inlet out of the engine flow stream.

PCELL (exhaust) - A minimum of one pressure sensor in the test cell near the plane of the common nozzle exhaust out of the engine flow stream.

P4SCAV - No. 4 bearing compartment scavenge pressure: pressure level at low and high power

General requirements

No. 4 bearing compartment scavenge valve position

WF - Two fuel flow measurement devices

FN - Engine thrust measurement system

Low oil pressure switch position

Oil quantity indicator

Scavenge oil filter differential switch position

Nacelle temperature sensors

Fuel inlet pressure and temperature

Specific humidity

Lower heating valve of the fuel that is used

Starter air pressure

Main oil differential pressure

Specific gravity of the fuel that is used.

Oil tank oil temperature

Fuel filter differential switch position

VFAVM (vibration) one duel channel transducer.

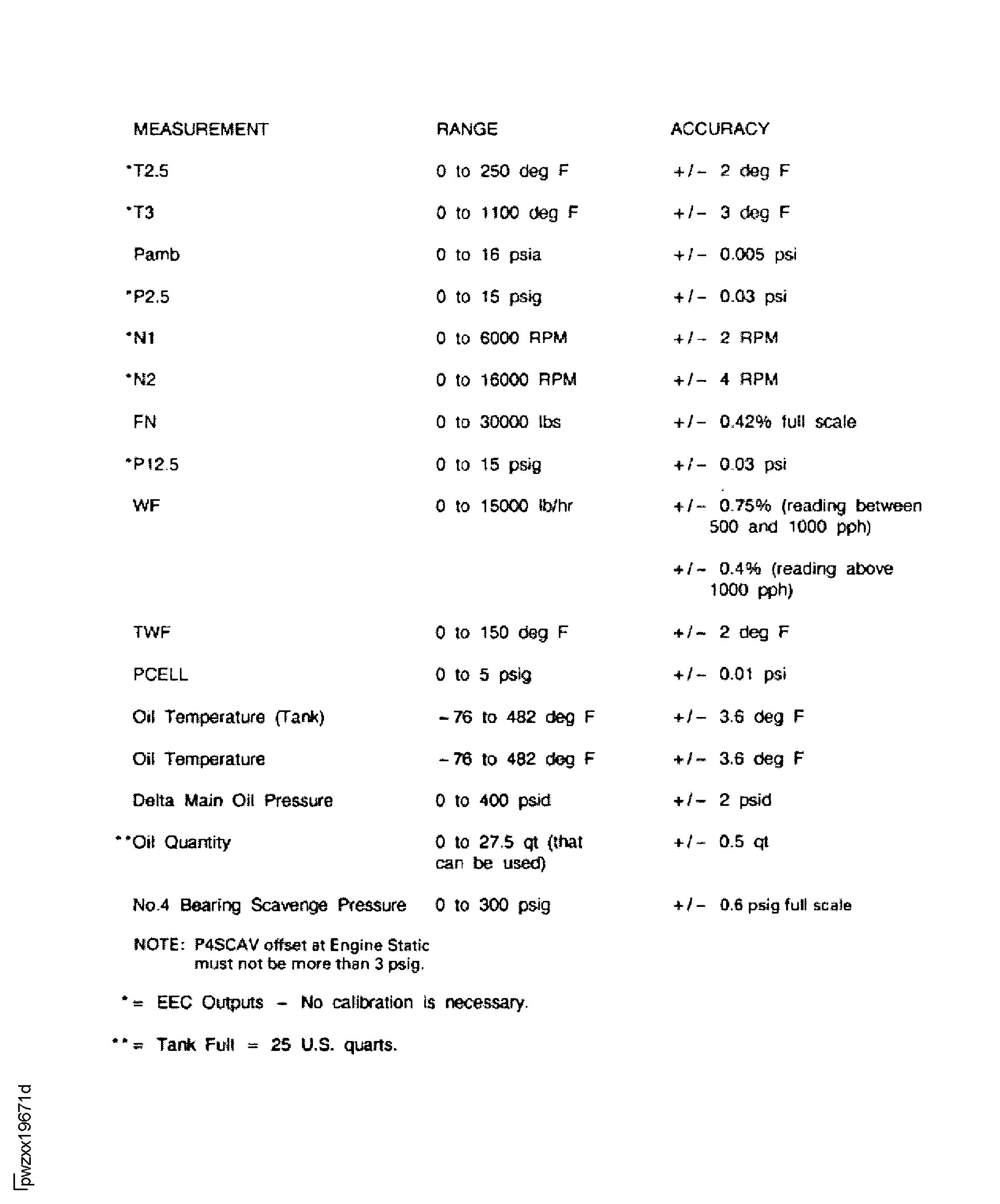

Instrumentation Accuracy

Refer to Figure or instrumentation accuracy.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Figure: Instrumentation accuracy

Instrumentation accuracy