Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 71-00-00-700-066-B00 Adjust Procedure For The Oil Pressure Pump Trim Valve, Testing-000

Adjust the Trim Valve

Obtain corrected oil pressure at idle. Refer to TASK 71-00-00-700-051-B00 (TESTING-000, CONFIG-002) for limits. Record the corrected oil pressure.

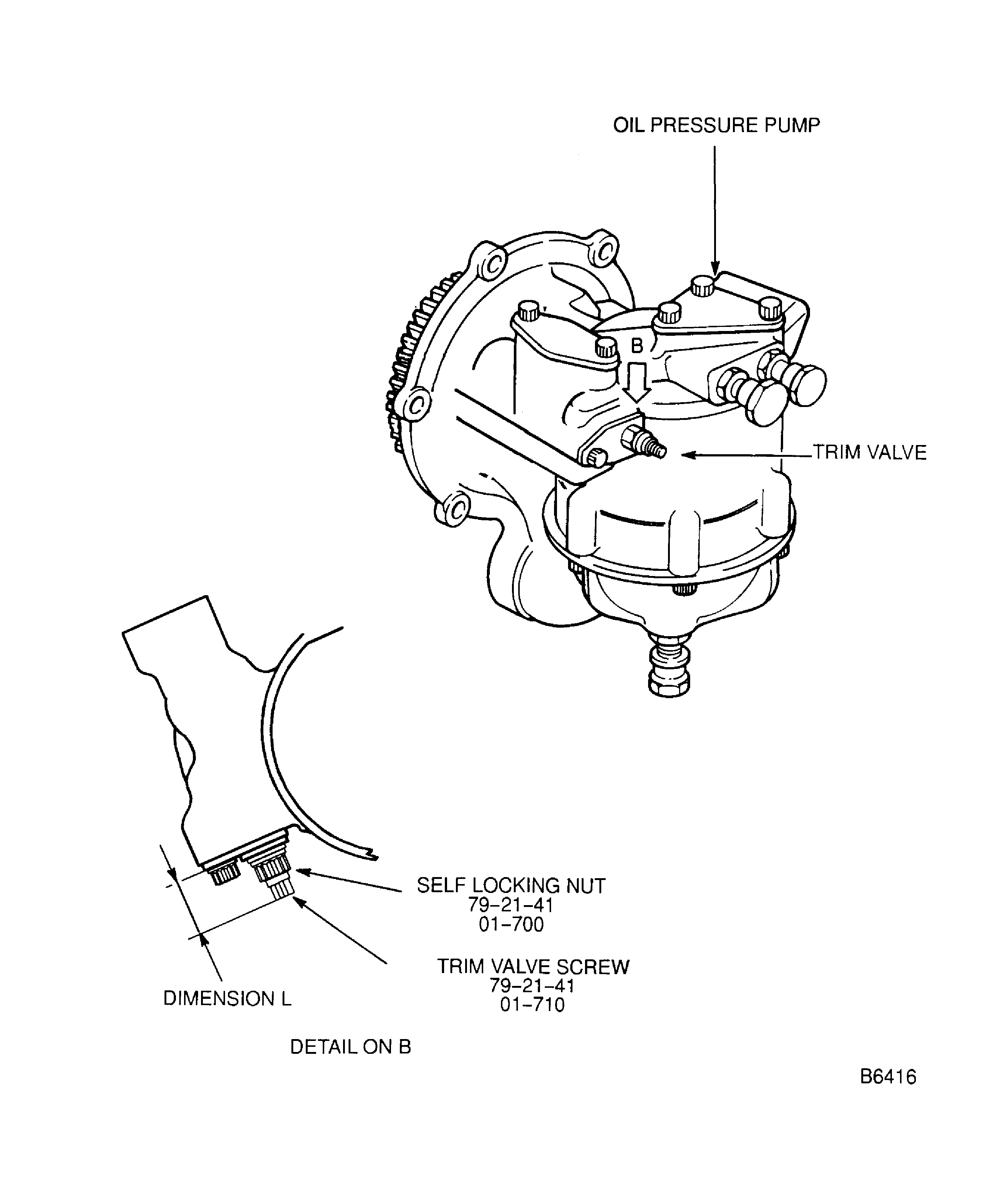

Identify the trim valve located on the oil pressure pump and filter assembly. Refer to Figure.

Deleted.

Temporarily identify relative position of trim valve to pump casting. Use marker.

Adjust the trim valve. Refer to Figure.

Hold the trim valve screw with a suitable wrench and loosen the self locking nut. Turn counterclockwise to loosen the self locking nut.

Turn clockwise the trim valve screw as necessary.

Record the rotation amount of the trim valve screw.

Hold the trim valve screw with a wrench and turn clockwise the self locking nut.

Torque the locking nut to between 290 to 370 lbf.in (33 to 42 Nm).

Measure and record the dimension L. Use a sliding caliper.

Do an idle check. Refer to TASK 71-00-00-700-003 (TESTING-003).

Check and record the measured oil pressure at idle.

Correct the oil pressure at idle.

If corrected DMOP is above the lower limit, clear the engine for further service.

If corrected DMOP is still below the lower limit, start procedure again.

If you do not get minimum DMOP, reject the pump.

NOTE

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Sliding Caliper | LOCAL | Sliding Caliper |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

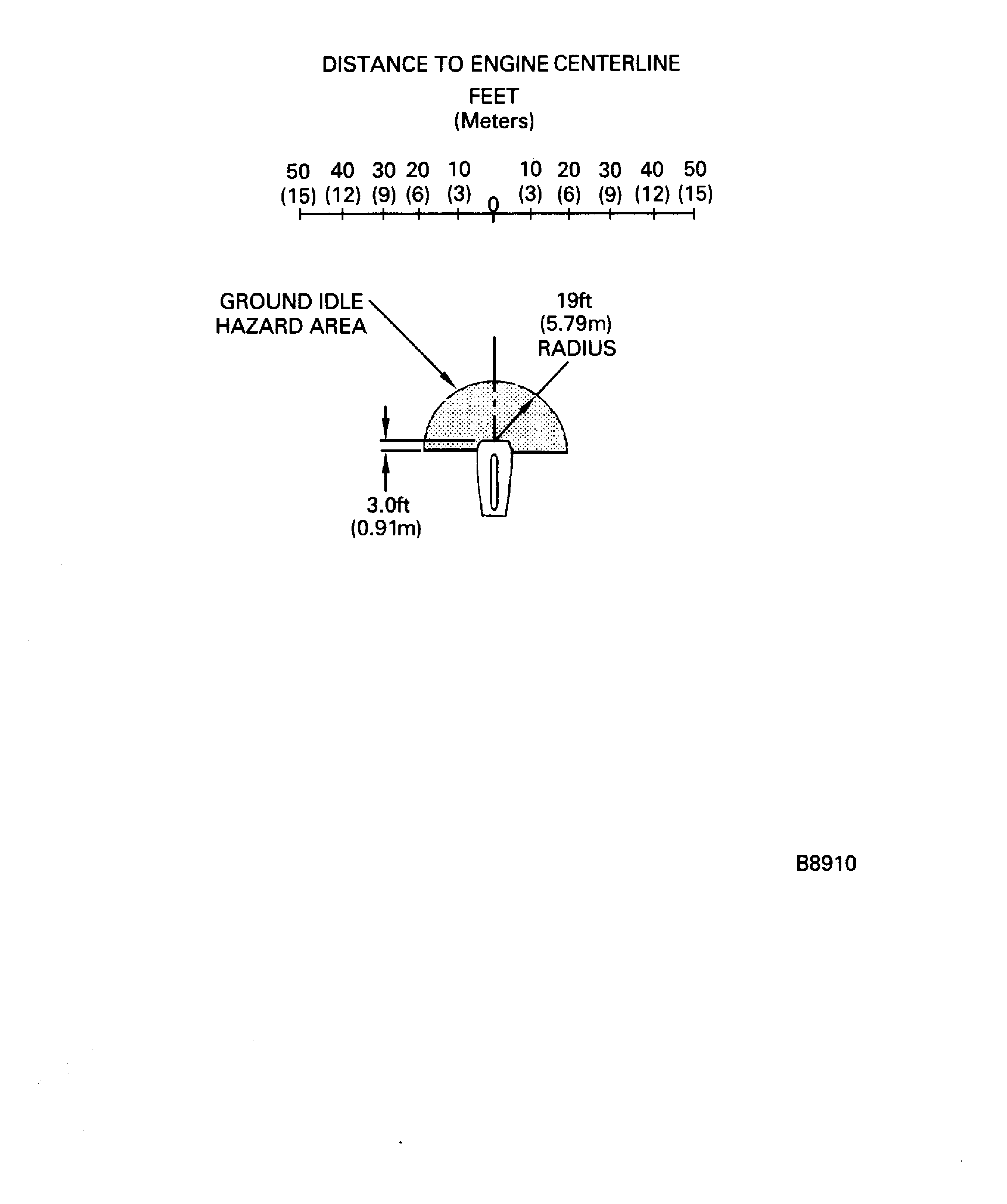

Figure: Air intake (ground idle)

Air intake (ground idle)

Figure: Jet Wake Velocity Contour Air Intake (Maximum Takeoff Thrust) (Deleted)

Jet Wake Velocity Contour Air Intake (Maximum Takeoff Thrust) (Deleted)

Figure: Jet Wake Velocity Contour (Ground Idle Thrust) (Deleted)

Jet Wake Velocity Contour (Ground Idle Thrust) (Deleted)

Figure: Jet Wake Velocity Contour (Maximum Takeoff Thrust) (Deleted)

Jet Wake Velocity Contour (Maximum Takeoff Thrust) (Deleted)

Figure: Jet Wake Temperature Contour (Maximum Takeoff Thrust) (Deleted)

Jet Wake Temperature Contour (Maximum Takeoff Thrust) (Deleted)

Figure: Main Oil Pressure (Mop) Limits (Deleted)

Main Oil Pressure (Mop) Limits (Deleted)

Figure: Differential Main Oil Pressure (Dmop) Idle Correction Equation (Deleted)

Differential Main Oil Pressure (Dmop) Idle Correction Equation (Deleted)

Figure: Engine Interface Unit (Eiu) Inputs (Deleted)

Engine Interface Unit (Eiu) Inputs (Deleted)

Figure: Gearbox crank pad location

Gearbox crank pad location

Figure: Start fault diagnostics

Start fault diagnostics

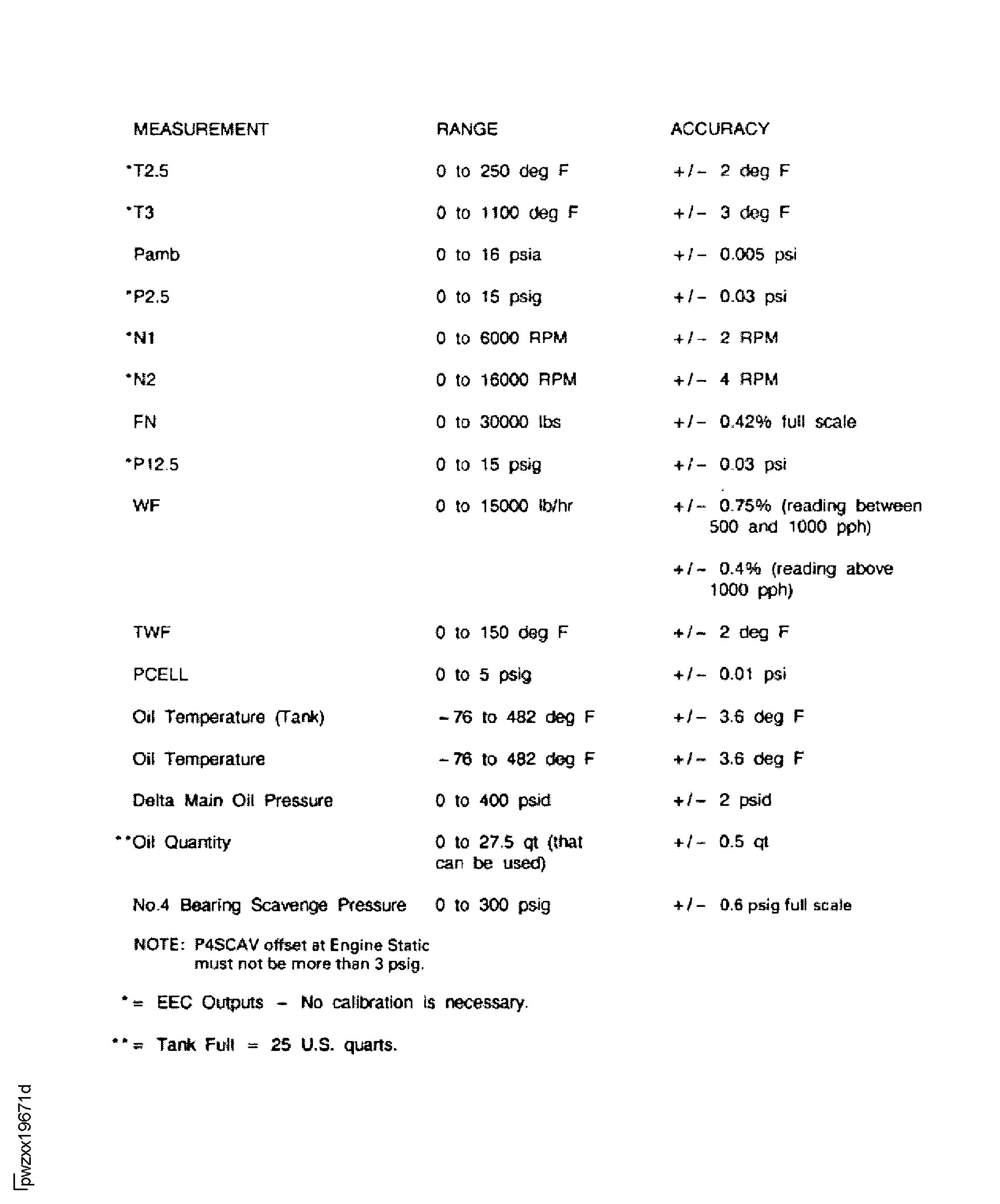

Figure: Instrumentation accuracy

Instrumentation accuracy

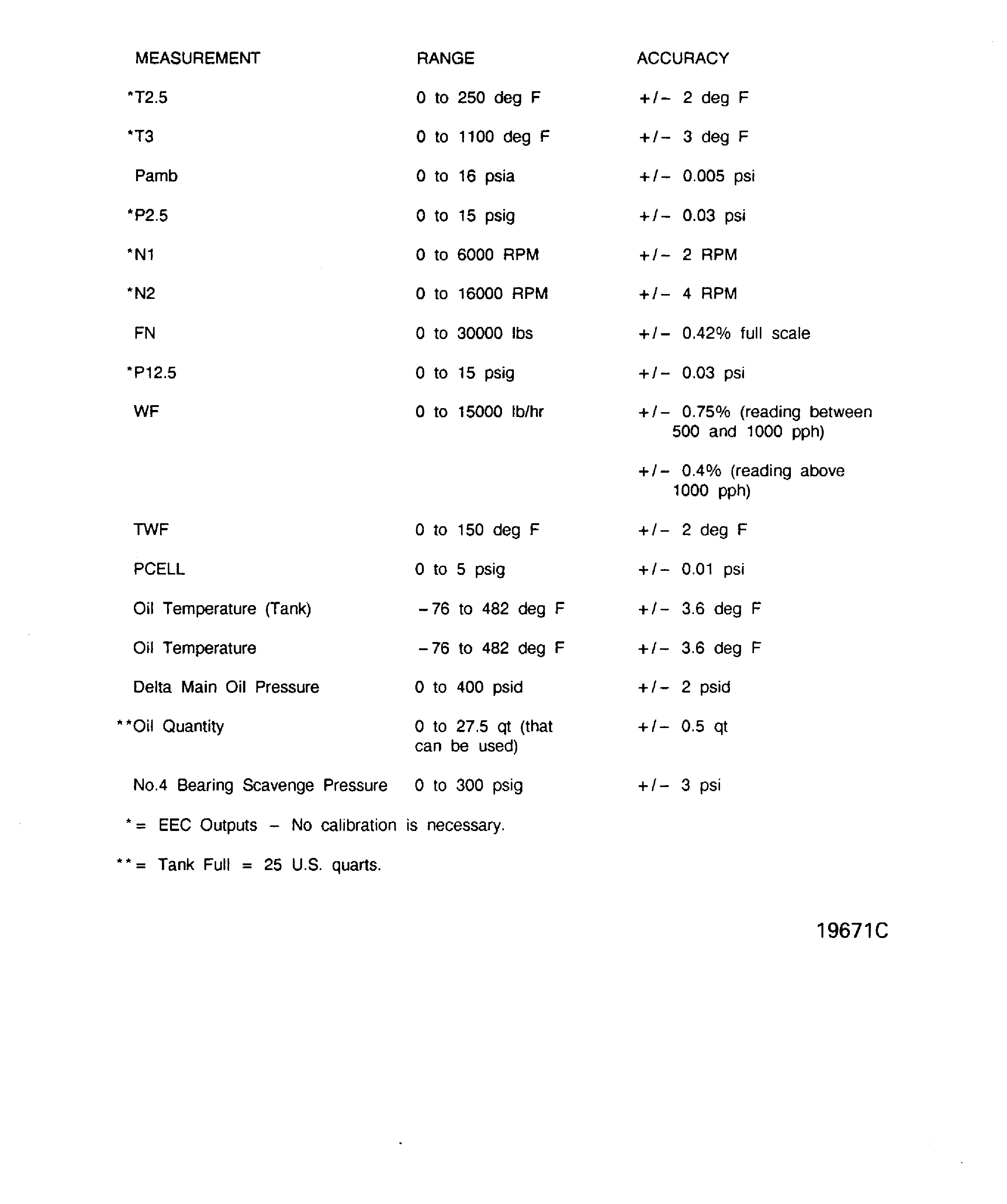

Figure: Instrumentation accuracy

Instrumentation accuracy

Figure: Fill the engine oil tank

Fill the engine oil tank

Figure: Adjust the trim valve

Adjust the trim valve