Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-52-43-300-006 EEC Core Harness And Voltage Divider Harness Assembly - Adding Sealant To BiFi Connectors To Avoid Moisture Ingress, Repair-006 (VRS9906)

General

This TASK details the procedure for the adding sealant to BiFi connectors to avoid moisture ingress.

Effectivity

Equipment and materials

General

All illustrations/Figs

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3J12704 Wrench and holder | LOCAL | IAE 3J12704 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-146 LOCKWIRE | LOCAL | CoMat 02-146 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | X222X | CoMat 08-013 | 75 ml | Silcoset 152 (when ordering small tube tip is necessary) |

Spares

NONESafety Requirements

NONEProcedure

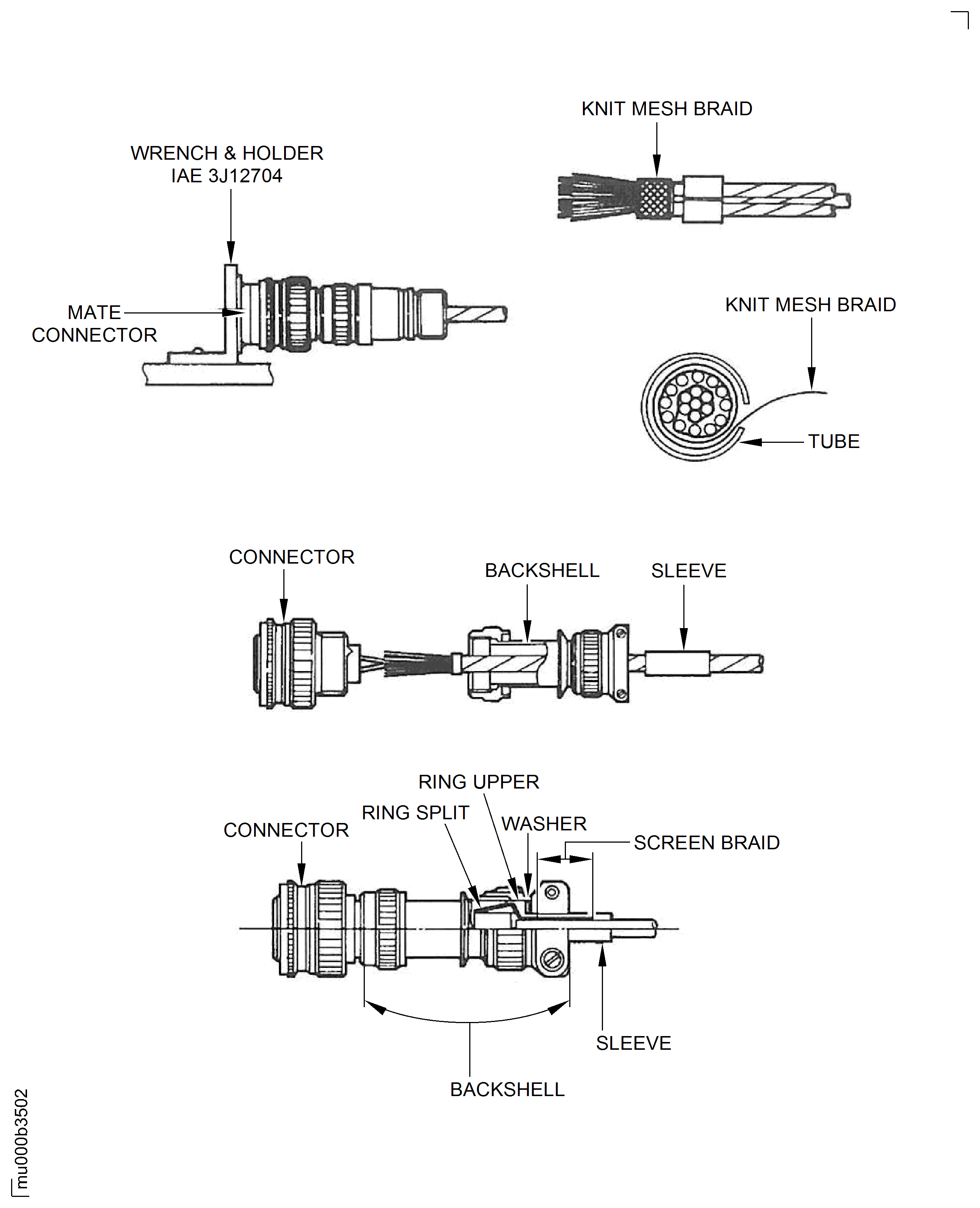

Refer to Figure.

Remove the safety wire, two screws, and clamp bar. Carefully push the bush rearwards. After removing clamp with bushing and lifting it up, ground cables have to be lifted as much as possible but without damaging or severing them. Be very careful to prevent damage.

Remove the clamp bar and move back the bush.

SUBTASK 71-52-43-360-001Prepare the Harness Adjacent to the Electrical Connector or Receptacle

Refer to Figure.

lnstall the electrical connector assembly to the IAE 3J12704 Wrench and holder, 1 off. Disconnect the backshell nut and move it along the cables.

Remove the backshell nut.

SUBTASK 71-52-43-360-002Remove the Backshell Nut from the Backshell

Fill the back of the connector with CoMat 08-013 COLD CURING SILICONE COMPOUND (one 75 ml tube can be used to fill both connectors) to completely cover the contacts inlets and sealing plugs with homogeneous layer of sealant (no more than 35 ml per connector). During silicone application on inside of connector it is recommended to do some wiggling with harness, to ensure that silicone layer is distributed evenly.

Wait until Silicon is fully cured 48 hours at 59 to 95 deg F (15 to 35 deg C) and in between 40 percent and 70 percent relative humidity. Do not apply a load during this time.

SUBTASK 71-52-43-360-003Applying Cold Curing Silicone Compound

NOTE

The connector must be dry before starting the task. lf the connector is damp, use the cloth to wipe it. The cables must be undamaged. lf cables are damaged, repair them first.Attach and tighten the backshell nut to the backshell so the different parts hold the screen braid tails.

SUBTASK 71-52-43-360-004lnstall the Backshell Nut to the Backshell

Push the bush forward so it packs the cables at the forward clamp bars. Attach the clamp bars together with the two screws, tighten the screws.

lnstall the bush and clamp bar adjacent to the electrical connector or receptacle.

Safety the backshell, nuts, and screws with CoMat 02-146 LOCKWIRE.

Safety the parts.

SUBTASK 71-52-43-360-005 Finish the Harness Adjacent to the Electrical Connector or Receptacle

Use permanent marker.

Make a mark VRS9906/A0 on the identification sleeve of the harness adjacent to the part number.

SUBTASK 71-52-43-360-006Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions