Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-02-02-350-501 Specified Types Of Damage

General

This TASK gives names to specified types of damage. This is to prevent errors which can occur when different names are used for the same type of damage. Always use the correct name for the specified type of damage or condition when an inspection is made on a component.

The definition of damages contained in this section does not include the Ball and Roller Bearings. For Ball and Roller Bearing Inspection/Description of Damages refer to TASK 70-29-01-290-501.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure.

TYPE OF DAMAGE

RELATED DATA

RELATED CONDITION

Arced

Flashed-over

The effects that can be seen (burned or fused metal) of an unwanted electrical discharge between two electrical connections

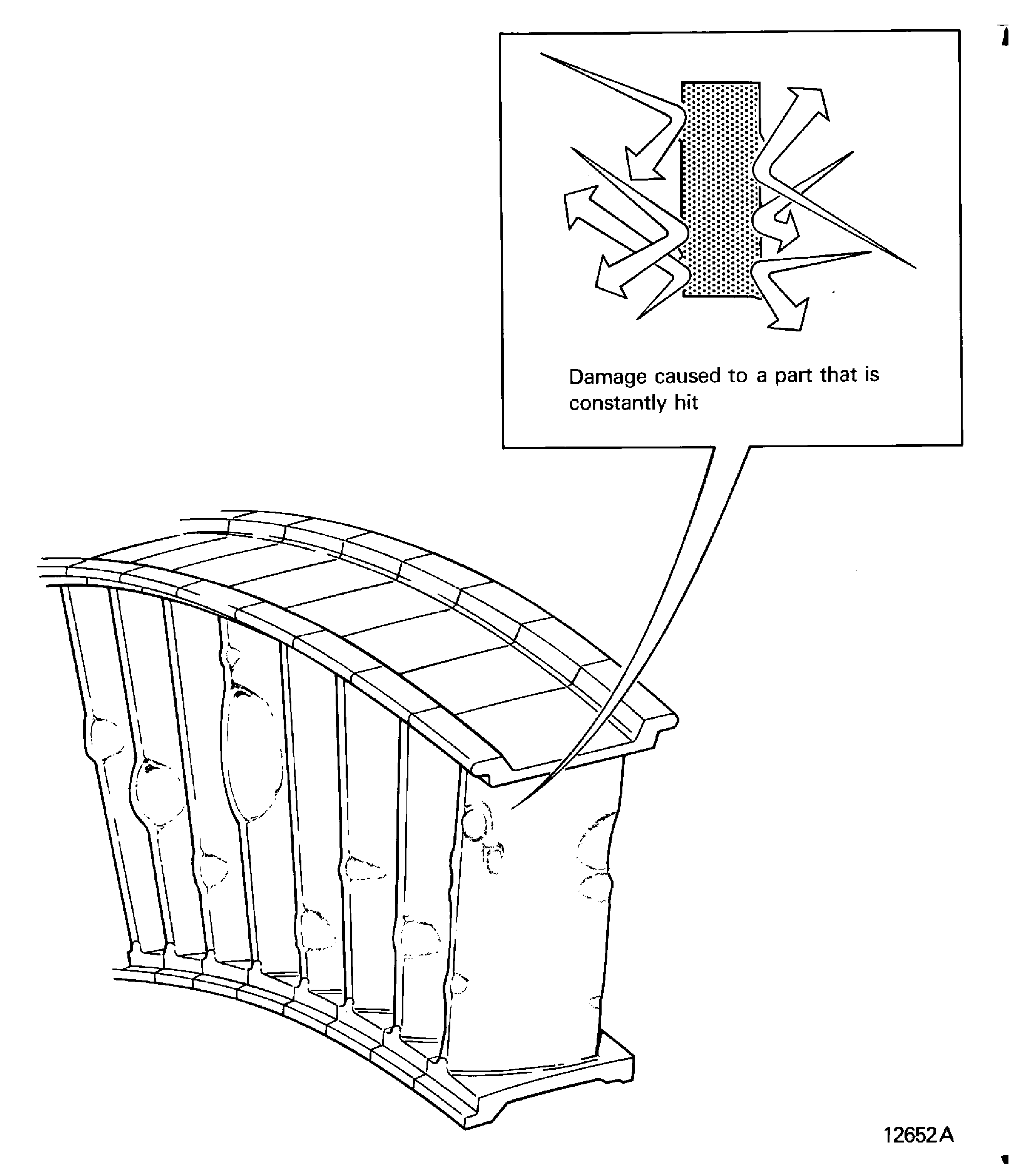

Battered

Damaged by impacts

Is damage caused to a part when it is constantly hit. Refer to Figure

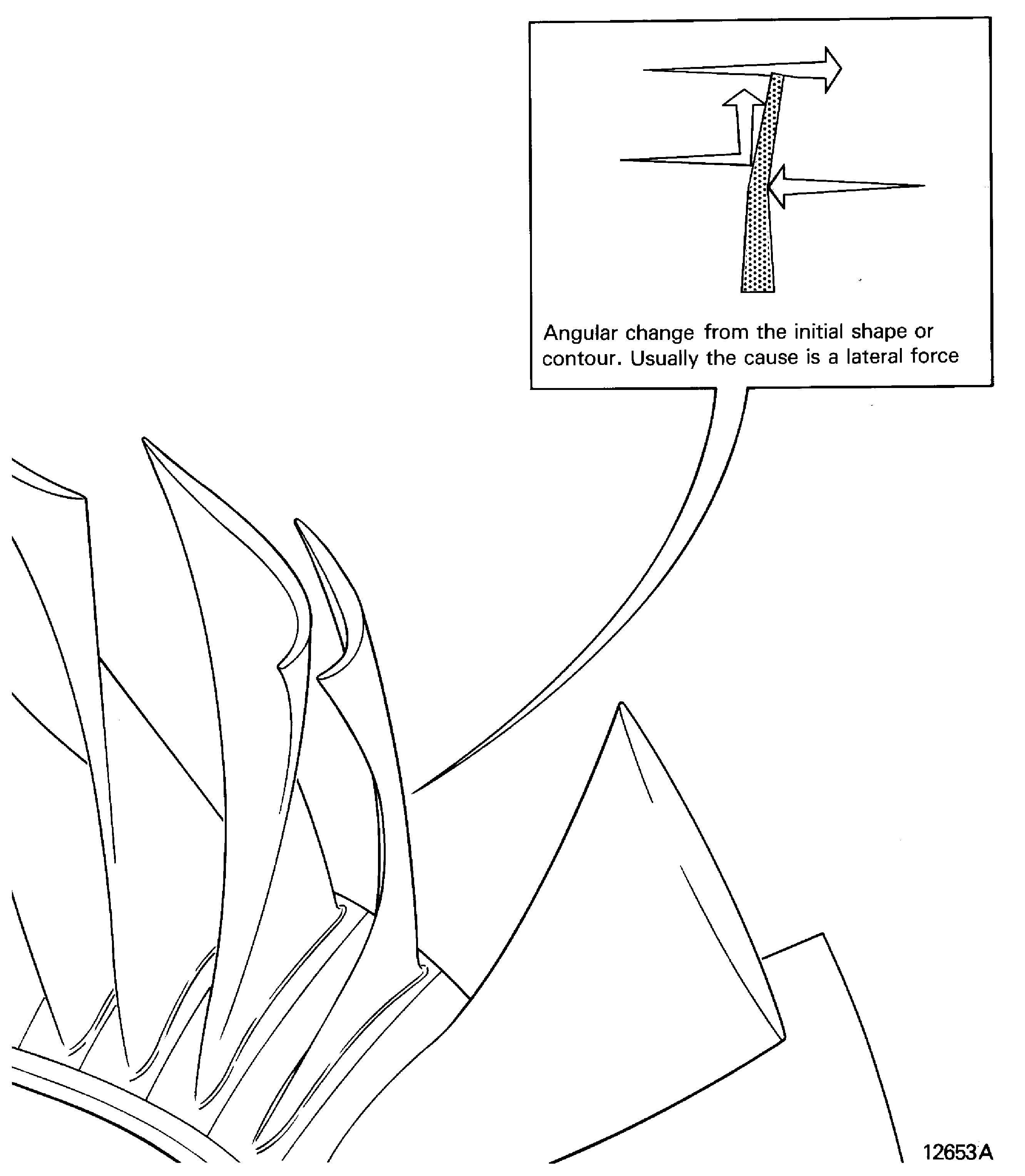

Bent

Creased, folded, kinked, leaning

Is angular change from the initial shape or contour usually the cause is a lateral force. Refer to Figure

Binding

Sticking, tight

Is decreased movement such as a tightened condition which results from very hot or very cold temperatures or an unwanted particle between surfaces

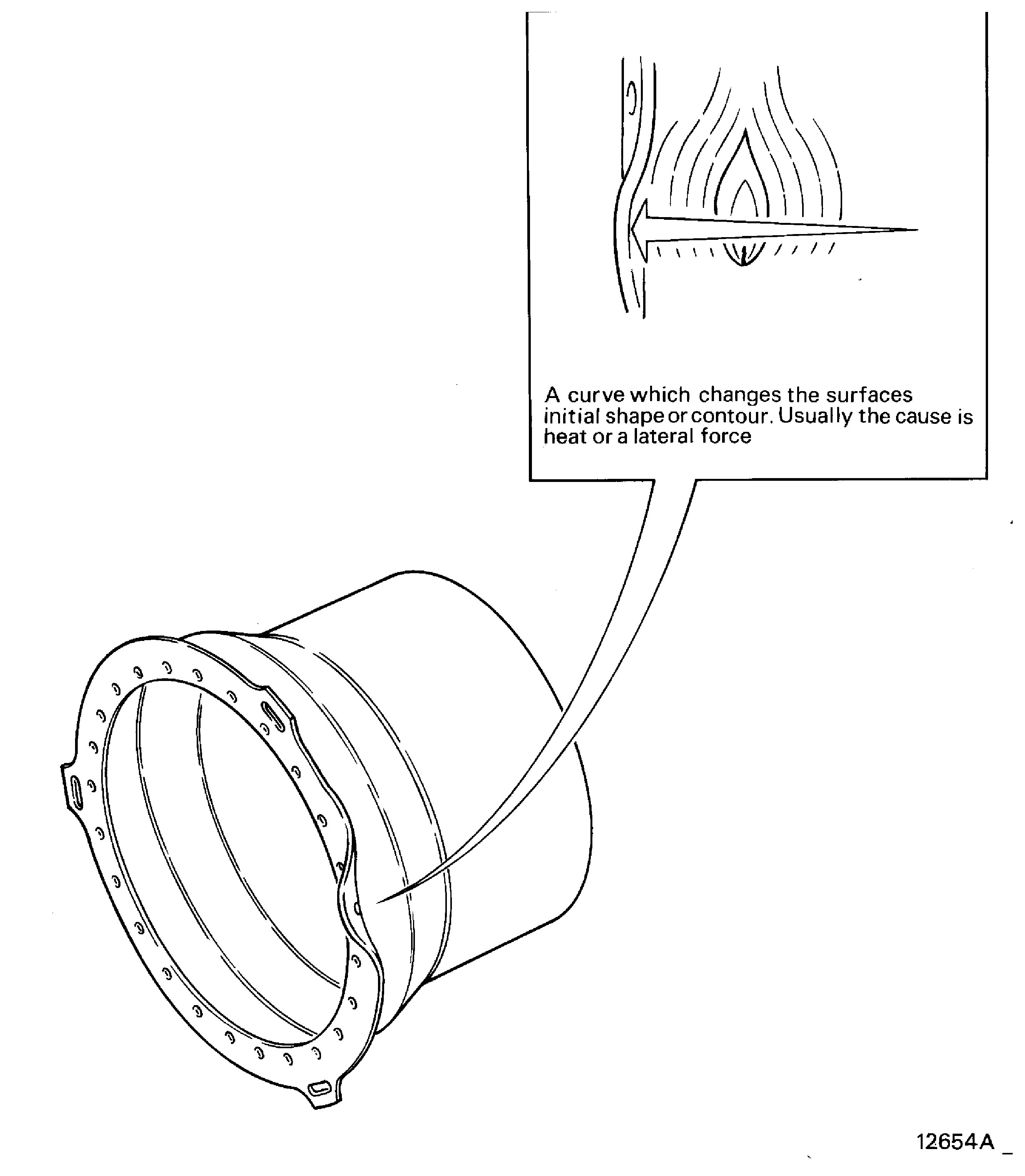

Bowed

-

A curve which changes the surfaces usual shape or contour. Usually the cause is heat or a lateral force. Refer to Figure

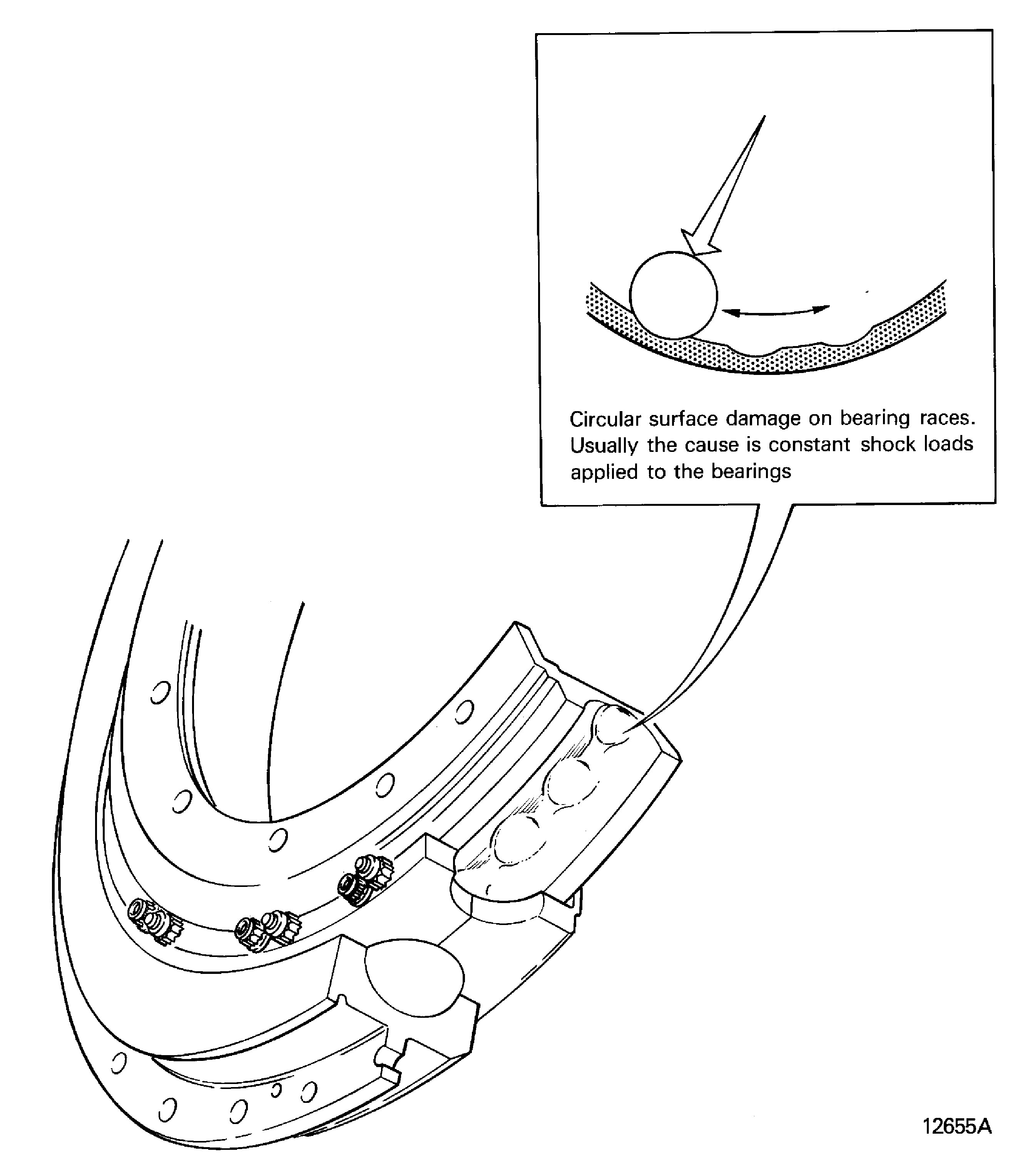

Brinelled

-

Circular surface damage on bearing races. Usually the cause is constant shock loads given to the bearing. Refer to Figure

False Brinelling

Roller bearings: It is seen as axial lines across the roller track which are surface blemishes. This is permitted.

Ball bearings: Are two marks related to each ball that can be seen on the ball track which are surface blemishes. This is permitted

Brittle

Perished

A change in the elasticity of the material

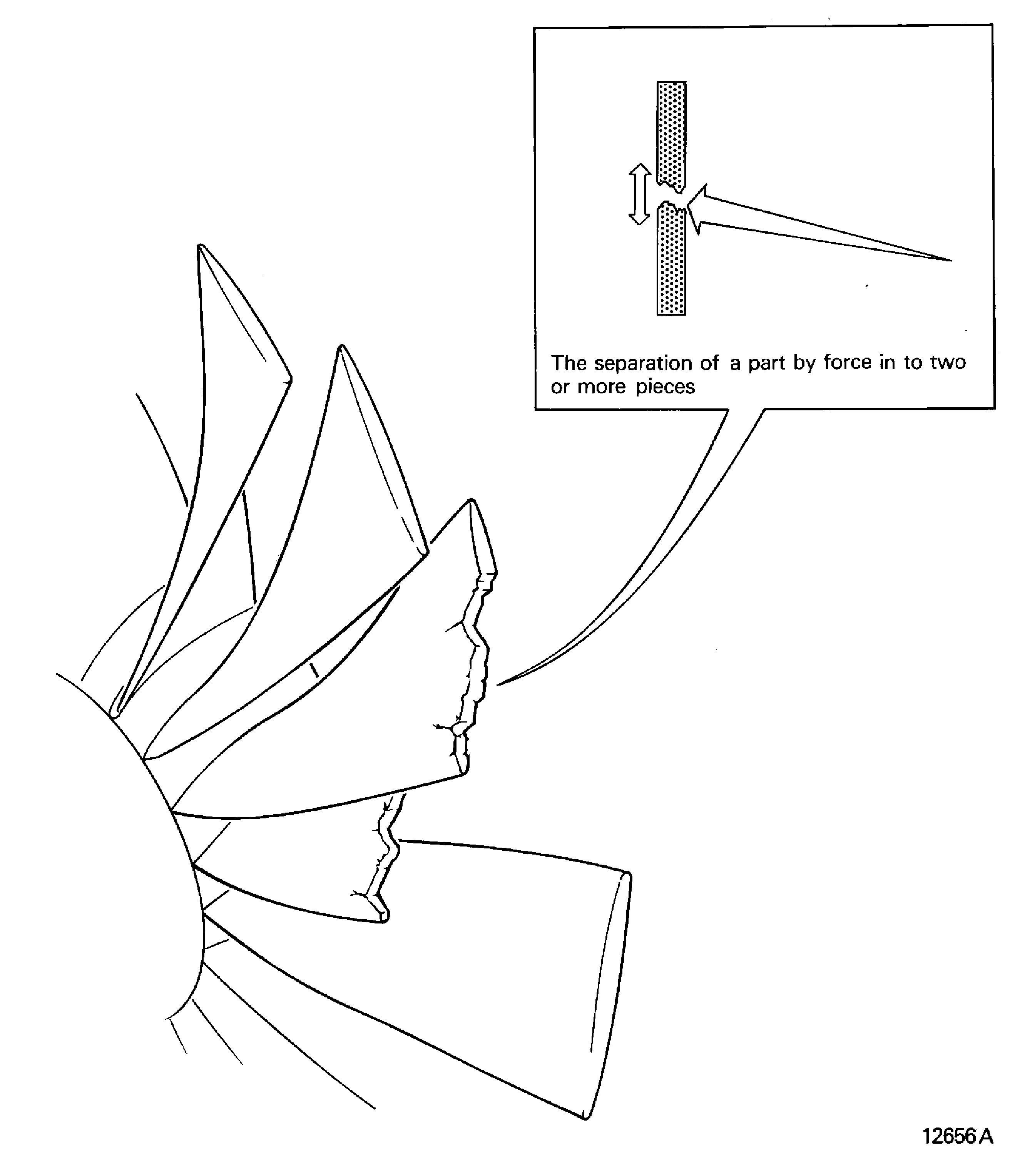

Broken

Fractured

The separation of a part by force, into two or more pieces. Refer to Figure

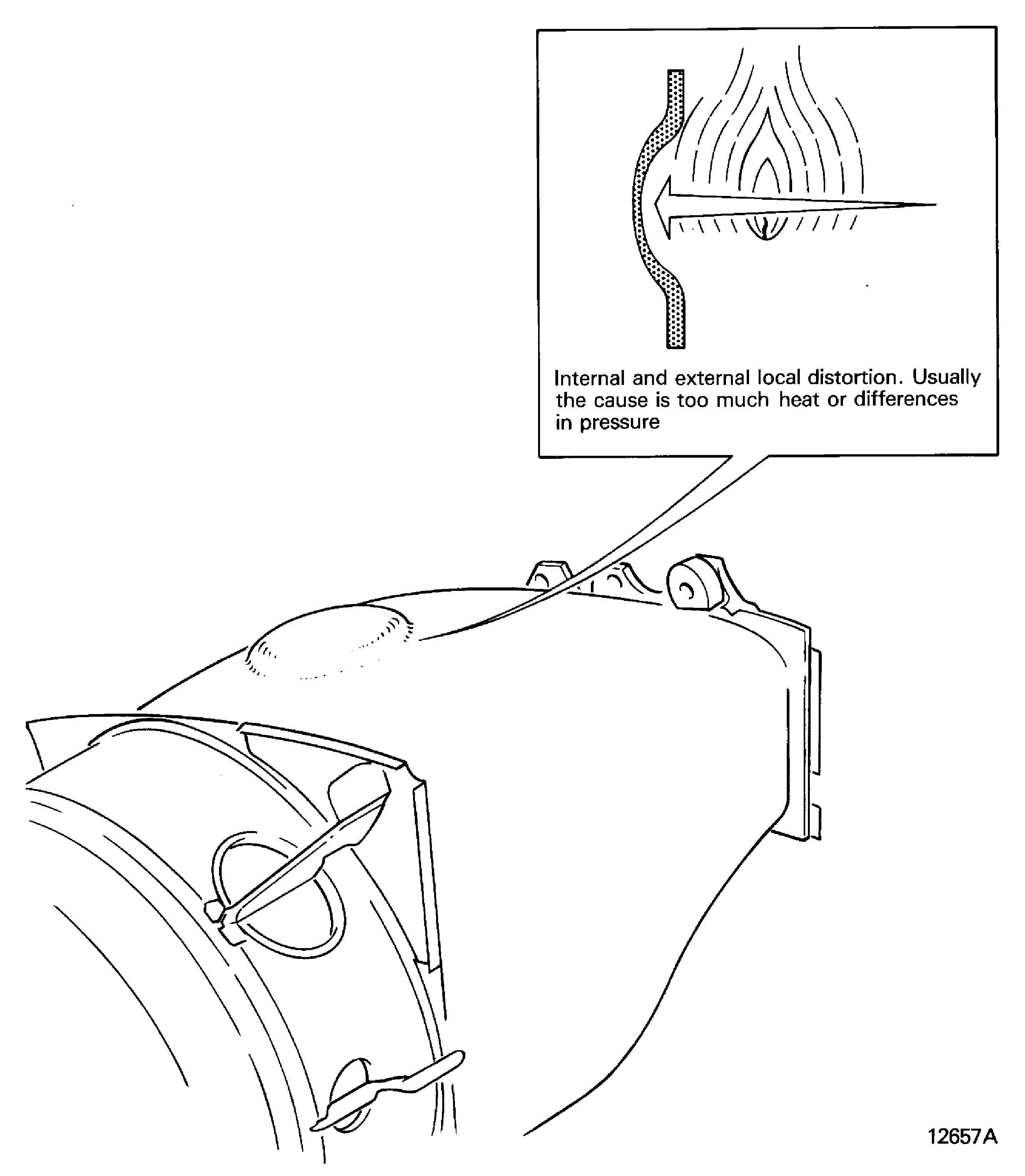

Bulged

Ballooned, swollen

Internal and external local distortion. Usually the cause is too much heat or differences in pressure. Refer to Figure

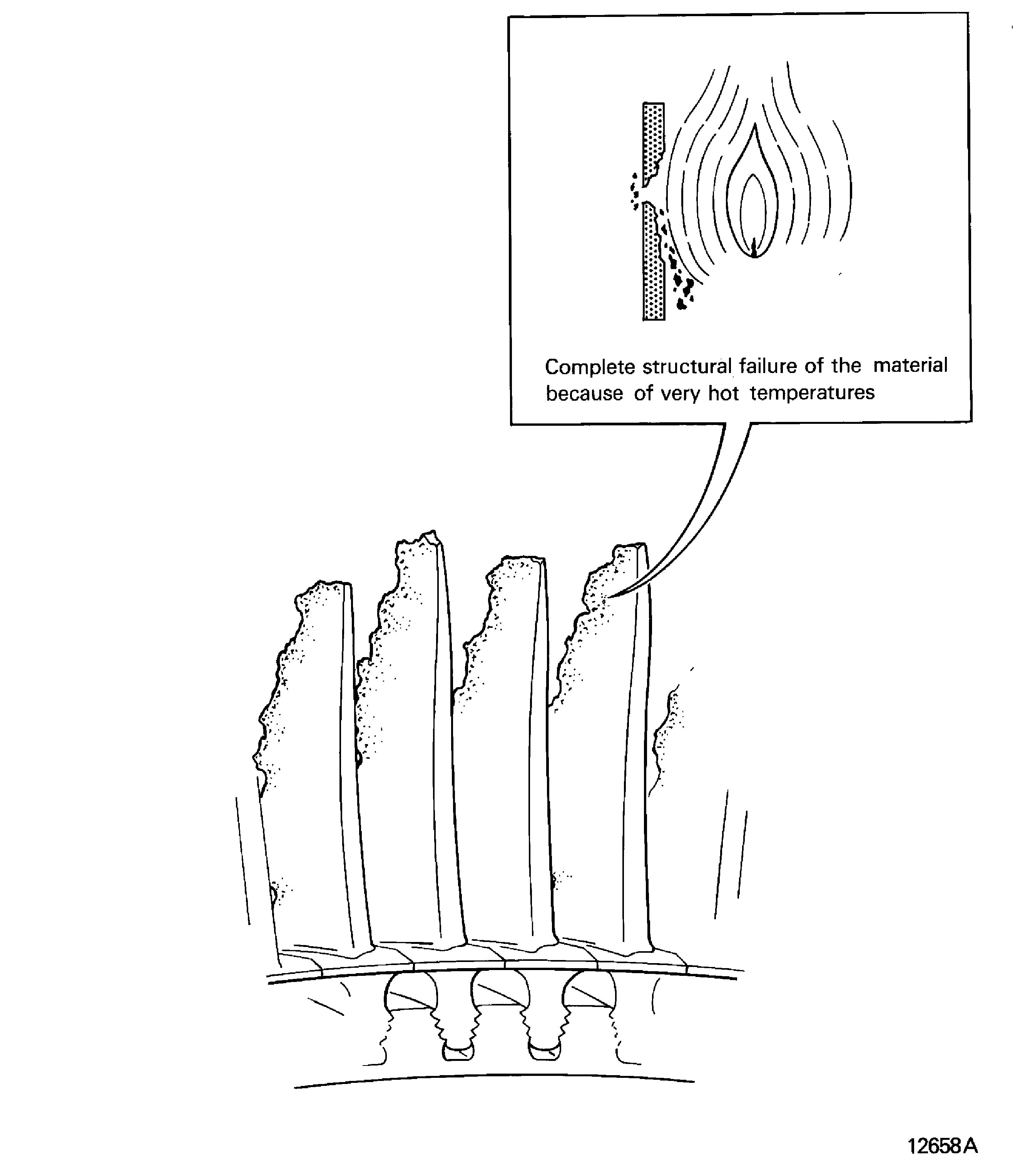

Burned

Charred

A complete structural failure of the material because of very hot temperatures. Refer to Figure

Burnish

A shiny area resulting from rubbing against a hard, smooth surface; may contain scratches of no apparent depth.

Burrs

-

Rough edges or sharp projections on the surface of a material

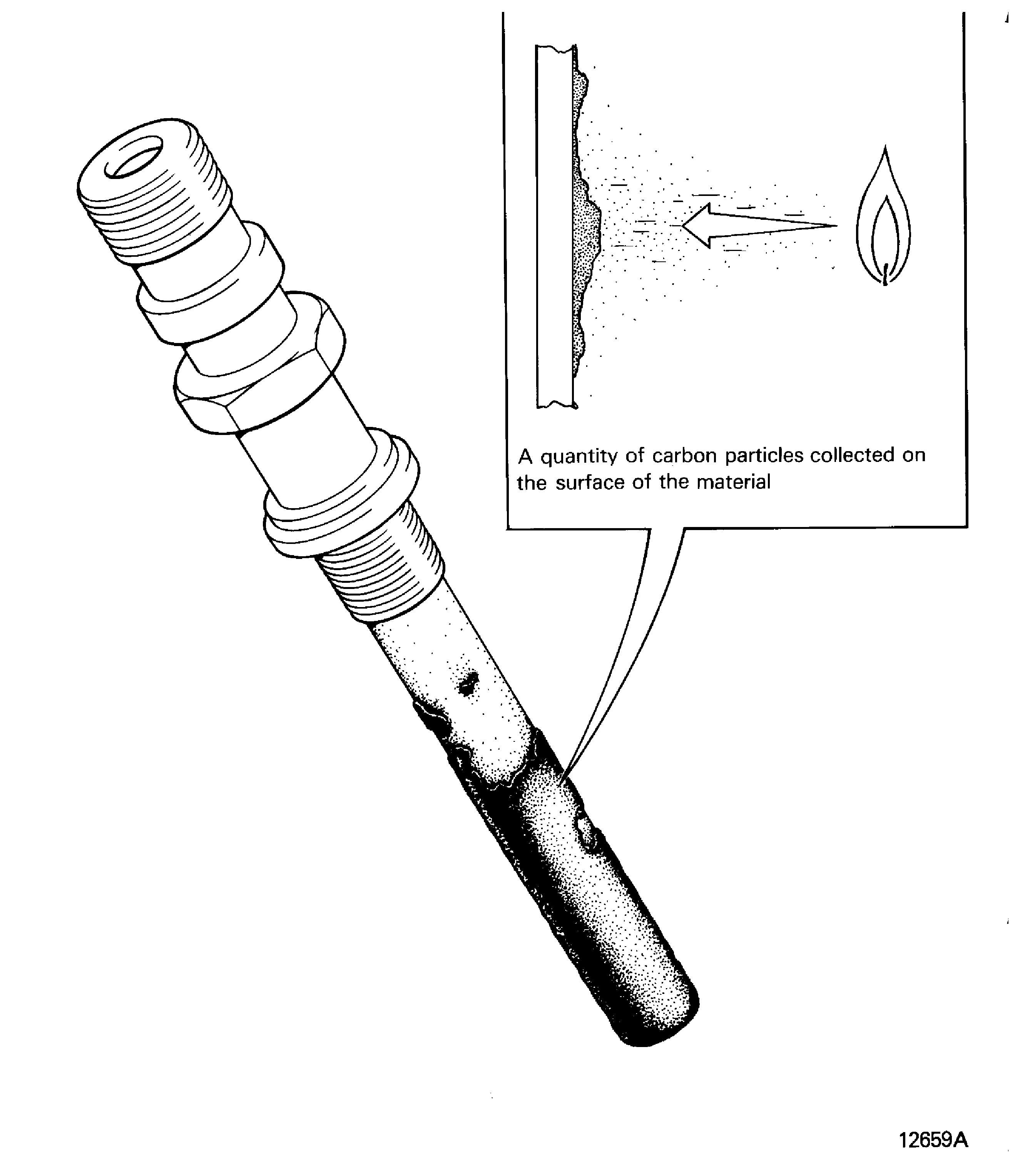

Carboned

Carbon covered, carbon tracked, coked

A quantity of carbon particles collected on the surface of a material. Refer to Figure

Chafed

Scraped, scuffed

Friction wear damage, usually the cause is two parts that rub together with a small amount of movement

Checkered

Crazed

Surface cracks; usually the cause is heat

Chipped

-

Material broken off the edge, corner or surface. Usually caused when a material is hit

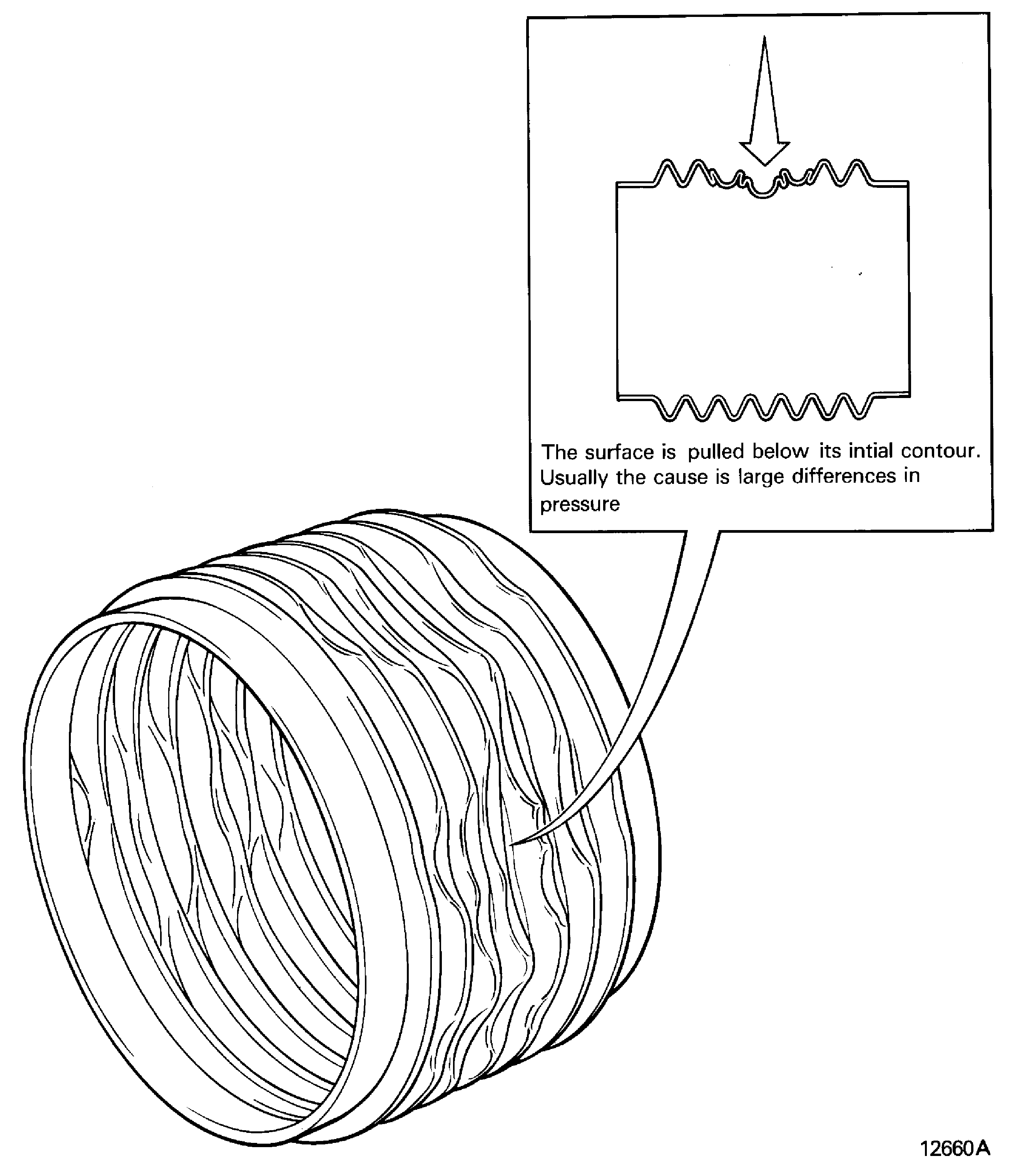

Collapsed

Crushed

The surface is pulled below its initial contour. Usually the cause is large differences in pressure. Refer to Figure

Corroded

Rusted, oxidation, etched, sulphidation

Slow deterioration of the material because of a chemical effect. Usually seen as oxide particles on the surface

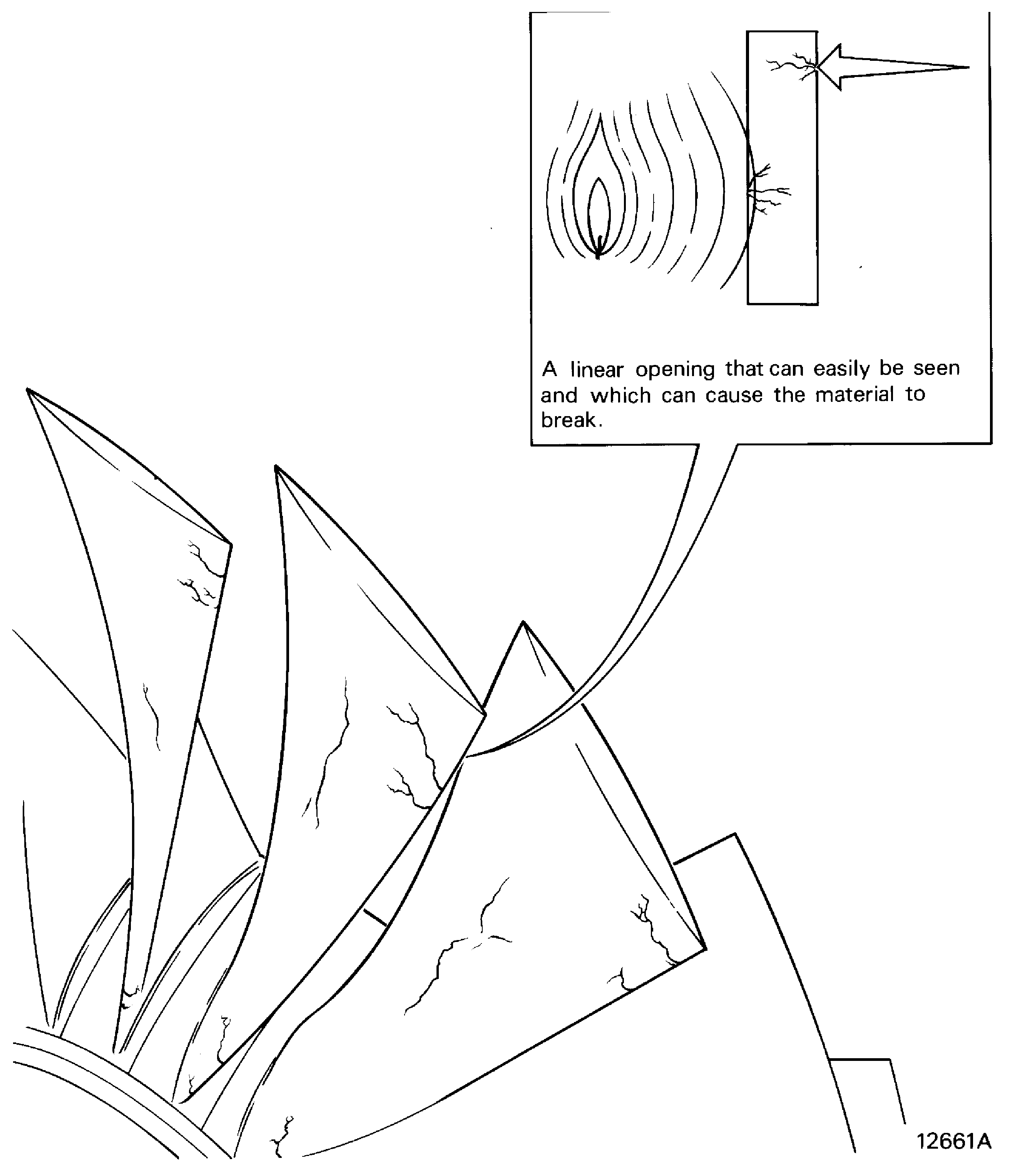

Cracked

-

A linear opening that can easily be seen and which can cause the material to break. (Special fluorescent or magnetic penetrants are not necessary). Refer to Figure

Crossed

-

Material damage to a part, for example, crossed thread. Alternatively a part incorrectly assembled, for example, crossed wires

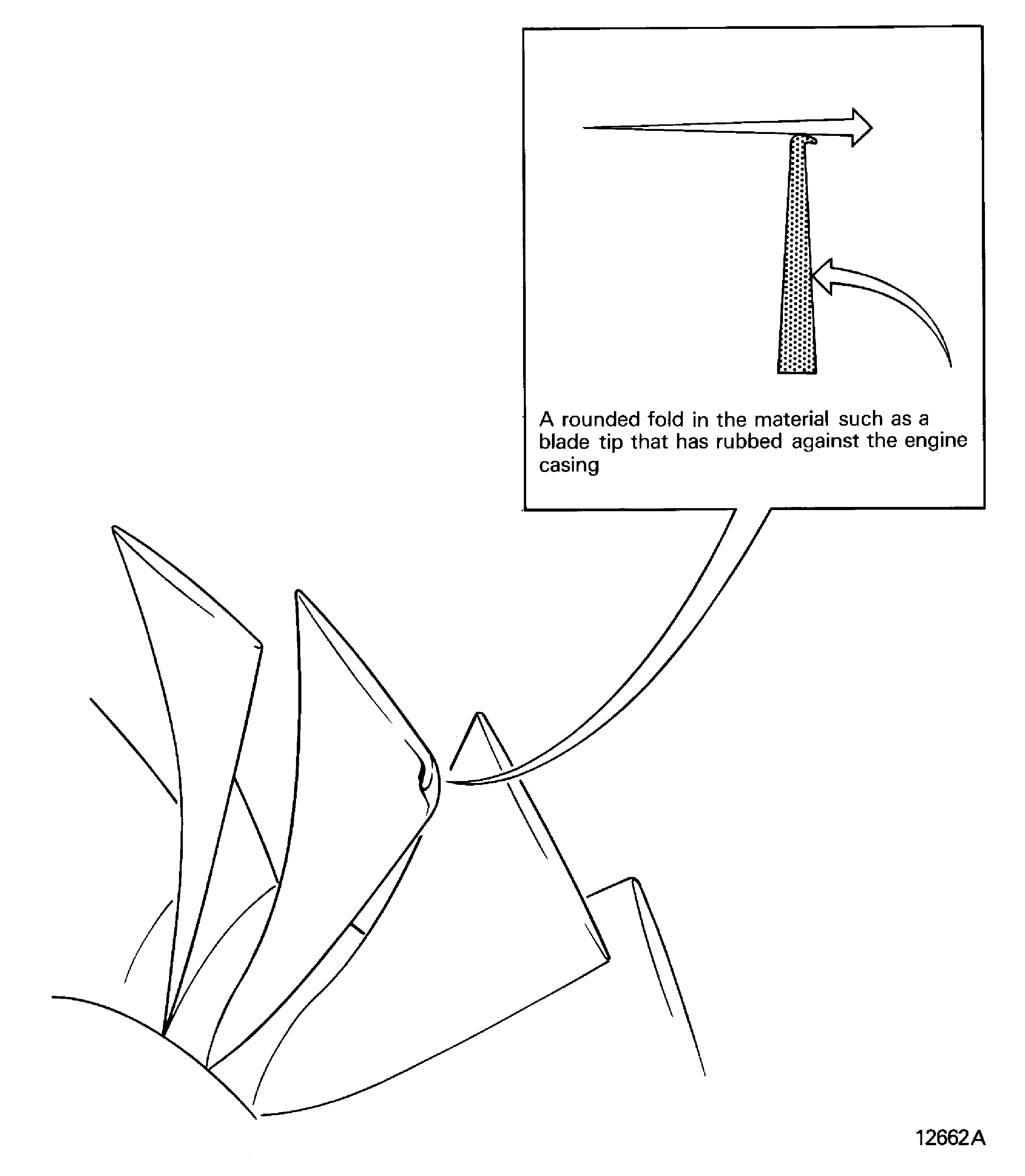

Curled

-

A rounded fold in the material such as a blade tip that has rubbed against the engine casing. Refer to Figure

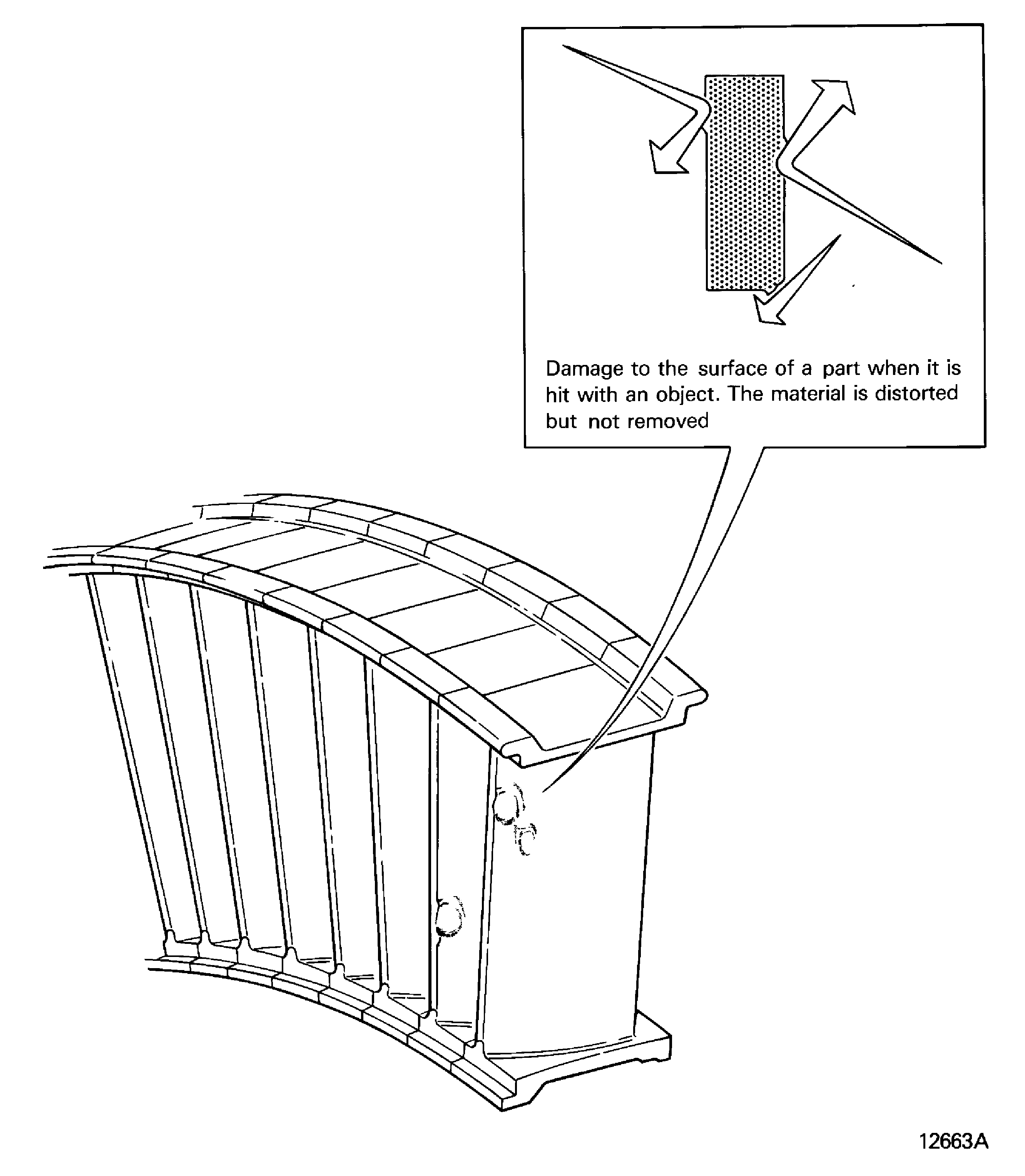

Dented

-

Damage to the surface of a part when it is hit with an object. The material is distorted but not removed. Refer to Figure

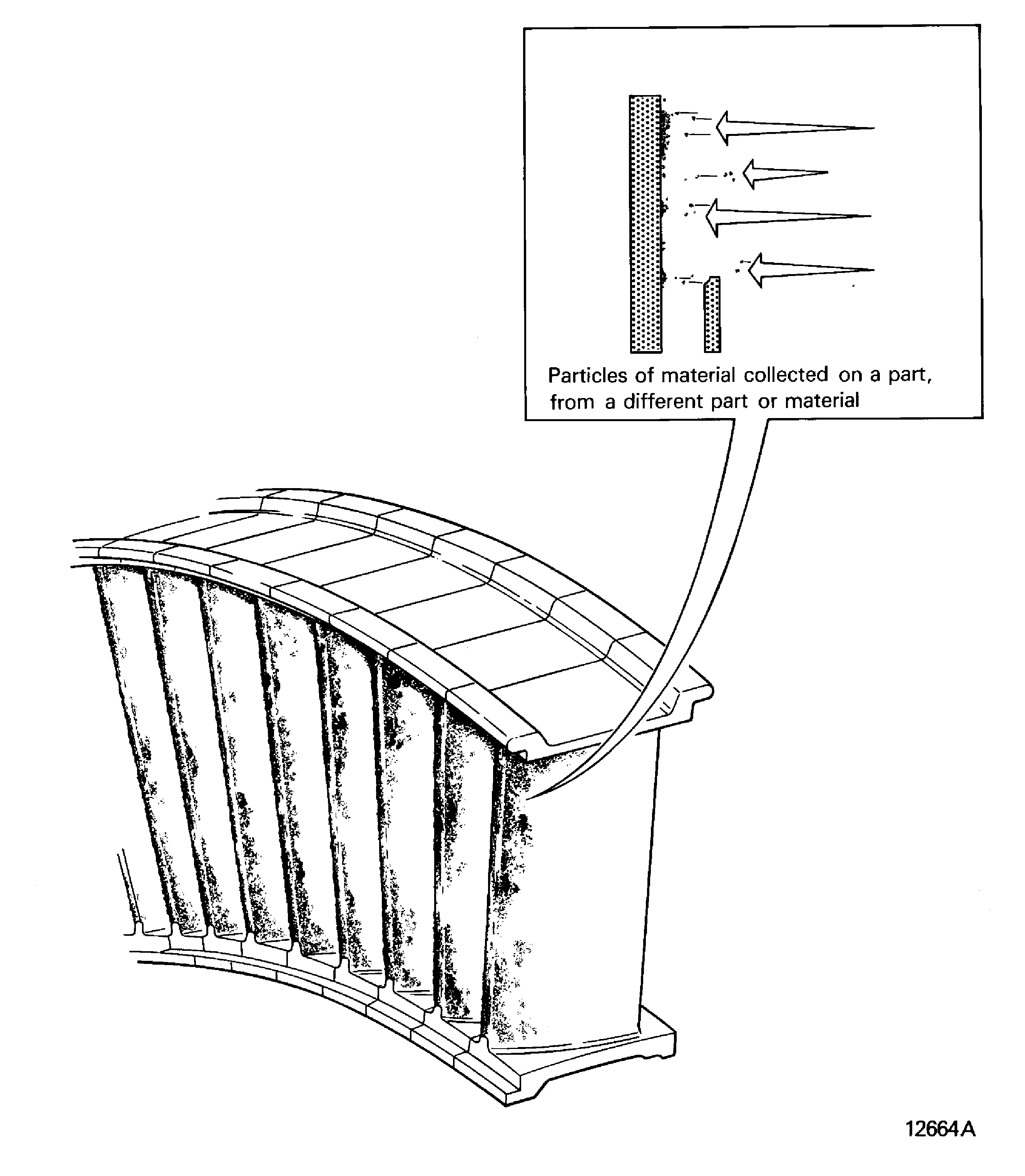

Deposits

Metalized

Particles of material collected on a part from a different part or material. Refer to Figure

Disengaged

Separated, loose

This occurs only to parts that are usually permanently attached to each other

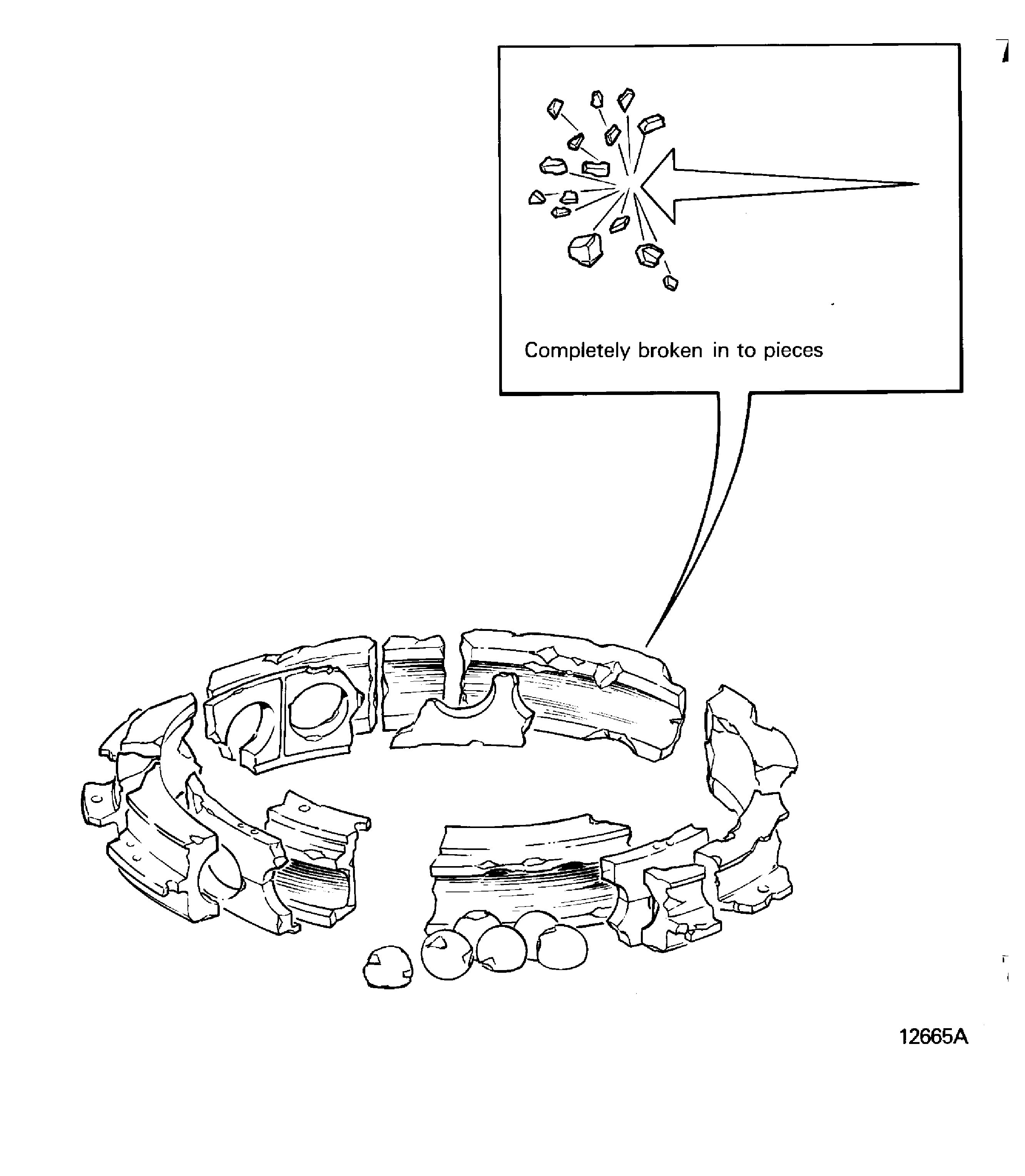

Disintegrated

Shattered

Completely broken in pieces. Refer to Figure

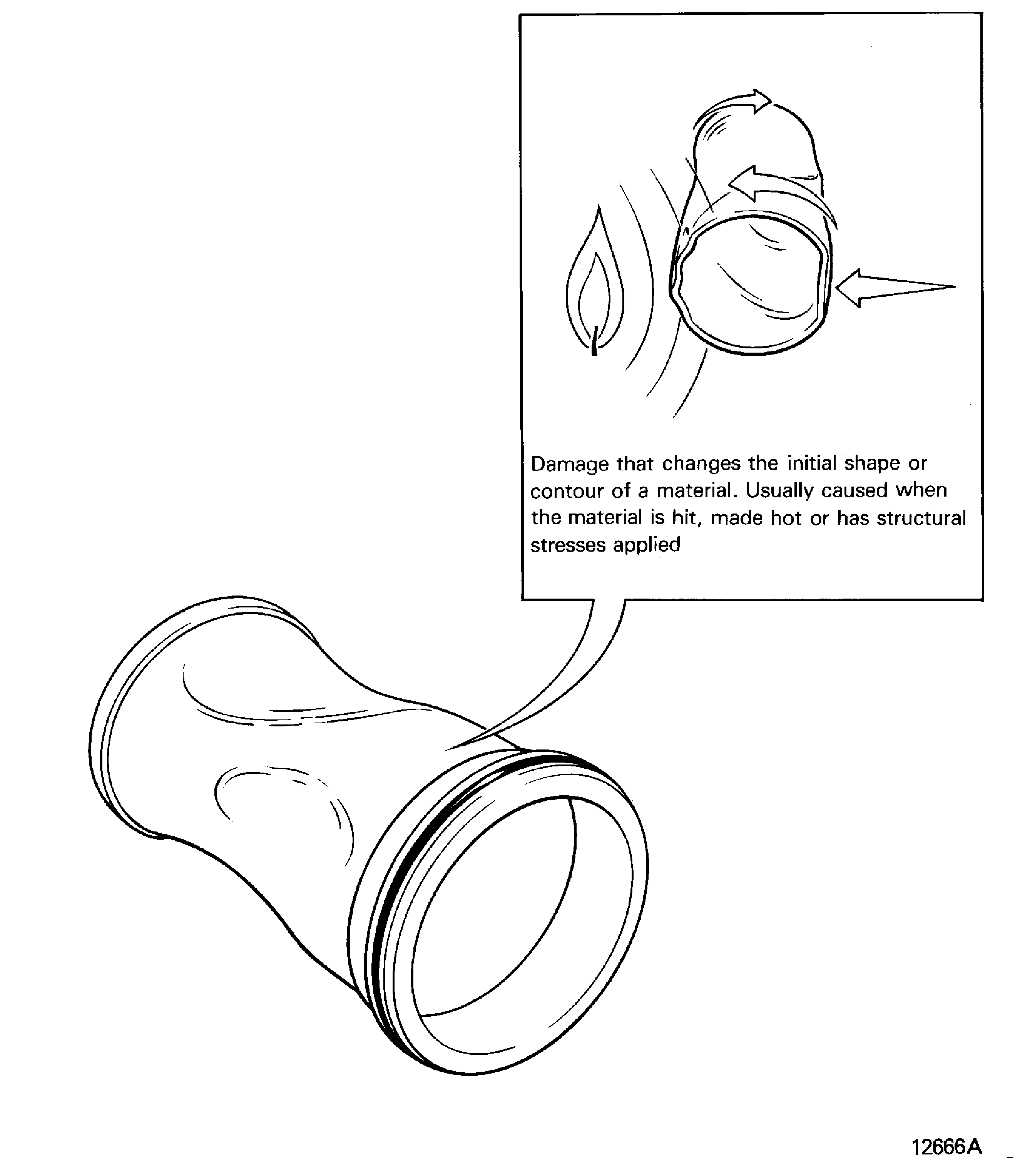

Distorted

Buckled, depressed twisted, warped

Is damage that changes the initial shape or contour of a material. Usually caused when the material is hit, made hot or has structural stresses applied. Refer to Figure

Eccentric

Non-concentric

Occurs when a part has the point about which it turns moved off center

Eroded

-

The flow of fluids or gases cause the material to wear; heat or grit makes this occur more quickly

Extruded

-

Plastic deformation because of high pressure between parts

Feathered edge

-

The edge of the material is made thinner

Flattened out

-

Permanent damage more than the tolerance limits. Usually caused when the material is compressed

Frayed

-

Worn (rubbed) in to strips

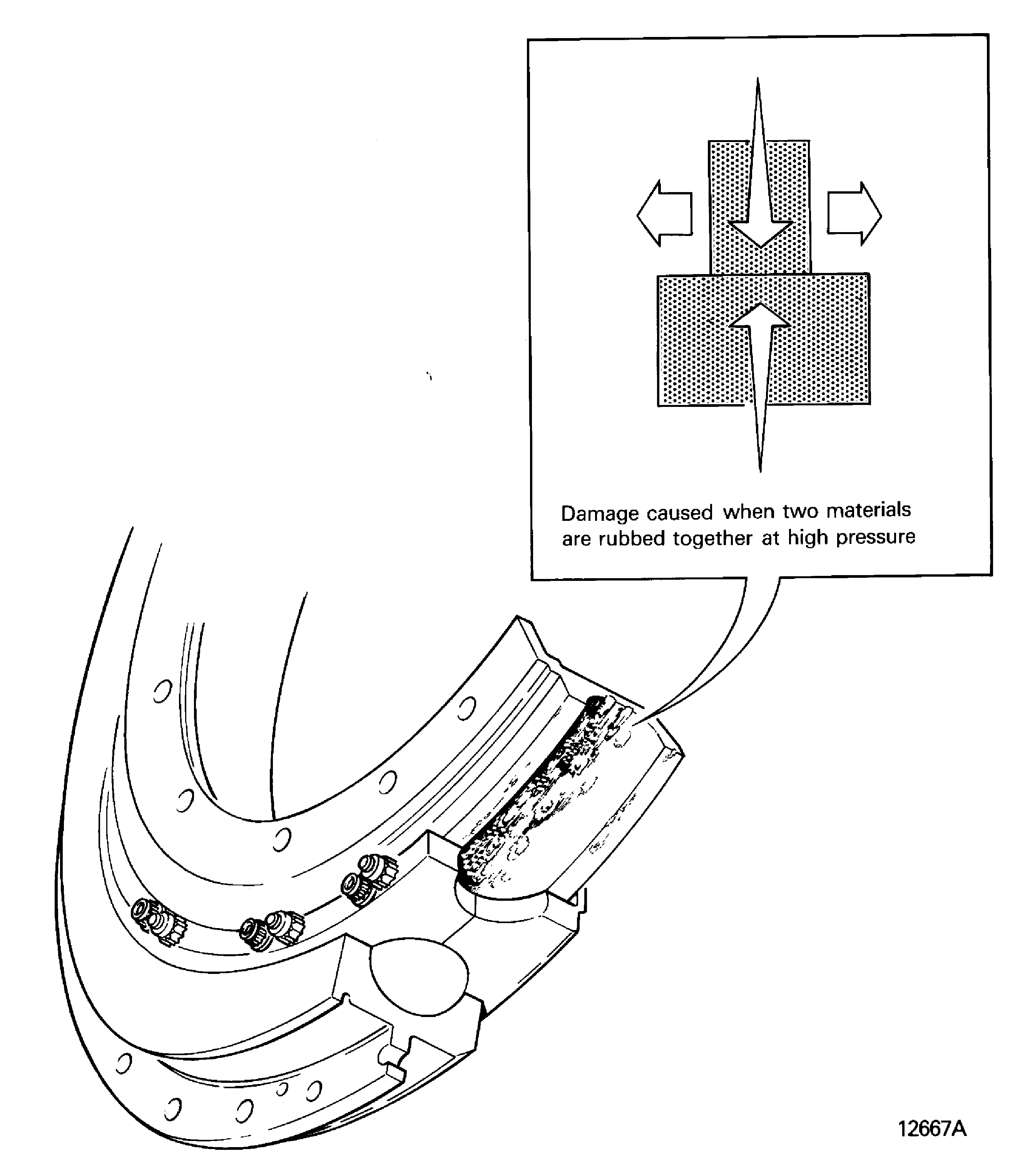

Fretted

-

Damage caused when two materials are rubbed together

Fused

-

When two materials become attached to each other, usually the cause is heat, friction or current flow

Galled

Fretted, spiked

Damage caused when two materials are rubbed together at high pressure. Refer to Figure

Glazed

-

This is seen as a hard glossy surface because of heat, varnish, incorrect loads or when the surface is rubbed

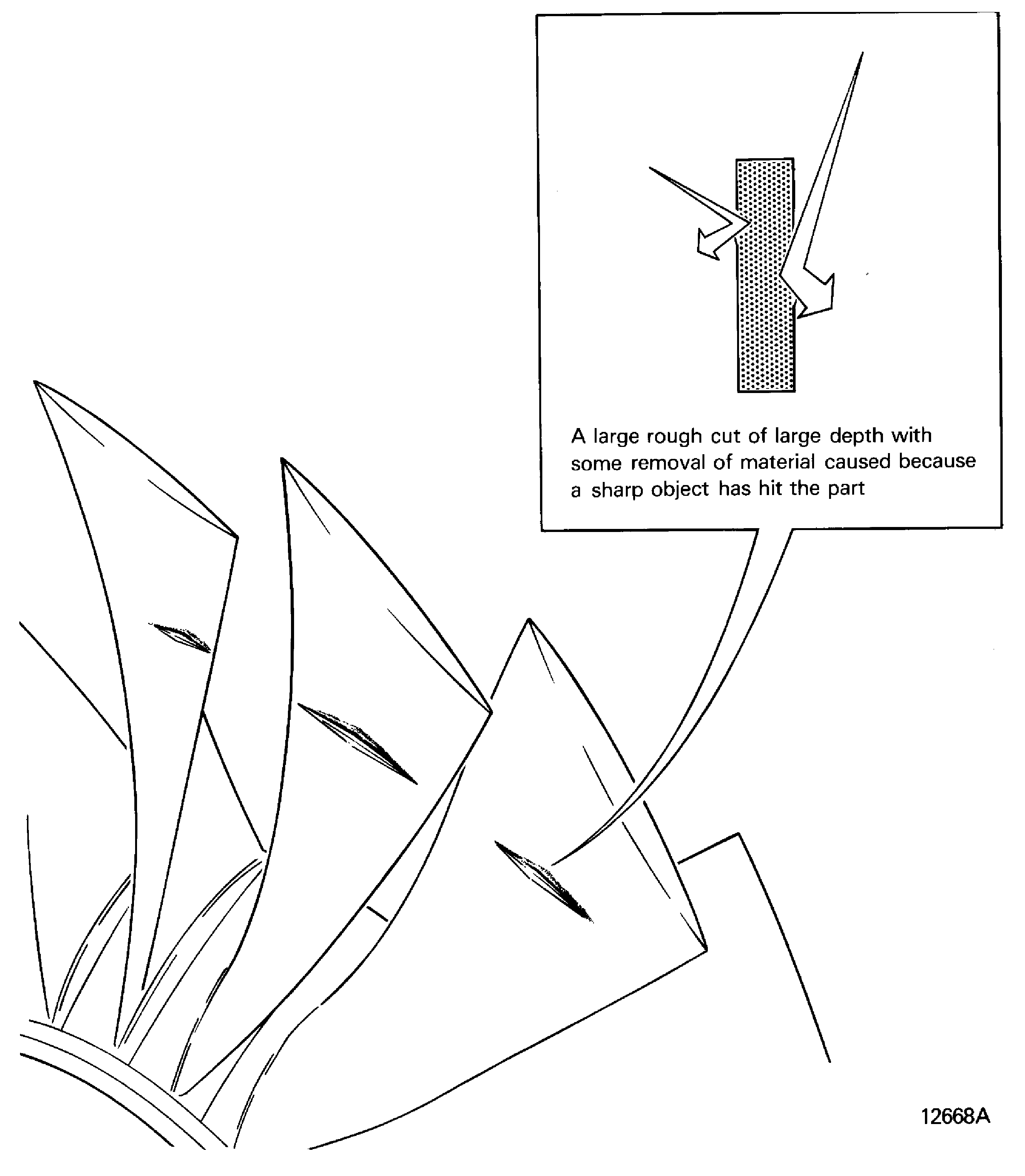

Gouge

-

A large rough cut of large depth with the removal of some material, caused because a sharp object has hit the part. Refer to Figure

Grooved

Furrowed, fluted

A smooth rounded score, because of wear, with rounded corners and smooth on the groove bottom

Imperfection

An interruption (non-uniformity) in the normal surface condition of a part configuration which must be evaluated for acceptance to an assigned standard.

Indications

-

Small cracks or other small defects that can not be seen without fluorescent or magnetic penetrants

Melted

-

Distortion to the initial shape or contour because of heat friction or pressure

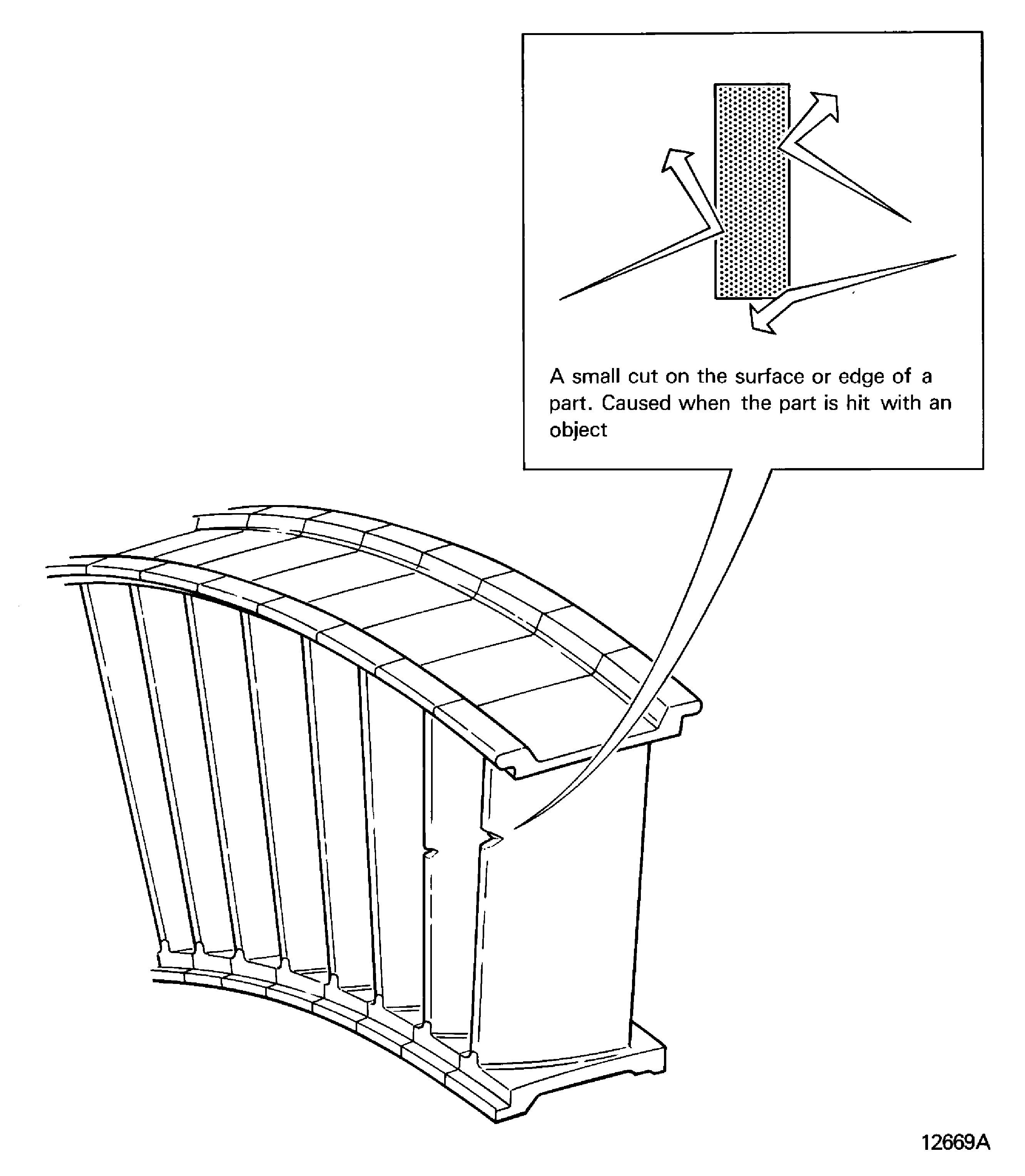

Nicked

-

A small cut on the surface or edge of a part caused when the part is hit with an object. Refer to Figure

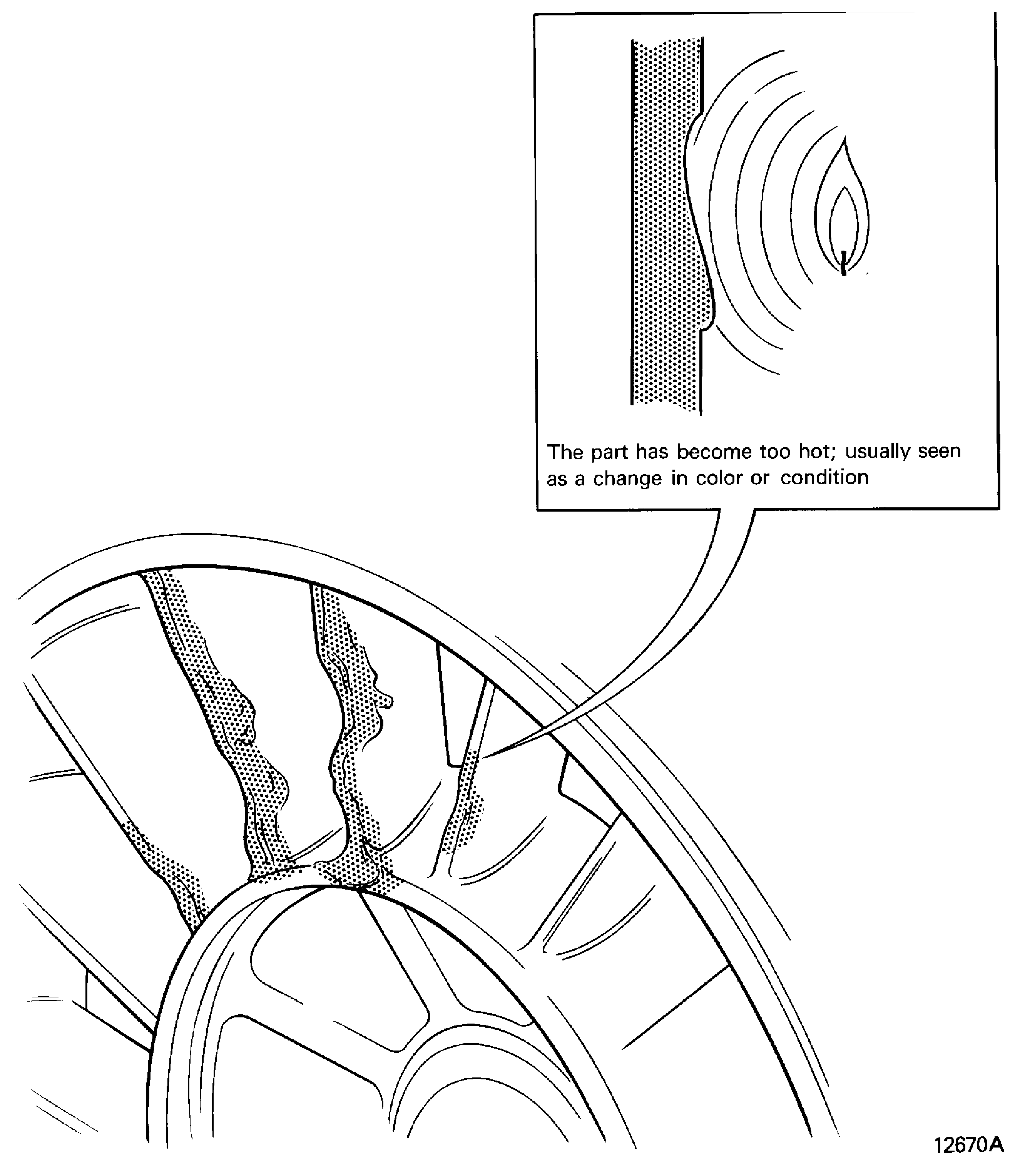

Overheated

Heat discolored, heated excessively, seen as a change in color or condition. hot spot

The part has become too hot, usually Refer to Figure

Part missing

Lost

Related only to a detail that is usually permanently attached

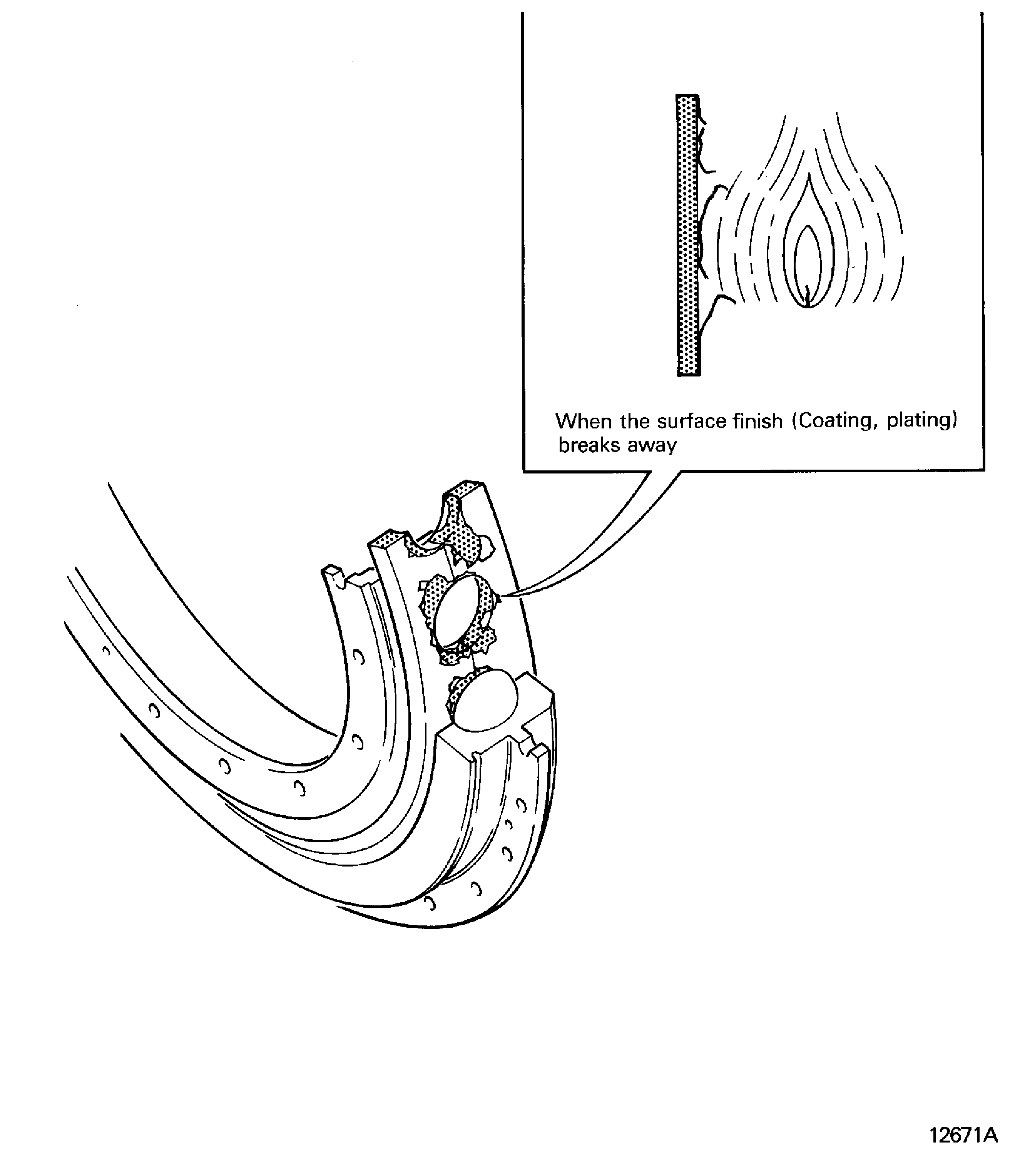

Peeled

Blistered, flaked, exfoliated

Is when the surface finish (coating, plating) breaks away. Refer to Figure

Peened

-

A group of very small dents caused when the part is hit many times

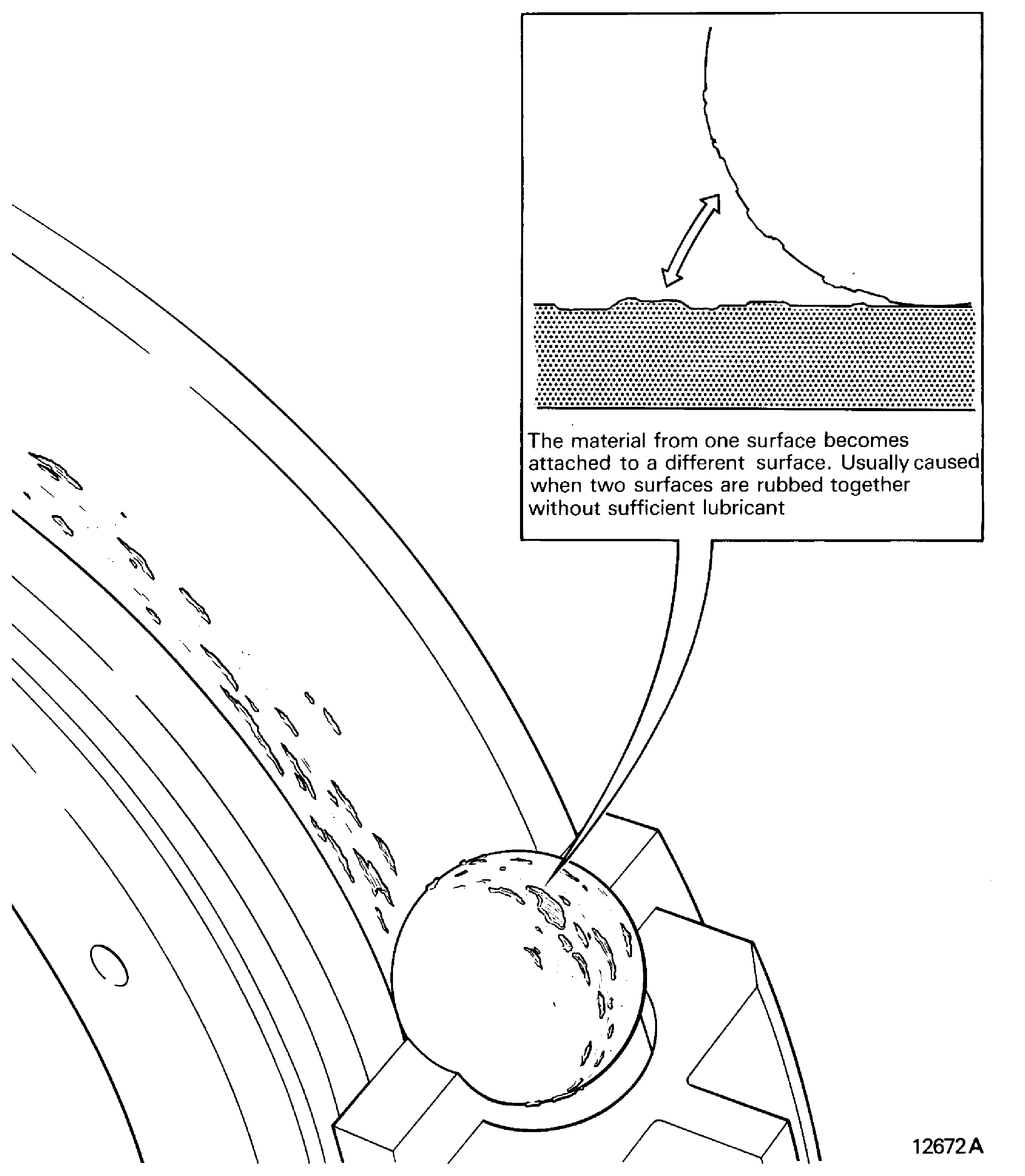

Pick-up

-

The material from one surface becomes attached to a different surface. Usually caused when two surfaces are rubbed together without sufficient lubricant. Refer to Figure

Pierced

Hole in the part

The part has a hole made in it

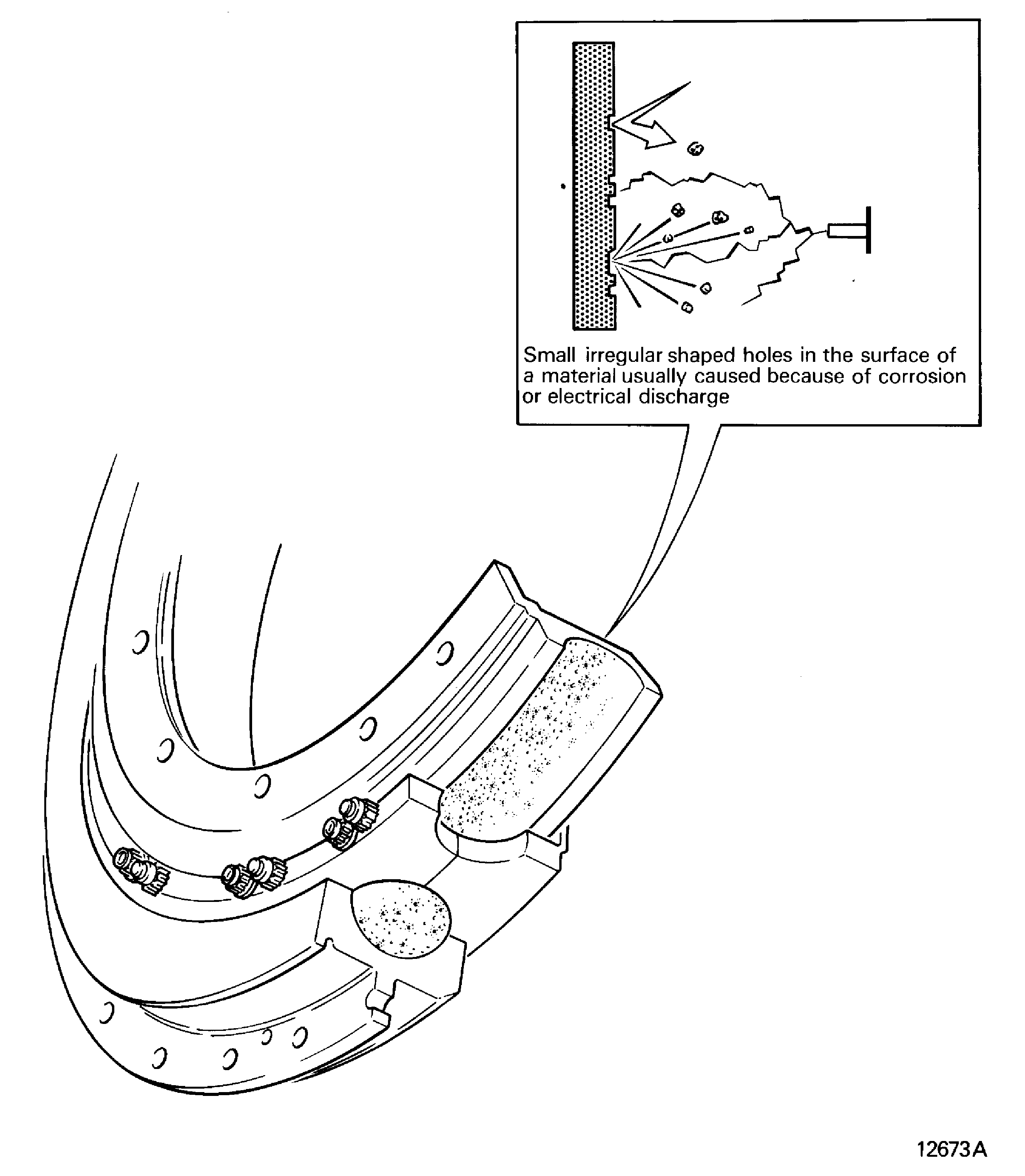

Pitted

-

Small irregular shaped holes in the surface of a material. Usually caused because of corrosion or electrical discharge. Refer to Figure

Plugged

Clogged, obstructed, restricted passage

The flow is decreased or prevented because of blockage

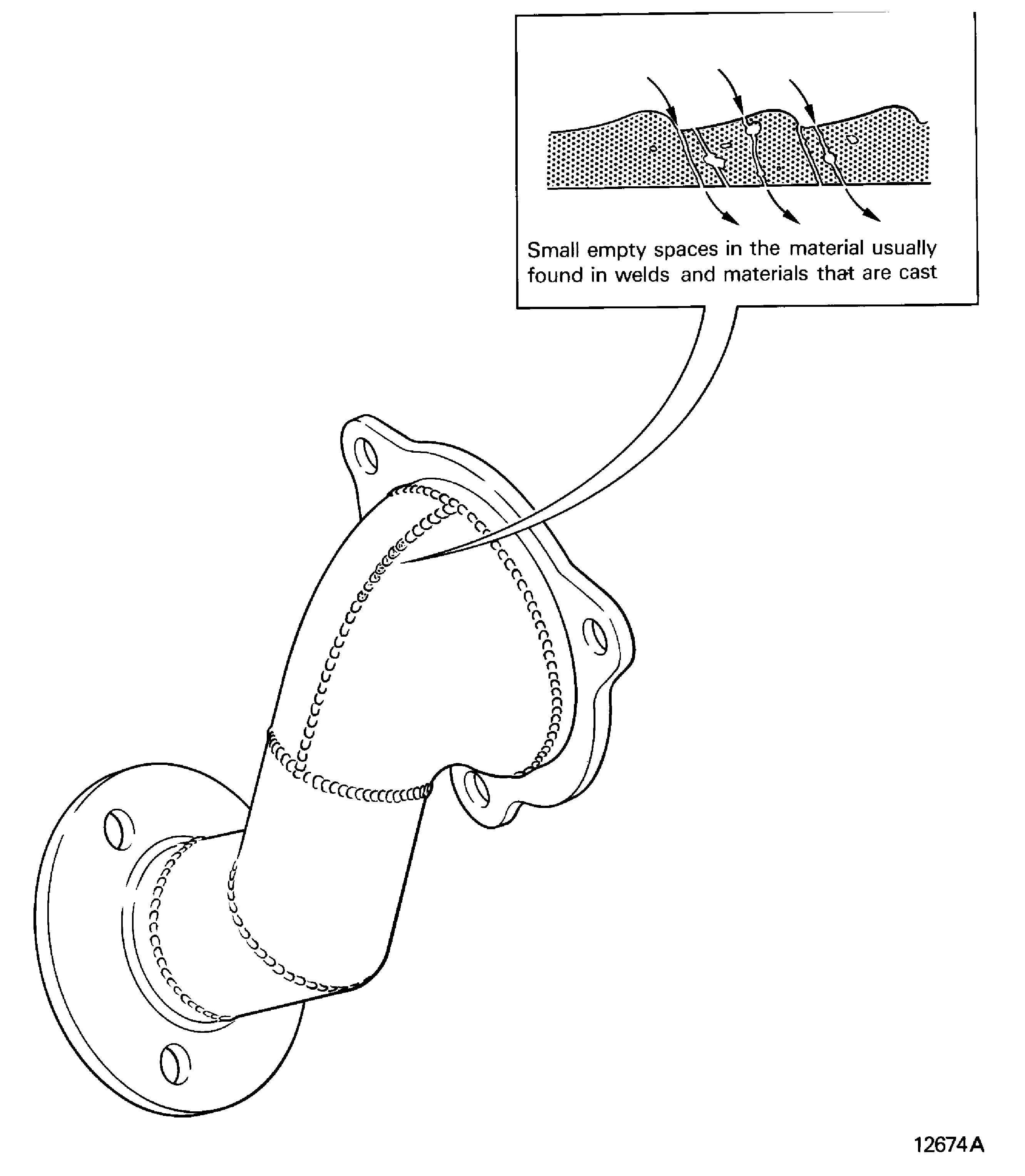

Porous

Pock-marked, perforated weld

Small empty spaces in the material usually found in welds and materials that are cast. Refer to Figure

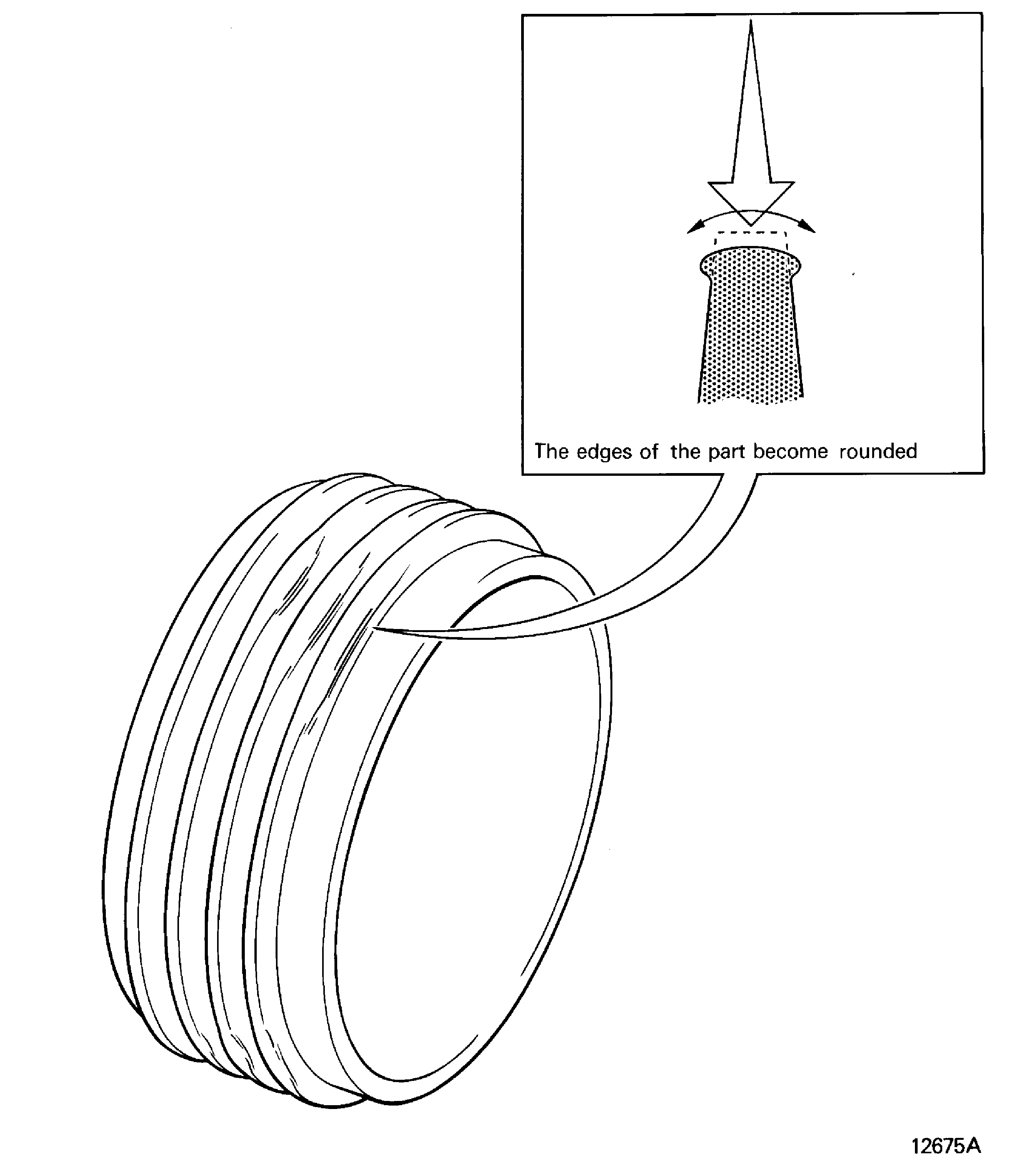

Rolled over

Lipped, turned metal

The edges of the part become rounded. Refer to Figure

Rough

-

When the operation (not the surface) is not smooth

Rubbed

Abraded

To move with pressure or friction against a different surface. Such as compressor rub

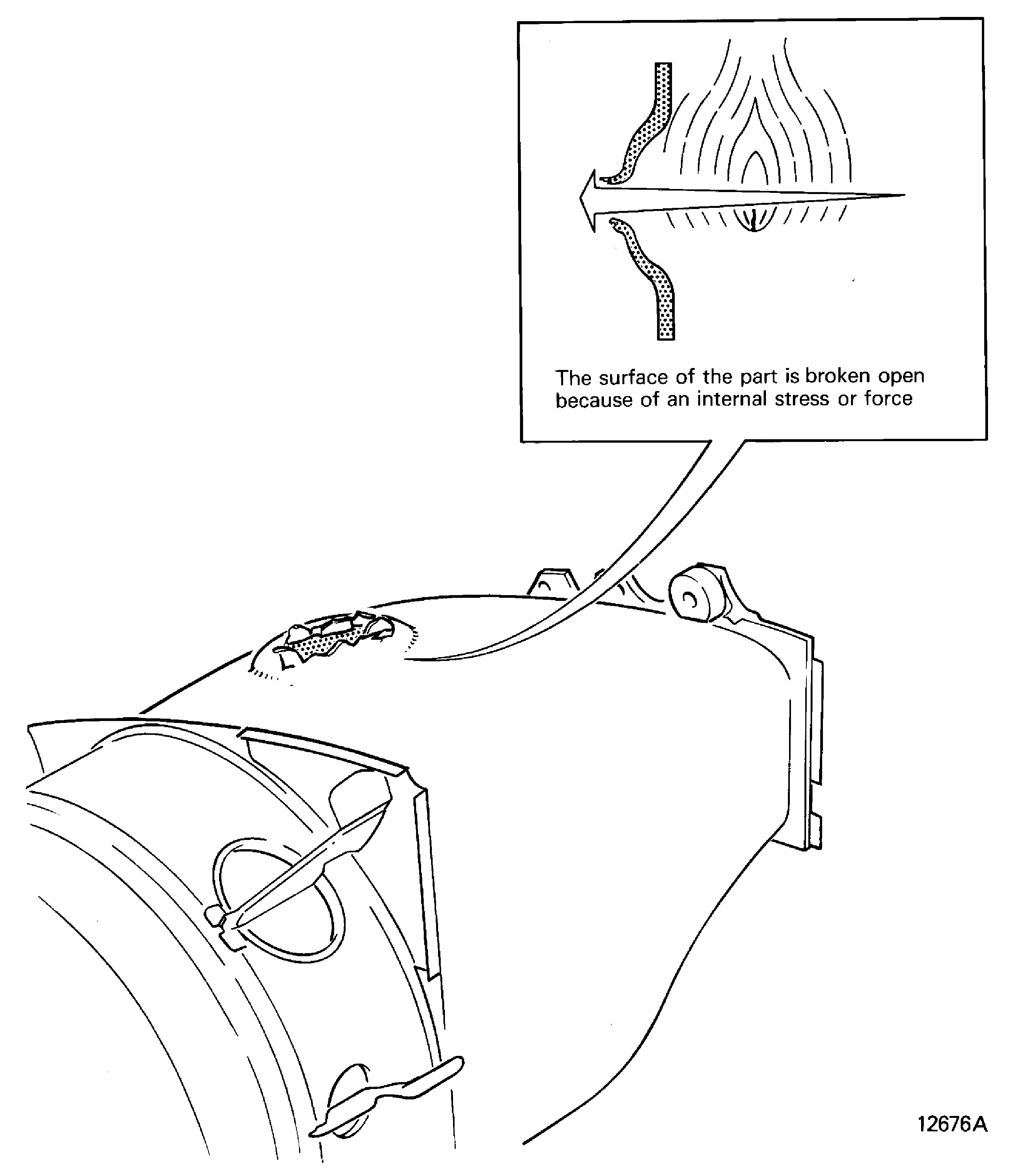

Ruptured

Blown, burst, split

The surface of the part is broken open because of an internal stress or force. Refer to Figure

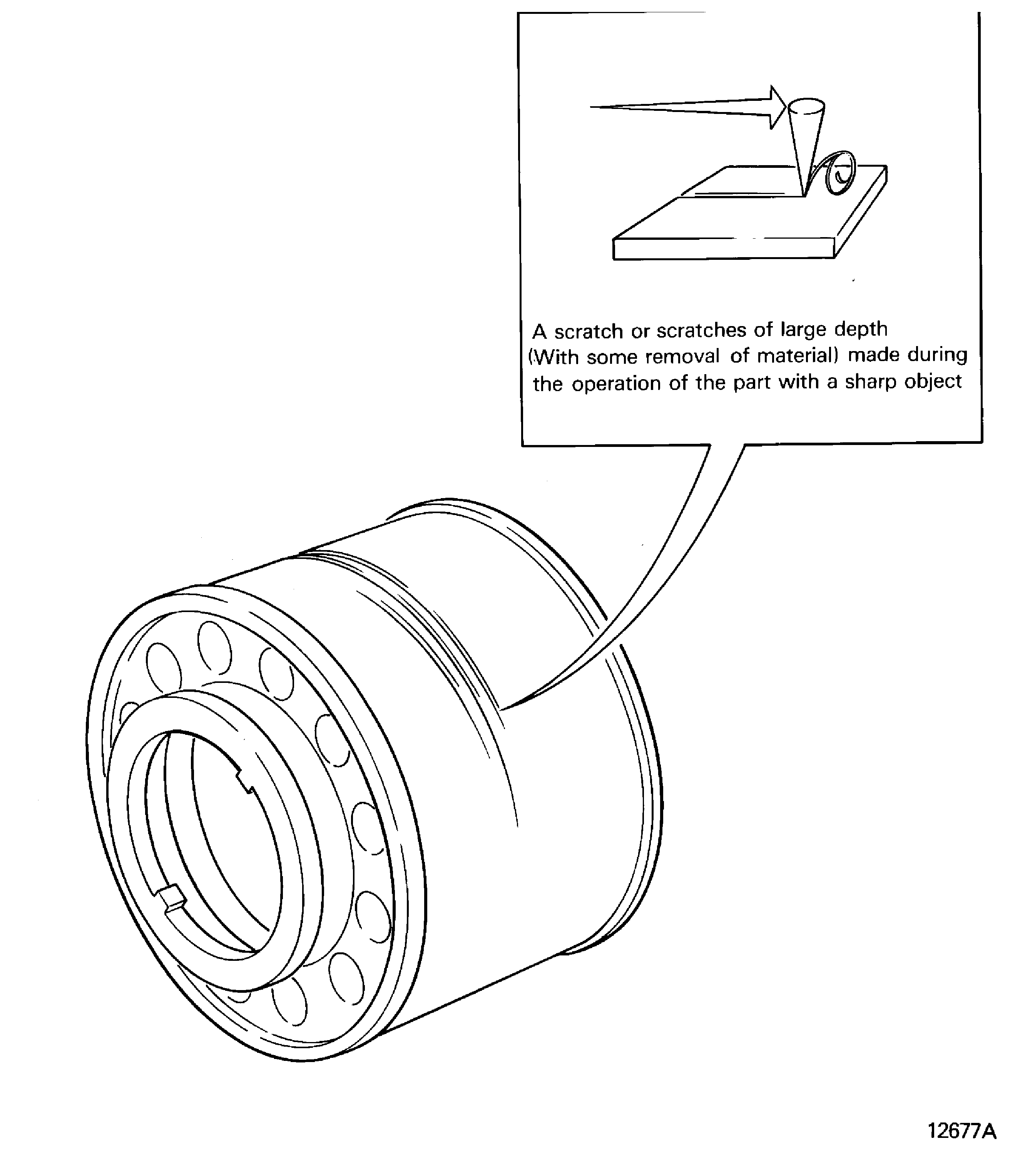

Scored

-

A scratch or scratches of large depth (with some removal of the material) made with a sharp object during the operation of the part. Refer to Figure

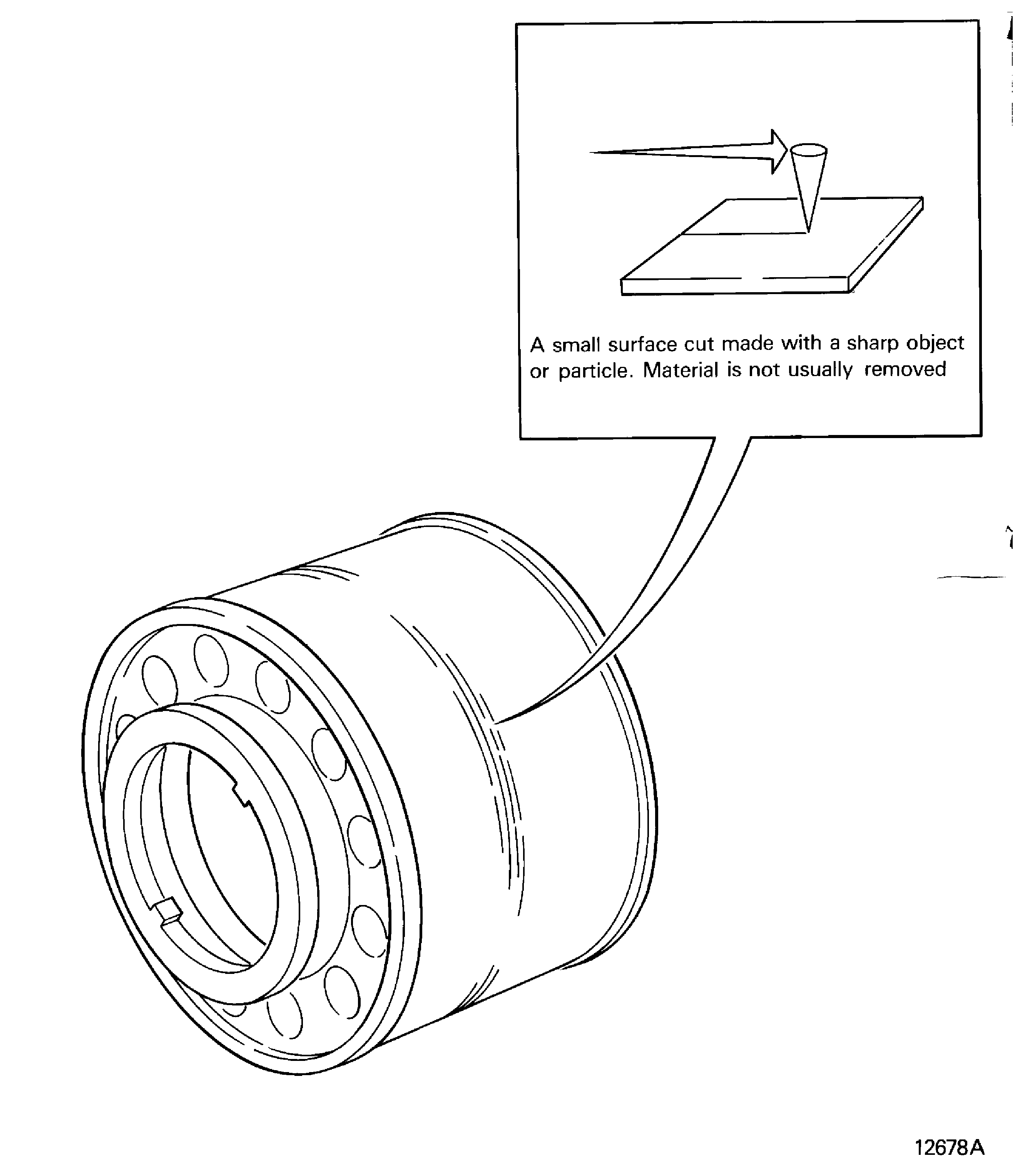

Scratch

-

A small surface cut with not much depth made with a sharp object or particle. Material is not usually removed. Refer to Figure

Seized

Frozen, jammed, stuck

Movement between the parts is stopped because the clearance is not sufficient. Caused because of heat or unwanted particles

Shallow imperfection

An imperfection which appears to penetrate the surface finish texture, does not have a dark bottom and would not cause a stylus having a nose radius ranging in size from 0.030 in. - 0.0365 in. (0.762 mm - 0.927 mm) to hesitate (catch) when passed over it.

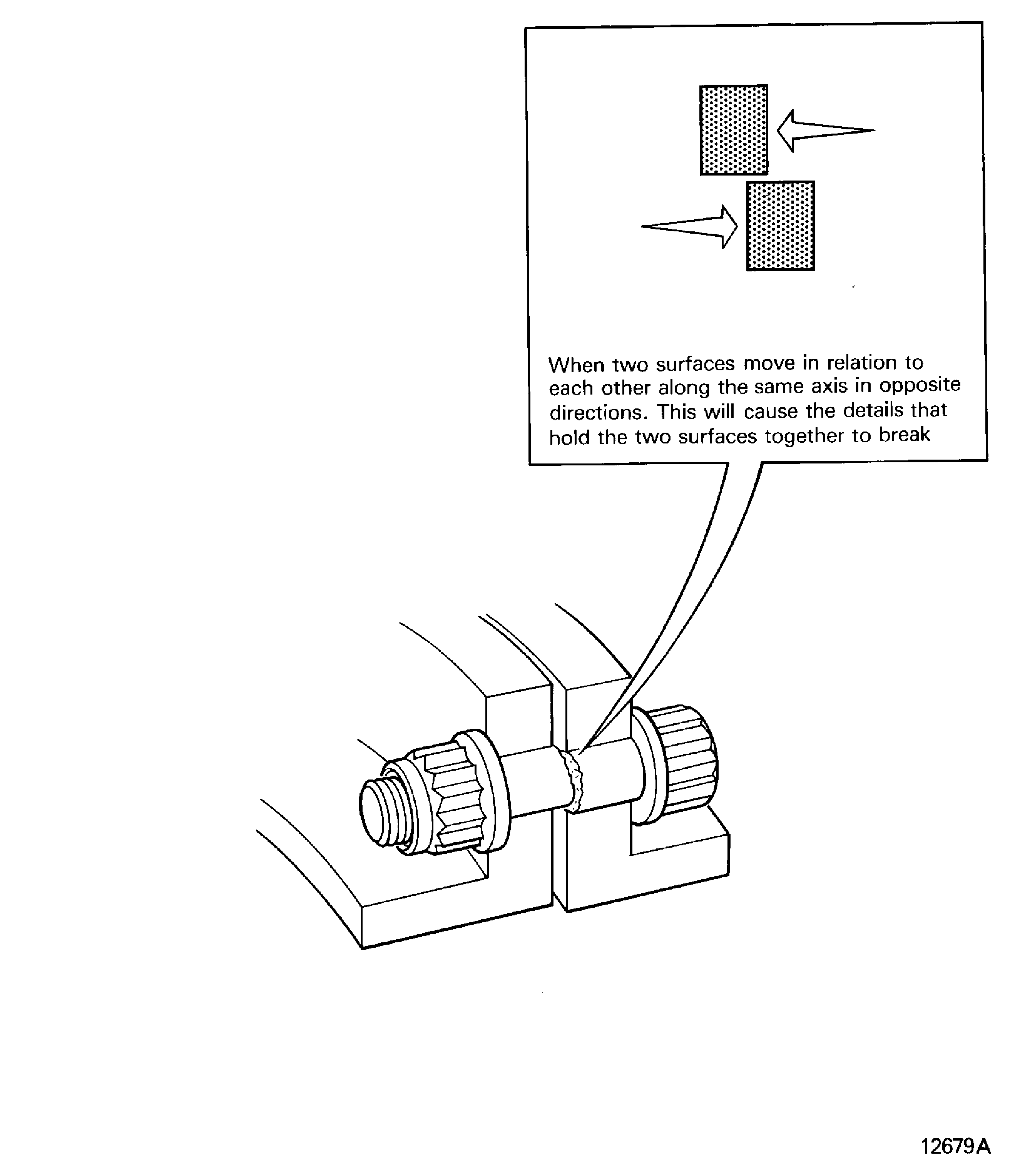

Sheared

Cut

Is when two surfaces move in relation to each other along the same axis in opposite directions. This will cause the details that hold the two surfaces together to break. Refer to Figure

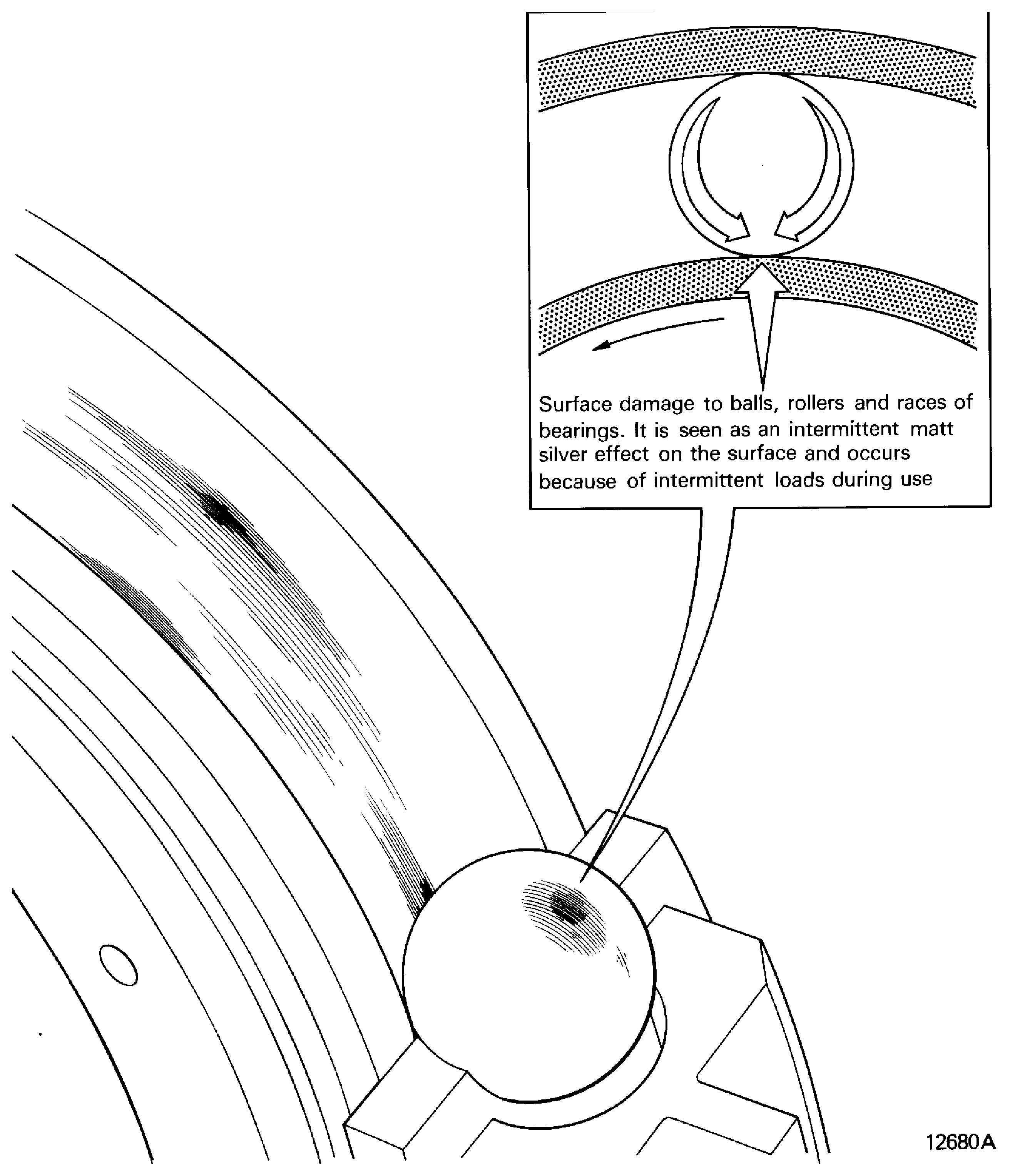

Skidding

-

Is surface damage to balls, rollers and races of bearings. It is seen as an intermittant matt silver effect on the surface and occurs because of intermittant loads during use. Refer to Figure

Sludged

Gummed

Very small particles of unwanted material collected in one location

Softened

Perished

Below the specified elasticity

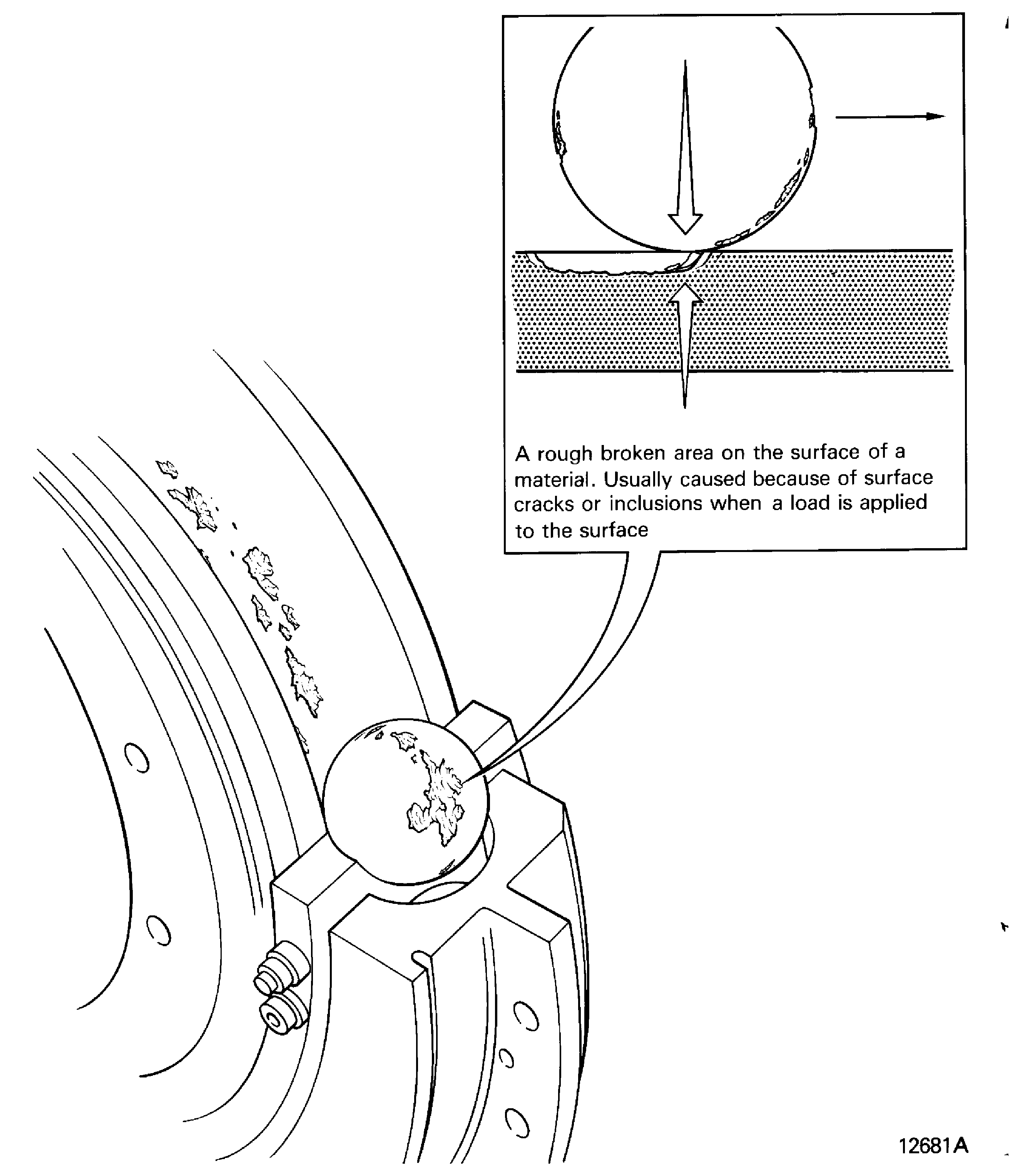

Spalled

Plucked

A rough broken area on the surface of a material. Usually caused because of surface cracks or inclusions when a load is put on the surface. Refer to Figure

Spinning

Damage caused when a bearing race is turned too much

Stretched

Growth

The part is made larger as a result of conditions of operation

Stripped

-

The removal of material by force. Usually related to threads and insulation

Superficial imperfection

An imperfection which disrupts the surface and appears smooth-edged but does not penetrate the surface roughness texture. This condition is so slight, considered less than a shallow imperfection, that a stylus need not be used to evaluate it.

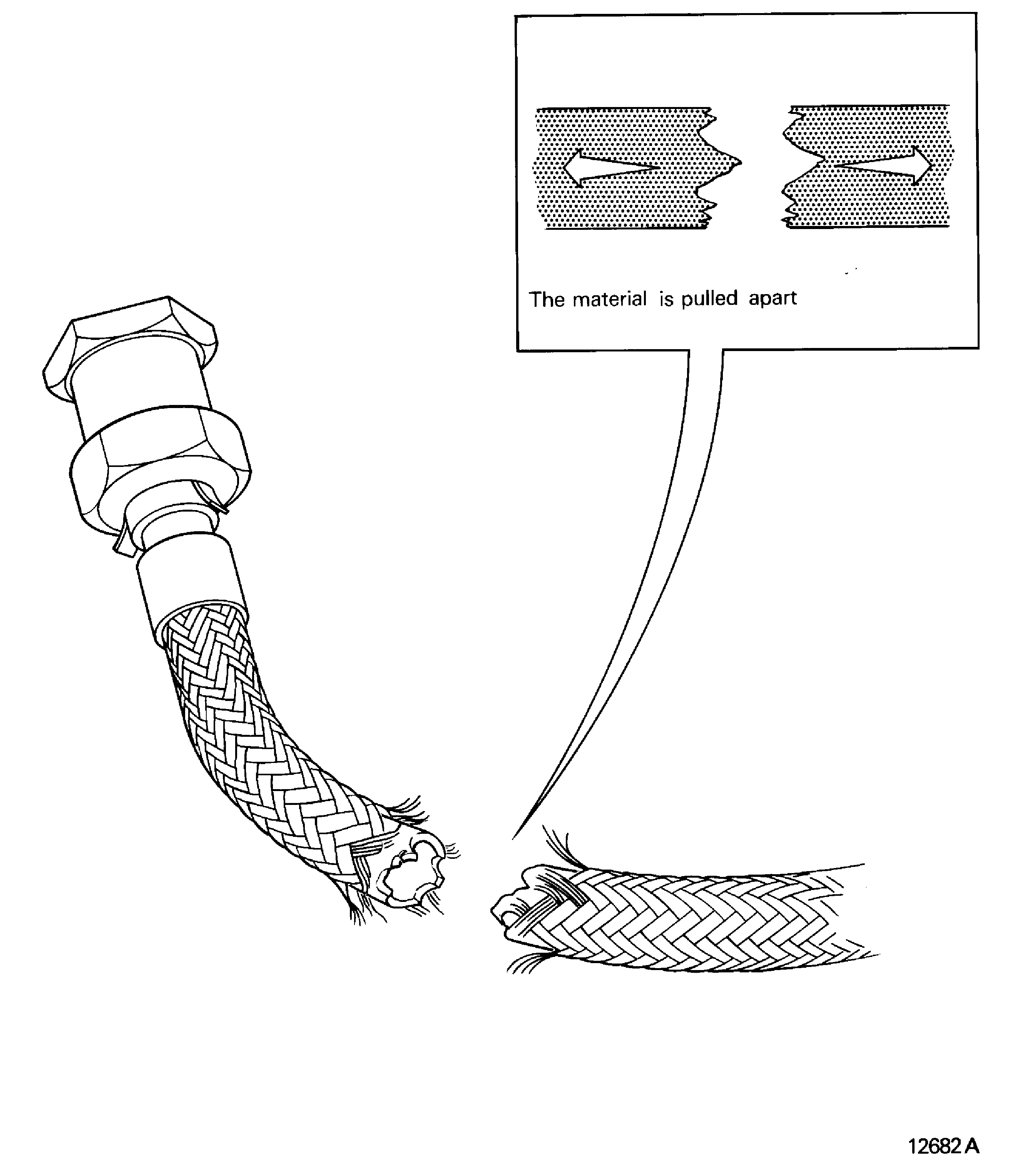

Torn

-

The material is pulled apart. Refer to Figure

Untwisted

Unwound

An unsatisfactory decrease in the angular adjustment. The part tries to become straight

Worn

-

The material of the part is erroded away because of operation or use

Wrecked

-

The damage is too bad for continued use

SUBTASK 70-02-02-350-001 The Types of Damage to Metal Parts

SUBTASK 70-02-02-350-002 The Condition of Metal Parts

TYPE OF DAMAGE

RELATED DATA

RELATED CONDITION

Acceptable

OK

Satisfactory for continued use

Not inspected

-

Class of part

-

The nozzle guide vane class is the

too low

angular deviation between the airfoil

chord and the buttresses

Class of part

-

The nozzle guide vane class is the

too high

angular deviation between the airfoil

chord and the buttresses

Clearance above

-

Unsatisfactory tolerances have

maximum

collected. (Not because of wear)

Clearance above

-

Unsatisfactory tolerances have

minimum

collected. (Not because of wear)

Clearance end

-

-

too much

Compression or

-

Compression or tension load is lower

tension below

than specified

minimum

Compression or

-

Compression or tension load is higher

tension above

than specified

maximum

Damaged during

-

-

transit

Deterioration

-

-

in storage

Dimension below

-

Below the engineering drawing

minimum

dimension or other specified

dimension

Dimension above

-

Above the engineering drawing

maximum

dimension or other specified

dimension

Emission low

-

Is the low output of electrical tubes;

it shows an unsatisfactory tube

Finish not to

-

Is the condition of the surface

specification

finish; not surface damage

Frequency out

-

The frequency of vibrations of a part

of limits

are above permitted limits

Hardness below

-

Found with Rockwell, Brinell or

limits

alternative hardnesss tests

Hardness above

-

Found with Rockwell, Brinell or

limits

alternative hardness tests

Magnetism low

-

Low or no magnetism of permanently

magnetized parts

Mis-matched

-

A condition caused because of the

incorrect relation of parts

Mis-positioned

Mis-aligned,

The incorrect installation of a part

reversed, cocked

which results in damage to the part

or related parts

Obsolete

Superseded

The part is not in use

Out of balance

-

The weight is not equally symmetrical

around the axis. This condition is to

be examined if there is no apparent

damage

Out of round

Elongated

The diameters of the part are not

constant

Out of square

-

The related surfaces are not at the

specified right angle

Part removed

-

A part removed as a precaution until

pending

an investigation is done and a

investigation

technical decision is made on its

condition

Received

-

-

disassembled

Resistance high

-

High electrical resistance in an

electrical circuit that causes

incorrect circuit operation

Resistance low

-

Low electrical resistance in an

electrical circuit that causes

incorrect circuit operation

Tension or

-

Tension or compression load is lower

compression

than is specified

below minimum

Tension or

-

Tension or compression load is higher

compression

than is specified

above maximum

Time expiration

Part retired

The part is not used because of a

time limit

Voltage erratic

-

Caused because of the intermittant

or irregular flow of current

Voltage - none

-

Caused because of an unwanted current

(circuit shorted

path to ground or between leads of

or grounded)

circuits that are usually at a

different voltage

Voltage - none

-

Caused because an electrical circuit

(circuit open)

is not complete because of a break

between electrical connections

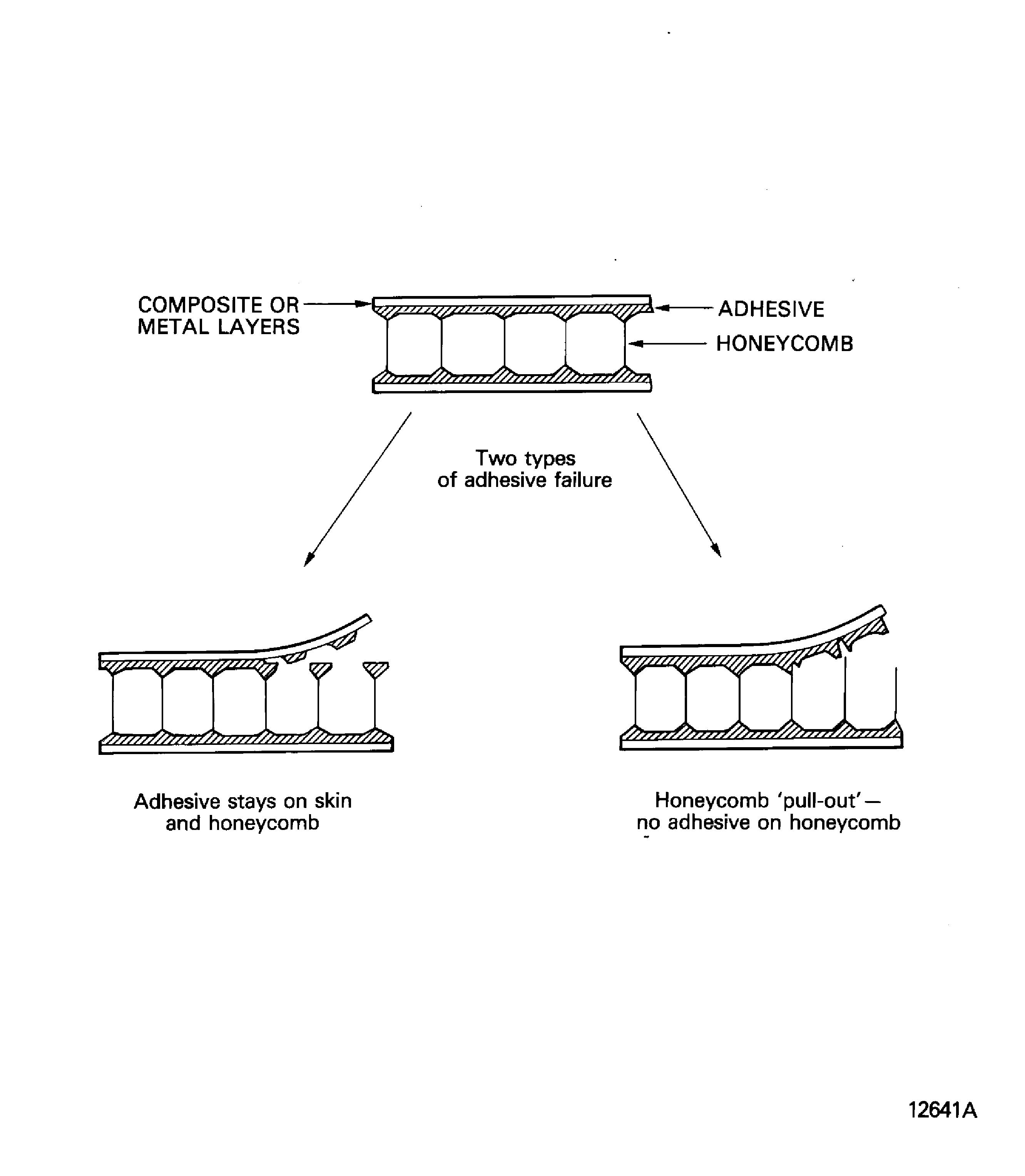

Failure at the joint between the adhesive and the honeycomb. The adhesive stays on the surface layer but not on the honeycomb. This is usually known as pull out. Refer to Figure.

NOTE

Unbond which occurs in composites can also occur in honeycomb structures with metal perforate and non-perforate surface layers.

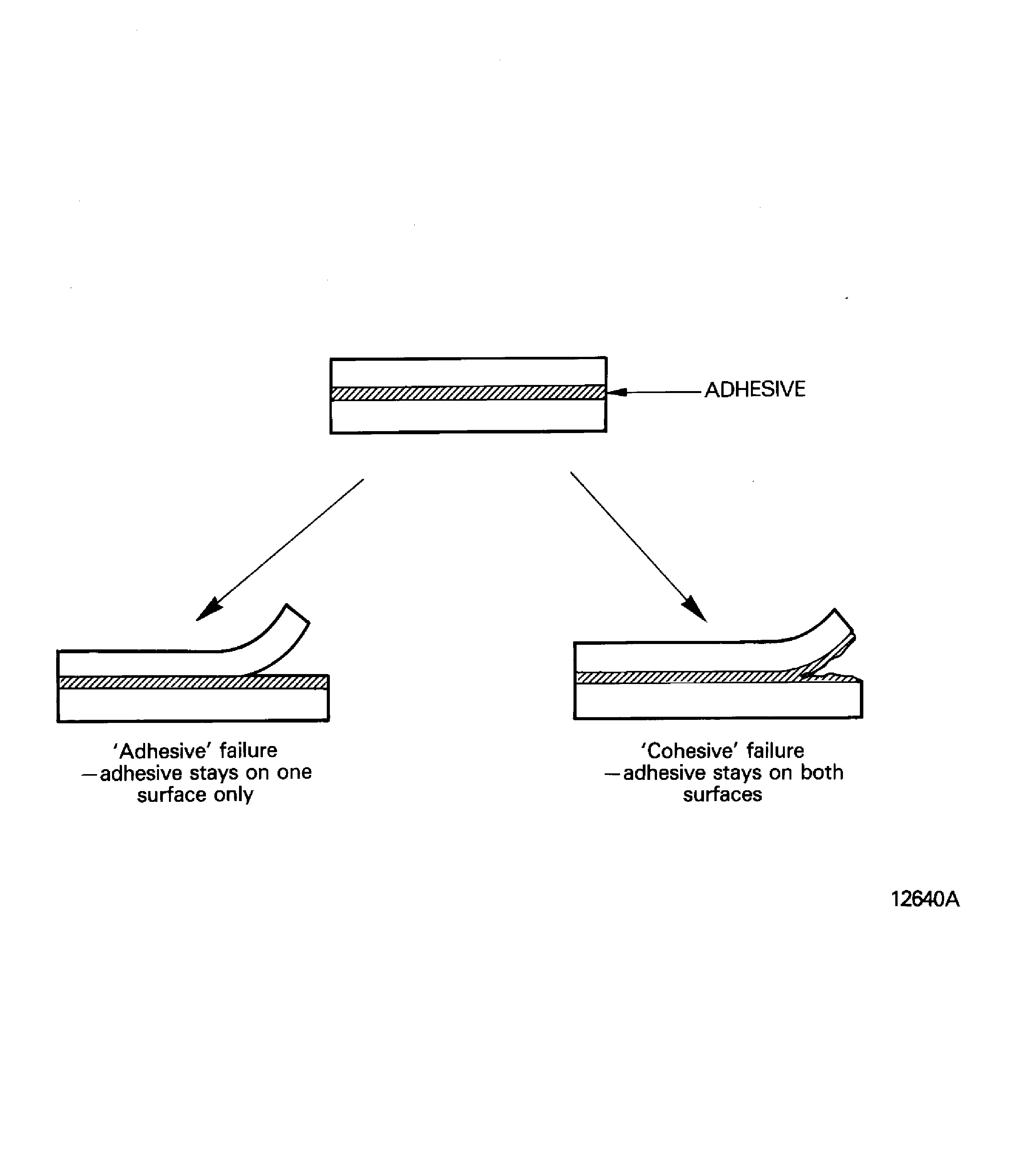

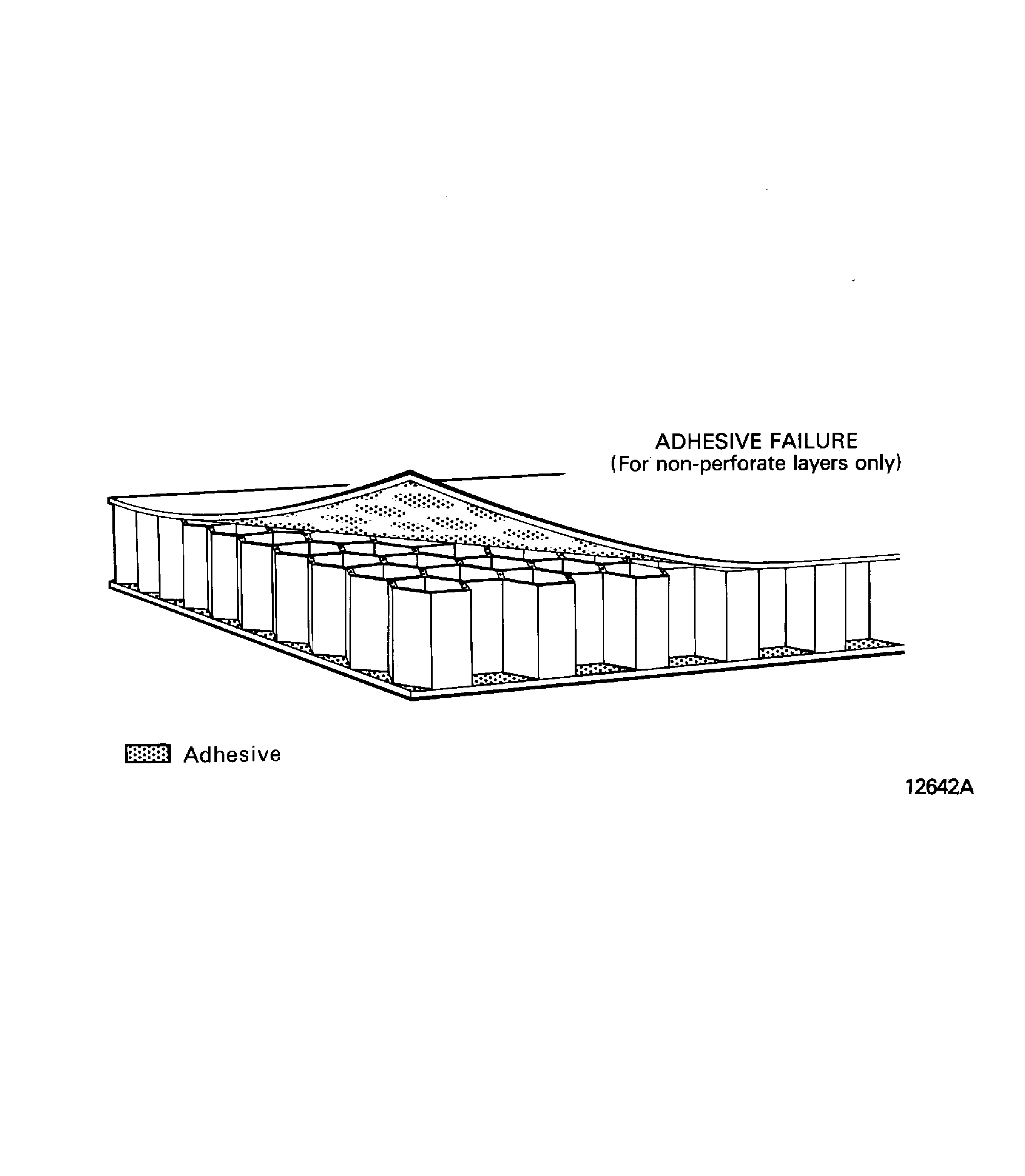

Adhesive failure.

This is failure at the joint between the bonded surface and the adhesive. The adhesive stays on one of the surfaces.

For honeycomb structures, adhesive failure can be divided in to two types.

NOTE

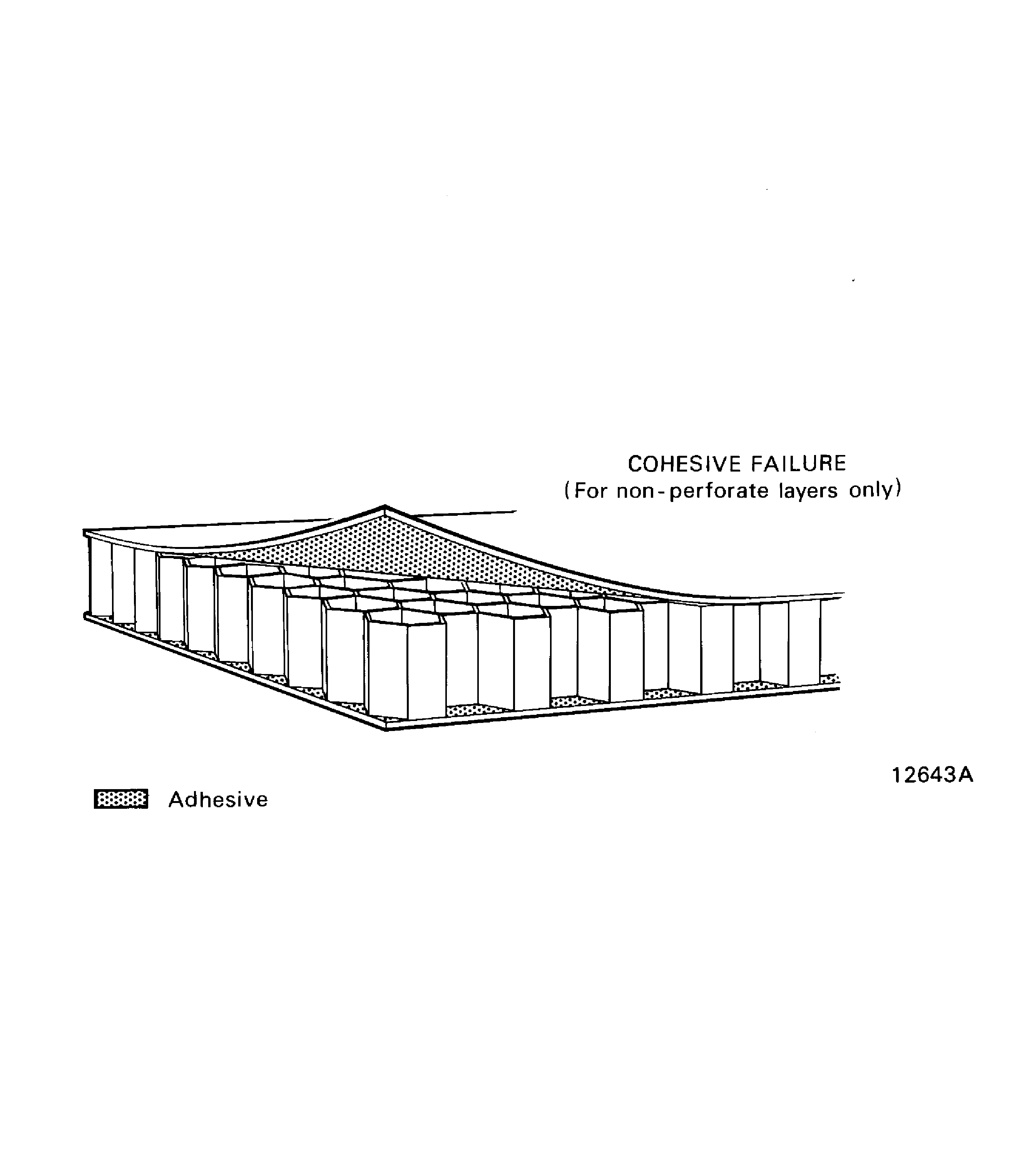

The adhesive will stay on the surface layer at the locations related to the honeycomb cells.Cohesive failure.

This is failure in the adhesive material. The adhesive stays on each surface. Refer to Figure.

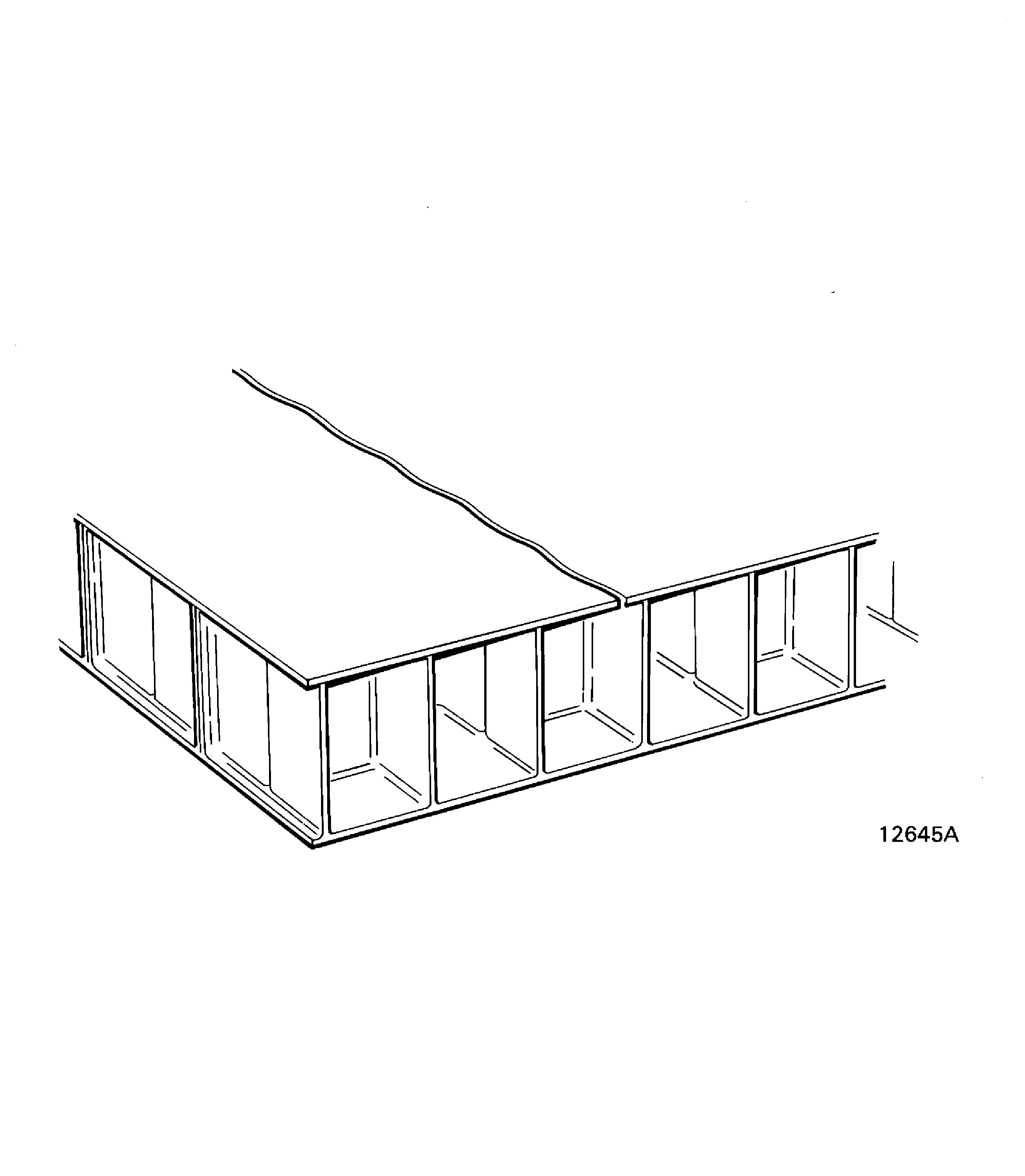

Unbond (or Disbond).

The separation of two bonded surfaces. Refer to Figure. There are two types of unbond as follows:

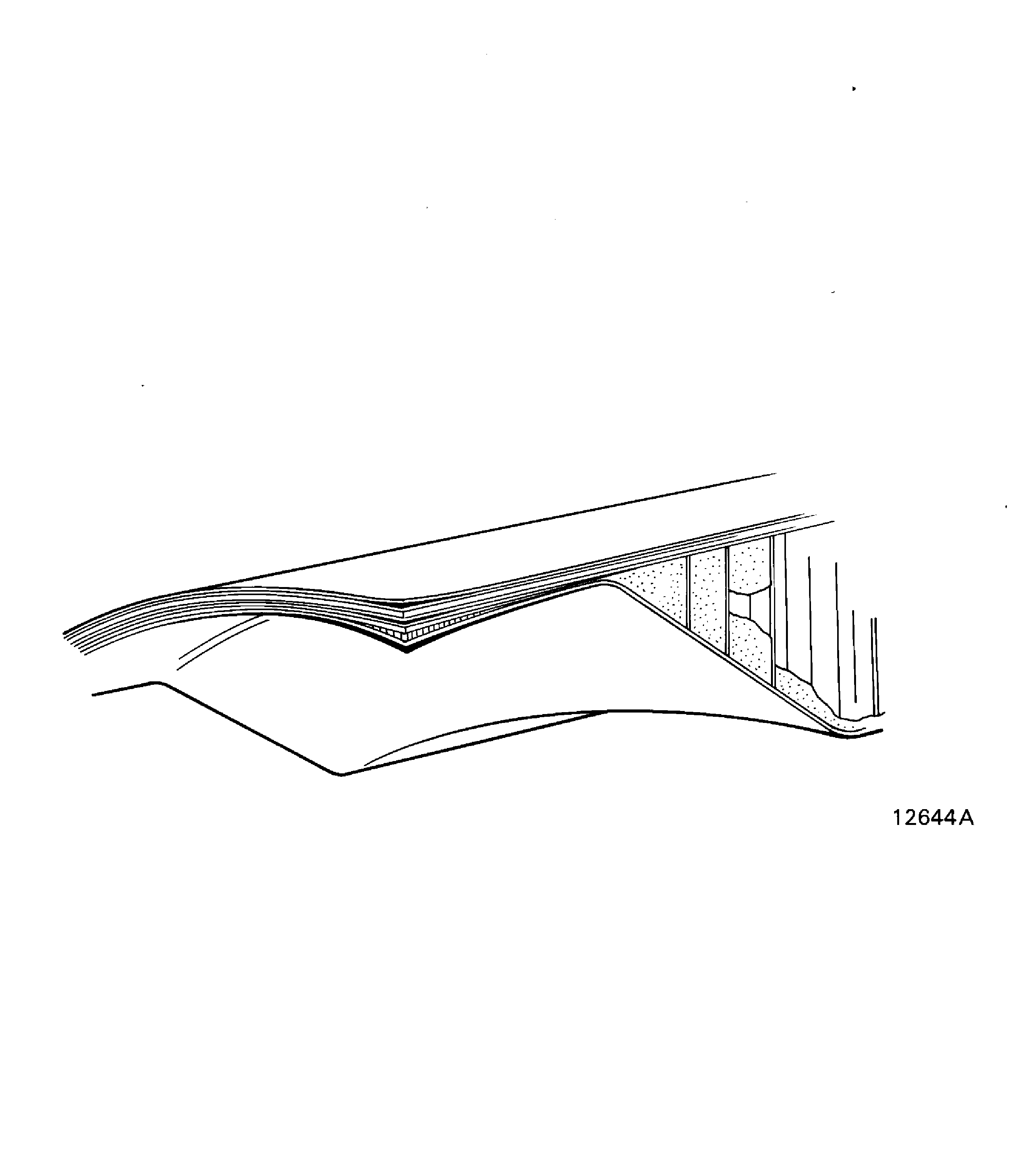

Cracked or split.

A crack or split through a composite laminate; is seen as a small opening in the composite surface layer or the complete composite thickness. It is usually caused when the material is hit or because of distortion. Refer to Figure.

Fretted.

This is seen as a rubbed surface with the protection removed from the fibers, this can result in broken fibers. Refer to Figure.

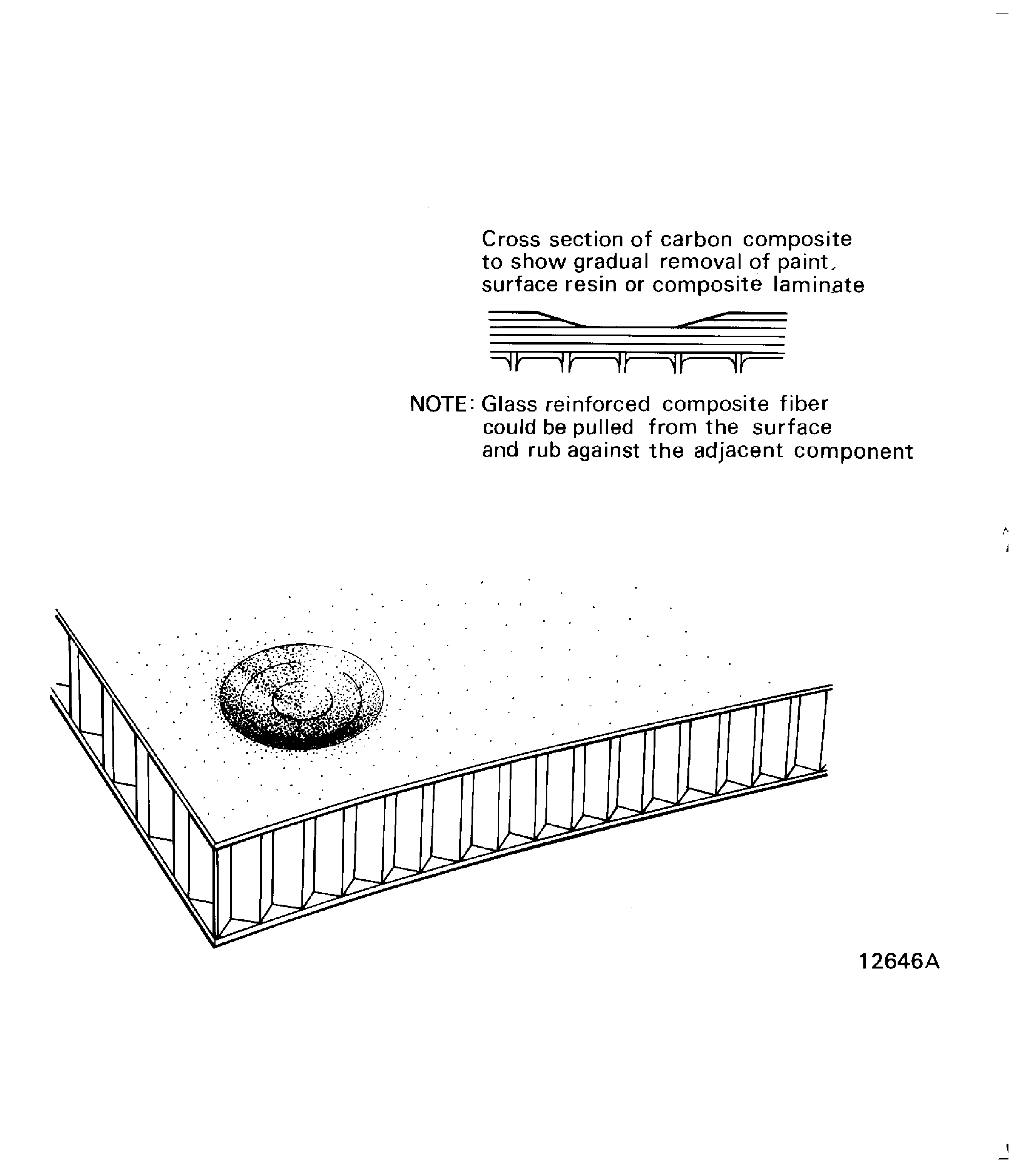

Eroded.

This is seen as the removal of the surface resin layer caused because of the effects of weather. When the protection is removed from the fibers it can make the surface rough. It is possible for the fibers to become eroded. Refer to Figure.

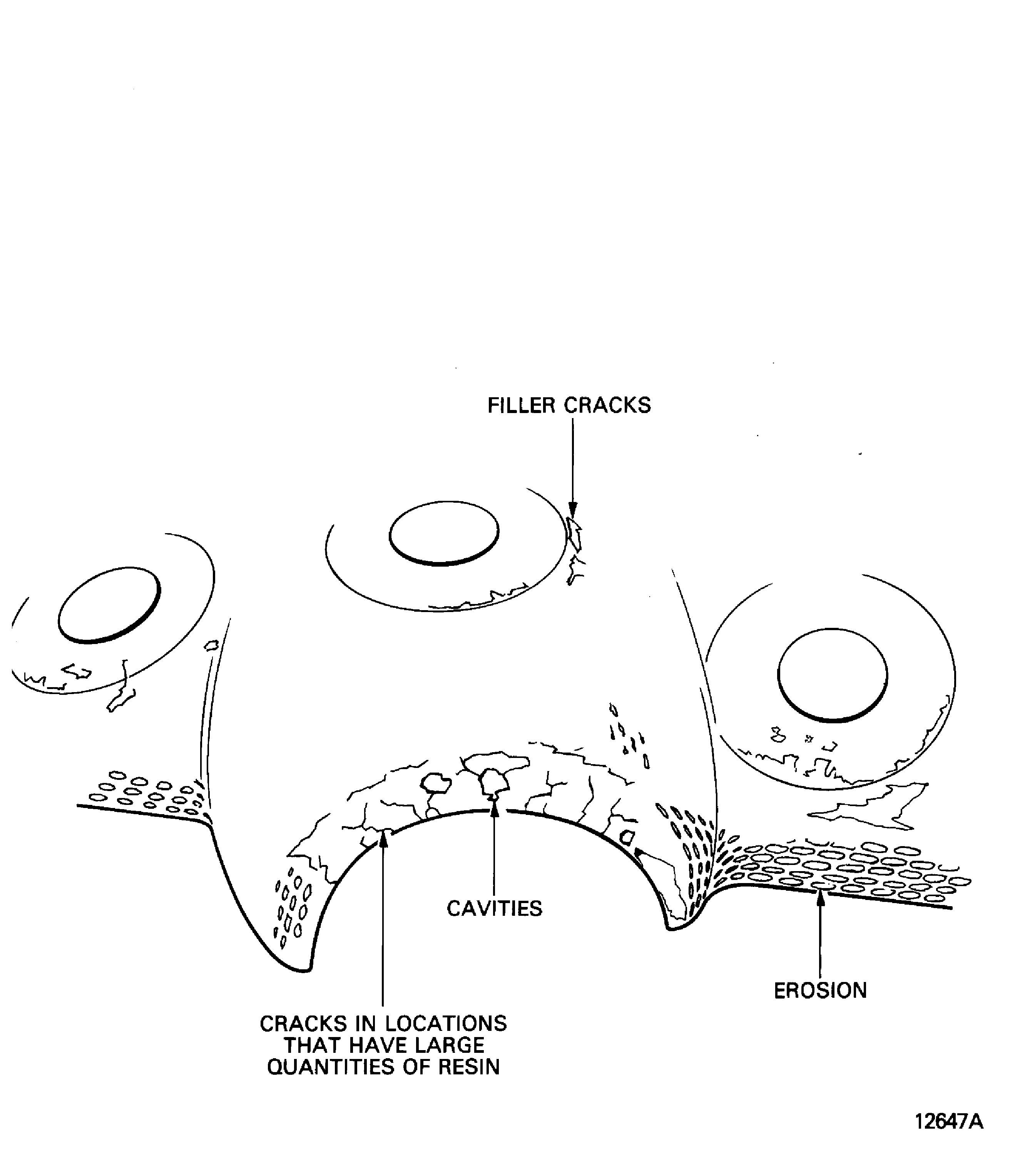

Cavity.

This is an empty space that occurs usually in the surface layers with a large quantity of resin or infilled locations. Refer to Figure.

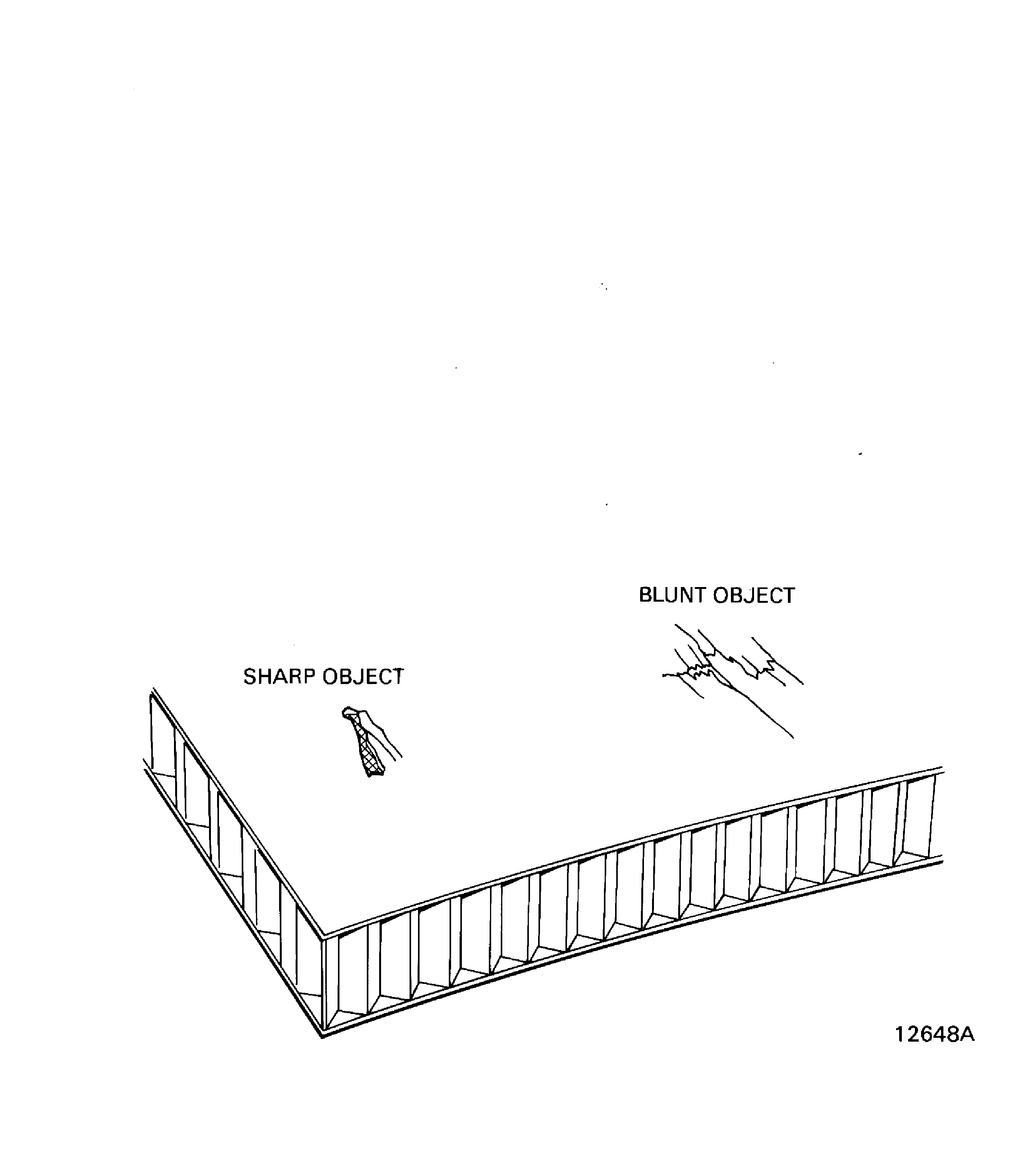

Sharp object.

Usually a split or a crack, possibly with related delamination near the damage. Refer to Figure.

NOTE

In honeycomb sandwich structures, impact damage could include other types of damage to the honeycomb.Blunt object.

Usually delamination of the layers with a possible related split, crack or unbond. Damage usually extends out of the immediate location of the damage. Refer to Figure.

Impact damage.

There are two groups of impact damage:

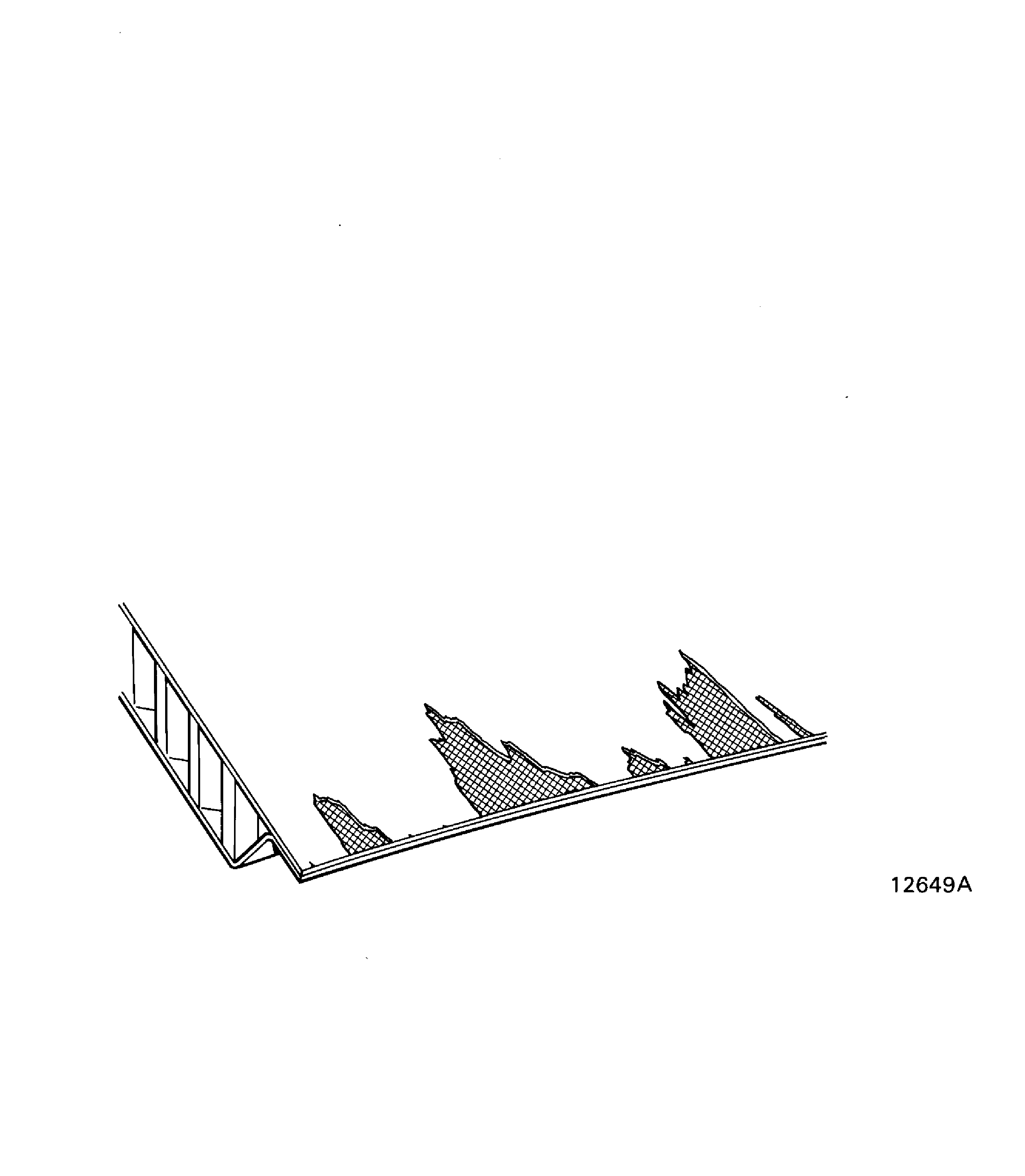

Torn fibers.

Strips of lifted surface fibers, pulled and peeled along the fiber length. Damage is frequently made larger because of the air flow until the fiber breaks. Refer to Figure.

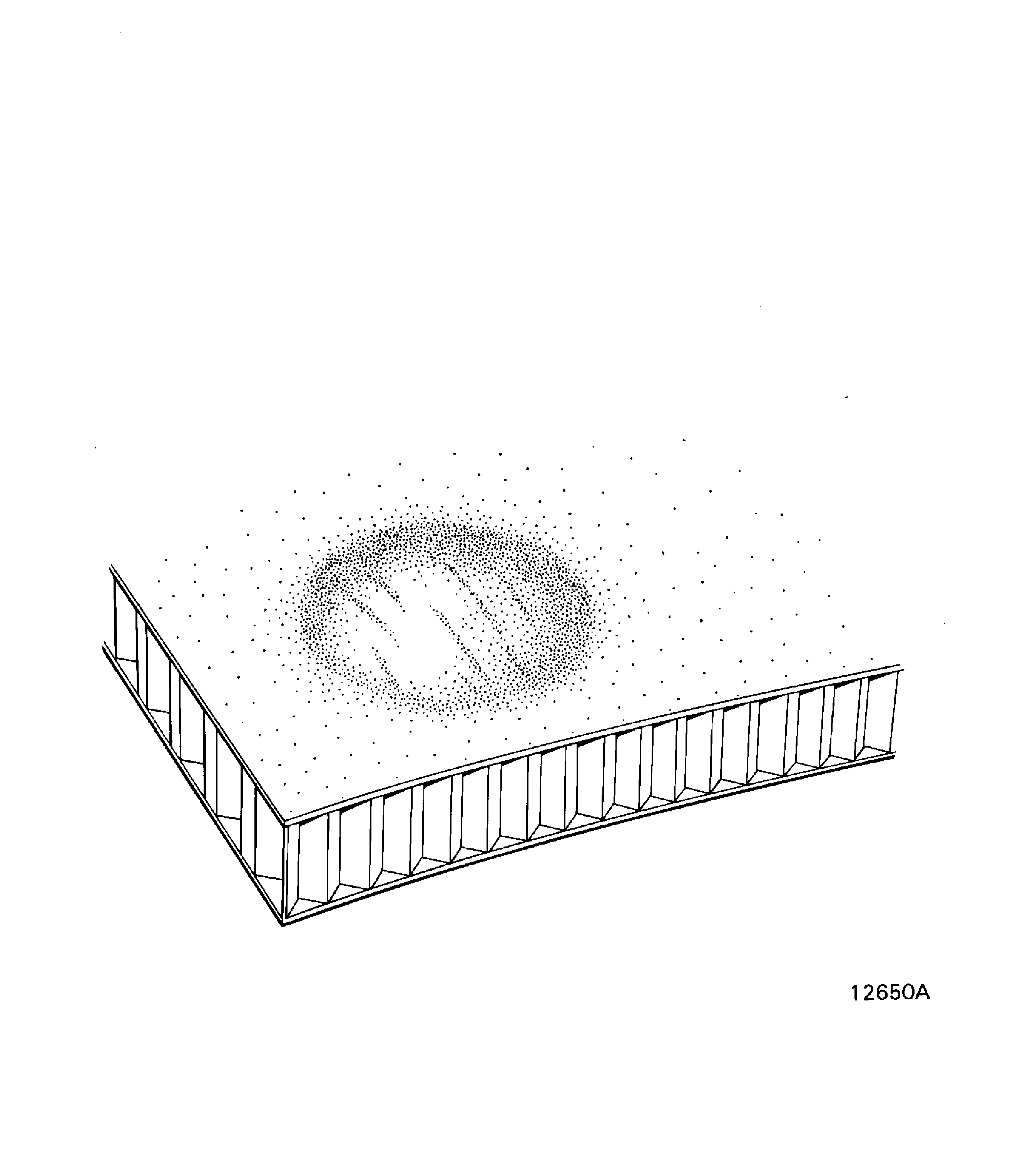

Blistered.

This is bubbles on the surface caused because of local delamination below the surface layer. Refer to Figure.

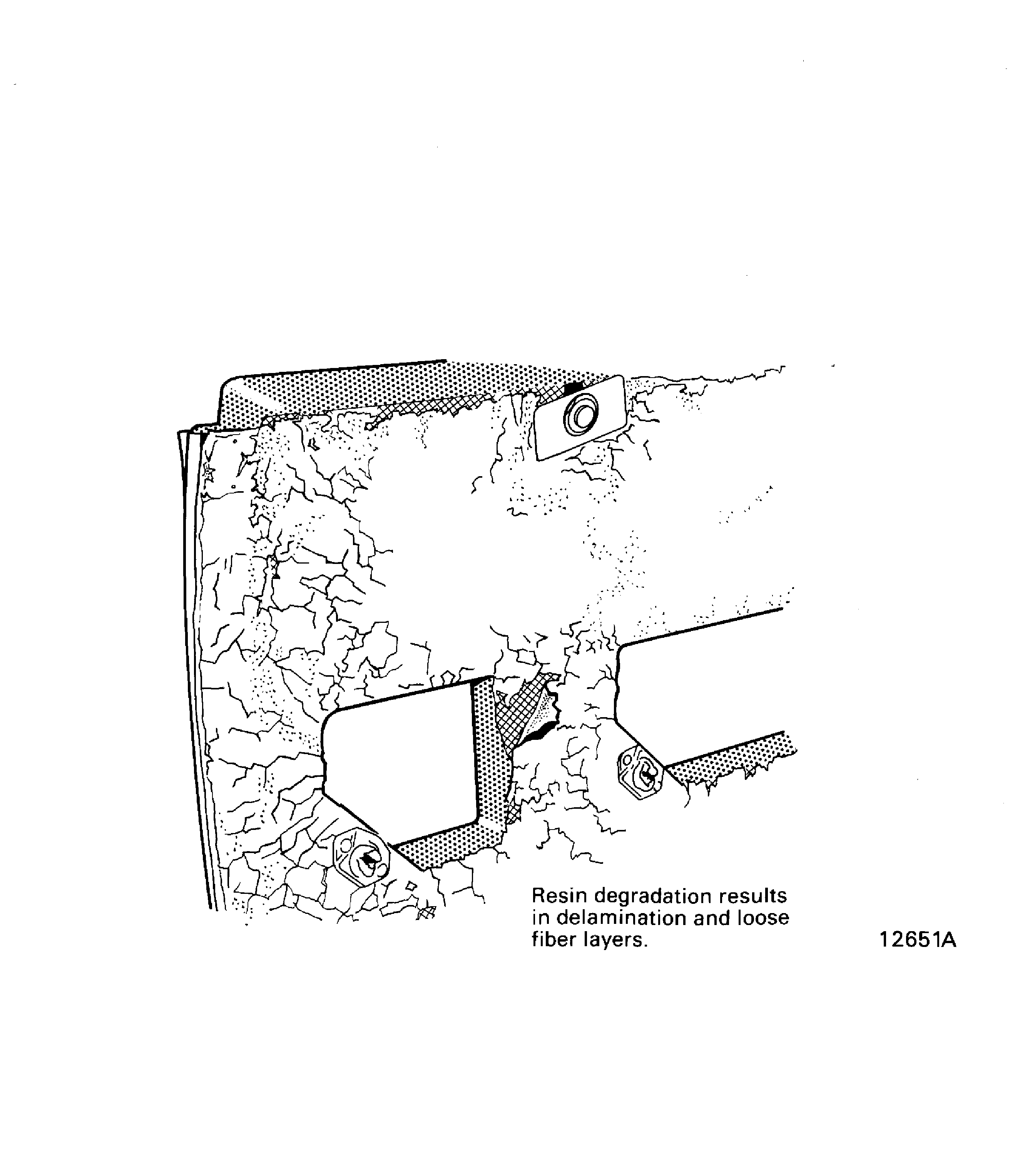

Resin degradation.

This is deterioration of the resin of a composite laminate, at the surface and also internally, which results in delamination and loose fibers. Refer to Figure.

Fire or heat damage.

This can cause one or all of the conditions that follow:

SUBTASK 70-02-02-350-003 Types of Damage to Composite Materials

Figure: Battered

Battered

Figure: Bent

Bent

Figure: Bowed

Bowed

Figure: Brinelled

Brinelled

Figure: Broken

Broken

Figure: Bulge

Bulge

Figure: Burned

Burned

Figure: Carboned

Carboned

Figure: Collapsed

Collapsed

Figure: Crack

Crack

Figure: Curled

Curled

Figure: Dent

Dent

Figure: Deposits

Deposits

Figure: Disintigrated

Disintigrated

Figure: Distorted

Distorted

Figure: Galled

Galled

Figure: Gouge

Gouge

Figure: Nick

Nick

Figure: Overheated

Overheated

Figure: Peeled

Peeled

Figure: Pick-up

Pick-up

Figure: Pitted

Pitted

Figure: Porous

Porous

Figure: Rolled-over

Rolled-over

Figure: Ruptured

Ruptured

Figure: Scored

Scored

Figure: Scratch

Scratch

Figure: Sheared

Sheared

Figure: Skidding

Skidding

Figure: Spalled

Spalled

Figure: Torn

Torn

Figure: Unbond

Unbond

Figure: Unbond

Unbond

Figure: Unbond (Adhesive failure)

Unbond (Adhesive failure)

Figure: Unbond (Cohesive failure)

Unbond (Cohesive failure)

Figure: Delaminated

Delaminated

Figure: Cracked/Split

Cracked/Split

Figure: Fretted

Fretted

Figure: Eroded and Cavities

Eroded and Cavities

Figure: Impact damage

Impact damage

Figure: Torn fibers

Torn fibers

Figure: Blistered

Blistered

Figure: Scorched

Scorched