Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-23-00-230-501 Fluorescent Penetrant Inspection (FPI) General Information

Table of Contents

Introduction | ||

General | ||

Safety Precautions | ||

General FPI Method | ||

Frequency of Control Tests | ||

FPI System Control Tests | ||

FPI Materials and Their Control | ||

FPI Equipment and its Control | ||

Calibration of Non-certified Test Panels | ||

Preparation of the Surface | ||

Vacuum Drying | ||

Penetrant Removers | ||

Equipment Suppliers | ||

Commonly used Terms |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-012 FILTER PAPER | LOCAL | CoMat 02-012 | ||

| CoMat 01-060 ACETONE (CH3)2CO | LOCAL | CoMat 01-060 | ||

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 06-032 DRY DEVELOPER | 37676 | CoMat 06-032 |

Spares

NONESafety Requirements

NONEProcedure

Fluorescent penetrant inspection (FPI) processes are non destructive methods of inspecting materials and parts for surface discontinuities and imperfections. FPI techniques use either water-washable fluorescent penetrants, or post-emulsifiable fluorescent penetrants that use separate emulsifiers. The Engine Manual will specify the parts that require FPI and the FPI procedure to be used.

SUBTASK 70-23-00-860-002 Introduction

Removal of base material, thermal spray coatings (such as plasma, HVOF, dual wire arc and D-Gun) or plating during dimensional or hardface restoration repairs on rotating parts (for example airseals, blades, disks, drums, shafts, tierods, retaining plates and spacers).

Removal of chromium plate from rotating and non-rotating parts.

Pressure testing of tube and manifold assemblies.

FPI is necessary after:

Honeycomb, feltmetal or composite details.

Inspection after grinding of HPC platforms, LPT platforms or rotor blade tips in an assembly.

FPI is not necessary for:

General guidance on when Fluorescent Penetrant Inspection is necessary is given in the paragraphs that follow.

For fluorescent penetrant procedures to be satisfactory, defects must be open to the surface to permit entry of the penetrant. It is important that all surfaces are fully clean of paint and other surface coatings, grease, oil, scale, or corrosion. Refer to the engine manual for the applicable cleaning procedure.

To maintain satisfactory results, periodic checks are necessary. The frequency of each necessary check is given in the table in Step.

Do not use a lower sensitivity procedure than that specified in the Engine Manual for the part. Where a medium/normal sensitivity procedure is specified, it is permitted to use a high-sensitivity procedure as an alternative, but it is not recommended because it can cause parts to be rejected because of unrelated indications and/or it can result in too much background fluorescence which can cover related indications.

Fluorescent Penetrant Inspection.

The FPI procedures used in the FPI of V2500 parts are listed in the table as follows:

TASK Number

Title

Medium Sensitivity Post-emulsified Fluorescent Penetrant Inspection

Medium Sensitivity Water-washable Fluorescent Penetrant Inspection

High Sensitivity Post-emulsified Fluorescent Penetrant Inspection

Ultra High Sensitivity Post-emulsified Fluorescent Penetrant Inspection

Local Application, Fluorescent Penetrant Inspection

High Sensitivity Water-washable Fluorescent Penetrant Inspection

SUBTASK 70-23-00-230-001 General

CAUTION

THE USE OF VISIBLE DYE PENETRANTS ON ENGINE PARTS IS NOT PERMITTED. ABSORPTION OF VISIBLE DYE PENETRANT WILL MASK INDICATIONS AND DECREASE THE SENSITIVITY OF FPI.SURFACE TREATMENT (SUCH AS ABRASIVE BLASTING), IF NOT USED CORRECTLY, CAN CAUSE DAMAGE TO THE SURFACE LAYER. THIS WILL PREVENT AN ACCURATE NON-DESTRUCTIVE INSPECTION OF THE SURFACE DEFECTS. THE EFFECT WILL CHANGE, WITH THE DIFFERENT MATERIALS AND PROCEDURES USED. ALWAYS OBEY THE INSTRUCTIONS IN THE STANDARD PRACTICES AND ENGINE MANUALS. THEY WILL GIVE THE BEST NON-DESTRUCTIVE INSPECTION RESULTS.LIGHT-SENSITIVE SPECTACLES MUST NOT BE USED DURING THE FLUORESCENT PENETRANT INSPECTION PROCEDURES, BECAUSE EXPOSURE TO ULTRAVIOLET LIGHT CAN CAUSE A 50 PERCENT DECREASE IN THE LIGHT TRANSMITTED THROUGH SUCH SPECTACLES.PAINTED BULBS MUST NOT BE USED FOR INSPECTION OF PARTS.NOTE

Fluorescent Penetrant Inspection must not replace visual inspection procedures, but must be used as an extension to visual inspection.SUBTASK 70-23-00-860-001 Safety Precautions

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURER'S MATERIALS SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS. THESE CONTAIN INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL PRECAUTIONS INTO CONSIDERATION.

WARNING

THE ULTRA-VIOLET LAMPS MUST ALWAYS BE KEPT IN GOOD CONDITION. LAMPS WITH BROKEN OR DEFECTIVE FILTERS ARE DANGEROUS TO THE EYES. A REGULAR INSPECTION OF THE FILTERS IS NECESSARY. ALWAYS TURN OFF THE LAMP IMMEDIATELY IF THE ELEMENT BECOMES OPEN BECAUSE OF A BROKEN OR DAMAGED GLASS FILTER.To maintain satisfactory results constant checks are necessary, the necessary checks are given in the table as follows:

Frequency of Check

Check to be done

Remarks

Daily

Calibrated Pressure gages, Temperature gages or other Equipment

At the start of each shift

Make sure the equipment is clean.

Make sure the tank levels and water temperature is correct

At the start of each shift

Examine the ultra-violet lamps

At the start of each shift

Check indications can be detected

"Daily system capability test"

At the start of each shift

Check condition of the dry developer.

Weekly

Check the fluorescent brightness

Weekly

Remover Check

Monthly

Measure UV Light-source output

Monthly

Measure water content of penetrant

Monthly

Inspection Area

Every Three Months

Check the fluorescent intensity

Every Six Months

Clean the tanks

Clean more frequently if necessary.

To manufacturer's Instruction but at least every 12 Months

Light Meters and Refractometers

On Receipt

White Light Test on New Bulbs

SUBTASK 70-23-00-230-003 Frequency of Control Tests

Do an initial system validation test at each sensitivity level in use (refer to test panel calibration Step). The number of artificial discontinuities found must be the larger of (i) or (ii) as follows:

Capability Test:

Initial Validation of System.

SUBTASK 70-23-00-230-004 FPI System Control Tests

Soak a CoMat 02-012 FILTER PAPER (3.15 x 3.15 inches (80 x 80 mm)) in a sample of the used fluorescent penetrant. Soak a second filter paper in a sample of the new or reference fluorescent penetrant.

Compare the color intensity of the used fluorescent penetrant with that of the new or reference fluorescent penetrant under UV-light, by the method that follows:

Fluorescence brightness test.

NOTE

This test is not necessary if you discard the penetrant in three months or less after you filled the tank with the penetrant.It is permitted to use ASTM E1135 standard test method for comparing the brightness of fluorescent penetrants as an alternative to this procedure.Prepare a reference or standard solution of 1 percent of the new penetrant mixed with 99 percent of CoMat 01-060 ACETONE (CH3)2CO or CoMat 01-031 ACETONE (CH3)2CO. Also prepare a 1 percent test solution made up from the penetrant in use.

Soak a CoMat 02-012 FILTER PAPER (3.15 x 3.15 inches (80 x 80 mm)) in the reference or standard solution and soak a second filter paper in the penetrant in use.

Compare the fluorescent intensity of the used fluorescent penetrant with that of the new or reference fluorescent penetrant, as follows:

Fluorescent intensity test:

NOTE

This test is not necessary if you discard the penetrant in three months or less after you filled the tank with the penetrant.It is permitted to use ASTM E1135 standard test method for comparing the brightness of fluorescent penetrants as an alternative to this procedure.

Test the contents of penetrant in immersion tanks and recirculation machines by the methods as follows:

Penetrants.

NOTE

These tests are not necessary for spray booths that do not apply used penetrant to parts.The calibration curve is produced by preparing 5 samples of remover at 90 percent, 95 percent, 100 percent, 105 percent and 110 percent of the proposed working concentration. The refractive index of these samples are measured and plotted onto a chart to produce a calibration curve of refractive index versus remover concentration.

The refractive index of the penetrant remover is compared against a prepared calibration curve of refractive index versus remover concentration. The remover concentration is calculated from the graph.

NOTE

This check is not necessary if the emulsifier is discarded within one week after the tanks are initially filled.Refer to Step for the manufacturer's recommended concentration.

Check the refractive index (concentration) of the penetrant remover every week with the refractometer or alternatively test to the latest revision of ASTM D-95 or to B.S.4385.

NOTE

A new calibration curve must be made whenever the make or type of remover is changed.

Penetrant Removers/Emulsifier.

Examine the CoMat 06-032 DRY DEVELOPER to make sure it is dry and light. If the powder has become solid, it must be discarded.

At the start of each work shift, it is necessary to check all dry developer, that is used more than one time. Check as follows:

Dry Developers.

SUBTASK 70-23-00-230-005 FPI Materials and Their Control

Do all necessary calibrations of equipment initially, as scheduled, and after maintenance or repair. It is necessary for the operator to have a calibration schedule for the control of all equipment that must be calibrated, and a record of when it was completed and the next scheduled service or calibration.

FPI equipment must be regularly calibrated, approved or controlled.

Each FPI line must satisfactorily complete the "Daily System Capability Test" (Refer appropriate paragraph in Step).

General.

It is necessary to do the UV light intensity check for all UV lights that you use to do part inspection.

It is not necessary to do the UV light intensity check for the UV lights that you see only to monitor the fluorescent penetrant process (that is, the UV lights that you use to make sure that you correctly apply or remove the penetrant).

Charge the battery, change the battery or get a different UV light unit.

Do the check of the UV light intensity before you use the UV light unit to examine parts.

If the UV light intensity is not satisfactory at the start of the inspection, do the subsequent procedure before you use the UV light unit to examine parts:

For battery powered UV lights that operate continuously, do a check of the UV light intensity after each 2 hours of operation and at the end of each inspection.

For battery powered LED UV flashlights that you use as evaluation aids intermittently during a shift, do a check of the UV light intensity at the start of the inspection and at the end of the shift.

For UV light units that operate on battery power, it is necessary to do a check of the UV light intensity at the start of the inspection and after battery change.

For all other UV light units, do a check of the UV light intensity one time each day.

When you install a new light bulb or LED in a UV light unit, do a check of the UV light intensity of the unit before you use it to do an inspection.

Do an intensity check of the UV lights at the applicable interval.

NOTE

It is permitted to change the time interval between these checks if there is sufficient technical/reliability data to substantiate this change (that is, if there is sufficient test data to show that the new interval will also give the necessary quality) and the change is approved by the applicable engineering organization.For some types of light sources, the UV light must be on for 10 minutes minimum to let the light increase to full intensity. Refer to the manufacturer's instructions.

Make sure the light is at full intensity before you do the intensity check.

Measure the intensity of the UV light with a UV-A light sensor and a calibrated light meter that measures UV-A light only or measures UV-A light and white light. The applicable intensity must be as specified in the subsequent table:

NOTE

It is permitted to move the light sensor around to find the peak meter reading.Table 4. Type Of Light Source

Minimum UV-A Intensity

Measurement Location

Hand held UV Light

1000 microwatts per sq cm

15 in. (381 mm) from the front of the lamp

UV Light Borescope

1000 microwatts per sq cm

1.5 in. (38.1 mm) from the front end of the borescope

Fixed/Mounted UV Light

1000 microwatts per sq cm

At sufficient locations to make sure that the light has the necessary intensity at all intended working distances*

Low Intensity UV Light Pencil Lamp

1000 microwatts per sq cm

0.50 in. (12.7 mm) from the lamp

Light Emitting Diode (LED) UV Flashlight/Torch

1000 microwatts per sq cm

15 in. (381 mm) from the front end of the flashlight/torch

Battery Powered UV Light

2000 microwatts per sq cm

15 in. (381 mm) from the front of the lamp

*The intended working distances are the distances between the fixed/mounted UV lights and the inspection surfaces of all the different types of parts that you examine with these lights.

Use the subsequent procedure to do the intensity check:

UV Lights.

Calibrate the UV light meter every six months.

NOTE

It is permitted to extend the maximum time between calibrations if there is sufficient technical data to substantiate this change, and the change is approved by the inspection operation's quality organization.

UV Light Meter

Calibrate the white light meter every six months.

NOTE

It is permitted to extend the maximum time between calibrations if there is sufficient technical data to substantiate this change, and the change is approved by the inspection operation's quality organization.

White Light Meter

SUBTASK 70-23-00-230-006 FPI Equipment Controls

CAUTION

DO NOT USE EQUIPMENT IF IT DOES NOT OPERATE CORRECTLY. REPAIR AND CALIBRATE THE EQUIPMENT BEFORE YOU USE IT AGAIN. DO NOT USE ANY EQUIPMENT WITH AN EXPIRED DATE ON THE CALIBRATION STICKER.It is necessary to do an initial qualification of all FPI test panels before you use them and to requalify each test panel annually. For suppliers of suitable test panels refer to Step.

It is necessary to qualify test panels for each penetrant sensitivity level that the facility uses. It is necessary to use a separate test panel for each sensitivity level that the FPI system uses and to identify each test panel with the applicable sensitivity level.

Do the applicable FPI SPOP with new FPI materials and the maximum specified parameters.

The test panel must show no cracks or damage that have a negative effect on the usefulness of the test panel and must show no singular cracks that radiate out from the typical pattern of a star burst (that is, a group of linear indications that radiate from a common center to make an approximately circular image) indications of the artificial discontinuities. If the panel has such cracks or damage, it is necessary to replace the panel.

Examine the test panel for the artificial discontinuities that the selected sensitivity level must show. Each artificial discontinuity, other than the smallest artificial discontinuity (Artificial Discontinuity A), must show as a star burst. The smallest artificial discontinuity (Artificial Discontinuity A) can show as a pinpoint or a star burst.

Table 5. Sensitivity Level

IAE Process No

Minimum No. of Artificial Discontinuities that Show Indications

Medium/Normal

(AMS 2644 Level 2)

SPM TASK 70-23-01-230-501 and SPM TASK 70-23-02-230-501

Three largest (Artificial Discontinuities C, D and E)

High

(AMS 2644 Level 3)

SPM TASK 70-23-03-230-501 and SPM TASK 70-23-08-230-501

Four largest (Artificial Discontinuities B, C, D and E)

Ultra High

(AMS 2644 Level 4)

All five

For the initial qualification, the longest dimension of each indication area must agree with the specified sizes in the subsequent list. Record the longest dimension of each indication area as the baseline measurement of each indication area.

Table 6. Artificial Discontinuity

Discontinuity Size

A

0.015 - 0.032 in. (0.381 - 0.813 mm)

B

0.046 - 0.062 in. (1.168 - 1.575 mm)

C

0.075 - 0.093 in. (1.905 - 2.362 mm)

D

0.125 - 0.171 in. (3.175 - 4.343 mm)

E

0.180 - 0.250 in. (4.572 - 6.350 mm)

For annual requalification, the longest dimension of each indication area must agree with the specified size relative to the baseline measurement:

Table 7. Artificial Discontinuity

Longest Dimension of Indication

A

Initial Qualification Baseline Measurement +/-30 percent

B

Initial Qualification Baseline Measurement +/-30 percent

C

Initial Qualification Baseline Measurement +/-30 percent

D

Initial Qualification Baseline Measurement +/-30 percent

E

Initial Qualification Baseline Measurement +/-30 percent

It is permitted to see individual indications that are 0.015 in. (0.381 mm) or smaller in the discontinuity area(s).

Measure each indication under UV light. The measurement must be of the actual indication size and not of the area that the penetrant has flowed to.

Record the initial qualification results and the annual requalification results in the test panel records and send the results to the inspection department that will use the test panel.

Clean the test-piece as specified in the SPM TASK 70-11-03-300-503 (Ultrasonic may be used).

Store the test piece fully immersed in a sealed container of degreasing fluid, refer to the SPM TASK 70-11-26-300-503.

Clean the test-piece.

Do the subsequent procedure to do the initial qualification and the requalification of the test panels:

After the initial qualification gives approval to a test panel, give the test panel a unique identification, such as a serial number, that identifies the test panel with the FPI method and sensitivity for which the test panel will be used.

SUBTASK 70-23-00-230-007 FPI Test Panel Initial Qualification and Annual Requalification

With vacuum assistance, you can use lower temperatures and reduced drying times as follows:

Table 8. Minimum Surface Temperature

Maximum Pressure during Drying Cycle

Minimum Drying Time

176 deg F (80 deg C)

25 mbar

10 minutes

140 deg F (60 deg C)

15 mbar

10 minutes

104 deg F (40 deg C)

10 mbar

10 minutes

Less than 104 deg F (40 deg C)

Not Permitted

Not Permitted

The minimum time may be used only if the surface temperature of the part is measured and has reached the temperature necessary. If the surface temperature of the part is not measured, the part must be dried for 60 minutes minimum.

Always refer to the equipment manufacturer's instructions for correct operation of the vacuum drying system.

SUBTASK 70-23-00-180-002 Vacuum Drying

For the emulsifier concentration limits for medium sensitivity post-emulsified fluorescent penetrant inspection, refer to TASK 70-23-01-230-501. For the emulsifier concentration limits for high sensitivity post-emulsified fluorescent penetrant inspection, refer to TASK 70-23-03-230-501. For the emulsifier concentration limits for ultra-high sensitivity post-emulsified fluorescent penetrant inspection, refer to TASK 70-23-04-230-501.

SUBTASK 70-23-00-290-001 Penetrant Remover Concentration

Refer to V2500 Vendor List in the V2500 Interactive Electronic Technical Publication for the suppliers that the specified Vendor Codes identify.

Peak wavelength must be 365 nm (3650 Angstroms) plus or minus 5 in ambient temperatures of 60 - 104 deg F (10 - 40 deg C).

Visible light must not be more than 20 Lux (2 foot candles) at minimum working distance.

The UV-A intensity at a working distance of 15 in. (381 mm) must not be more than 10,000 microwatts per sq cm.

For all purchases of UV light sources, the manufacturer must provide documentation that the supplied UV light sources agree with the requirements in the subsequent list:

General

The subsequent table contains approved UV light meters; but other UV light meters that agree with the specified requirements in SUBTASK 70-23-00-230-006 are permitted.

Table 9. Manufacturer

Model

Vendor Code

Gould-Bass Co

DLM-1000 Digital Radiometer

7Z769

Labino AB

Labino Apollo 1.0 Radiometer And Photometer, Part Number M500

SWN96

Magnaflux

Part Number 625024 UV-A

Digital Light Meter

37676

K5549

Marktec Corp.

UV-2500 II

S9502

Megatron Ltd

DL3

*

Megatron Ltd

DL3/C

*

Megatron Ltd

DL5

*

Spectronics Corp.

DM-365N

20772

Spectronics Corp.

DM-365X

20772

Spectronics Corp.

DM-365XA

20772

Spectronics Corp.

Accumax XRP-3000

20772

Spectronics Corp.

DSE-100X with

DIX-365 sensor

20772

Spectronics Corp.

DSE-100X with

DIX-555A/L sensor

20772

UVP LLC

UVX-36

4W3A0

*This model is no longer manufactured, but it is permitted to continue to use this model.

UV Light Meters

The subsequent table contains light emitting diode (LED) UV-A flashlights/torches that are approved for local inspection of fir-trees slots on Low-Pressure Turbine (LPT) Disks and Hubs and on High Pressure Turbine (HPT) Disks and Hubs:

Table 11. Manufacturer

Model

Vendor Code

Labino AB

Labino Torch Light Model UVG3 Spotlight

SWN96

Spectronics Corp.

Spectroline Opti-Lux Model OLX-365B

20772

LED UV-A flashlights/torches for local inspection of fir trees slots on Low Pressure Turbine (LPT) Disks and Hubs and on High Pressure Turbine (HPT) Disks and Hubs

The subsequent table contains hand held LED UV lights that are approved for full field inspection of parts:

Table 12. Manufacturer

Model

Vendor Code

Labino AB

Labino BigBeam Standard Version Floodlight

SWN96

Labino AB

Labino BigBeam Standard Version Midlight

SWN96

Labino AB

Labino BigBeam Helios Version Floodlight

SWN96

Labino AB

Labino BigBeam Helios Version Midlight

SWN96

Labino AB

Labino MidBeam Standard Version

SWN96

Labino AB

Labino MidBeam Aerospace Version

SWN96

Spectronics Corp.

Spectroline Tritan 365 Model TRI-365

20772

Spectronics Corp.

Spectroline Tritan 365 Model TRI-365D

20772

Spectronics Corp.

Spectroline Tritan 365 Model TRI-365DBB

20772

Spectronics Corp.

Spectroline Tritan 365 Model TRI-365PWB

20772

For each hand held LED UV light unit, the manufacturer must supply a spectroradiometer certificate that identifies the unit by serial number or other unique identification and shows that the unit supplies a wavelength of 365 - 370 nm (3650 - .3700 Angstroms).

It is permitted to use other hand held LED UV lights that meet with the following requirement:

Hand held LED UV Lights for full-field inspection of parts

The subsequent list contains high intensity UV light sources that are approved for hole inspection. Use liquid light guides or equivalent equipment with these light sources.

Table 13. Manufacturer

Model

Vendor Code

Olympus Corp.

Model ALS-6250U

*

Avanel Industries Inc.

Model ALS-UV3000

55060

Intertest, Inc.

Lumatec Superlite UV/White Light Model SUV-DC-E (Part Number EM 10486)

0C800

*This model is no longer manufactured, but it is permitted to continue to use this model.

High intensity UV light sources for hole inspection

Low intensity UV pencil lamps for inspection of small diameter holes and tight cavities

SUBTASK 70-23-00-290-002 Equipment and Equipment Suppliers

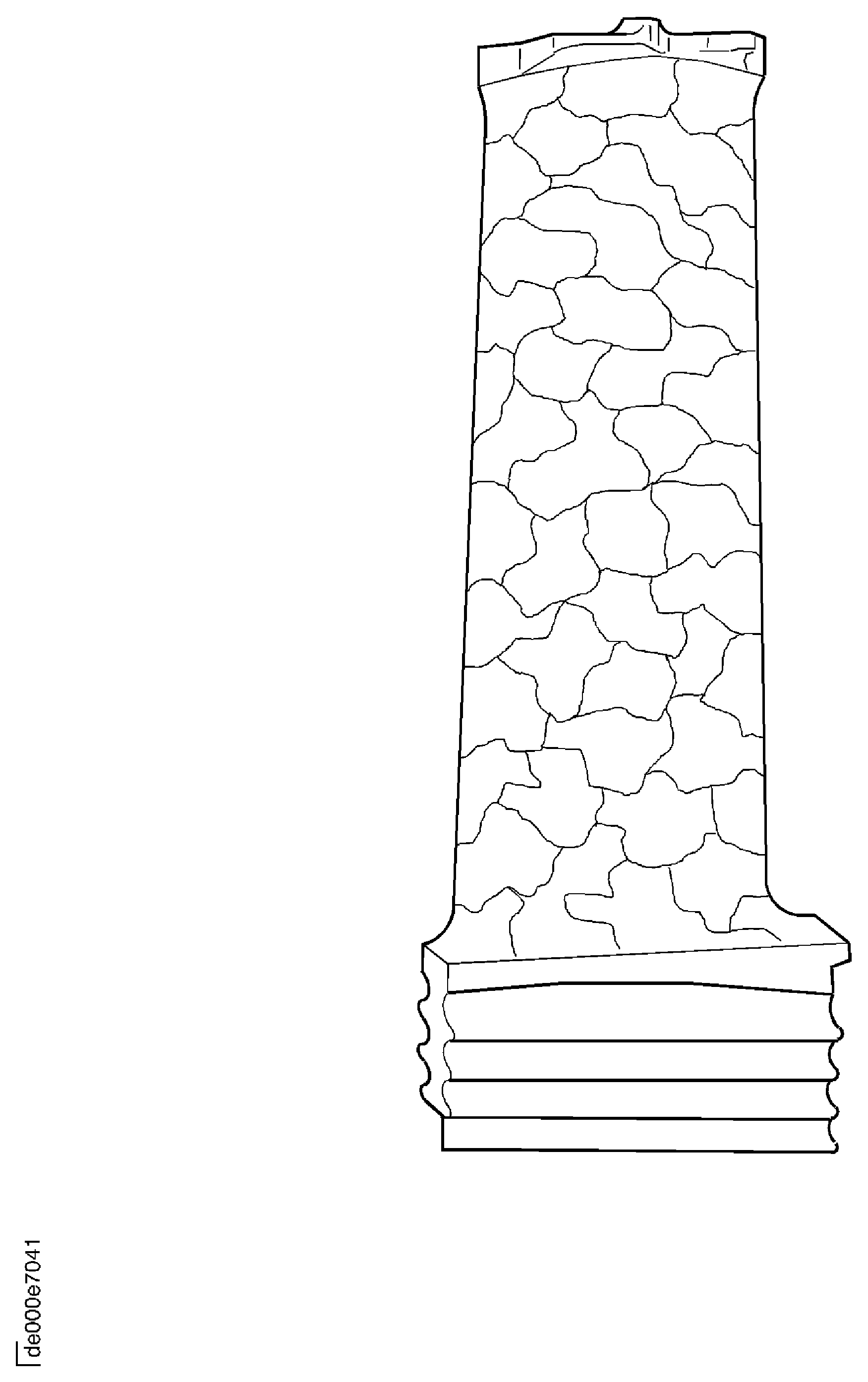

Figure: Alligatoring on Turbine Blade Surface Coating

Alligatoring on Turbine Blade Surface Coating