Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-24-01-240-501 Magnetic Particle Inspection Procedures

General

Magnetic particle inspection is a Non-Destructive Inspection (NDI) procedure. It is used to find cracks and inclusions, on or near the surface of ferro-magnetic parts. It cannot be used on alloys that are not magnetic, which include Austenitic steels.

This procedure gives the data on how to find defects with magnetic ink, which is a fluid that contains ferro-magnetic particles. The procedure is used only when specified in the Engine Manual. Data is also included on alternative procedures that can be used with different equipment.

All persons who do these inspection procedures must be fully approved by the applicable authority.

The procedure to be used is controlled by the dimensions and shape of the part to be examined; also, the direction in which the magnetic field is applied. The Engine Manual gives the procedures to find the possible defects, the necessary amperages, the inspection procedures and other related instructions.

Magnetic Inks and Procedures

The magnetic inks contain small ferro-magnetic particles, held in suspension in a fluid such as kerosene. Particles with a color are used to add contrast to the surface of the part when the inspection is made in white light. Alternatively, fluorescent particles are used for inspection in ultra-violet light.

The inks must be kept fully shaken during use to make sure that the particles are held in suspension in the fluid.

The inks can be applied by 'flowing-on, spraying or immersion'. When the inks are applied during magnetization the procedure is known as the 'simultaneous inking' or the 'wet continuous technique'. When the inks are applied after magnetization the procedure is known as the 'residual technique'.

When the 'simultaneous inking' or the 'wet continuous technique' is used you start to apply the ink before you turn the current on; then stop before you turn the current off. When the 'residual technique' is used you apply the ink after the part is magnetized.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-011 MAGNETIC PARTICLES, FLUORESCENT, DRY POWDER | X222X | CoMat 06-011 | ||

| CoMat 06-058 FLUX INDICATOR | 2R128 | CoMat 06-058 | ||

| CoMat 06-176 MAGNETIC PARTICLE SUSPENSION FLUID, HIGH FLASH POINT | 37676 | CoMat 06-176 | ||

| CoMat 06-180 MAGNETIC, INK FLUORESCENT | X222X | CoMat 06-180 |

Spares

NONESafety Requirements

WARNING

Procedure

Solvent-base suspension vehicles:

The water must be in the correct condition to give sufficient wetting, particle dispersion, and corrosion protection. Refer to The "Water Break" test of water-based vehicles below to see if the wetting is sufficient.

NOTE

Usually, the percentage of wetting agent in the suspension must be higher for smooth part surfaces than for rough surfaces.When you add the wetting agent, monitor the pH of the suspension to make sure that the quantity of wetting agent that you add does not cause the pH of the suspension to increase to more than 10.0 or decrease to less than 6.0.

The water-based suspension must have the same concentration of iron particles that you use in petroleum-based suspensions.

It is permitted to use water as a carrier for the particles if the magnetic particle or ink manufacturer's instructions specify that water is a permitted carrier, and the water agrees with these conditions:

Water-base suspension vehicles:

Use a clean part that has a surface finish that is approximately the same as the surface finish on the parts that will have an inspection.

Flood the part with the conditioned water (suspension) (that is, flow the suspension on the part to put a film/layer of suspension on the full part surface).

Examine the film/layer of suspension on the part surface. Compare the film/layer on the part with the conditions in the chart below:

Appearance Of The Part

Result

Part has a continuous film/layer of suspension on the full/total surface.

The suspension has sufficient wetting agent.

The film/layer of suspension has breaks that show the bare surface of the part.

The suspension does not have sufficient wetting agent, or the part is not sufficiently clean.

The "Water Break" test of water-based vehicles:

NOTE

To get a satisfactory inspection, it can be necessary to use a narrower range that is between the limits of the specified magnetic oxide concentration range (such as 0.1 to 0.2 volume percent or 0.3 to 0.4 volume percent).NOTE

Dry powder fluorescent magnetic particles that agree with the requirements of the latest revision of SAE AMS3044 are permitted as an alternative to CoMat 06-011 MAGNETIC PARTICLES, FLUORESCENT, DRY POWDER.Use the manufacturer's instructions to mix CoMat 06-011 MAGNETIC PARTICLES, FLUORESCENT, DRY POWDER or CoMat 06-180 MAGNETIC, INK FLUORESCENT with applicable carrier/suspension vehicle to get a magnetic oxide concentration of 0.1 to 0.4 volume percent, or use a magnetic ink that agrees with the requirements of the latest revision of SAE AMS3045.

SUBTASK 70-24-01-240-001 Make-up of the Magnetic Inks

The use of CoMat 06-058 FLUX INDICATOR is recommended to find the direction and minimum strength of the applied magnetic field during magnetization of the parts. It is also used to find the magnetic procedures and values to be used when the solenoid coil and magnetic flux flow inspection procedures are used.

SUBTASK 70-24-01-240-006 Performance Checks

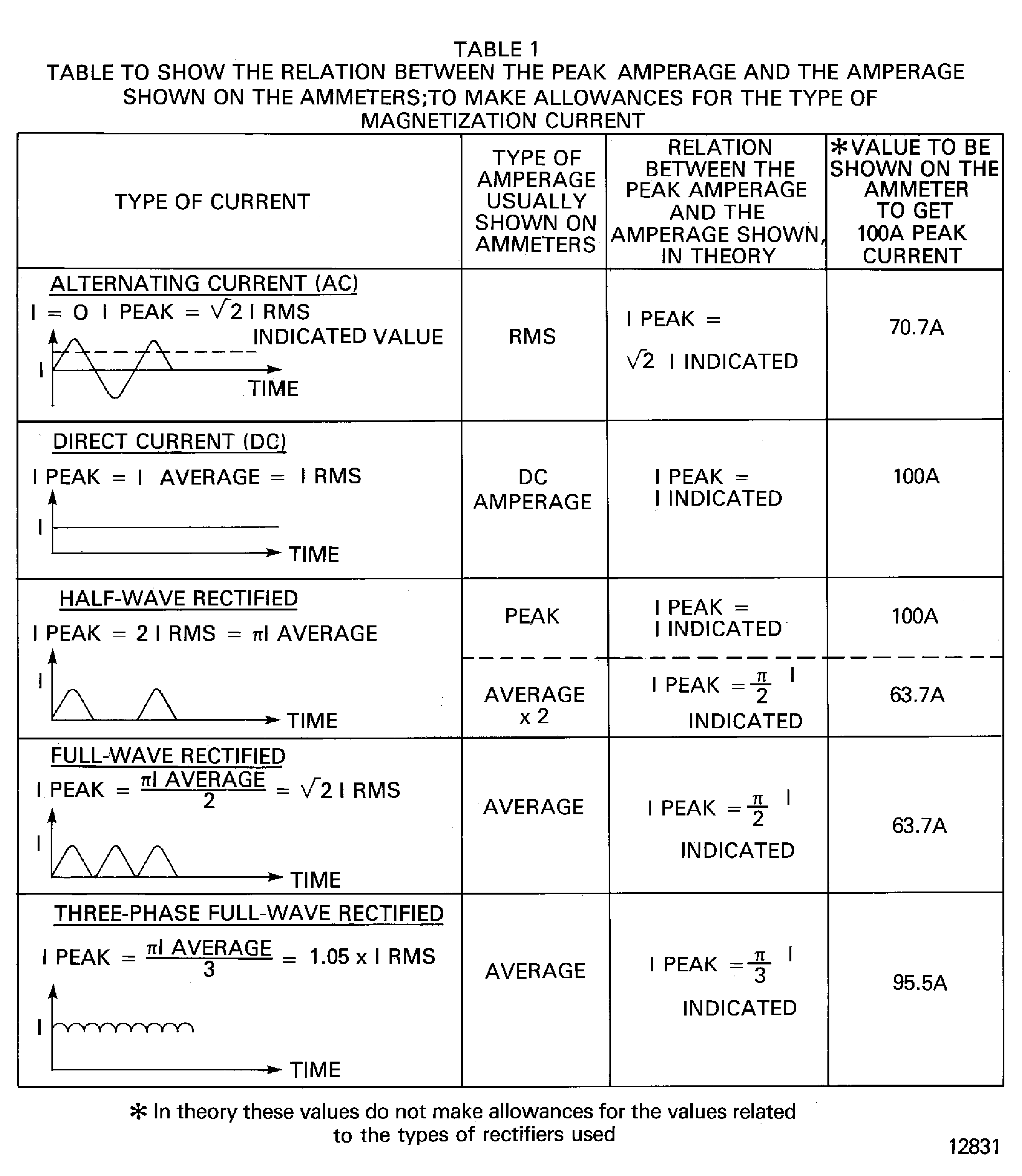

Root mean square (RMS) is usual for AC outputs. Refer to Figure.

The different scales used on output ammeters are:

When AC magnetization or rectified AC is recommended, the necessary amperage will be specified in the Engine Manual. They will use AC outputs, with single-phase inputs and an ammeter scale in RMS values, unless specified differently. If machines with a different specification to these conditions are used, change the RMS values to peak current values. To change a meter indication to peak current, use the correction value of the machine. The necessary meter indication of the machine will be acceptable when the peak current is the same as that recommended.

When the solenoid coil inspection procedure is used as the magnetization force, use the values specified in the Engine Manual. These values are for a 16in. (406 mm) diameter, multi-wound (five-turn), coil. If different diameter coils are used, apply the formula given in Step.

SUBTASK 70-24-01-240-008 Magnetization Procedures

Put the part into the demagnetization coil.

Turn on the coil current.

Move the part through the coil.

Remove the part from the coil, to a minimum distance of 5 ft (1.5 m).

Turn off the coil current.

Make sure that the part is fully demagnetized.

Procedure To Demagnetize Parts:

SUBTASK 70-24-01-240-009 Demagnetization Procedures

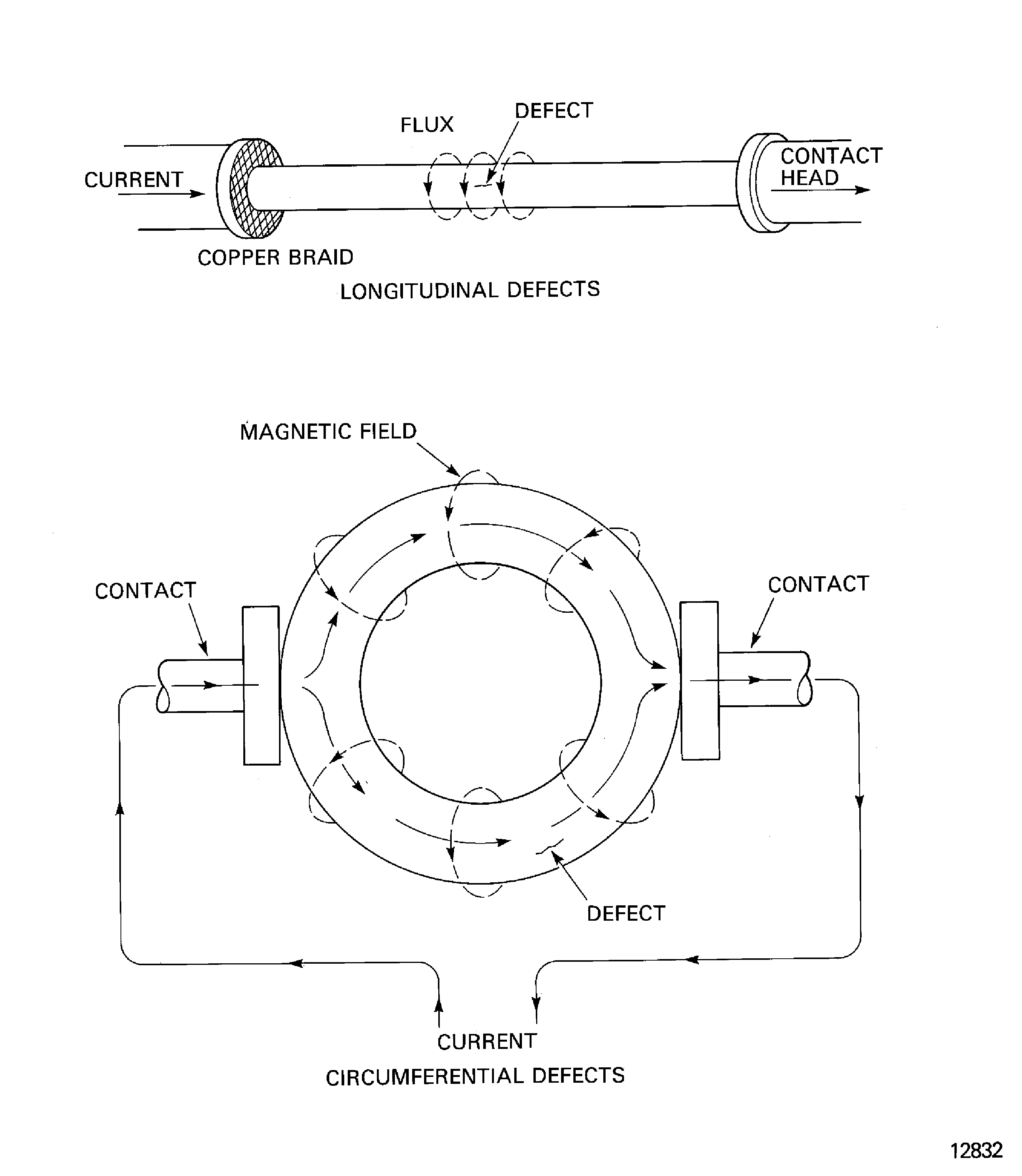

This procedure is used to find defects which are parallel to the direction of current flow (That is longitudinal in long parts and circumferential in circular parts). Refer to Figure.

Application:

Remove the grease from the part, as specified in SPM TASK 70-11-03-300-503.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Make sure that the magnetic ink is fully shaken, then apply it to the part. Apply the necessary current through the part for a minimum total time of two seconds. The two seconds minimum magnetizing time can be the total of a fast-succession series of shorter times (such as a fast succession of four 0.5 second magnetization times).

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Clean the part as specified in SPM TASK 70-11-03-300-503.

Apply temporary rust protection to the part, as specified in SPM TASK 70-38-05-380-501.

Procedure:

SUBTASK 70-24-01-240-010 Current Flow Inspection Procedures

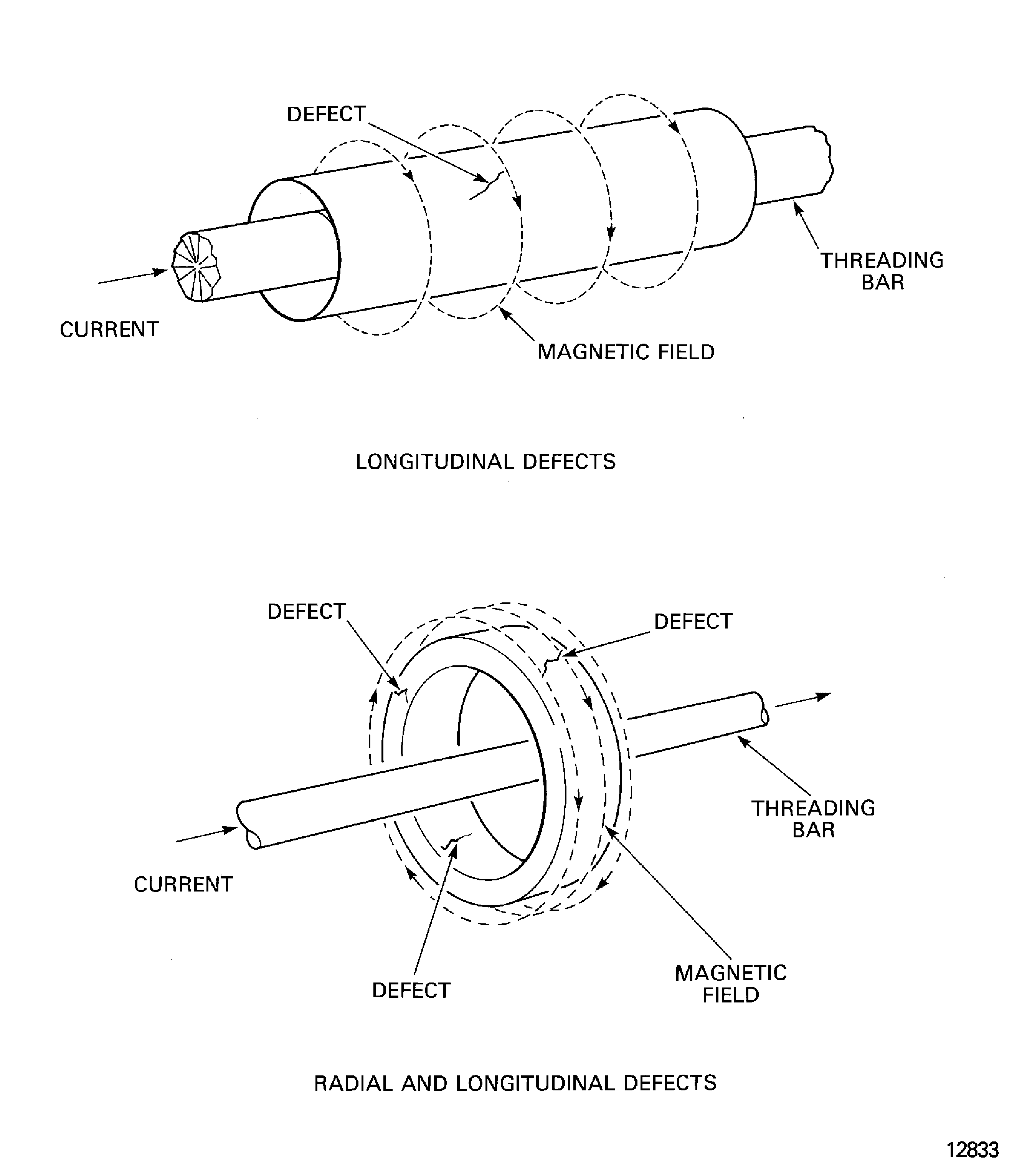

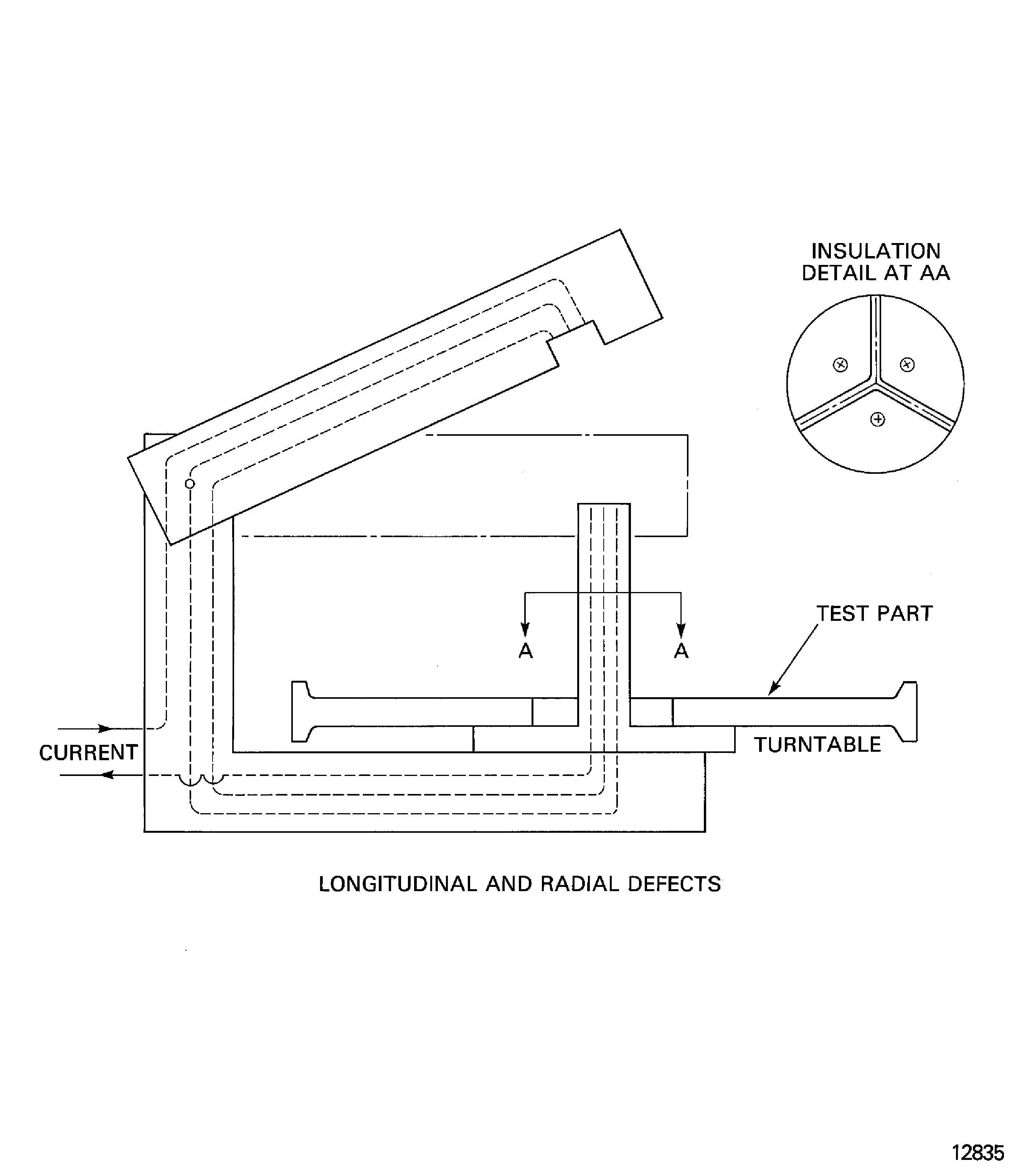

This procedure is used to find longitudinal defects in long parts and radial defects in circular parts; that can be put on to a single conductor, through which the necessary current flows. The magnetic field is at 90 degrees to the threading bar. When the part is magnetized, all defects in the magnetic field will be shown. Refer to Figure.

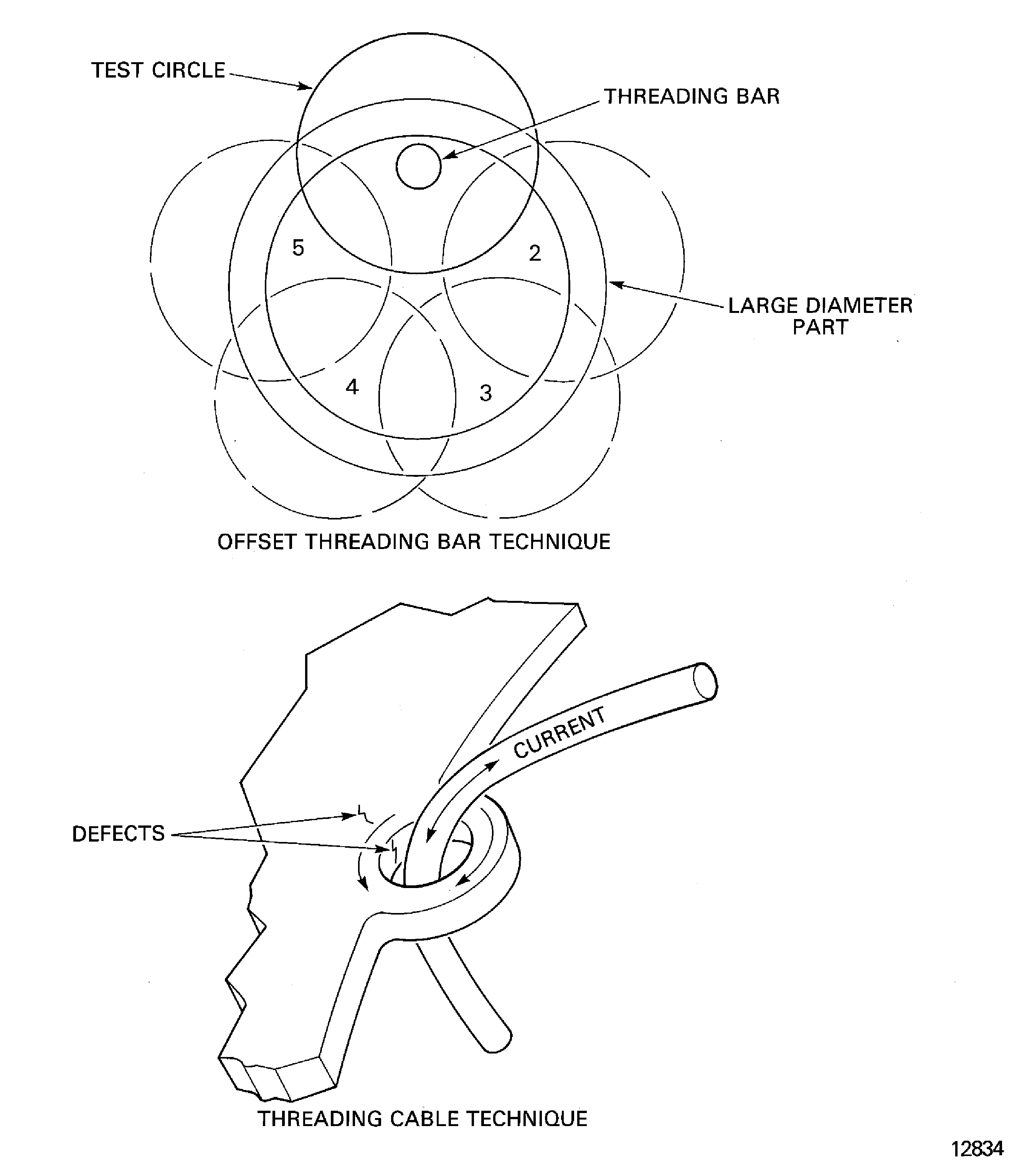

When the 'offset threading bar technique' is used, different magnetizations will be necessary at equal distances around the circumference. This will make sure that magnetic cover is complete. The magnetic ink is then applied to each magnetic point. Refer to Figure.

A threading cable, energized by the magnetic particle inspection machines, can also be used to examine the areas around holes. Refer to Figure.

Application:

Remove the grease from the part, as specified in SPM TASK 70-11-03-300-503.

Demagnetize the part. Use the procedure to demagnetize Parts in Step.

CAUTION

WHEN PARTS WITH A SMALL INTERNAL DIAMETER ARE MAGNETIZED, INSULATION MATERIAL MUST FIRST BE APPLIED TO THE THREADING BAR. THIS IS TO MAKE SURE THAT THE PARTS CANNOT TOUCH THE BAR, ARC AND BECOME DAMAGED.Put the threading bar into the internal diameter, then install the assembly on to the magnetic particle inspection machine.

NOTE

When an inked part is to be moved before inspection, it is necessary to be very careful when you touch the part. This is to make sure that distortion of the magnetic indications does not occur.Apply the magnetic ink by the 'simultaneous inking' or the 'wet continuous technique'. Apply the recommended current through the threading bar to magnetize the part. This must be done in different steps during a maximum time of five seconds. Turn the part during this step to make sure that the ink is applied to all surfaces.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Clean the part as specified in SPM TASK 70-11-03-300-503.

Apply temporary rust protection to the part, as specified in SPM TASK 70-38-05-380-501.

Procedure:

SUBTASK 70-24-01-240-011 Threading Bar Inspection Procedures

The equipment used for this procedure (which is also known as the 'knife method' or 'split coil method'), is shown on Figure.

Application:

Remove the grease from the part, as specified in SPM TASK 70-11-03-300-503.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Clean the part as specified in SPM TASK 70-11-03-300-503.

Apply temporary rust protection to the part, as specified in SPM TASK 70-38-05-380-501.

Procedure:

SUBTASK 70-24-01-240-012 Multiple Threading Bar/Split Coil Inspection Procedures

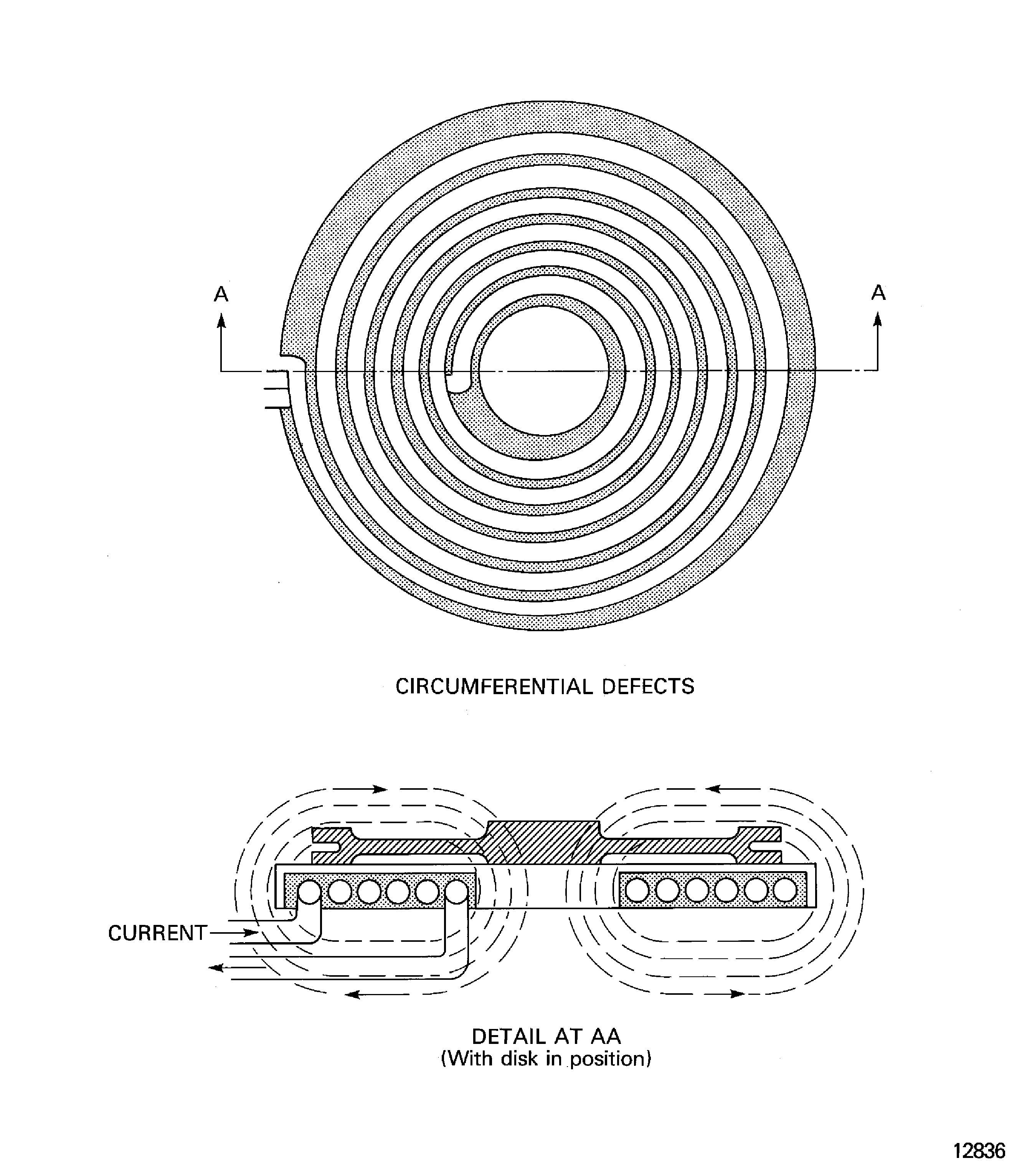

The equipment used is a close-wound flat coil. The coil diameter must be 4 in. (100 mm) or more larger than that of the part to be magnetized. Refer to Figure.

Application:

Remove the grease from the part, as specified in SPM TASK 70-11-03-300-503.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Magnetization And Inspection Procedure

Clean the part as specified in SPM TASK 70-11-03-300-503.

Apply temporary rust protection to the part, as specified in SPM TASK 70-38-05-380-501.

Procedure:

SUBTASK 70-24-01-240-013 Flat Spiral Coil Inspection Procedure

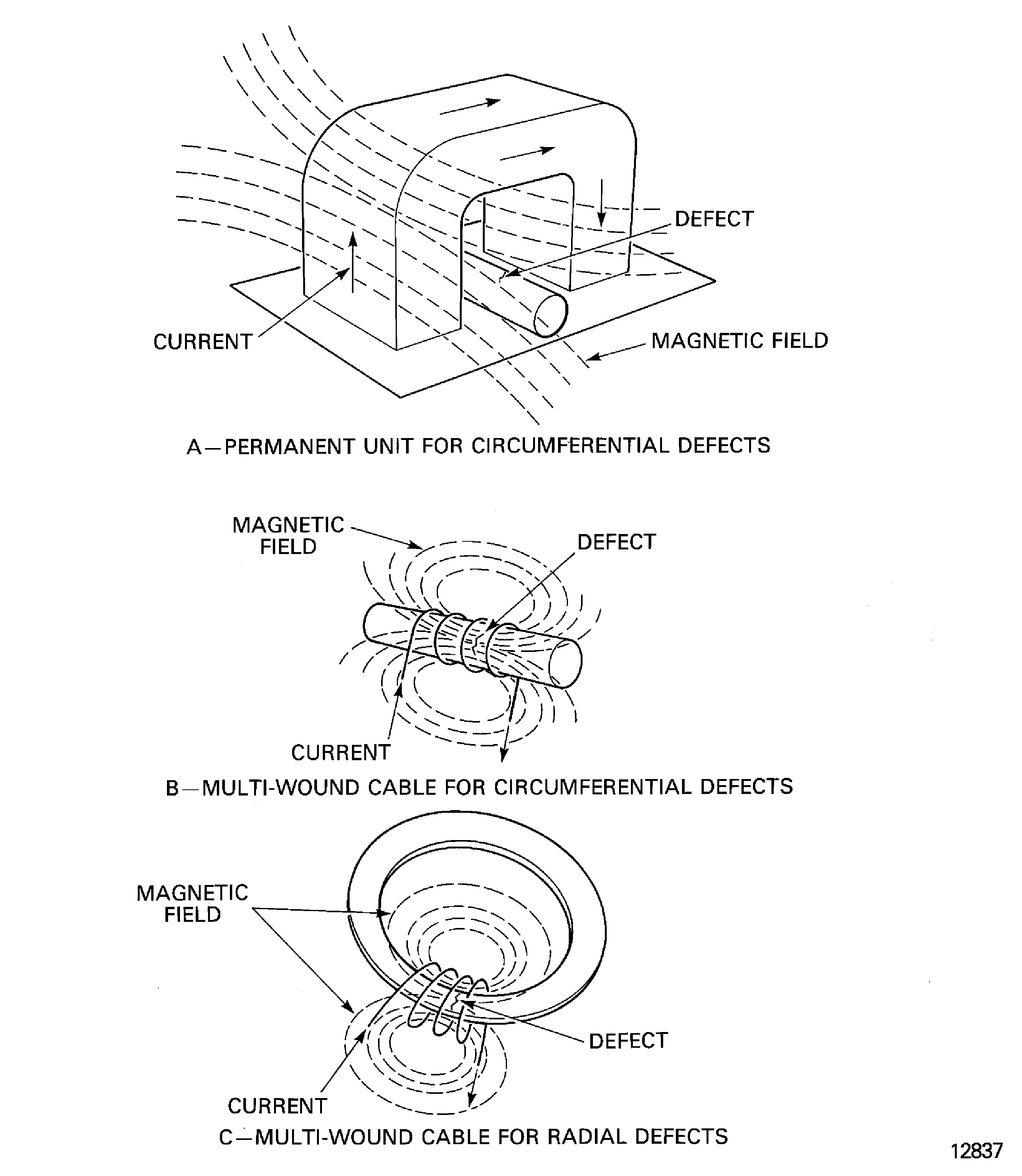

This procedure is used to find circumferential, and transverse, defects as shown on Figure. The procedure also gives sufficient longitudinal magnetization for parts with a length to diameter ratio of more than three to one.

NOTE

The magnetization forces necessary for a solenoid coil inspection procedure (as specified in the Engine Manual), are for a 16 in. (406 mm) multi-wound (five-turn) coil.When the length to diameter ratio is less than three to one, the magnetization force must be two times that calculated from the formula. Also, for such parts, the magnetic flux flow inspection procedure is better than coil inspection procedures. The strength of the magnetic field is measured with a magnetic flux indicator. Only that piece of the part, which is in the coil at the time, will be magnetized. Different magnetization steps along the length of the part will then be necessary when long parts are examined.

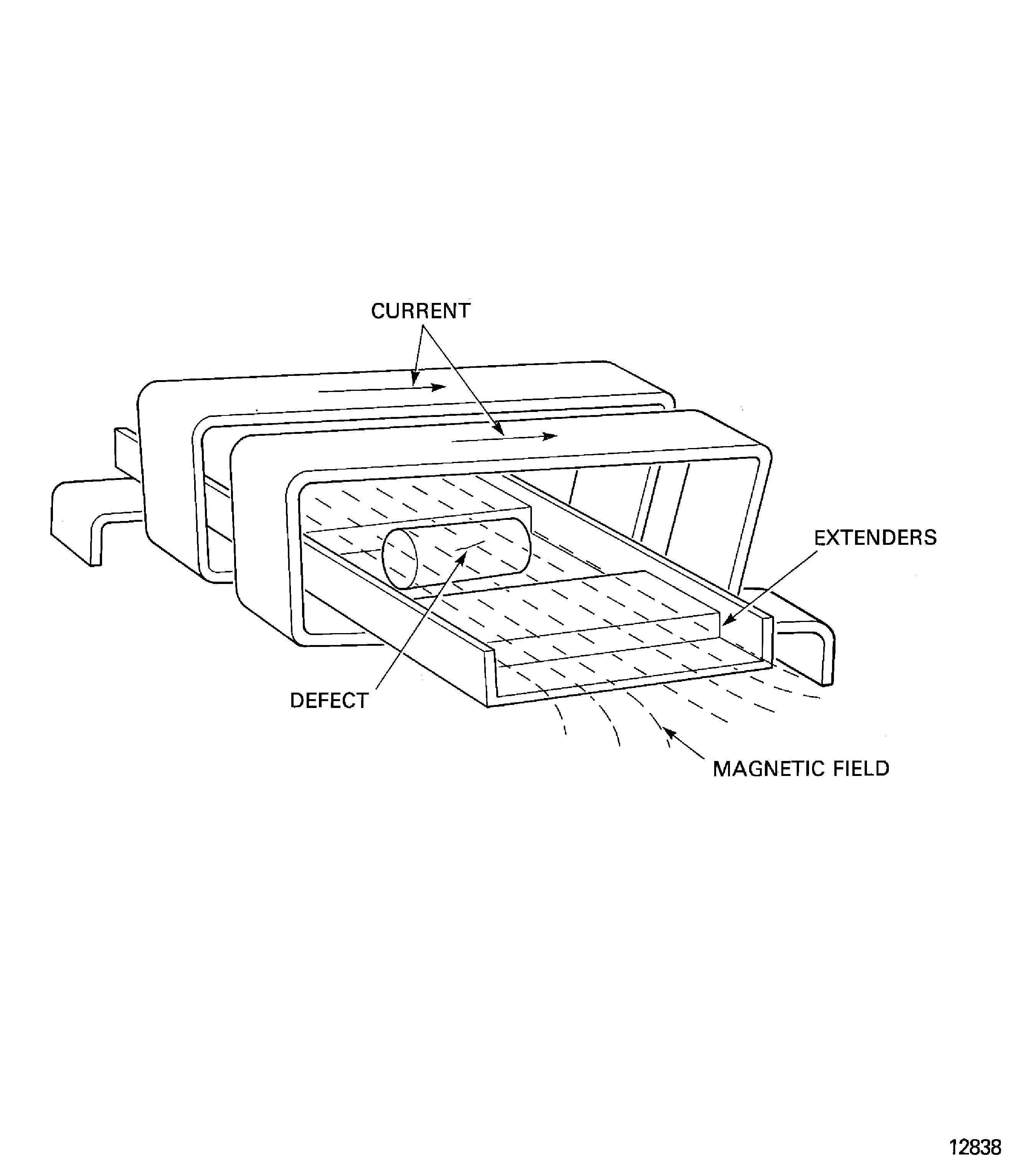

With short parts the necessary current becomes very high because of the small length to diameter ratio. To decrease the high current, extenders are used (refer to Figure). The defects shown are those transverse to the magnetic lines of force and at least two checks will be necessary on each part.

Application:

Remove the grease from the part, as specified in SPM TASK 70-11-03-300-503.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Clean the part as specified in SPM TASK 70-11-03-300-503.

Apply temporary rust protection to the part, as specified in SPM TASK 70-38-05-380-501.

Procedure:

SUBTASK 70-24-01-240-014 Solenoid Coil Inspection Procedures

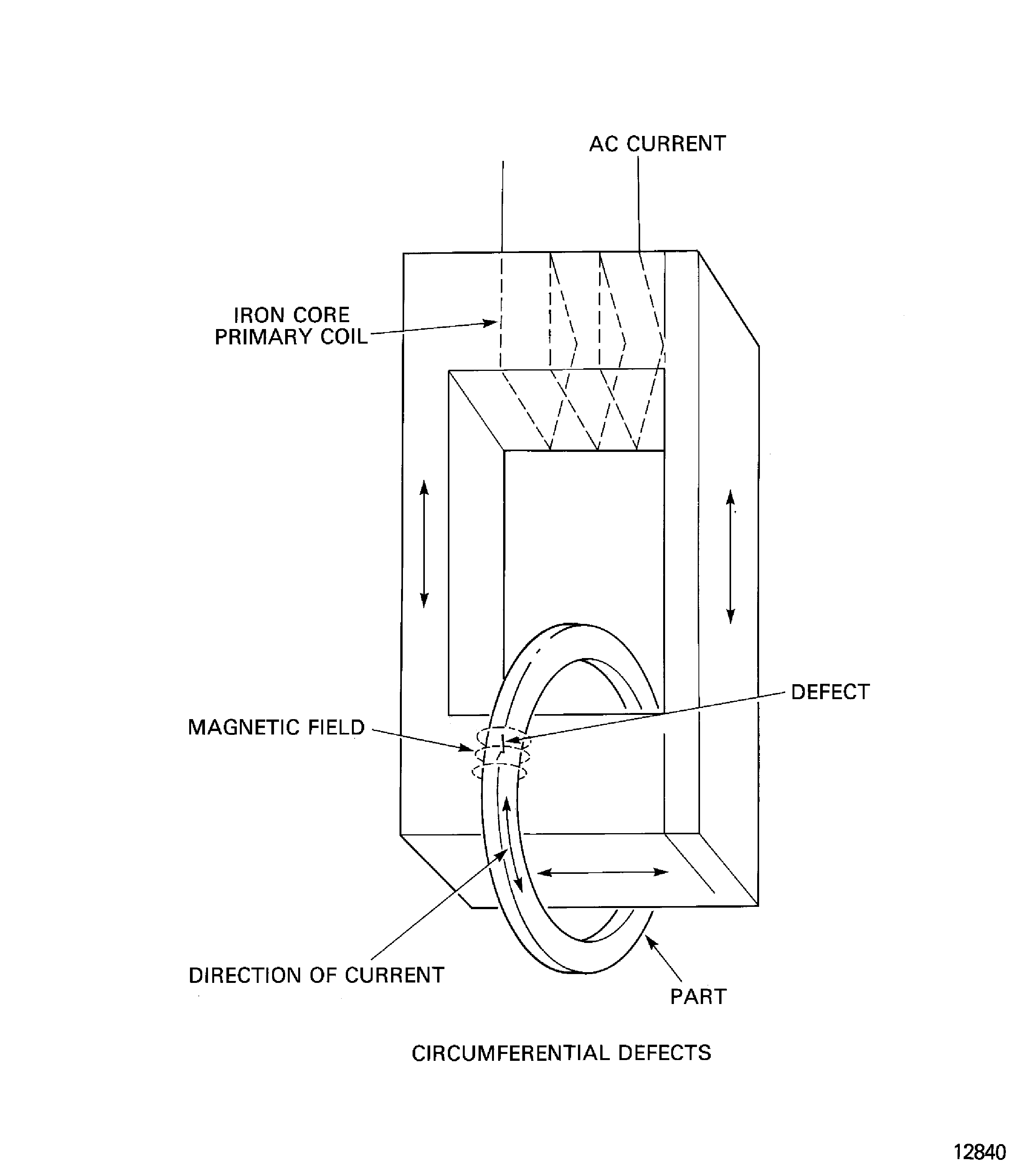

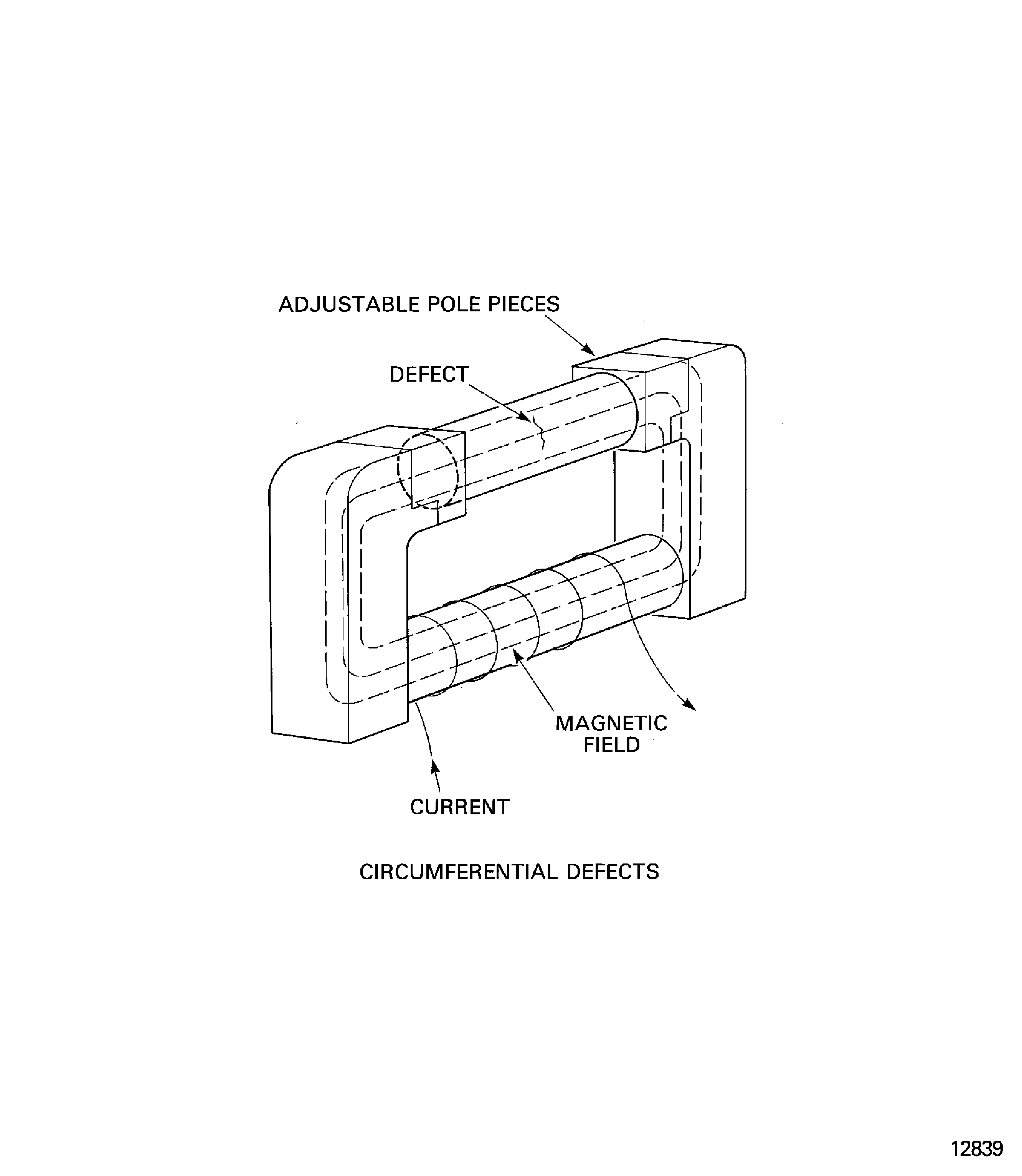

During the magnetic flux flow inspection procedure, direct current (DC) flows through a coil that contains an iron core. The core is then magnetized to become an electro-magnet. When a part touches the poles, it becomes a keeper for the magnetic field (refer to Figure).

Application:

Remove the grease from the part, as specified in SPM TASK 70-11-03-300-503.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Clean the part as specified in SPM TASK 70-11-03-300-503.

Apply temporary rust protection to the part, as specified in SPM TASK 70-38-05-380-501.

Procedure:

SUBTASK 70-24-01-240-015 Magnetic Flow Inspection Procedure

The equipment used is almost the same as a transformer. The primary coils are wound on to a laminated iron core which is divided when installed into the part to be examined (refer to Figure). When the current is applied to the primary coils, the core becomes energized, which then causes a current in the ring. It is this current that causes the magnetic field in the part.

Application:

Remove the grease from the part, as specified in SPM TASK 70-11-03-300-503.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Demagnetize the part. Use the procedure to demagnetize parts in Step.

Clean the part as specified in SPM TASK 70-11-03-300-503.

Apply temporary rust protection to the part, as specified in SPM TASK 70-38-05-380-501.

Procedure:

SUBTASK 70-24-01-240-016 Current Induction Inspection Procedure

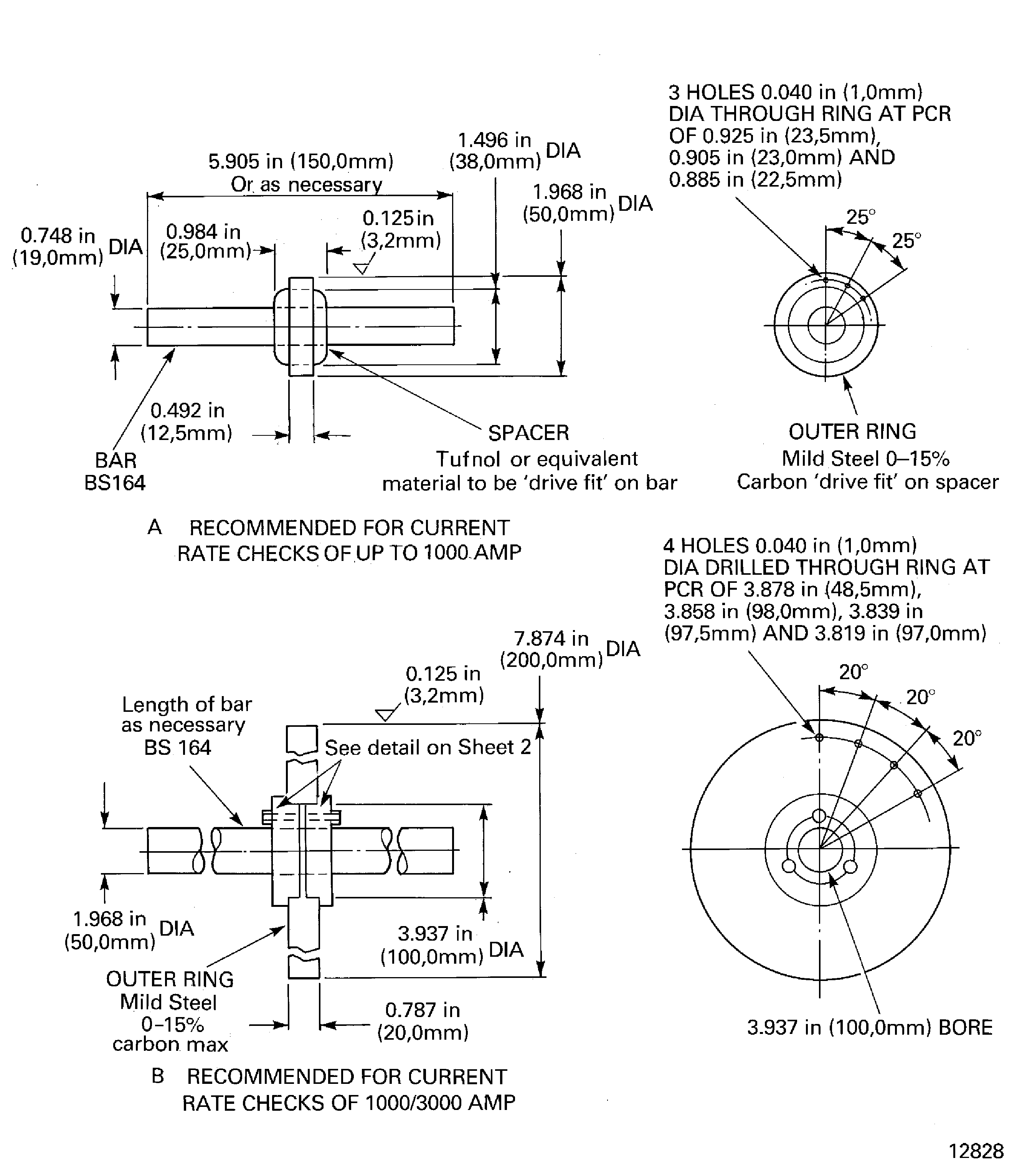

Figure: Test pieces for circumferential magnetization

Test pieces for circumferential magnetization

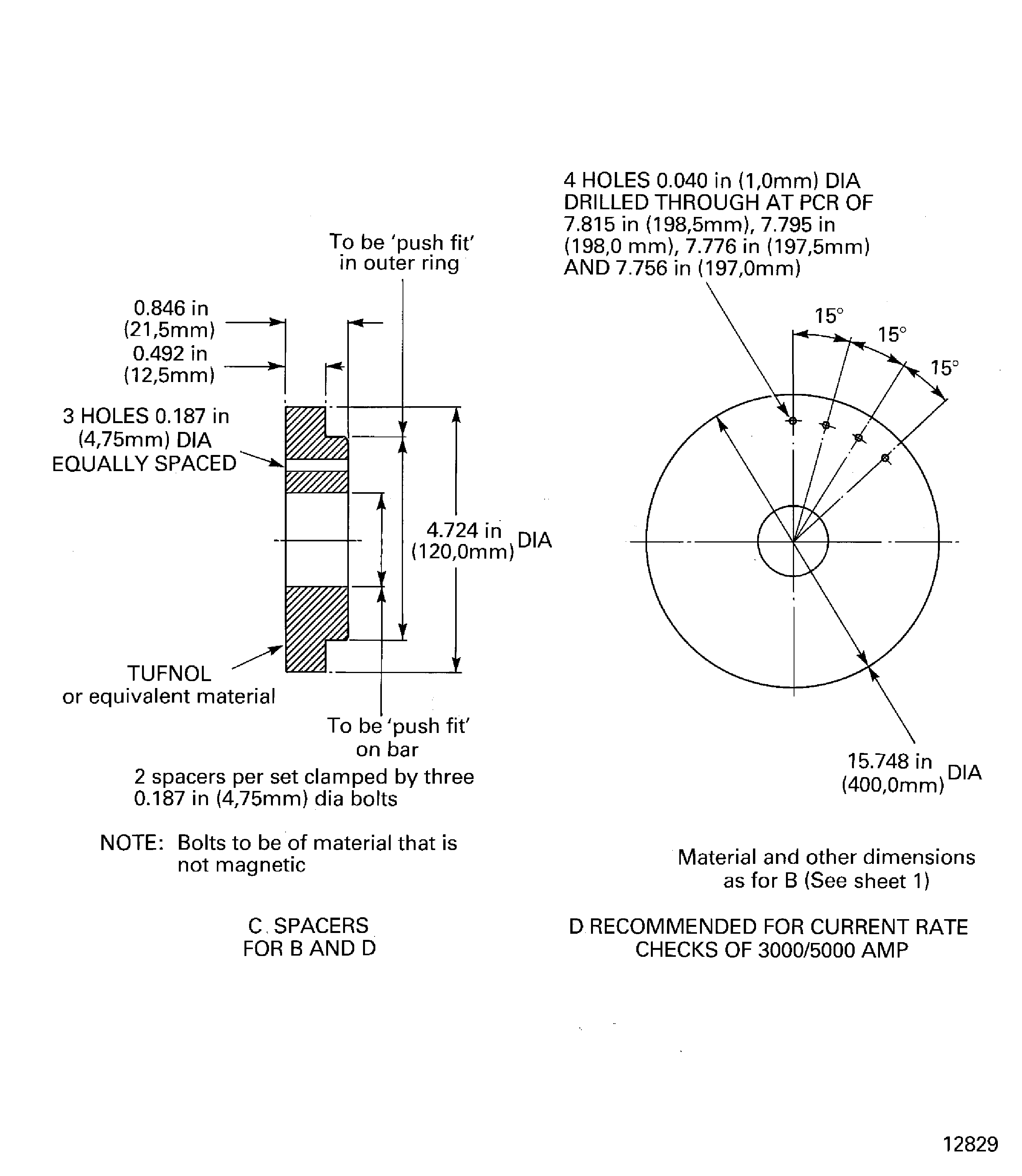

Figure: Test pieces for circumferential magnetization

Test pieces for circumferential magnetization

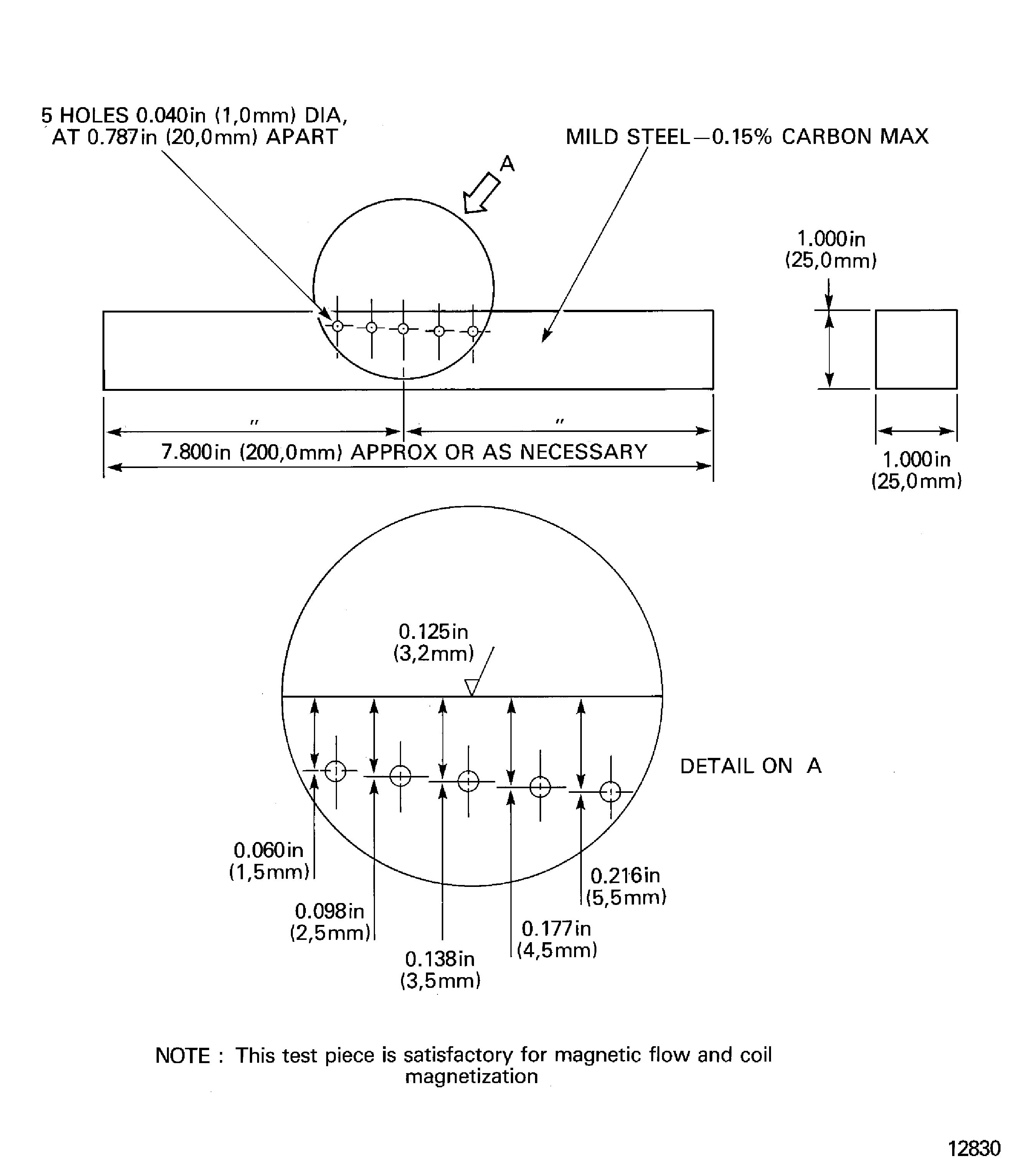

Figure: Test piece for longitudinal magnetization

Test piece for longitudinal magnetization

Figure: Relation between peak and indicated amperages

Relation between peak and indicated amperages

Figure: Current flow inspection procedures

Current flow inspection procedures

Figure: Threading bar inspection procedures

Threading bar inspection procedures

Figure: Threading bar inspection procedures

Threading bar inspection procedures

Figure: Multiple threading bar/split coil inspection procedures

Multiple threading bar/split coil inspection procedures

Figure: Flat spiral coil inspection procedure

Flat spiral coil inspection procedure

Figure: Solenoid coil inspection procedures

Solenoid coil inspection procedures

Figure: Solenoid coil with built-in extenders for transverse defects

Solenoid coil with built-in extenders for transverse defects

Figure: Magnetic flow inspection procedure

Magnetic flow inspection procedure

Figure: Current induction inspection procedure

Current induction inspection procedure