DMC:V2500-00-70-25-01-00A-353A-D|Issue No:001.00|Issue Date:2014-05-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991:

SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.

Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021)

The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).

Common Information

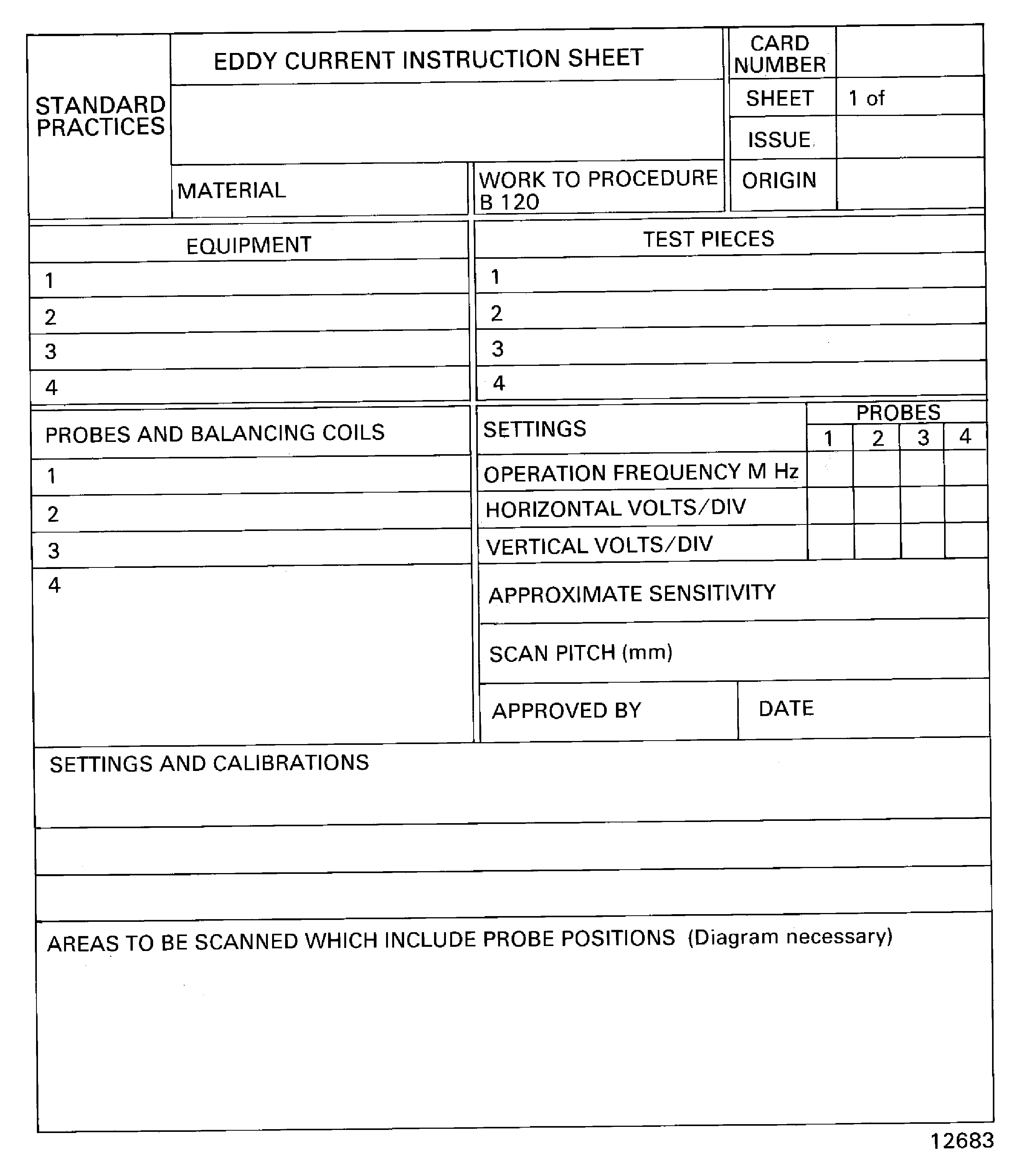

TASK 70-25-01-250-501 Eddy Current Inspection

General

NOTE

To identify the consumable materials refer to the PCI.

Preliminary Requirements

Pre-Conditions

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|

| CoMat 02-115 TEFLON TAPE | 81349 | CoMat 02-115 | | |

Spares

NONESafety Requirements

NONEProcedure

SUBTASK 70-25-01-250-001 Demagnetize the Component (only Ferro-Magnetic Parts)

It is necessary for ferro-magnetic parts to be demagnetized before the eddy current inspection is done. This is to make sure the material is in the correct condition. Refer to the SPM TASK 70-24-01-240-501 for the specified demagnetization procedure.

SUBTASK 70-25-01-250-002 Clean the Part and Remove the Grease with Vapor

Make sure the surface to be examined is clean. This will make sure the surface condition is correct for the probe. It is also important that the probe can move freely across the surface without too much vibration. As this will give incorrect indications on the eddy current display.

Make sure the part is below 104 deg F (40 deg C) before an eddy current inspection is done.

SUBTASK 70-25-01-250-003 Set Up Equipment and Connect Probes

The eddy current instrument, related probe and the part must be set up as specified in the inspection procedure. CoMat 02-115 TEFLON TAPE is to be applied to the probe tip. This will keep probe wear to a minimum and give free movement of the probe across the surface.

SUBTASK 70-25-01-250-004 Set the Instrument for Use

Set the instrument to the ON position and let it become stable for at least 10 minutes.

Adjust the intensity and focus controls to give the necessary light spot on the oscilloscope screen. Do not set the intensity higher than is necessary to view the screen satisfactorily. In the storage mode, too bright a spot will cause blooming of the screen.

Adjust the frequency range switch and the fine frequency switch to get the specified frequency. Adjustments must be made until the correct value is shown on the frequency display on the front panel.

Set the vertical and horizontal deflection switches to the positions specified in the instructions.

Use the specified test block and set the balance, lift-off and sensitivity as follows:

Position the probe on the surface of the specified test block away from the edges and away from the test block defect.

When a sensitivity is not specified in the instructions, set the sensitivity control to the middle position. Push in the automatic balance control.

When the balance is set, adjust the vertical and horizontal position controls to center the light spot on the screen. It is possible that the beam finder control will have to be operated.

While the probe is lifed from the surface and released; turn the phase control until the lift-off line is along the horizontal axis, from the screen center to the left. (Unless specified differently).

Move the probe across the defect in the test block to get a positive indication on the screen. Compare the limits of the indication with those in the instructions.

NOTE

Do not change the sensitivity when the probe is moved to the part that is to be examined.

Increase or decrease the sensitivity adjustment as necessary and continue to balance, lift-off and move the probe; until the specified limits are the same as those in the instructions.

SUBTASK 70-25-01-250-005 Eddy Current Inspection Procedure

Position the probe on the surface of the part and adjust the balance and lift-off again.

Move the probe across the area to be examined. Monitor the screen for unusual signals and identify those that are defects. Refer to the applicable manual or repair procedure.

Eddy current inspection equipment:

It is necessary to use a table that turns and a device to move the probe across the complete part. The table must turn at between 10 and 30 rpm. The probe must be moved at a rate of 0.04in. (1.0 mm) per rpm. This system can be manual or power operated.

Probes are special items and will be specified in the instructions for each inspection.

Requirements After Job Completion

Follow-On Conditions

NONE