Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-29-00-220-501 The General InFormation For Ball And Roller Bearing Inspection

General

This TASK gives the general procedure and the precautions necessary when an inspection is made on the anti-friction ball and roller bearings.

These are precision components which operate in high speed conditions and are highly stressed.

Special precautions are necessary when you make an inspection on these components (refer to step C.).

To make sure no damage is caused to these components only an approved person must do the inspection.

Be careful with these components when you move or touch them, do not hold them more than necessary.

The special precautions you must use during all the inspection procedures are as follows:

All persons who work with these components must use gloves made of synthetic rubber.

Alternatively, you can use nylon gloves with palms and fingers made of polyethylene.

Cotton gloves are also permitted but they must have the specified properties as follows.

No fibers or loose material must come off the gloves.

Monitor the gloves in use and isolate them before they become dirty with skin grease and salts from the hands; if this is not done it will cause corrosion on the surface of the components.

The use of a specified hand protection agent is also permitted.

Always use CoMat 12-015 CORROSION PREVENTIVE, FINGERPRINT REMOVER or CoMat 12-016 CORROSION PREVENTIVE THIN FILM on these components when the precautions in steps (1) to (4) have not been used.

Make sure that if these components are disassembled in to their disconnected parts they are all kept together as a set.

You must be very careful not to let the parts from one component to become part of a different component assembly.

Keep each components parts (of the type which are assembled together) independently in its container during all the movements and operations.

Do not let these components become magnetized because of electrical induction. If you are not sure if these components have become magnetized then you must demagnetize them.

Do not let these assembled components or parts of these disassembled components hit against the work surfaces; or baskets used in the procedures to clean; or other hard surfaces.

Always do the preservation procedure (to keep the component from corrosion and damage) if the inspection is not continuous or is completed. Refer to the SPM TASK 70-53-01-620-501.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 12-015 CORROSION PREVENTIVE, FINGERPRINT REMOVER | 0AM53 | CoMat 12-015 | ||

| CoMat 12-016 CORROSION PREVENTIVE THIN FILM | 2H517 | CoMat 12-016 |

Spares

NONESafety Requirements

WARNING

Procedure

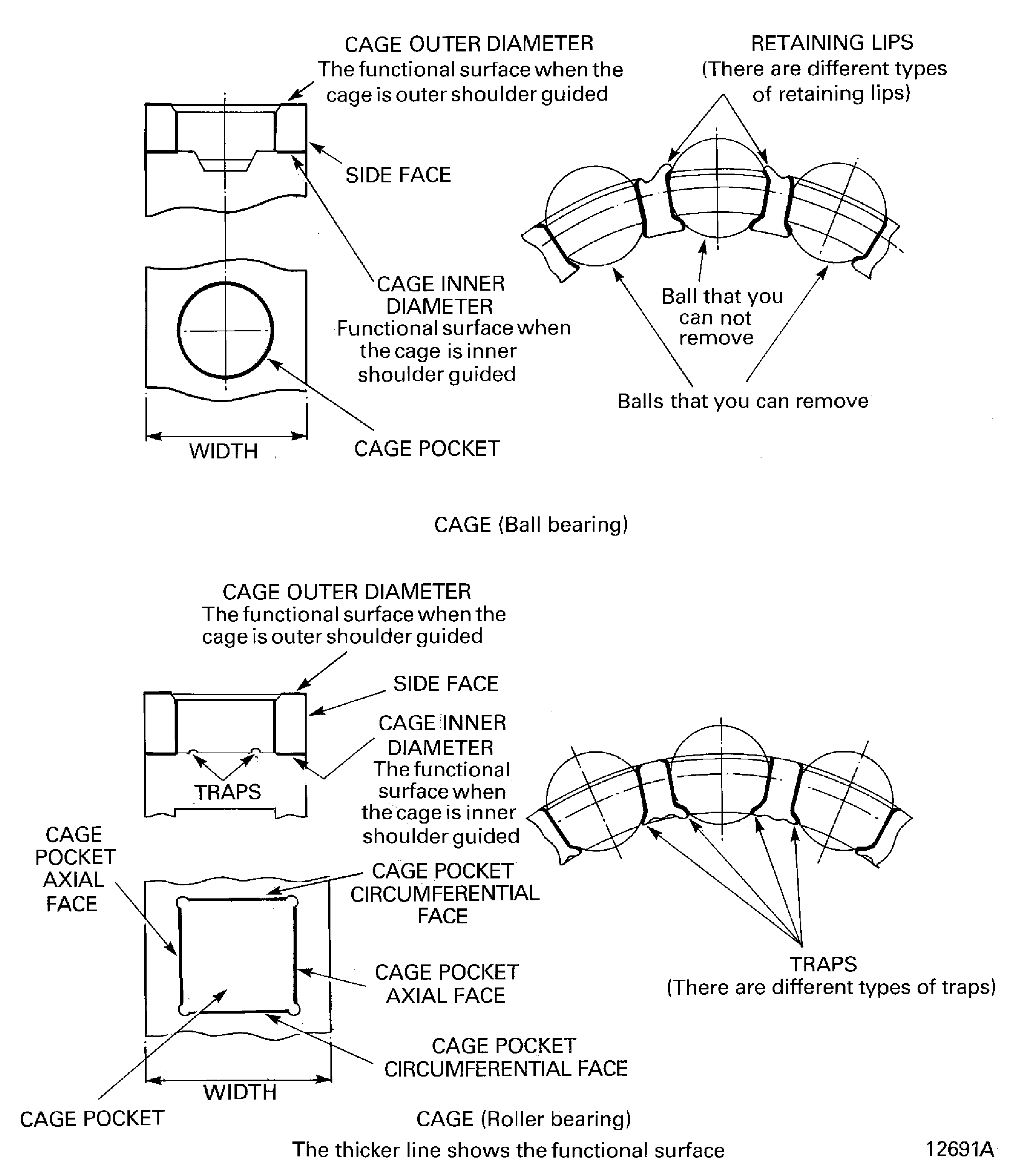

Figure: Ball bearings

Ball bearings

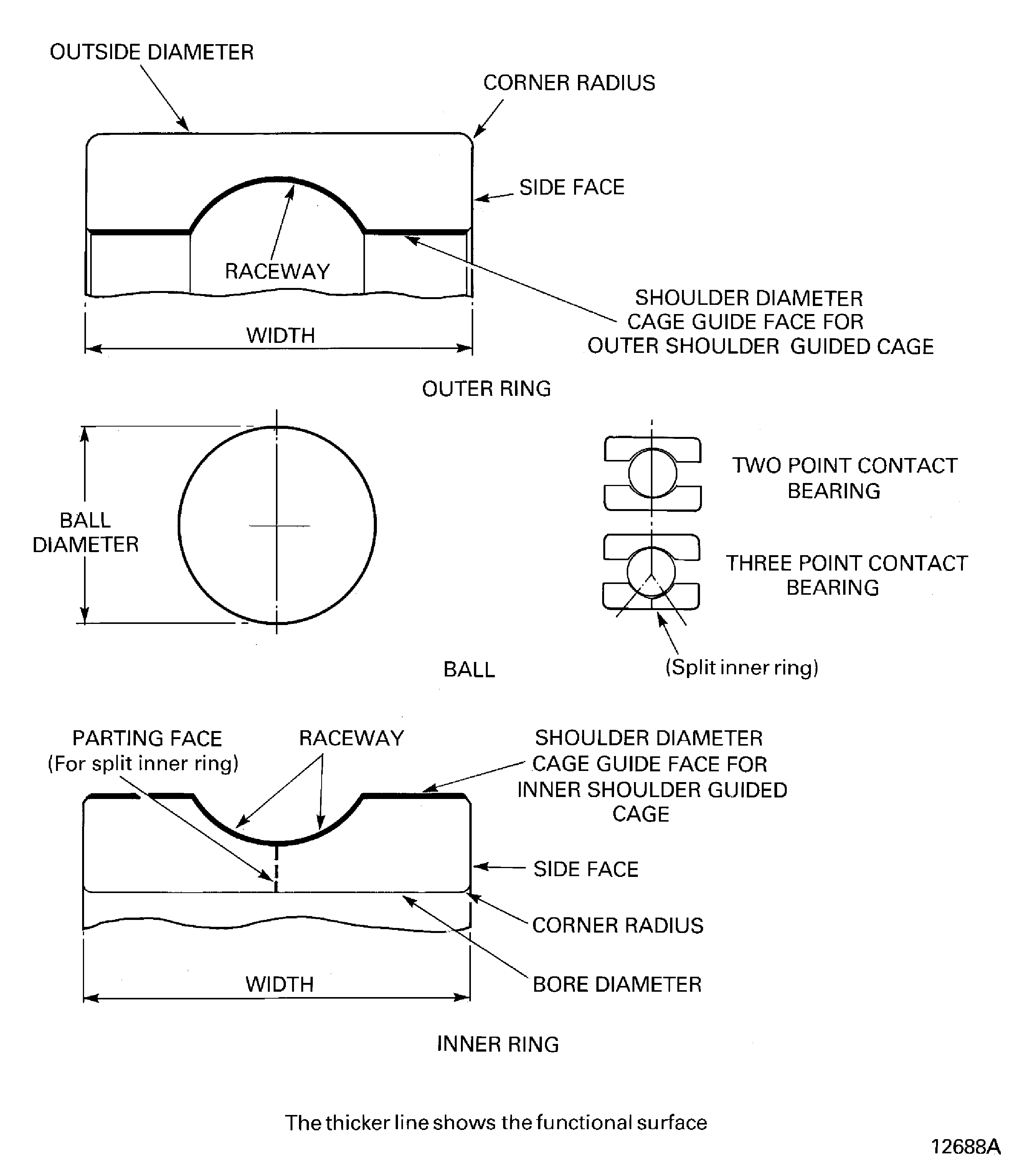

Figure: Cylindrical roller bearings

Cylindrical roller bearings

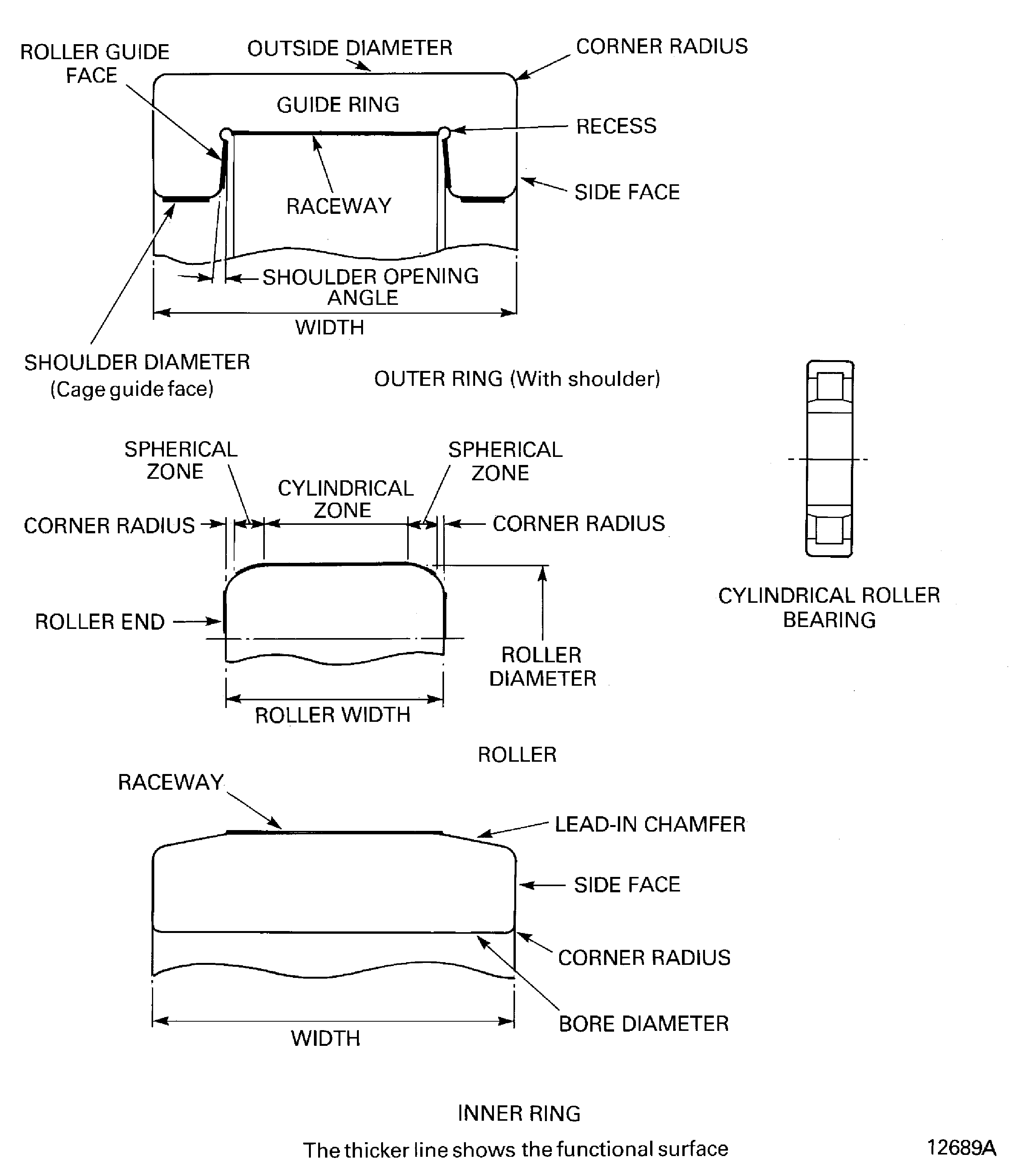

Figure: Angular-contact ball bearings

Angular-contact ball bearings

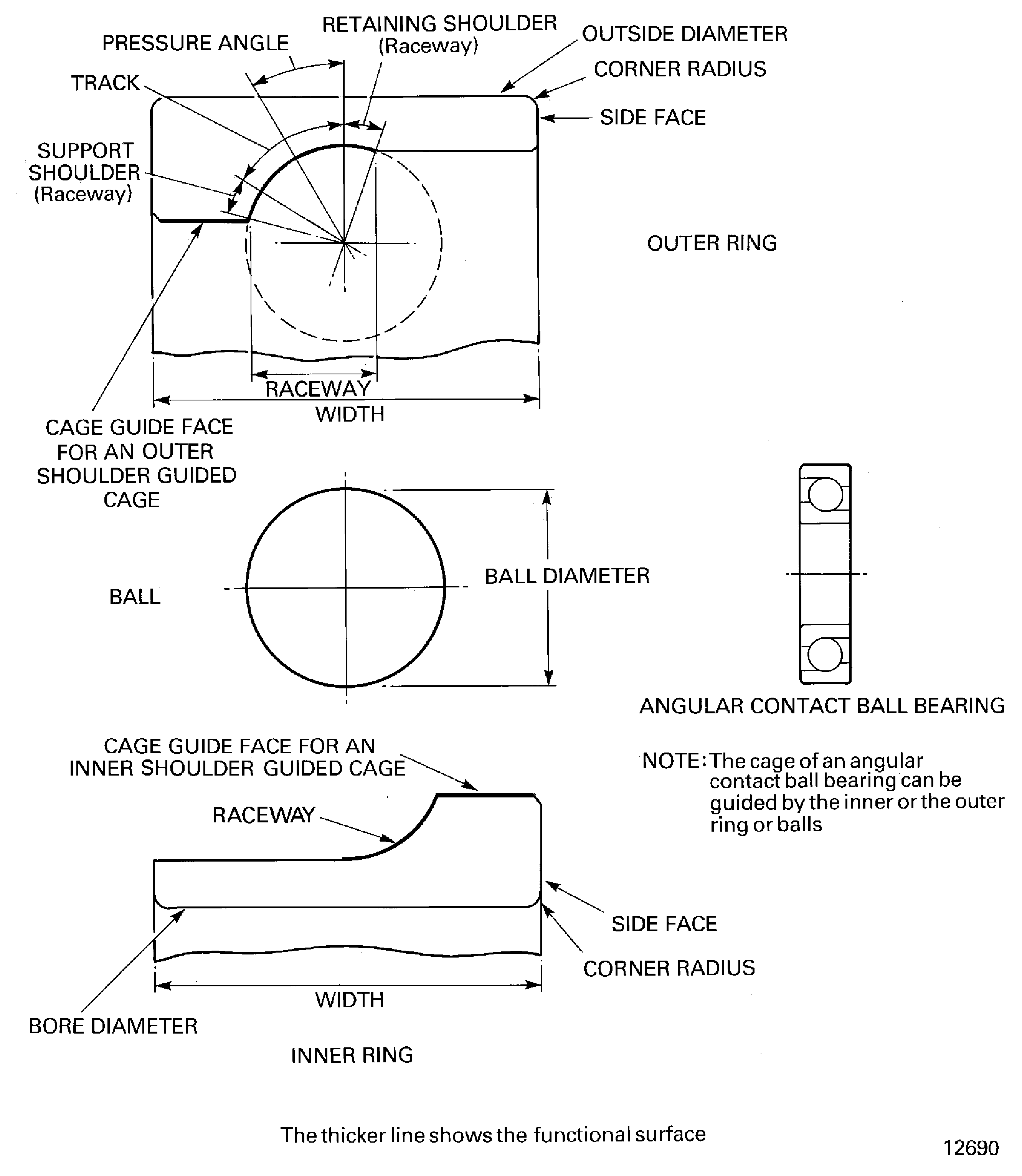

Figure: Cages

Cages