Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-31-10-310-501 Resistance Welding

General

Resistance welding is a procedure used to connect metals together where the adjacent areas of a part are melted, a pressure is applied, but no filler material is added. The procedure uses an electrical resistance, given by the parts, as the heat source.

Spot welding usually uses pointed or rounded electrodes which touch, and are then removed from, the work piece at specified times and rates.

Stitch welding - (That is, spot welding with an overlap) uses the spot welding types of electrodes, to give a continuous seam. Seam welding can be used as an alternative for stitch welding but, unless specified differently, stitch welding must not be used as an alternative for seam welding.

Seam welding is a procedure which uses roller type electrodes.

Tack welds are temporary spot welds, used only to hold the work piece, which are not usually approved. They must be put in the location of the full weld and must not change the quality of that weld.

Symbols

The melted area dimensions, strengths, distances, quantities and other manufacturing instructions, related to the welds, are shown as standard symbols. These symbols on the Repair illustrations.

Notes, which give more data, can be added to the symbols.

Electrodes

The welding electrodes must have mechanical and electrical properties, which are satisfactory to make the approved welds in the materials and with the thickness necessary for the assemblies.

It is recommended that the electrodes are machine dressed. Electrodes must be redressed when the shapes of the edges and/or ends change sufficiently so that the specified conditions (Refer to Step, step 5.E.), are not possible.

Welding Schedules

The welding schedules necessary to make welds with strengths not lower, and/or melted area dimensions not smaller, than those specified - (On illustrations, by related welding symbols and added notes), will be found by the assembly and test of not less than five subsequent test pieces before welding the parts. The welding schedules will also include all data about the machine set up.

The test pieces will be made from materials of the same, or equivalent, specification number and the same nominal thickness, cleaned the same as the parts shown and will, when possible, be approximately the shape of the area of part shown. The overlap in the test pieces will not be larger than the overlap in the part which is to be repaired.

When there are welding schedules, the assembly and test of equivalent test pieces must show that they are correct when

The heat input is changed (by more than 10 percent), or

A different machine adjustment is made (by more than 5 percent) from the value found for that welding schedule.

During welding, it is necessary to approve the schedules at least before and after each assembly run.

Different approved weld schedules are not necessary for thickness combinations that are within the limits that follow if you can get, more than one time, the approved fused zone size with a weld heat (current) setting that lies within schedule; all other conditions are the same.

Foil

The variation in thickness (with regard to the initial schedule) of the outer sheet is within plus or minus 0.001 in.(0.025 mm).

The variation in the total thickness of the combination is within plus or minus 0.003 in. (0.076 mm).

Sheet (outer) up thru 0.040 in. (1.016 mm) thick

The variation in thickness of either outer sheet is within plus or minus 0.004 in. (0.102mm).

The variation of the total thickness of the combination is within plus or minus 0.006 in.(0.152 mm).

Sheet (outer) greater than 0.040 in. (1.016 mm) thick

The variation in thickness of either outer sheet is within plus or minus 10 percent for aluminum and magnesium alloys, or plus or minus 20 percent for materials other than aluminum and magnesium.

The variation in the total thickness of the combination is within plus or minus 10 percent.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

WARNING

Procedure

The strengths of the different spot welds must not be less than the values specified on the illustration. Strength tests are not necessary for the usual approval. The melted area diameters of the different spot and projection welds (as measured at each interface in the joint) must not be smaller than the values specified on the illustration.

When the melted area width of seam and stitch welds is specified, it must (where measured at each interface in the joint) not be lower than that specified in the illustration at the start of an assembly run. At the end of the run, the melted area width must not be less than 90 percent of that specified for seam welds or less than 70 percent of that specified for stitch welds.

Strength and dimensions.

The difference in shear strength, in a subsequent group of welded aluminum and magnesium alloy test pieces, must be plus or minus 12.5 percent (of the average value, in at least 90 percent of the test pieces) and plus or minus 25 percent (of the average value, in the remaining test pieces). The shear strength of annealed and stress relieved test pieces, of materials other than aluminum and magnesium alloys, must not change by more than 10 percent (of the average value, in at least 86 percent of the test pieces) or plus or minus 20 percent (of the average value, in the remaining test pieces).

Constant quality.

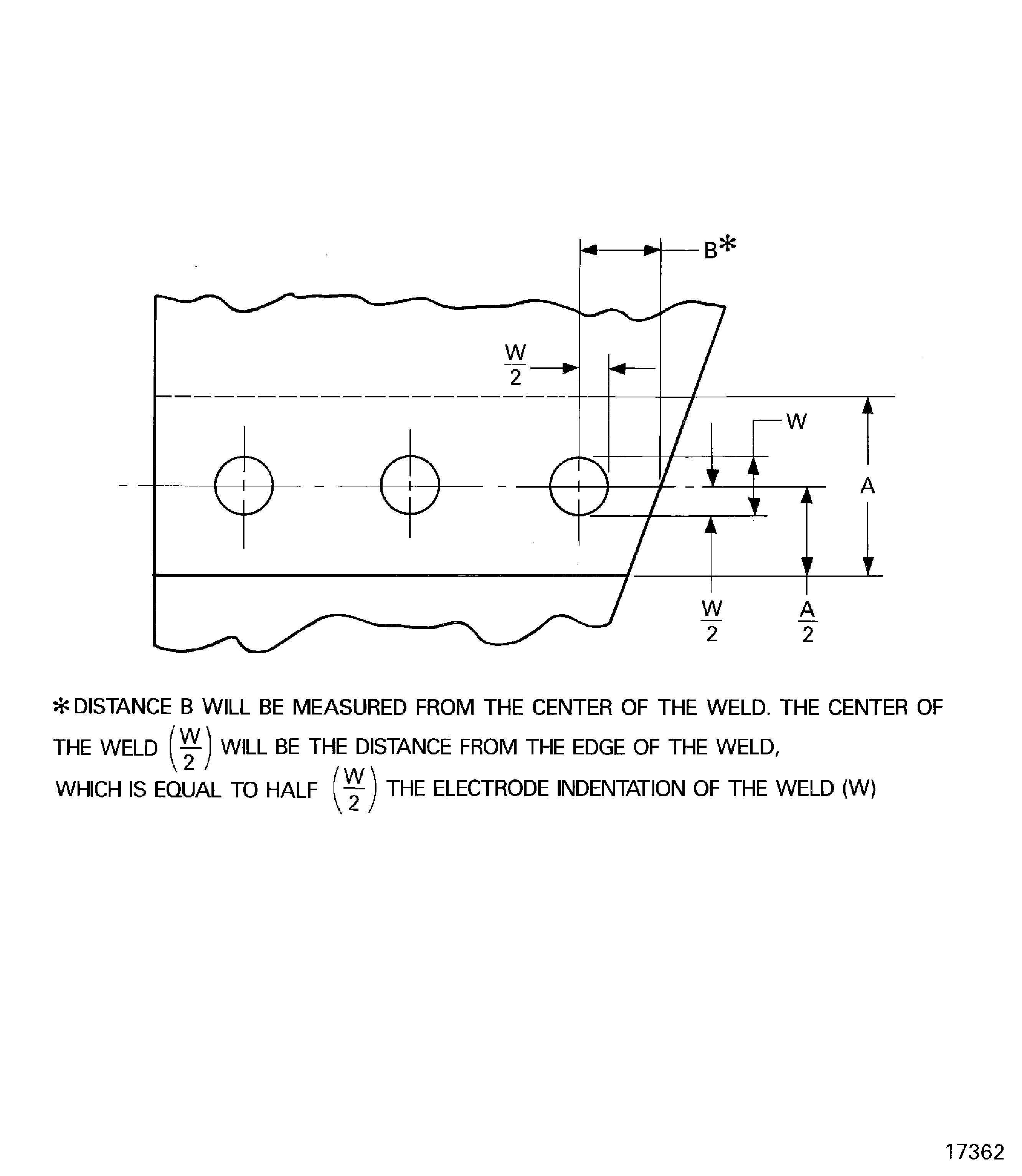

Position - (Refer to Figure).

If the deep drawing of parts causes the weld area to become thin, the thickness of each such part in the joint (where the permitted indentation is calculated) will be used as the correct thickness at the welded joint or 82 percent of the nominal thickness of the initial material, or that which is larger.

For parts other than foil backed, porous sheet, abradable materials:

Indentation.

Unless specified differently in the text or illustration, the weld penetration (into each outer piece), at the centerline of the weld nugget, must not be less than 20 percent of the indentation thickness of the thinnest piece to be attached and not larger than 80 percent of the indentation thickness of the related pieces.

For parts other than foil backed, porous sheet, abradable materials:

NOTE

The penetration can be as high as 90 percent of the indentation thickness of the related pieces in titanium and titanium alloy welds.

Penetration.

The number of spots to the inch (or millimeter), for a length of stitch welds on a group of parts (as measured along a 1.000 in. (25.4 mm) length of weld), must not be less than that on the control test piece with the least number of spots to the inch (or millimeter). Only the control tests, related to that group of parts, can be used to find the permitted limit.

Distance A/2 - (Refer to Figure), from the center of the weld to the edges of the piece, must be less than plus or minus 0.060 in. (1.52 mm) of the distance necessary - (Refer to step 5.B. and the repair illustration).

Edge distance B, of the spot welds - (Refer to Figure), must be less than plus or minus 0.060 in. (1.52 mm) of the distance necessary - (Refer to step 5.B. and the repair illustration).

Unless specified differently in the text or repair illustration, the tolerances that follow are permitted:

Tolerances.

SUBTASK 70-31-10-310-060 Technical Data

CAUTION

WIRE BRUSHES USED TO CLEAN THE CORROSION FROM HEAT-RESISTANT STEELS AND ALLOYS, MUST HAVE BRISTLES MADE OF AUSTENITIC CORROSION-RESISTANT STEEL. WHEN WIRE BRUSHES ARE USED, ALWAYS MAKE SURE THAT THE UNWANTED MATERIALS ARE FULLY REMOVED AND NOT ONLY POLISHED.Wire brushes or silicon carbide abrasives can be used for the rough removal of protective coatings, unwanted materials and surface scale. Silicon carbide abrasives are to be used for the last surface cleaning procedure and the removal of oxides; then, clean by the solvent wipe method. Refer to the SPM TASK 70-11-26-300-503.

Cleaning.

Weld the necessary test-pieces. Make sure that the destructive and mechanical tests agree with the instructions, given in Step, step 5 - Technical Data.

Welding.

SUBTASK 70-31-10-310-061 Resistance Welding Procedures

Figure: Positions of seam, spot and stitch welds

Positions of seam, spot and stitch welds