Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-35-25-300-001-H01 Replace The Harness Tie(s) Of The Electrical Harness, Repair-001 (VRS7002)

General

This TASK details the procedure for the replacement of the harness ties.

Refer to repair, VRS7002 SPM TASK 70-35-25-300-001 (REPAIR-001) for the following:

Effectivity

Equipment and materials

General

All illustrations/Figs

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-159 LACING TAPE | LOCAL | CoMat 02-159 | ||

| CoMat 02-184 LACING TAPE | LOCAL | CoMat 02-184 | ||

| CoMat 02-018 BRUSH, PAINT | LOCAL | CoMat 02-018 | ||

| CoMat 07-084 SILICONE VARNISH | LOCAL | CoMat 07-084 |

Spares

NONESafety Requirements

NONEProcedure

NOTE

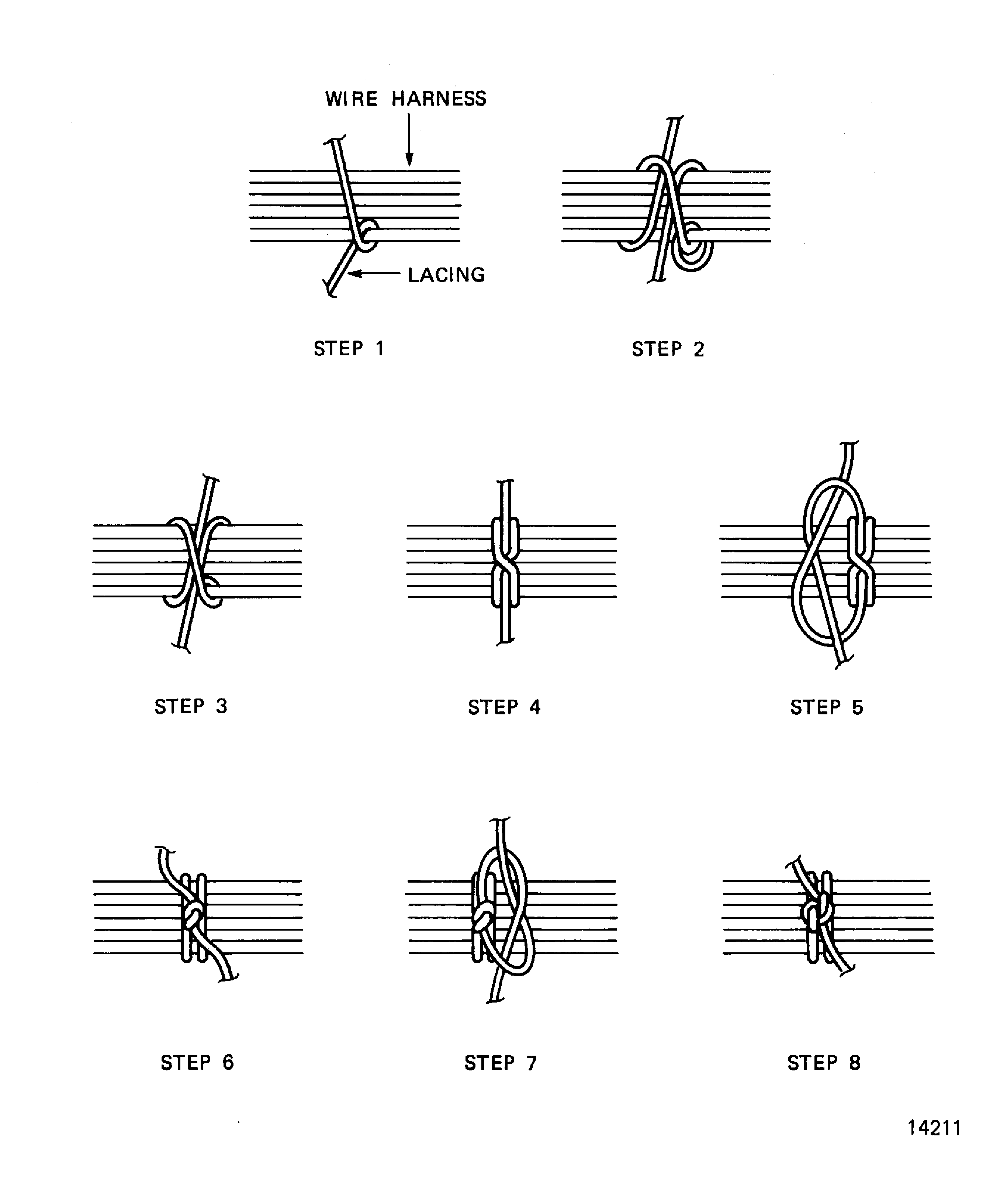

Lace the wire bundles together tightly. All the breakouts from the harness must be in the same plane as the wire bundle centreline (refer to Figure). Keep the wires in the harness as straight as possible and make sure the wires are not twisted. When the harness is more than 1.5 in. (38.10 mm) in diameter, it must be laced two times at each position.Remove the ties that are damaged, or those necessary to give access to the damaged cables.

Refer to Figure and Figure for the procedure for lacing the wire bundles. use CoMat 02-159 LACING TAPE to tie the wire bundles. Put the ties not more than 2.0 in. (50.80 mm) apart.

Replace the general ties as necessary.

Refer to Figure and Figure for the procedure for lacing the wire bundles. Use CoMat 02-184 LACING TAPE (black) to tie the wire bundles on the general clamp position. Use CoMat 02-159 LACING TAPE to tie the wire bundles approximately 1.0 in. (25.4 mm) from the centre of the general clamp position.

Replace the ties at a general clamp position, as necessary.

Refer to Figure and Figure for the procedure for lacing the wire bundles. Use CoMat 02-184 LACING TAPE (black) to tie the wire bundles. Put the ties approximately 0.335 in. (8.50 mm) from the center of the datum clamp position.

Replace the ties at a datum clamp position, as necessary.

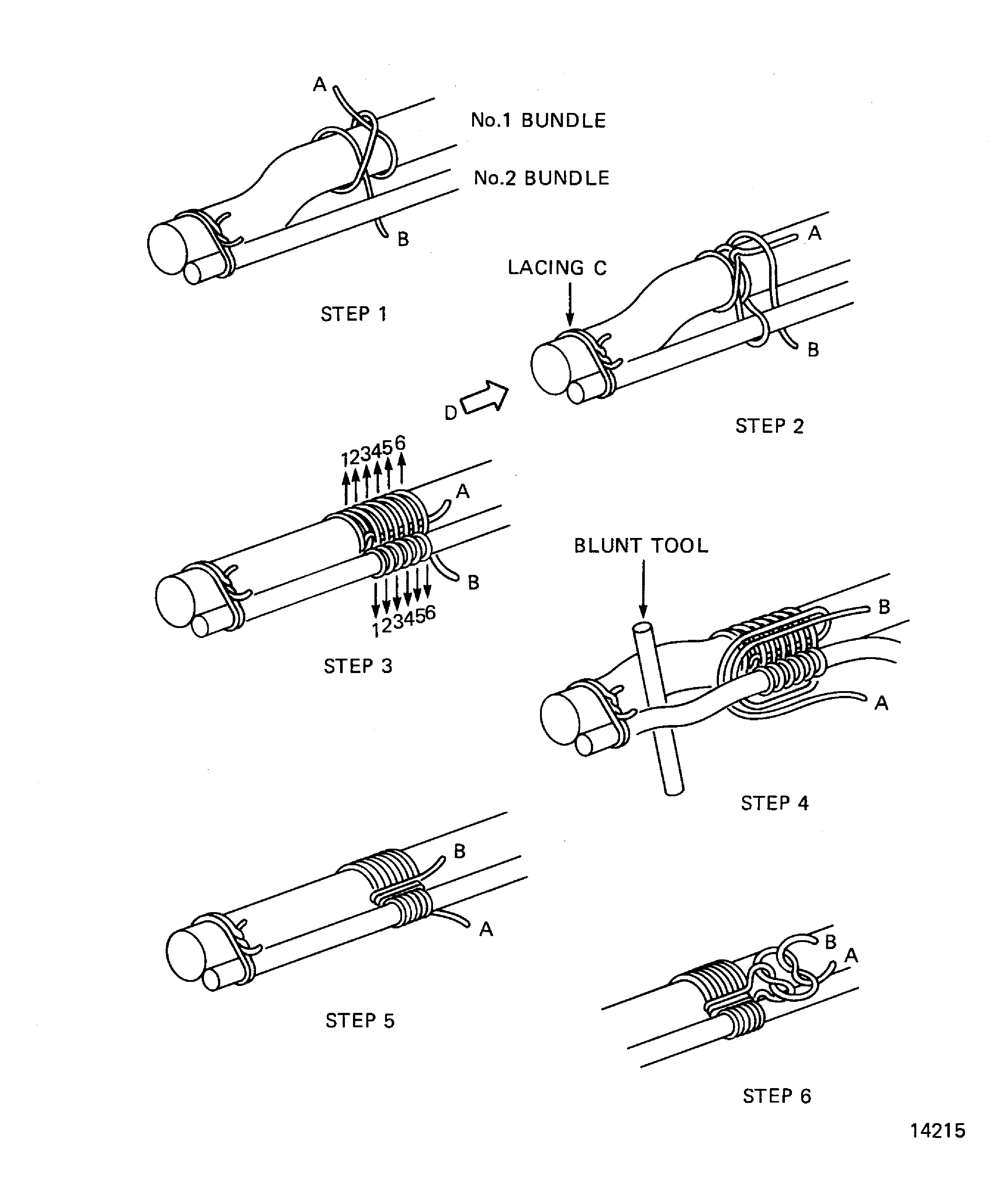

Make a clove hitch around the No 1 bundle.

Pull each end of the tape so that it is tight. Pull the end A away from the lacing C that holds the No 1 and No 2 bundles together. Look in the direction of arrow D. Wind the end B around the No 2 bundle in a counter clockwise direction for one turn. Put the end of the tape between the No 1 and No 2 bundles. Continue to wind the tape around the No 1 bundle in a clockwise direction for one turn. Make sure that the end B is above the end A.

Repeat the step above until you wind the bundles six times.

Pull the end B after each winding so that the lacing is tight. Use a blunt tool to make a clearance between the No 1 and the No 2 bundles. Wind the end A around the six laces and between the No 1 and the No 2 bundles. Do this in a counter clockwise direction for one turn. Wind the end B around the six laces and between the No 1 and the No 2 bundles. Repeat this in a clockwise direction for one turn.

Repeat the step above until you wind the laces three times.

Pull the ends of the tape after each winding so that the lacing is tight. Complete the lacing with a square knot.

Refer to Figure for the procedure for lacing the wire bundles. Use CoMat 02-159 LACING TAPE to tie the wire bundles. Start the procedure at a point between the No 1 and the No 2 bundles and do the steps that follow:

Replace the ties at the connection of two wire bundles, as necessary.

SUBTASK 70-35-25-350-045 Replace the Ties

Use CoMat 02-018 BRUSH, PAINT and CoMat 07-084 SILICONE VARNISH. Apply the varnish to the knot of each of the ties. When the varnish is dry cut off the two ends of the ties approximately 0.350 in. (8.90 mm) from the knot.

WARNING

KEEP FLAMES AND ELECTRICAL EQUIPMENT THAT IS NOT FLAMEPROOF AWAY FROM THE WORK AREA. THE SILICONE VARNISH IS FLAMMABLE.

WARNING

DO NOT GET THE SILICONE VARNISH ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GLOVES, GOGGLES AND A MASK. DO NOT BREATHE THE FUMES. IF YOU GET THE VARNISH ON YOUR SKIN OR IN YOUR EYES, GET MEDICAL HELP IMMEDIATELY.Seal the ties.

SUBTASK 70-35-25-350-047 Seal the Ties

Use permanent marker.

Make a mark VRS7002/H on the identification sleeve of the harness adjacent to the part number.

SUBTASK 70-35-25-350-058 Identify the Repair

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions