Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-36-02-360-501 Adhesive Bonding, Sealing And Filling Agents

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 08-005 HEAT CURING EPOXIDE RESINADHESIVE | 00BB6 | CoMat 08-005 | ||

| CoMat 08-010 HEAT CURING FILM ADHESIVE | LOCAL | CoMat 08-010 | ||

| CoMat 08-015 RESIN | LOCAL | CoMat 08-015 | ||

| CoMat 08-016 HARDENER | LOCAL | CoMat 08-016 | ||

| CoMat 08-017 NYLON FLOCK | LOCAL | CoMat 08-017 | ||

| CoMat 08-018 ADHESIVE | X111X | CoMat 08-018 | ||

| CoMat 08-021 EPOXY PASTE ADHESIVE | 33564 | CoMat 08-021 | ||

| CoMat 08-022 HEAT CURING FOAMING ADHESIVE | LOCAL | CoMat 08-022 | ||

| CoMat 08-025 HEAT CURING FILM ADHESIVE | LOCAL | CoMat 08-025 | ||

| CoMat 08-048 RESIN | LOCAL | CoMat 08-048 | ||

| CoMat 08-047 HARDENER | 0LCV8 | CoMat 08-047 | ||

| CoMat 08-050 EPOXY PASTE ADHESIVE | LOCAL | CoMat 08-050 | ||

| CoMat 08-079 HEAT CURING FILM ADHESIVE | LOCAL | CoMat 08-079 | ||

| CoMat 08-104 EPOXY PASTE ADHESIVE | 33564 | CoMat 08-104 | ||

| CoMat 08-114 TOUGHENED ACRYLIC ADHESIVE+INITIATOR | K6835 | CoMat 08-114 | ||

| CoMat 08-012 COLD CURING SILICONE COMPOUND | X222X | CoMat 08-012 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | X222X | CoMat 08-013 | ||

| CoMat 08-036 SILICONE RUBBER COMPOUND | LOCAL | CoMat 08-036 | ||

| CoMat 08-125 SEALANT, POLYSULPHIDE | F0107 | CoMat 08-125 | ||

| CoMat 08-141 SEALANT - TWO PART POLYSULPHIDE | 0NYS9 | CoMat 08-141 | ||

| CoMat 08-142 POLYSULPHIDE COMPOUND | X222X | CoMat 08-142 | ||

| CoMat 08-146 POLYSULPHIDE SEALANT | 0NYS9 | CoMat 08-146 | ||

| CoMat 08-004 ADHESIVE | LOCAL | CoMat 08-004 | ||

| CoMat 08-006 FILLER, TWO PACK | 00BB6 | CoMat 08-006 | ||

| CoMat 08-023 FILLER | LOCAL | CoMat 08-023 | ||

| CoMat 08-148 FILLER, FAST CURE TWOPACK | LOCAL | CoMat 08-148 | ||

| CoMat 04-002 JOINTING COMPOUND ALUM.HIGH TEMP | K6835 | CoMat 04-002 | ||

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-060 ACETONE (CH3)2CO | LOCAL | CoMat 01-060 | ||

| CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER | LOCAL | CoMat 01-201 | ||

| CoMat 02-099 LINT-FREE CLOTH | X222X | CoMat 02-099 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | X222X | CoMat 05-003 | ||

| CoMat 05-004 ABRASIVE MEDIUM, ALUMINUM OXIDE, 140/400 GRADE | X222X | CoMat 05-004 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | 0KHE3 | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | 0KHE3 | CoMat 05-017 | ||

| CoMat 06-021 SURFACE INSPECTION FLUID | LOCAL | CoMat 06-021 | ||

| CoMat 08-011 PRIMER | LOCAL | CoMat 08-011 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | X222X | CoMat 08-014 | ||

| CoMat 08-020 EPOXY PRIMER,RED | LOCAL | CoMat 08-020 | ||

| CoMat 08-080 PRIMER | IE277 | CoMat 08-080 | ||

| CoMat 08-371 18/8 ANNEALED STAINLESS STEEL WIRE | LOCAL | CoMat 08-371 | ||

| DELETED | LOCAL | DELETED | Removed CoMat 01-160 | |

| CoMat 08-007 BONDING ADHESIVE | X111X | CoMat 08-007 | ||

| CoMat 08-032 PRIMER | B1571 | CoMat 08-032 | ||

| CoMat 08-170 DELETED | LOCAL | CoMat 08-170 | ||

| CoMat 08-012A COLD CURING SILICONE COMPOUND | 00BB6 | CoMat 08-012A | ||

| CoMat 08-012B COLD CURING SILICONE COMPOUND | IE146 | CoMat 08-012B | ||

| CoMat 08-012C COLD CURING SILICONE COMPOUND | IE146 | CoMat 08-012C | ||

| CoMat 08-013A COLD CURING SILICONE COMPOUND | U4065 | CoMat 08-013A | ||

| CoMat 08-013B COLD CURING SILICONE COMPOUND | 01139 | CoMat 08-013B | ||

| CoMat 08-013C COLD CURING SILICONE COMPOUND | 00BB6 | CoMat 08-013C | ||

| CoMat 08-013D COLD CURING SILICONE COMPOUND | K6835 | CoMat 08-013D | ||

| CoMat 08-013F COLD CURING SILICONE COMPOUND | 00BB6 | CoMat 08-013F | ||

| CoMat 08-014A PRIMER, SILICONE ADHESIVE/SEALANT | 00BB6 | CoMat 08-014A | ||

| CoMat 08-014B PRIMER, SILICONE ADHESIVE/SEALANT | 00BB6 | CoMat 08-014B | ||

| CoMat 08-014C PRIMER, SILICONE ADHESIVE/SEALANT | K7652 | CoMat 08-014C | ||

| CoMat 08-014D PRIMER, SILICONE ADHESIVE/SEALANT | K6835 | CoMat 08-014D | ||

| CoMat 08-014E PRIMER, SILICONE ADHESIVE/SEALANT | 02JVK | CoMat 08-014E | ||

| CoMat 08-014F PRIMER, SILICONE ADHESIVE/SEALANT | 02JVK | CoMat 08-014F | ||

| CoMat 08-032A PRIMER | 02JVK | CoMat 08-032A | ||

| CoMat 08-032B PRIMER | 02JVK | CoMat 08-032B |

Spares

NONESafety Requirements

NONEProcedure

SUBTASK 70-36-02-360-031 Contents

Scope

Safety Precautions

Introduction

Index of Adhesives, Sealants and Filling Agents

Equipment and Consumable Materials Process

Mixing of Epoxy Resins

Preparation of Components -

Aluminum, Titanium, Stainless-Steel and Nickel-Based Parts

Fibre-Reinforced Composite Parts

Steel Parts

Fluorocarbon Viton Rubber Parts

Silicone Rubber Parts

Water Break Check

Inspection

SUBTASK 70-36-02-360-035 Safety Precautions

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURER'S MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS. THESE CONTAIN INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.

WARNING

MATERIALS MUST BE PREPARED AND USED IN WELL VENTILATED AREAS.

WARNING

DO NOT LET THEM TOUCH YOUR SKIN. WEAR GLOVES AND OVERALLS TO PREVENT UNCURED MATERIALS COMING INTO CONTACT WITH THE SKIN. AT THE END OF WORK, OR IF YOU HAVE RESIN ON YOUR SKIN, WASH THE SKIN THOROUGHLY WITH THE AID OF RESIN REMOVING CREAM.

WARNING

YOU MUST NOT EAT, DRINK OR SMOKE AT LOCATIONS WHERE THESE MATERIALS ARE USED.Epoxy resins.

Epoxy resins are used extensively throughout the aerospace industry for bonding composite, honeycomb, and metal parts. They are available as one and two part pastes, one part powders, or as supported or unsupported films.

Epoxy resins harden by chemical reaction at various temperatures depending on type. The chemical type of the hardener will dictate the properties of the material. Cured epoxy resins are generally brittle materials (especially the heat cure grades) with good fluid resistance (especially heat cured grades). As a general rule, the heat cured grades will withstand higher temperatures before degradation than room temperature cured grades. The highest temperature materials will operate continuously at 200 deg C (392 deg F).

Acrylic adhesives.

Acrylics adhesives and sealants cure rapidly at room temperature (typically in minutes). The resin is applied to one substrate and the hardener is applied to the other. Acrylic materials are tough, have good impact resistance and have good resistance peel. They can be used at operating temperature up to 100 deg C (212 deg F).

Cyanoacrylate adhesives.

Cyanoacrylates harden through reaction with weak bases (usually moisture). They have a very rapid cure (typically seconds) but have poor resistance to water/ moisture when cured. They have an 80 deg C (176 deg F) maximum operating temperature. They are used as an assembly aid. They will not fill gaps or bond porous surfaces due to low viscosity, although gel grades have been developed for these purposes.

There are a number of different type of adhesive/sealant products available. The common ones are:

Some adhesive products are 1-part systems, and do not need mixing. Some adhesives are supplied in pre-measured kits such as Sem-kits or blister packs. These offer the advantage of not having to weigh each of the components, but the mixing procedure is just as important as non pre-measured kits. Other products, notably epoxy resins, are supplied as two separate components, which need mixing before use. The manufacturer's data must always be referred to in addition to this Standard Practice and the repair documentation.

Adhesives should be stored in a cool dry environment. The storage temperature depends on the specific type of material. Some can be stored at room temperature while others require refrigeration at 4 deg C (40 deg F) or freezer storage at -18 deg C (0 deg F). Refer to the manufacturers storage instructions for the appropriate storage conditions.

SUBTASK 70-36-02-360-038 Introduction

SUBTASK 70-36-02-360-032 Index of Adhesives, Sealants and Filling Agents

WARNING

TO PREVENT CONTACT WITH YOUR SKIN, WEAR PROTECTIVE GLOVES WHEN YOU MAKE-UP AND USE ADHESIVES.Epoxy Resin Adhesives:

CoMat 08-015 RESIN/CoMat 08-016 HARDENER Epoxy Resin Adhesive

CoMat 08-015 RESIN/CoMat 08-016 HARDENER (Epoxy Resin) with CoMat 08-017 NYLON FLOCK Filled Epoxy Adhesive

CoMat 08-018 ADHESIVE - Epoxy Paste

CoMat 08-048 RESIN with CoMat 08-047 HARDENER Epoxy Resin Adhesive

Acrylic Adhesives:

CoMat 08-114 TOUGHENED ACRYLIC ADHESIVE+INITIATOR Toughened Acrylic Adhesive

Silicone Adhesive Sealants:

Polysulfide Adhesive Sealants:

CoMat 08-141 SEALANT - TWO PART POLYSULPHIDE Two Part Polysulfide Sealant

CoMat 08-142 POLYSULPHIDE COMPOUND Polysulfide Compound

CoMat 08-146 POLYSULPHIDE SEALANT Polysulfide Sealant

Contact Adhesives:

CoMat 08-004 ADHESIVE Contact Adhesive

Fillers:

CoMat 08-023 FILLER (Green)

CoMat 08-148 FILLER, FAST CURE TWOPACK Filler Fast Cure Two Pack

Joining Compounds:

CoMat 04-002 JOINTING COMPOUND ALUM.HIGH TEMP - High Temperature Joining Compound

Container.

A container is needed to contain the resin during measuring and mixing. The recommended containers are translucent High Density Polyethylene (HDPE) with a height to diameter ratio of one. A radius in the bottom of the container helps prevent unmixed resin from being trapped. The translucent sides allow the user to inspect for any unmixed resin. Alternately uncoated paper or clean metal containers may be used.

Measuring Scale.

A calibrated measuring scale is necessary to weigh the resin and hardener components. The scale can be electronic, triple beam or equal arm with a single beam. The accuracy must be better than 1% of the smallest amount to be weighed. For example, if the amount to be weighed is 10 g, then the accuracy of the scale shall be 0.1 g. Spring scales must not be used. A tare feature is useful in minimizing weighing errors; this lets the balance be re-zeroed after the container and each component are added.

The basic consumable materials that are used for adhesive mixing are identified below. Since there is such a large selection of each of these items, only general guidance is given. The user of these materials needs to evaluate the application and determine the appropriate selection.

NOTE

Take care to make wood tools are stored in a dry area because wood can absorb moisture.Heating Devices.

Some adhesives can be cured at elevated temperatures. This can be done using infra red heaters, hot air guns, air re-circulatory ovens or heater blankets. If the engine manual or repair scheme does not specify the equipment to use select the appropriate device for access to the repair area and temperature capability. The device used must be calibrated and capable of maintaining the required temperature uniformity at the bond line.

Clamps.

Many assemblies will need to be clamped in position while the adhesive cures. This can be done using weights, mechanical clamps or tape. The clamping arrangement must not damage the component. Tape must be approved and have the required temperature capability. The clamping feature must not be bonded to the component and must be removed when the adhesive has cured.

Standard Equipment.

Acetone ((CH2)2CO), technical grade

Acetone ((CH3)2CO), reagent grade

Distilled or deionized water

Lint-free cloth

Joining compound (Aluminum - high temperature)

Abrasive medium (Aluminum oxide grit 120-220 mesh)

Abrasive medium (Aluminum oxide grit 140-400 mesh)

Garnet paper (80-grit)

Garnet paper (60-grit)

Surface inspection fluid

Primer

Primer (for Silcoset 151, 152, 153 and also RTV 102, 106,112 and 116)

Epoxy primer (Red)

Primer

18/8 Annealed stainless steel wire

NOTE

Deleted

SUBTASK 70-36-02-360-036 Equipment and Consumable Materials

CAUTION

DO NOT USE WAXED OR COATED CONTAINERS. THE COATING MAY DISSOLVE AND CONTAMINATE THE MATERIAL.Mixing the resin and hardener starts the cure process. The cure process is an exothermic reaction which generates heat. If the environment can reduce the heat created by the curing reaction, then the pot life is relatively long. If the heat is not reduced, the temperature of the mixture increases and this can cause a very short pot-life, and dangerous heat build-up. Consider the pot-life in relation to the resin mass and the wetted area of the mixture. To increase the pot-life after mixing pour the resin into a shallow tray or onto a film. This prevents heat build-up and can maximize the pot-life.

NOTE

Check the shelf life of the resin and hardener. Do not use if outside the manufacturer's shelf life.NOTE

Make sure that the mixed quantity can be used before the end of the pot-life (recommended amount 250 g). If large quantities of resin are required store the weighed resin and hardener separately then mix them just before they are needed.

General.

Mix the resin and hardener thoroughly with a spatula. Stir slowly to avoid mixing excessive air into the mixture. The resin should be mixed for a minimum of 3 minutes, or until the mixture has a uniform color and texture, whichever takes longer. Make sure that the material on the container walls is totally included in the mixture.

Instructions.

SUBTASK 70-36-02-360-037 Mixing of Epoxy Resins

WARNING

TO PREVENT CONTACT WITH YOUR SKIN, WEAR PROTECTIVE GLOVES WHEN YOU USE MAKE-UP AND USE ADHESIVES.

WARNING

MIXING LARGE QUANTITIES OF EPOXY RESINS OR FILLERS CAN LEAD TO A DANGEROUS HEAT BUILD UP. NEVER MIX MORE THAN THE MANUFACTURER'S RECOMMENDED AMOUNT, OR THE AMOUNT SPECIFIED IN THIS STANDARD PRACTICE.

CAUTION

THE RESIN AND HARDENER MUST BE AT ROOM TEMPERATURE BEFORE OPENING THE CONTAINERS. THIS PREVENTS CONDENSATION OF MOISTURE ON THE RESIN AND HARDENER. CLOSE THE CONTAINERS IMMEDIATELY BECAUSE OPEN CONTAINERS PERMITS THE RESIN AND HARDENER TO ABSORB MOISTURE. MOISTURE CAN PREVENT THE CORRECT CURE.

CAUTION

SURFACES TO BE BONDED MUST BE FULLY CLEAN. TO PREVENT CONTAMINATION, A PREPARED SURFACES MUST NOT BE TOUCHED BY HAND AFTER IT HAS BEEN CLEANED. BONDING MUST BE DONE IMMEDIATELY AFTER THE SURFACE PREPARATION.Degrease the contact surfaces by SPM TASK 70-11-26-300-503 or SPM TASK 70-11-03-300-503.

Dry abrasive blast with CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE at approximately 20 psi (140 kPa). Refer to SPM TASK 70-12-02-120-501. Alternatively, hand abrade with abrasive paper (60 - 180 grit Aluminum Oxide, Silicon Carbide, or Garnet paper is permitted).

Degrease the contact surfaces by SPM TASK 70-11-26-300-503 or SPM TASK 70-11-03-300-503.

Aluminum parts shall be chromate conversion coated by TASK 70-38-02-300-503.

Check for cleanliness of the surface with a water-break test, refer to Step.

SUBTASK 70-36-02-360-010 Prepare Aluminum, Titanium, Stainless-Steel and Nickel-Base Parts

CAUTION

MATING SURFACES MUST BE FULLY CLEAN. PREPARED SURFACES MUST NOT BE TOUCHED BY HAND OR OTHERWISE CONTAMINATED.

CAUTION

BONDING MUST BE CARRIED OUT WITHIN 8 HOURS OF PREPARATION.Degrease the contact surfaces by SPM TASK 70-11-26-300-503.

Degrease the contact surfaces by SPM TASK 70-11-26-300-503.

Check for cleanliness with a water-break test, refer to Step.

SUBTASK 70-36-02-360-011 Prepare Fibre-Reinforced Composite Parts

CAUTION

MATING SURFACES MUST BE FULLY CLEAN. PREPARED SURFACES MUST NOT BE TOUCHED BY HAND OR OTHERWISE CONTAMINATED.

CAUTION

BONDING MUST BE CARRIED OUT WITHIN 8 HOURS OF PREPARATION.Degrease the contact surfaces by SPM TASK 70-11-26-300-503 or SPM TASK 70-11-03-300-503.

Dry abrasive blast with CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE at approximately 20 psi (140 kPa). Refer to SPM TASK 70-12-02-120-501. Alternatively, hand abrade with abrasive paper (60 - 180 grit Aluminum Oxide, Silicon Carbide, or Garnet paper is permitted).

Degrease the contact surfaces by SPM TASK 70-11-26-300-503 or SPM TASK 70-11-03-300-503.

NOTE

The surface break test is not necessary.

SUBTASK 70-36-02-360-012 Prepare Steel Parts (Steel Alloys Other Than Stainless Steel)

CAUTION

MATING SURFACES MUST BE FULLY CLEAN. PREPARED SURFACES MUST NOT BE TOUCHED BY HAND OR OTHERWISE CONTAMINATED.

CAUTION

BONDING MUST BE CARRIED OUT WITHIN 8 HOURS OF PREPARATION.Clean the mating surfaces with CoMat 02-099 LINT-FREE CLOTH made moist with CoMat 01-031 ACETONE (CH3)2CO or CoMat 01-060 ACETONE (CH3)2CO.

SUBTASK 70-36-02-360-013 Prepare Fluorocarbon Viton Rubber Parts

CAUTION

MATING SURFACES MUST BE FULLY CLEAN. PREPARED SURFACES MUST NOT BE TOUCHED BY HAND OR OTHERWISE CONTAMINATED.

CAUTION

BONDING MUST BE CARRIED OUT WITHIN 8 HOURS OF PREPARATION.Clean the silicon rubber part with CoMat 02-099 LINT-FREE CLOTH made moist with CoMat 01-031 ACETONE (CH3)2CO or CoMat 01-060 ACETONE (CH3)2CO.

Clean the mating surfaces with CoMat 02-099 LINT-FREE CLOTH made moist with CoMat 01-031 ACETONE (CH3)2CO or CoMat 01-060 ACETONE (CH3)2CO.

SUBTASK 70-36-02-360-014 Prepare Silicone Rubber Parts

CAUTION

MATING SURFACES MUST BE FULLY CLEAN. PREPARED SURFACES MUST NOT BE TOUCHED BY HAND OR OTHERWISE CONTAMINATED.

CAUTION

BONDING MUST BE CARRIED OUT WITHIN 8 HOURS OF PREPARATION.With a clean soft brush, quickly apply a uniform layer of clean CoMat 01-201 DISTILLED, DEIONIZED, DEMINERALIZED, OR REVERSE OSMOSIS (RO) WATER to the mating surface.

Remove the water with clean CoMat 01-031 ACETONE (CH3)2CO, or CoMat 01-060 ACETONE (CH3)2CO and let the surface dry.

SUBTASK 70-36-02-360-044 Water Break Check

Deterioration of part B will occur if it becomes moist. Immediately after use close the cover to seal the container.

When mixed the life of the adhesive is approximately 48 hours, at 68 deg F (20 deg C). This can be extended to four weeks, if the mixed adhesive is kept at 32 deg F (0 deg C).

CoMat 08-005 HEAT CURING EPOXIDE RESINADHESIVE is made up from two parts:

Part A (Filled grade) 100 parts by weight.

Part B (Curing agent) 64 parts by weight.

For application and cure, refer to Step.

SUBTASK 70-36-02-360-001 Make up of the Filled Grade Adhesive, CoMat 08-005

NOTE

For make-up, refer to Step.

Apply a thin layer of CoMat 08-005 HEAT CURING EPOXIDE RESINADHESIVE, to each of the mating surfaces.

SUBTASK 70-36-02-360-016 Apply and Cure the Filled Grade Adhesive, CoMat 08-005

This subtask is deleted because CoMat 08-007 BONDING ADHESIVE is no longer available.

SUBTASK 70-36-02-360-002 Deleted

The adhesive is made up from two parts:

CoMat 08-015 RESIN 70 parts by weight.

CoMat 08-016 HARDENER 30 parts by weight.

For application and cure, refer to Step.

SUBTASK 70-36-02-360-004 Make up of the Two-Part Low Temperature Curing Sealant/Adhesive, CoMat 08-015/CoMat 08-016

NOTE

The two parts must be mixed to make a smooth cream color paste.For make-up, refer to Step.

SUBTASK 70-36-02-360-021 Apply and Cure the Two-Part Low Temperature Curing Sealant/Adhesive, CoMat 08-015/CoMat 08-016

The adhesive is made up from three parts:

CoMat 08-015 RESIN 100 parts by weight.

CoMat 08-016 HARDENER 43 parts by weight.

CoMat 08-017 NYLON FLOCK 10 parts by weight.

For application and cure, refer to Step.

SUBTASK 70-36-02-360-005 Make up of the Nylon Flock Filled Low Temperature Curing Sealant/Adhesive, CoMat 08-015/CoMat 08-016 with CoMat 08-017

NOTE

The three parts must be mixed to make a smooth cream color paste. The CoMat 08-017 NYLON FLOCK must be uniformly spread throughout the mixture.For make-up, refer to Step.

SUBTASK 70-36-02-360-022 Apply and Cure the Nylon Flock Filled Low Temperature Curing Sealant/Adhesive, CoMat 08-015/CoMat 08-016 with CoMat 08-017

CoMat 08-021 EPOXY PASTE ADHESIVE is a two-part, general use, epoxy-resin based adhesive, which can be used at temperatures up to 248 deg F (120 deg C). It can also be used as a liquid shim.

For application and cure, refer to Step.

SUBTASK 70-36-02-360-006 Make up of the Epoxy Adhesive, CoMat 08-021

Make-up the CoMat 08-021 EPOXY PASTE ADHESIVE by Step.

For the best results apply a thin layer of the adhesive; but a thickness of 0.040 inch (1.02 mm) can give satisfactory results.

NOTE

The minimum cure time is one hour.

The adhesive will not cure at a temperature of less than 54 deg F (12 deg C).

When the temperature is increased to reduce the cure time, the glue line temperature must be monitored with a thermocouple, or other device.

Cure the adhesive by one of these combinations of time and temperature:

1 hour at 140 deg F or 60 deg C.

2 hours at 113 deg F or 45 deg C.

4 hours at 95 deg F or 35 deg C.

8 hours at 86 deg F or 30 deg C.

16 hours at 77 deg F or 25 deg C.

24 hours at 72 deg F or 22 deg C.

40 hours at 68 deg F or 20 deg C.

96 hours at 59 deg F or 15 deg C.

168 hours at 54 deg F or 12 deg C.

SUBTASK 70-36-02-360-025 Apply and Cure the Epoxy Adhesive, CoMat 08-021

CoMat 08-006 FILLER, TWO PACK is a two-part, low density, filler compound. Part A is a thick white paste and Part B is a thick blue paste.

NOTE

When mixed the pot-life of the filler at 72 deg F (22 deg C) is approximately one hour.For application and cure, refer to Step.

SUBTASK 70-36-02-360-007 Make up of the Two-Pack Blue Filler, CoMat 08-006

NOTE

If the area to be repaired is to a small, CoMat 08-148 FILLER, FAST CURE TWOPACK fast cure blue filler can be used in stead of CoMat 08-006 FILLER, TWO PACK blue filler (refer to Step).Make-up the CoMat 08-006 FILLER, TWO PACKto Step.

When the filler starts to cure (when it starts to feel hard), remove the excess filler. Use the tool blade for a burnishing effect.

NOTE

The minimum cure time is 30 minutes.

The filler will not cure at a temperature of less than 54 deg F (12 deg C).

The maximum temperature which can be used to cure the filler is 302 deg F (150 deg C). Surface scorching and an exothermic heat reaction can occur if a temperature greater than this is used.

If necessary, manually remove all surface scorching.

Cure the filler by one of these time and temperature combinations:

0.5 hour at 212 deg F or 100 deg C.

1 hour at 140 deg F or 60 deg C.

2 hours at 113 deg F or 45 deg C.

4 hours at 95 deg F or 35 deg C.

8 hours at 86 deg F or 30 deg C.

16 hours at 77 deg F or 25 deg C.

24 hours at 72 deg F or 22 deg C.

36 hours at 68 deg F or 20 deg C.

72 hours at 59 deg F or 15 deg C.

96 hours at 54 deg F or 12 deg C.

SUBTASK 70-36-02-360-026 Apply and Cure the Two-Pack Blue Filler, CoMat 08-006

CoMat 08-023 FILLER is a two-part, low density, filler compound; Part A is a thick blue paste and Part B is a thick yellow paste.

NOTE

When mixed the pot-life of the filler at 72 deg F (22 deg C) is approximately one hour.For application and cure, refer to Step.

SUBTASK 70-36-02-360-008 Make up of the Green Filler, CoMat 08-023

Make up the CoMat 08-023 FILLER, as specified in SUBTASK 70-36-02-360-008.

When the filler starts to cure (when it starts to feel hard), remove the excess filler. Use the tool blade for a burnishing effect.

NOTE

The minimum cure time is 30 minutes.

The filler will not cure at a temperature of less than 54 deg F (12 deg C).

The maximum temperature which can be applied to the filler is 302 deg F (150 deg C). Surface scorching and an exothermic heat reaction can occur if more than this temperature is used.

If necessary, manually remove all surface scorching.

Cure the filler by one of these time and temperature combinations:

0.5 hour at 212 deg F or 100 deg C.

1 hour at 140 deg F or 60 deg C.

2 hours at 113 deg F or 45 deg C.

4 hours at 95 deg F or 35 deg C.

8 hours at 86 deg F or 30 deg C.

16 hours at 77 deg F or 25 deg C.

24 hours at 72 deg F or 22 deg C.

36 hours at 68 deg F or 20 deg C.

72 hours at 59 deg F or 15 deg C.

96 hours at 54 deg F or 12 deg C.

SUBTASK 70-36-02-360-028 Apply and Cure the Green Filler, CoMat 08-023

CoMat 08-148 FILLER, FAST CURE TWOPACK filler, fast cure, is a two-part, low density, filler compound; Part A is a thick white paste and Part B is a thick blue paste.

NOTE

When mixed the pot-life of the filler at 72 deg F (22 deg C) is approximately 5 minutes. Do not mix any more than can be used within the pot life of the filler.For application and cure, refer to Step.

SUBTASK 70-36-02-360-029 Make up of Fast Cure Two-Pack Fast Cure Blue Filler, CoMat 08-148

Make up the CoMat 08-148 FILLER, FAST CURE TWOPACK filler, fast cure as specified in Step.

SUBTASK 70-36-02-360-030 Apply and Cure Two-Pack Fast Cure Blue Filler

This adhesive is a two-part epoxy made-up of either CoMat 08-048 RESIN high viscosity epoxy resin liquid and CoMat 08-047 HARDENER low viscosity liquid hardener.

Weigh out 100 parts of CoMat 08-048 RESIN and 8-10 parts of CoMat 08-047 HARDENER. Mix until a uniform mixture is obtained, or for 3 minutes, whichever is the longer time.

Mix to the instruction in Step.

Make up.

NOTE

Before mixing the temperature of the resin and hardener should be approximately 72 deg F (25 deg C) . CoMat 08-048 RESIN can become viscous at low temperatures. The viscosity can be reduced by warming the CoMat 08-048 RESIN to 30 deg C before to mixing.For use with a wet-lay up repair, refer to the instructions given in the repair scheme.

NOTE

Thin sections will require heating to above 25 deg C (77 deg F) to cure.

When cure times are accelerated by the application of heat, the temperature at the bond line must be monitored by thermocouples or another suitable method.

Application.

SUBTASK 70-36-02-360-046 Make up, Application and Cure of Two-Part Epoxy Adhesive, CoMat 08-048 and CoMat 08-047, Resin and Hardener Combination

CoMat 08-050 EPOXY PASTE ADHESIVE is a low viscosity two-part epoxy resin particularly suited to wet lay-up repairs. It is made-up of:

Part A - Unmodified liquid epoxy resin, yellow viscous liquid.

Part B - Low viscosity purple liquid.

Cure the adhesive for 220 minutes at 200 deg F (93 deg C). The increase the temperature (ramp-up rate) shall not exceed 5 deg F (3 deg C) maximum per minute. Alternatively, when specified by the Engine Manual, cure at 248 deg F (120 deg C) for 60 minutes. The temperature at the bond line must be monitored by thermocouples or another suitable method.

Application and Cure.

SUBTASK 70-36-02-360-048 Make up, Application and Cure of Epoxy Paste Adhesive, CoMat 08-050

CoMat 08-025 HEAT CURING FILM ADHESIVE is a lightweight film adhesive which has very high strength metal to metal and core to skin bonds. It is based on a filled, modified epoxy resin with a nominal thickness of 0,23 mm (0.009 inch) and a standard weight of 305 g/sq.m. and is suitable for use at operating temperatures up to 302 deg F (150 deg C). CoMat 08-025 HEAT CURING FILM ADHESIVE is always used with CoMat 08-020 EPOXY PRIMER,RED. CoMat 08-020 EPOXY PRIMER,RED primer is a violet, single component resin solution.

A glue line thickness of 0.002 to 0.004 inch (0.05 to 0.1 mm) should be produced after curing at 338 to 359 deg F (170 to 180 deg C).

Apply the CoMat 08-020 EPOXY PRIMER,RED primer, by brush or spray, to make a uniform layer up to 0.0004 inch (0,010 mm ) thick.

Prepare the Surface.

Remove the release paper and put the CoMat 08-025 HEAT CURING FILM ADHESIVE onto the primed surfaces. Where joints in the film adhesive are necessary, take care to ensure that the two films form a good butt joint.

Apply Film Adhesive.

To cure the CoMat 08-025 HEAT CURING FILM ADHESIVE, heat the components to 347 to 356 deg F 170 to 180 deg C) with a pressure of 46 to 60 p.s.i. (310 to 414 kPa). Keep at this temperature and pressure for 1 hour. Do not remove the bonding pressure until the glue-line temperature has reduced to less than 302 deg F (150 deg C).

Metal to metal bonding.

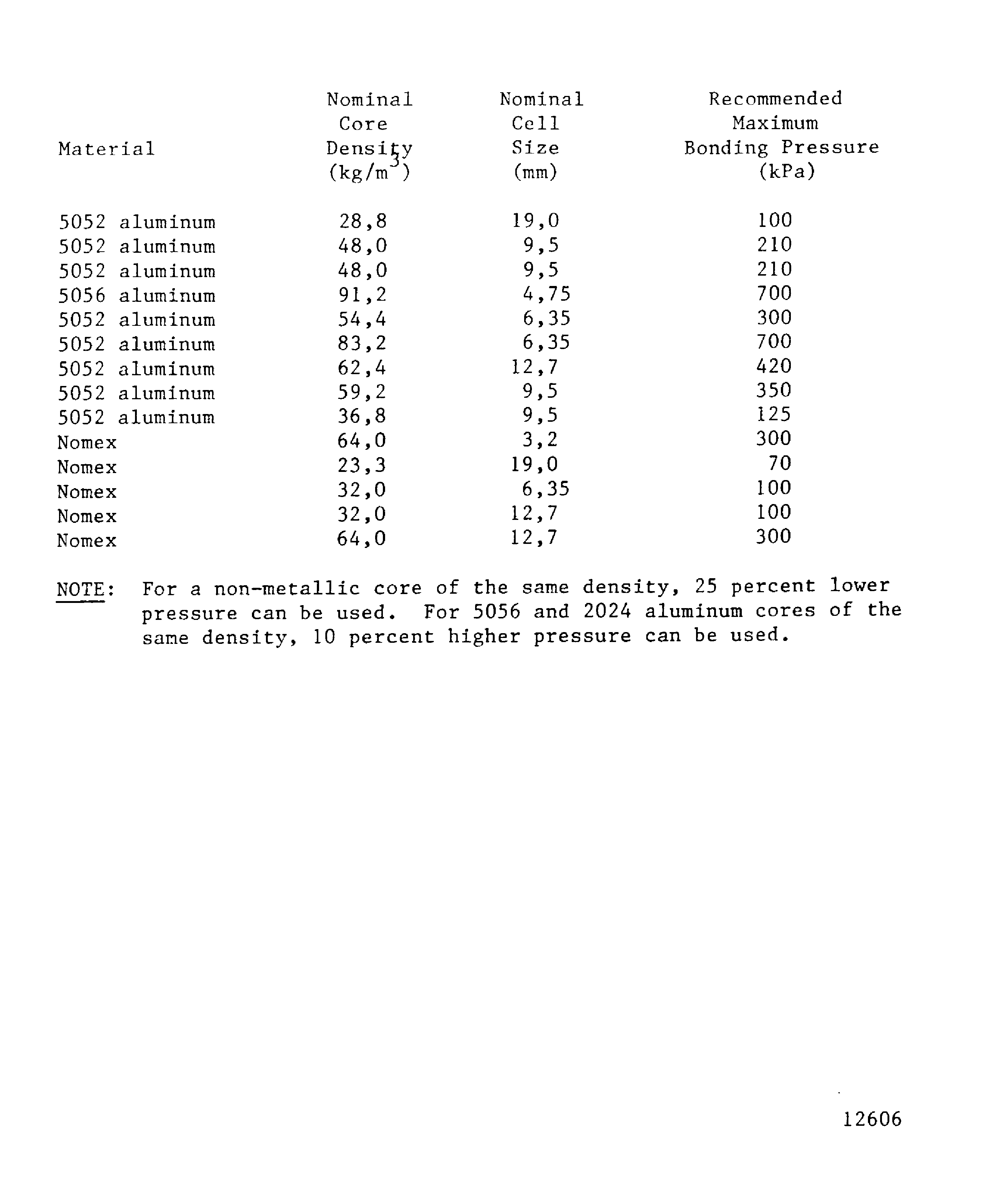

Heat the components to 347 to 386 deg F (170 to 180 deg C) with the pressure shown in Figure. Keep at this temperature and pressure for one hour. Do not remove the bonding pressure until the glue-line temperature has reduced to less than 302 deg F (150 deg C).

Core to skin bonding.

Cure the film adhesive.

SUBTASK 70-36-02-360-049 Application and Curing of Epoxy Film Adhesive, CoMat 08-025

CoMat 08-079 HEAT CURING FILM ADHESIVE is a lightweight film adhesive, suitable for both laminated and sandwich construction for continuous use at operating temperatures up to 356 deg F (180 deg C). The material should have a standard weight of 380 g/sq.m. and have a glue line thickness of 0.004 to 0.006 inch (0.10 to 0.15 mm) after curing.

After curing at 338 to 359 deg F (170 to 180 deg C) a glue line thickness of 0.002 to 0.004 inch (0.05 to 0.1 mm) should be produced.

Apply CoMat 08-020 EPOXY PRIMER,RED to make a uniform coat up to 0.0004 inch (0.010 mm) thick.

Let the CoMat 08-020 EPOXY PRIMER,RED epoxy primer dry in air for 1 hour at ambient temperature, or dry for 20 minutes at 158 deg F (70 deg C).

Prepare the Surface.

To cure the CoMat 08-079 HEAT CURING FILM ADHESIVE, heat the components to 347 to 356 deg F (170 to 180 deg C) with a pressure of 46 to 60 p.s.i. (310 to 414 kPa). Keep at this temperature and pressure for 1 hour. Do not remove the bonding pressure until the glue-line temperature has reduced to less than 302 deg F (150 deg C).

Metal to metal bonding.

To cure the CoMat 08-079 HEAT CURING FILM ADHESIVE, heat the components to 347 to 386 deg F (170 to 180 deg C) with the pressure shown in Fig. 70-00-00-860-707-001. Keep at this temperature and pressure for one hour. Do not remove the bonding pressure until the glue-line temperature has reduced to less than 302 deg F (150 deg C).

Core to skin bonding.

Cure the film adhesive.

SUBTASK 70-36-02-360-050 Application and Cure of Epoxy Film Adhesive, CoMat 08-079

CoMat 08-114 TOUGHENED ACRYLIC ADHESIVE+INITIATOR is a two-part cold curing acrylic paste adhesive. The optimum glue line thickness for this adhesive is less than 0.15 mm but glue lines of up to 1.0 mm can be used. For bonds up to 0.2 mm thick use the single side application, for bonds over 0.2 mm use a double sided application.

Cure the CoMat 08-114 TOUGHENED ACRYLIC ADHESIVE+INITIATOR at ambient temperature (77 deg F (25 deg C)) for 24 hours. The bond strength is sufficient to permit the part to be handled after 5 minutes and has 80% of the full bond strength after 3 hours. Thicker bonds will take longer to cure. The handling time will be increased if the temperature is reduced below 77 deg F (25 deg C). For example, at 36 deg F (2 deg C) the time necessary before the part can be handled increases to approximately 24 minutes .

SUBTASK 70-36-02-360-051 The Application and Cure of Toughened Acrylic Adhesive, CoMat 08-114.

Apply a thin film of CoMat 08-004 ADHESIVE by brushing to contact surfaces. Let the CoMat 08-004 ADHESIVE dry in air for 10 minutes followed by 45 minutes at 127 to 140 deg F (50 to 60 deg C).

CoMat 08-004 ADHESIVE is a single-part, heat curing, solvent-borne adhesive for non-structural applications.

SUBTASK 70-36-02-360-052 The Application and Cure of CoMat 08-004 Adhesive (Light Strength Rubber Adhesive)

The mixed CoMat 08-036 SILICONE RUBBER COMPOUND cold curing high strength silicone rubber has a pot life of approximately 2.5 hours at 59 to 77 deg F (15 to 25 deg C).

Preparation.

CoMat 08-036 SILICONE RUBBER COMPOUND is a two-part silicone rubber for use at a continuous operating temperatures up to 437 deg F (225 deg C) with occasional peaks up to 482 deg F (250 deg C). Part A is a beige base and Part B is a green liquid curing agent.

Apply a thin coat of CoMat 08-080 PRIMER to the prepared surfaces and let it dry in air for 1 hour. The primer must be applied to the prepared surfaces as soon as possible after preparation. If permitted by Engine Manual, the application of the primer can be omitted.

Apply the CoMat 08-036 SILICONE RUBBER COMPOUND to the mating surfaces as specified in the Engine Manual or Repair Scheme. Use an injection tool or spatula.

Cure the CoMat 08-036 SILICONE RUBBER COMPOUND for 24 hours at 59 to 77 deg F (15 to 22 deg C), or 2 hours at 115 to 126 deg F (49 to 52 deg C), unless specified differently in the Engine Manual.

SUBTASK 70-36-02-360-054 Application and Cure of Cold Curing High Strength Silicone Rubber, CoMat 08-036

Mix the CoMat 08-142 POLYSULPHIDE COMPOUND polysulfide compound in accordance with manufacturers instructions.

Apply the CoMat 08-142 POLYSULPHIDE COMPOUND polysulfide compound by injection, and/or spread with a spatula or comb. Minimum application life is 2 hours at 77 deg F (25 deg C) and 50% Relative Humidity. The maximum tack free time is 36 hours at 77 deg F (25 deg C) and 50% Relative Humidity.

NOTE

Lower humidity and temperature will increase the cure time.Cure the adhesive for 48 hours at 77 deg F (25 deg C) and 50% Relative Humidity, or alternatively, for 8 hours at 122 to 149 deg F (50 to 65 deg C). Do not cure at a temperature greater than 149 deg F (65 deg C).

When cure times are accelerated by the application of heat, the temperature at the bond line must be monitored by thermocouples or another suitable method.

SUBTASK 70-36-02-360-055 Make up, Application and Cure of Two-Part Polysulfide, CoMat 08-142

CoMat 08-125 SEALANT, POLYSULPHIDE is a two-part dichromate cured polysulfide rubber compound, which contains quantities of soluble metal chromate(s) for added corrosion protection. The product may be supplied in two separate containers. The mixed compound is suitable for injection or spatula application. The mixed compound has an application life of 30 minutes at 77 deg F (25 deg C) and 50% Relative Humidity and a maximum tack free time of 10 hours at 77 deg F (25 deg C) and 50% Relative Humidity.

Apply the CoMat 08-125 SEALANT, POLYSULPHIDE to the surface by injection, and/or spread with a spatula or comb.

NOTE

Lower humidity and temperature will increase the cure time.

SUBTASK 70-36-02-360-056 Two-Part Brushable Polysulfide, CoMat 08-125

CoMat 08-141 SEALANT - TWO PART POLYSULPHIDE 2-part is a two-part manganese dioxide cured, corrosion inhibiting, polysulfide rubber compound. The product may be supplied as a Sem-kit, or in two separate containers. The mixed compound is suitable for injection or spatula application.

Apply the CoMat 08-141 SEALANT - TWO PART POLYSULPHIDE 2-part to the surface by injection, and/or spread with a spatula or comb. The application life is 30 minutes at 77 deg F (25 deg C) and 50% Relative Humidity, and the maximum tack free time is 16 hours at 77 deg F (25 deg C) and 50% Relative Humidity.

NOTE

Lower humidity and temperature will increase the cure time.Cure the CoMat 08-141 SEALANT - TWO PART POLYSULPHIDE 2-part for 30 hours at 77 deg F (25 deg C) and 50% Relative Humidity.

SUBTASK 70-36-02-360-057 Two-Part Polysulfide, CoMat 08-141

CoMat 08-146 POLYSULPHIDE SEALANT is a two-part dichromate cured polysulfide rubber compound, which contains quantities of soluble metal chromate(s) for added corrosion protection. The product may be supplied in two separate containers, in Sem-kit form, or as a pre-mixed, frozen product. The mixed compound is suitable for injection or spatula application.

Mix the CoMat 08-146 POLYSULPHIDE SEALANT in accordance with manufacturer's instructions.

Apply the CoMat 08-146 POLYSULPHIDE SEALANT to the surface by injection, and/or spread with a spatula or comb. The minimum application life is 2 hours at 77 deg F (25 deg C) and 50% Relative Humidity, and the maximum tack free time is 18 hours at 77 deg F (25 deg C) and 50% Relative Humidity.

NOTE

Lower humidity and temperature will increase the cure time.Cure the CoMat 08-146 POLYSULPHIDE SEALANT for 48 hours at 77 deg F (25 deg C) and 50% Relative Humidity.

SUBTASK 70-36-02-360-058 Make up, Application and Cure of Two-Part Polysulfide, CoMat 08-146

CoMat 04-002 JOINTING COMPOUND ALUM.HIGH TEMP is an aluminum filler compound used to fill the space between the blade roots and the high pressure compressor disc serrations.

Degrease the surface. Refer to SPM TASK 70-11-26-300-503.

SUBTASK 70-36-02-360-009 Aluminum - High Temperature Joining Compound, CoMat 04-002

CoMat 08-010 HEAT CURING FILM ADHESIVE with very high strength metal to metal and core to skin bonds. The film adhesive has a filled epoxy resin base and is always used with CoMat 08-011 PRIMER (a violet colored, single-component, resin solution). It can be used at temperatures up to 248 deg F (120 deg C). CoMat 08-010 HEAT CURING FILM ADHESIVE has a thickness of 0.009 inch (0.23 mm) and a weight of 305 g/m2. If cured at 338 to 356 deg F (170 to 180 deg C) the glue line thickness should be 0.002 to 0.004 inch (0.05 to 0.10 mm).

Apply a uniform layer of CoMat 08-011 PRIMER, by brush or spray, to a maximum thickness of 0.0004 inch (0.010 mm).

Dry the CoMat 08-011 PRIMER for 1 hour at 64 to 77 deg F (18 to 25 deg C). Alternatively, dry the CoMat 08-011 PRIMER at 149 to 167 deg F (65 to 75 deg C) for 20 minutes.

NOTE

A roller can be used to apply the film adhesive and remove the air bubbles. A warm air blower or an iron, at a maximum temperature of 140 deg F (60 deg C), can be used to hold the film adhesive in position. The polyethylene backing film can then be removed and the heat source applied through the release paper; but the heat source must not touch the polyethylene.Cut the CoMat 08-010 HEAT CURING FILM ADHESIVE to shape, before the protective covers are removed. Remove the release paper, then apply to the primed mating surfaces. Where joints in the film adhesive are necessary, make sure that the two parts touch.

Cure core to skin joints at 347 to 356 deg F (175 to 180 deg C) for one hour with a pressure as specified in Figure. Do not release the pressure until the glue-line temperature has reduced to 194 deg F (90 deg C).

Cure the CoMat 08-010 HEAT CURING FILM ADHESIVE.

SUBTASK 70-36-02-360-019 Apply and Cure the Heat Curing Film Adhesive, CoMat 08-010

CoMat 08-012 COLD CURING SILICONE COMPOUND and CoMat 08-013 COLD CURING SILICONE COMPOUND silicone rubber compounds are used to bond metal to metal and metal to composite materials. They can also be used to fill and seal these materials. They are white pastes and cure after exposure to moist air. They can be used in air at continuous temperatures of up to 482 deg F (250 deg C). They can also be used for a maximum temperature of 572 deg F (300 deg C) but for a short time only. CoMat 08-012 COLD CURING SILICONE COMPOUND flows freely while CoMat 08-013 COLD CURING SILICONE COMPOUND is a thixotropic compound.

For best adhesion, use primer that is from the same manufacturer as the silicone rubber compound. Refer to Table 4.

Table 4. Primer/Manufacturer Cross Reference Silicone Rubber Compound

Primer

CoMat 08-014A PRIMER, SILICONE ADHESIVE/SEALANT, for plastics and rubber, CoMat 08-014B PRIMER, SILICONE ADHESIVE/SEALANT, for metals, CoMat 08-014C PRIMER, SILICONE ADHESIVE/SEALANT, for all materials

Apply a thin layer of CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT or CoMat 08-032 PRIMER to the prepared surfaces. Apply and cure primer in accordance with the manufacturer's instructions.

Apply the CoMat 08-012 COLD CURING SILICONE COMPOUND or CoMat 08-013 COLD CURING SILICONE COMPOUND, as specified in the Engine Manual, to each of the mating surfaces from the tube with an applicator nozzle. Use a corrugated scraper, or other tool, to spread the compound to the necessary thickness.

SUBTASK 70-36-02-360-020 Apply and Cure the Cold Curing Silicone Rubber Compounds, CoMat 08-012 and CoMat 08-013

NOTE

It is permitted to ignore the step to apply primer if permitted in the applicable Engine Manual procedure. The primer must be applied immediately after the mating surfaces are prepared. If the parts are not used immediately they must be kept in polyethylene bags but for a maximum of 24 hours only.When CoMat 08-018 ADHESIVE is specified, refer to Step.

SUBTASK 70-36-02-360-023 Apply and Cure the Heat Curing Structural Adhesive, CoMat 08-018

This subtask is deleted, refer to Step.

SUBTASK 70-36-02-360-024 Apply and Cure the Supported Embossed Liner Film Adhesive, CoMat 08-019

CoMat 08-022 HEAT CURING FOAMING ADHESIVE is used to bond honeycomb core material parts together, or to bonded sandwich panels. It can be used at temperatures up to 248 deg F (120 deg C). Before it is cured the adhesive has a thickness of 0.050 to 0.080 inch (1.27 to 2.03 mm).

SUBTASK 70-36-02-360-027 Apply and Cure the Foaming Film Adhesive, CoMat 08-022

CoMat 08-104 EPOXY PASTE ADHESIVE is a two-part epoxy resin base general purpose adhesive for use at operating temperature up to 248 deg F (120 deg C). It can also be used as a liquid shim.

Refer to Step for the mixing of epoxy resins.

Make up.

Cure the adhesive for 48 hours at ambient temperature.

Alternatively, cure the adhesive at 194 to 203 deg F (90 to 95 deg C) for 1 hour. The temperature to be increased (ramped-up) at not more than 5 deg F (3 deg C) per minute. The temperature at the bond line must be monitored by thermocouples or other suitable methods when cure times are accelerated by the application of heat.

Application and Cure.

NOTE

Better results will be obtained with a thin layer of adhesive but satisfactory results are still obtained with applications up to 0.04 inch (1.02 mm).

SUBTASK 70-36-02-360-059 Make up, Application and Cure of Epoxy Paste Adhesive, CoMat 08-104

Figure: Recommended maximum bonding pressures

Recommended maximum bonding pressures