DMC:V2500-00-70-43-02-00A-720A-D|Issue No:001.00|Issue Date:2013-03-20

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991:

SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.

Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021)

The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).

Common Information

TASK 70-43-02-400-501 Installation Of Open Wire Harnesses

Safety Precautions

General

The procedures that follow give the correct standards, necessary to install and complete the open wire electrical harnesses; on modules and engines.

Remove the harness from its container and put on a flat surface. Remove all the bends and folds, you can see.

Put the harness on the module or engine. Make sure you keep the approximate position of the breakouts, when available, as a guide; with the minimum of twist.

Find the datum mark positions on the harness, then set these positions on the module or engine, as specified in the Engine Manual. When necessary, attach the specified clips to the correct positions.

Put all other general clips at the necessary support positions.

Remove all identification sleeves that are damaged, or cannot be read, but make sure not to damage the harness wires; when the sleeves are removed.

NOTE

To identify the consumable materials, refer to the PCI.

NOTE

Make a note of the numbers, before the damaged sleeves are removed.

Preliminary Requirements

Pre-Conditions

NONEConsumables, Materials and Expendables

Spares

NONESafety Requirements

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.

Procedure

SUBTASK 70-43-02-400-001 Connectors

NOTE

This data does not apply to vendor accessory mounted receptacles.

Unless specified differently all square flange mounted receptacles must be installed with the main polarizing keyway forward on horizontal surfaces, and up on vertical surfaces.

All harness connectors must be visually examined to make sure they are clean, and have no pin or contact damage, before they are connected to their related receptacles.

NOTE

This condition can be examined if you try to carefully shake and tighten the connector body at the same time.

When engaged with their related receptacles, the coupling nuts of all connectors must be continuously tightened by hand; until the visual indicator color bands can not be seen and the coupling nuts are fully tightened.

NOTE

Because of the different standards of connector specification, used on the engine, it will be necessary to obey the recommended torque values, for the related shell dimensions, from the connector specifications.

To make sure the connectors are fully tightened, and/or where access to the connectors is not easy, soft jaw pliers or a mini strap wrench can be used.

The ratchet-type lock mechanism, on all connectors and back-clamps, must operate correctly; which will be felt when they are tightened.

Connectors, shells and back-clamps which are wire locked, must be locked together - (Refer to the SPM TASK 70-42-05-400-501).

SUBTASK 70-43-02-400-002 Terminal Junction Block Contacts

All contacts must be correctly and fully attached, to their related locations.

All contact locations that are not used, must have the correct blanks installed.

SUBTASK 70-43-02-400-003 Terminal Lugs

Before the wires are connected, to the terminal lugs, visually examine all connection points and terminal lugs for damage.

Make sure that the surfaces of all electrical ground points are prepared, as specified in the related specification.

Terminals must not be bent, unless specified differently.

SUBTASK 70-43-02-400-004 Clip Data

All clips must hold the harness bundles, to make sure they cannot move through the clips.

Always make sure that the wires and clip protection materials are not caught, when the clips are closed.

Also, the clips must not hold the bundles too tightly; to cause damage to the clips or bundles.

When two or more harness bundles go through the same clip the bundles must be parallel to each other, through the clip, to form one harness bundle.

NOTE

Only clips from the same part number range must be specified and used.

Because of known differences, in the outer diameters of the harness bundles, the specified clips will possibly be too large or too small. It is thus permitted to use clips three steps above or below the usual dimension. This procedure only applies to open wire and closed electrical harnesses.

Where the bundle dimension is between the specified clip steps, the larger clip must be used. The bundle diameter can then be increased with tape.

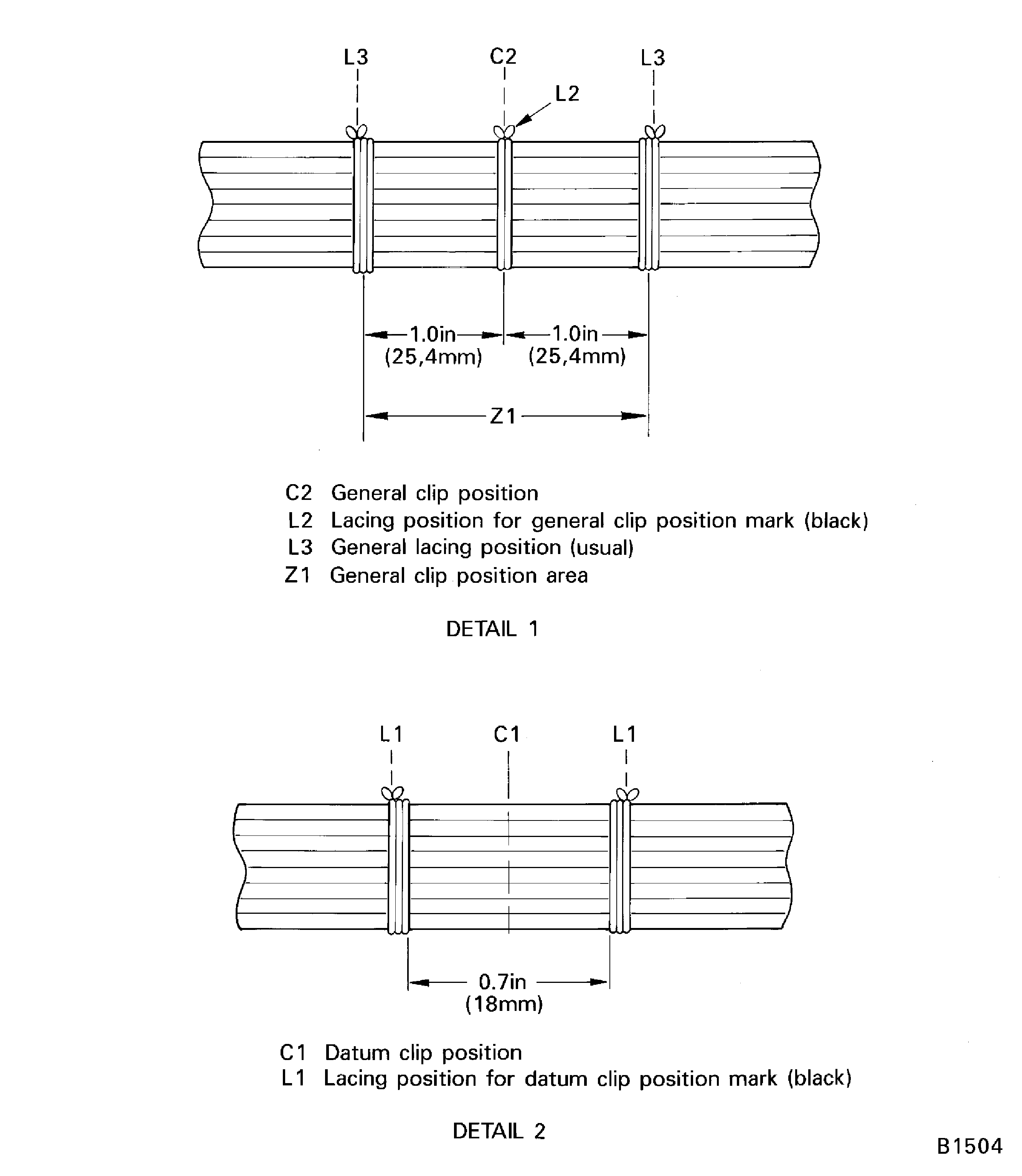

At general locations, the clip must not be installed above the clip center line tie mark; if available. It must be installed at the correct side of the tie mark, in the limits of the clip area - (Refer to Figure, Detail-1).

SUBTASK 70-43-02-400-005 Harness Routing and Clearances

The data that follows gives the minimum clearances necessary, between the harnesses and adjacent parts, when the engine is assembled. The minimum clearance necessary, during light thumb pressure, is specified as: Sufficient pressure to tighten the harness, without movement through the adjacent clips.

The harness bundles must follow, as near as possible, the specified routing; to keep an angle of 90 degrees with the clip.

Where adjustment is necessary, to keep the minimum clearance necessary, the clips must be loosened, to tighten the harness, then the clips must be tightened again.

To get better clearances and routing it is permitted to turn the clips, by plus or minus 10 degrees from their specified locations, if the minimum clearance is kept and no more force is put on the harness bundles, clip protection materials, or connector terminals.

SUBTASK 70-43-02-400-006 Minimum Clearances Necessary When Assembled

The minimum clearance between a harness and adjacent sharp edges, movable parts, or equipment that transmit flammable fluids is 0.25in. (6.4 mm).

The minimum clearance between a harness and other adjacent parts is 0.10 in. (2.6 mm).

NOTE

All other clearances, between harnesses and specified parts, are given in the Engine Manual.

The minimum clearance between a harness area, with rub protection, and other adjacent parts is also 0.10 in. (2.6 mm).

Maximum condition clearances must be available for harnesses near high temperature ducts, which give off heat.

Where harnesses are attached to support trays or brackets, with clips, the harness bundle can touch the support smooth surface, if the harness is sufficiently held; to prevent related movement between the harness bundle and the support.

Cables or wires which connect to equipment, that transmit flammable fluids or gasses, must have routings away from the equipment connections and pipes; unless specified differently.

Harness bundles, cables or single wires, must not be attached to, or held by, equipment or pipes that transmit fuel; unless specified differently.

SUBTASK 70-43-02-400-007 Control of Tension in Wire Bundles

The harness must not be too loose, when installed, and must obey the instructions that follow:

Unless specified differently, the harness must be sufficiently loose to install and remove the connectors or terminal lugs; without the interference of adjacent harness clips.

If a connector/receptacle, pin/socket, or terminal lug is damaged the harness must be sufficiently loose to permit the procedure that follows:

One more connection at connector positions - 0.25in. (6.35 mm) approximate tension.

Two more connections at terminal lug positions - 0.40in. (10.16 mm) approximate tension.

If the harness bundle is too loose it must, if possible, be absorbed between the clip positions before it.

NOTE

The minimum clearance is more important than that specified in Step (2) above.

The above instruction must keep the minimum clearances specified in Step.

NOTE

Harness bundles must not be made shorter and connector/receptacle, or terminal lugs, must not be connected again.

If all the above instructions are obeyed and the harness bundle is too loose, when examined again, the procedures that follow must also be obeyed.

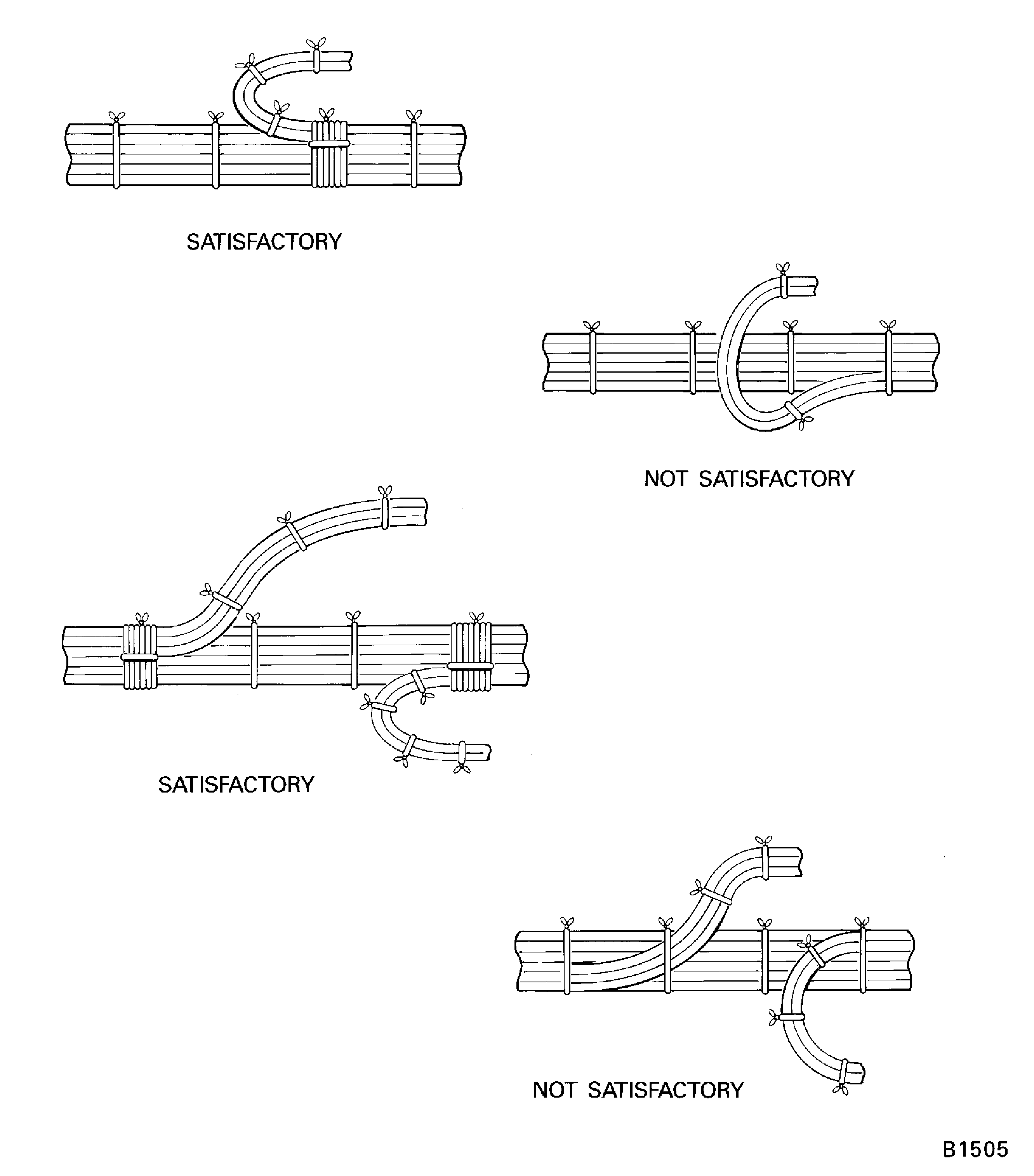

SUBTASK 70-43-02-400-008 Wire Bundle Breakouts

All wire bundle breakouts must make smooth curves, from their primary bundle, and go to the parts to which they will be connected; or attached to with clips.

To prevent too much force on the breakout tie, the bundle breakout must be in the same plane as the primary bundle. If this is not correct, during the harness installation, the primary bundle must be locally twisted; to get the necessary position.

The bundle breakout must not touch other wires or parts, after its exit from the primary bundle.

If the bundle breakout and primary bundle do touch, the bundle breakout must be attached to the primary bundle; to prevent movement, between the two bundles, at the points where they touch.

SUBTASK 70-43-02-400-009 Parallel and Across Bundles

When harnesses are parallel to, or go across, each other, near a contact exit, they must be attached together; to prevent movement in relation to each other.

NOTE

The bundles must not be forced together and, before they are attached together, apply a light thumb pressure; to make sure they are free to touch each other.

When necessary, release the harnesses from each other. Loosen the adjacent clips, adjust the harnesses, then tighten the clips again.

SUBTASK 70-43-02-400-010 Bird Caging

Bird Caging is the separation of bundle wires, between general tie positions on the harness, which can cause bulges and gaps in the bundle.

If, during harness installation because of the routing and position of the harness, bulges and gaps are found, in the harness bundle between ties which are more than the average wire diameter, a tie must be made at that point.

Where the above occurs on a radius bundle, it can be removed by local twists or ties.

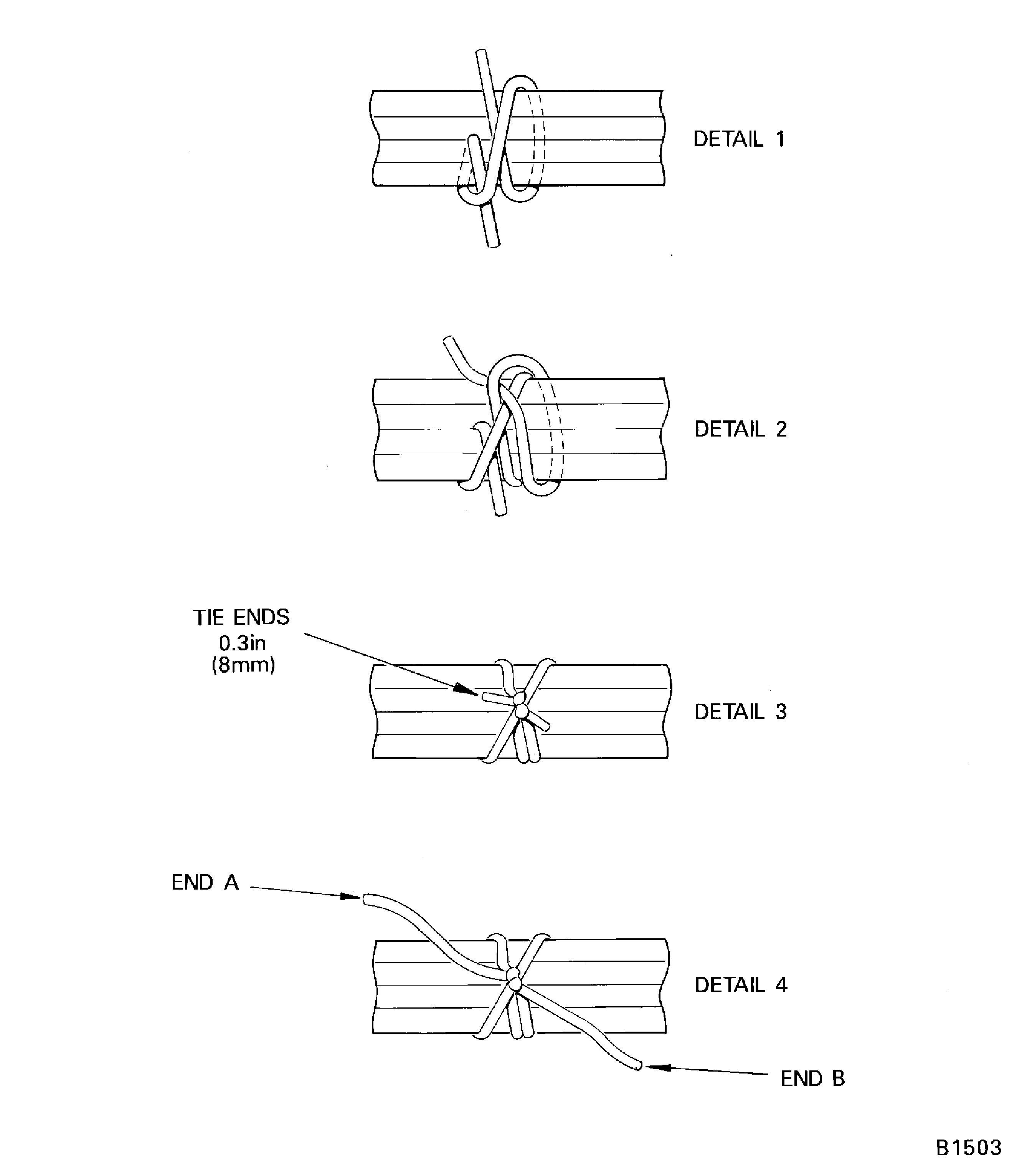

SUBTASK 70-43-02-400-011 Tying Instructions

All cables and wires must be made into correct bundles, then attached together with ties. Also, no insulation, cable or wire must be damaged or stressed; by ties that are too tight.

All tied knots must be cut, to keep 0.30 in. (8 mm) ends, unless specified differently.

SUBTASK 70-43-02-400-012 Bend Radii

General recommended bend radii:

10 x wire/bundle outer diameter, unless specified differently.

Sharp bends must be prevented in single and multiplied wire cables at clips, connector backshells, and where cables stop at terminal lugs.

Make sure that all changes, in the direction of harness routing, use the largest bend radius possible.

SUBTASK 70-43-02-400-013 Harness Installation

Make sure that the J-blades are not bent, by too much force, when the harness is assembled to the tube J-blade supports.

Bent J-blades can decrease the harness minimum clearances.

SUBTASK 70-43-02-400-014 Visual Inspection

The completed harness installation must be visually examined and must have no damage, such as: cuts, cracks, worn wires and damaged or loose harness ties.

All part number and/or identification marks must have no damage and be easy to read.

All damaged part number and/or identification sleeves must be replaced.

All damaged or loose ties found on the harness, during or after assembly, must be replaced; with new ties and in the same locations.

Make sure that all connectors and terminal lugs are installed, in their correct locations, and are fully attached.

Make sure that all wire locked connectors, shells and back clamps, are fully safetied. If necessary, replace the lockwire - (Refer to the SPM TASK 70-42-05-400-501).

Examine all areas for broken pieces and unwanted materials, which must be removed.

SUBTASK 70-43-02-400-015 Open Wire Harness Installation

General harness bundle lacing ties, refer to Figure.

Use the largest bundle of cables, where possible. Put the lacing through the center of the bundle and make a clove hitch - (Refer to Detail-1).

Make one more half hitch - (Refer to Detail-2).

Pull the two ends of the lacing tight and safety with a reef knot - (Refer to Detail-3).

The lacing ties must not be more than 2.00 in. (50 mm) apart.

General clip position mark lacing ties, refer to Figure, Detail-1.

Datum clip position mark lacing ties, refer to Figure, Detail-2.

Parallel and cross bundle lacing ties, refer to Step G.

Harness junction wire bundle breakout lacing ties, refer to Figure.

All wire bundle breakouts must be in the same plane, as the bundle center line, and be in the same direction as the breakout.

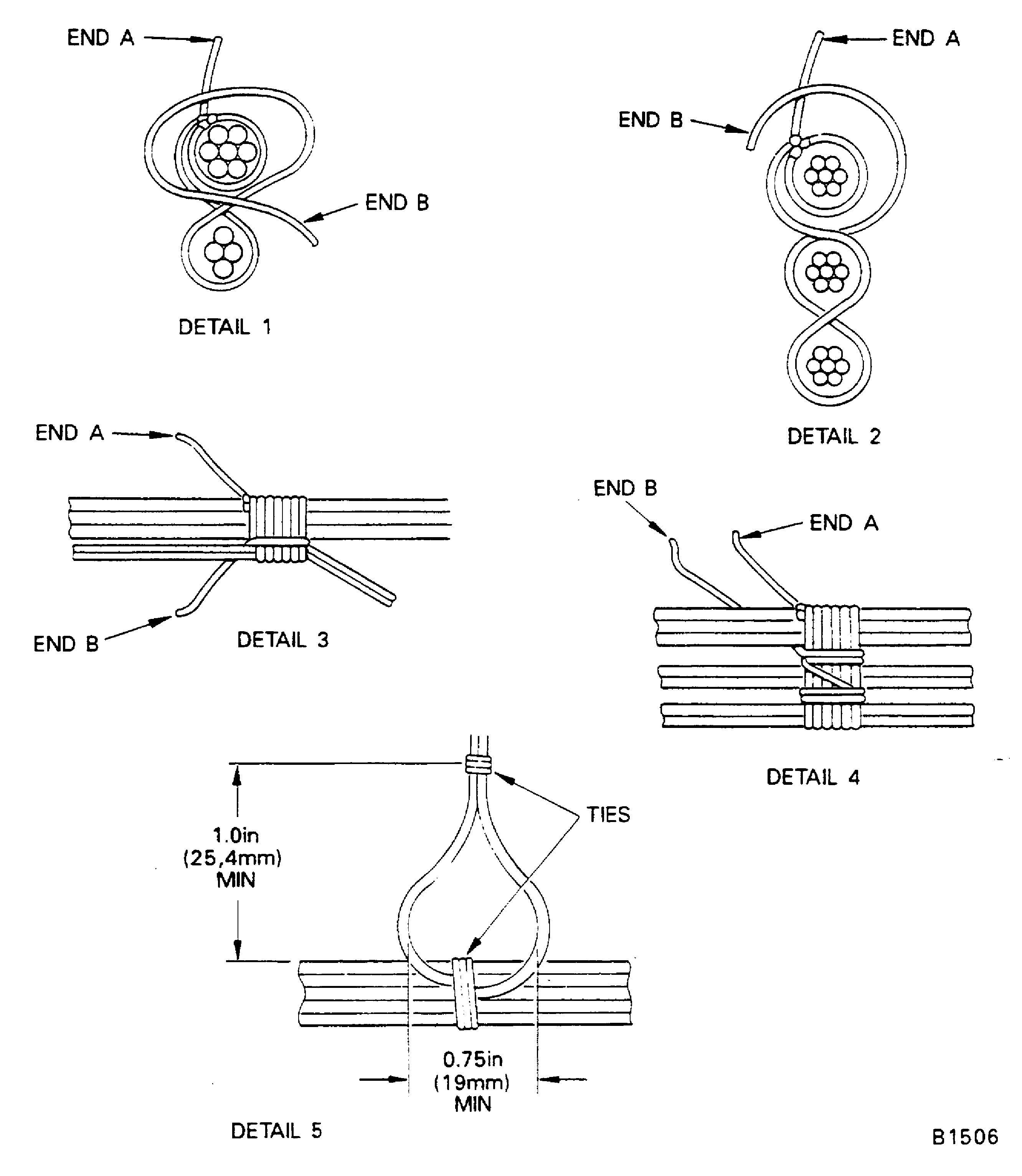

Harness junction wire bundle breakout lacing ties, refer to Figure.

At junctions use the largest bundle of cables, where possible. Put the lacing through the center of the bundle and make a clove hitch - (Refer to Detail-1).

Make one more half hitch - (Refer to Detail-2).

Pull the two ends of the lacing tight and safety with a reef knot - (Refer to Detail-3).

Make sure that there is sufficient lacing at end A to make one more reef knot; when junction lacing is completed - (Refer to Detail-3).

Harness breakout two-bundle lacing ties, refer to Figure.

Put end B between the primary and secondary bundles. Make a turn around the secondary bundle, then put the end between the primary and secondary bundles again. Pull tight, to make a figure-of-eight whip - (Refer to Detail-1).

Make a figure-of-eight and a double figure-of-eight, six times. Pull tight each time.

Move the lacing, across the six completed whippings, to the start point; then put the end between the primary and secondary bundles - (Refer to Detail-3).

Move the lacing back, across the six completed whippings, to the opposite side. Put the end between the primary and secondary bundles: then pull tight and make a frapping lashing.

Do this procedure again, until two more lashings are made. Move the lacing across the whipping, to the start point, for the last time. Pull tight, then tie the ends in a reef knot. Cut-off the unwanted lacing, to make minimum tail lengths of 0.30 in. (8 mm), at the knot. Apply CoMat 07-084 SILICONE VARNISH, to the knot.

Harness breakout three-bundle lacing ties, refer to Figure.

Put end B between two adjacent bundles, then around and between the other adjacent bundle. Make a turn, around this bundle, then go between the bundles. Pull tight, to make a double figure-of-eight - (Refer to Detail-2).

Make a figure-of-eight and a double figure-of-eight, six times. Pull tight each time.

Move the lacing, across the six completed whippings, to the start point; then put the end between the primary and secondary bundles - (Refer to Detail-4).

Move the lacing back, across the six completed whippings, to the opposite side. Put the end between the primary and secondary bundles, then pull tight, to make a frapping lashing.

Do this procedure again, until two more lashings are made. Move the lacing across the whipping, to the start point, for the last time. Pull tight, then tie the ends in a reef knot. Cut-off the unwanted lacing, to make minimum tail lengths of 0.30 in. (8 mm), at the knot. Apply CoMat 07-084 SILICONE VARNISH, to the knot.

NOTE

Applicable for a maximum of two wires, each side of tie.

Harness breakout two-end lacing ties, refer to Figure, Detail-5.

Requirements After Job Completion

Follow-On Conditions

NONE