Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-46-03-400-501 Installation Of Rigid Tubes

General

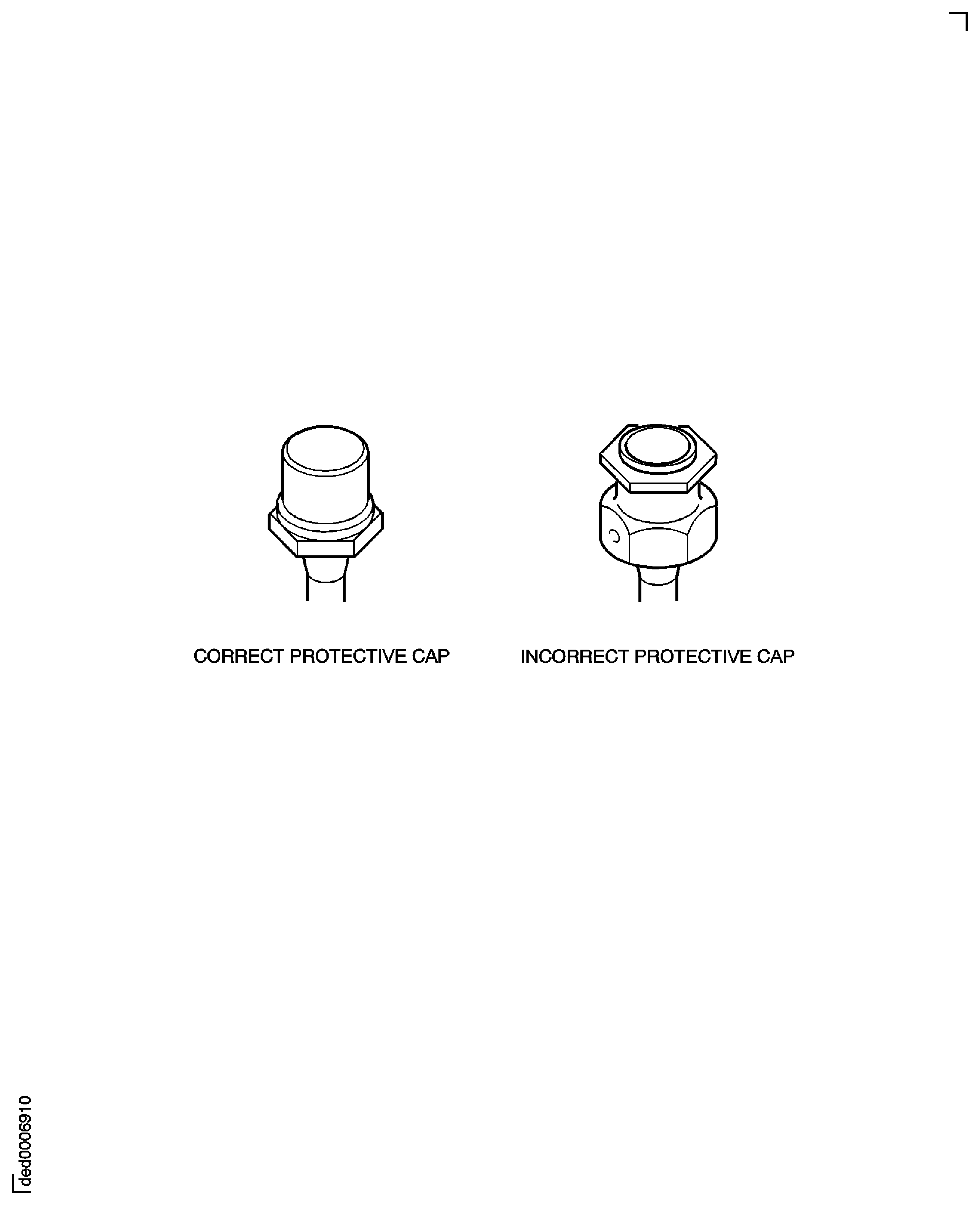

Use protective caps or other applicable material to prevent contamination of the inside of the tube and to prevent damage to the tube connectors.

Protective caps must be installed on the outside of the tube connectors. Refer to Figure for an example of the correct type of protective cap.

The protective caps must only be removed only when the tube is to have maintenance work done on it, or immediately before installation.

Before the tube is installed make sure that it is clean and has no damage.

Refer to the SPM TASK 70-41-00-400-501 for information on general torque tightening techniques and SPM TASK 70-41-01-400-501 for guidance on the use of torque wrenches and power tools.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

CAUTION

DO NOT APPLY FORCE THAT CAN TWIST OR BEND THE TUBE WHILE YOU INSTALL IT. THIS WILL PREVENT DAMAGE TO THE TUBE AND ENGINE COMPONENTS.Install the retaining bolts. The flange clearance holes must align with the tappings in the engine or component. If they do not, investigate and reject the tube if necessary.

Installation of Bolted Flanges.

CAUTION

DO NOT APPLY FORCE THAT CAN TWIST OR BEND THE TUBE WHILE YOU INSTALL IT. THIS WILL PREVENT DAMAGE TO THE TUBE AND ENGINE COMPONENTS.Engage the ferrule at the other end of the tube in its conical seat. If necessary adjust the tube by hand to align it, engage the nut onto its mating thread and tighten it with your fingers. Make sure that the tube is square to the rear of the nut.

Installation of tubes with single nut conical sealing joints.

SUBTASK 70-46-03-440-001 Installation of Tubes

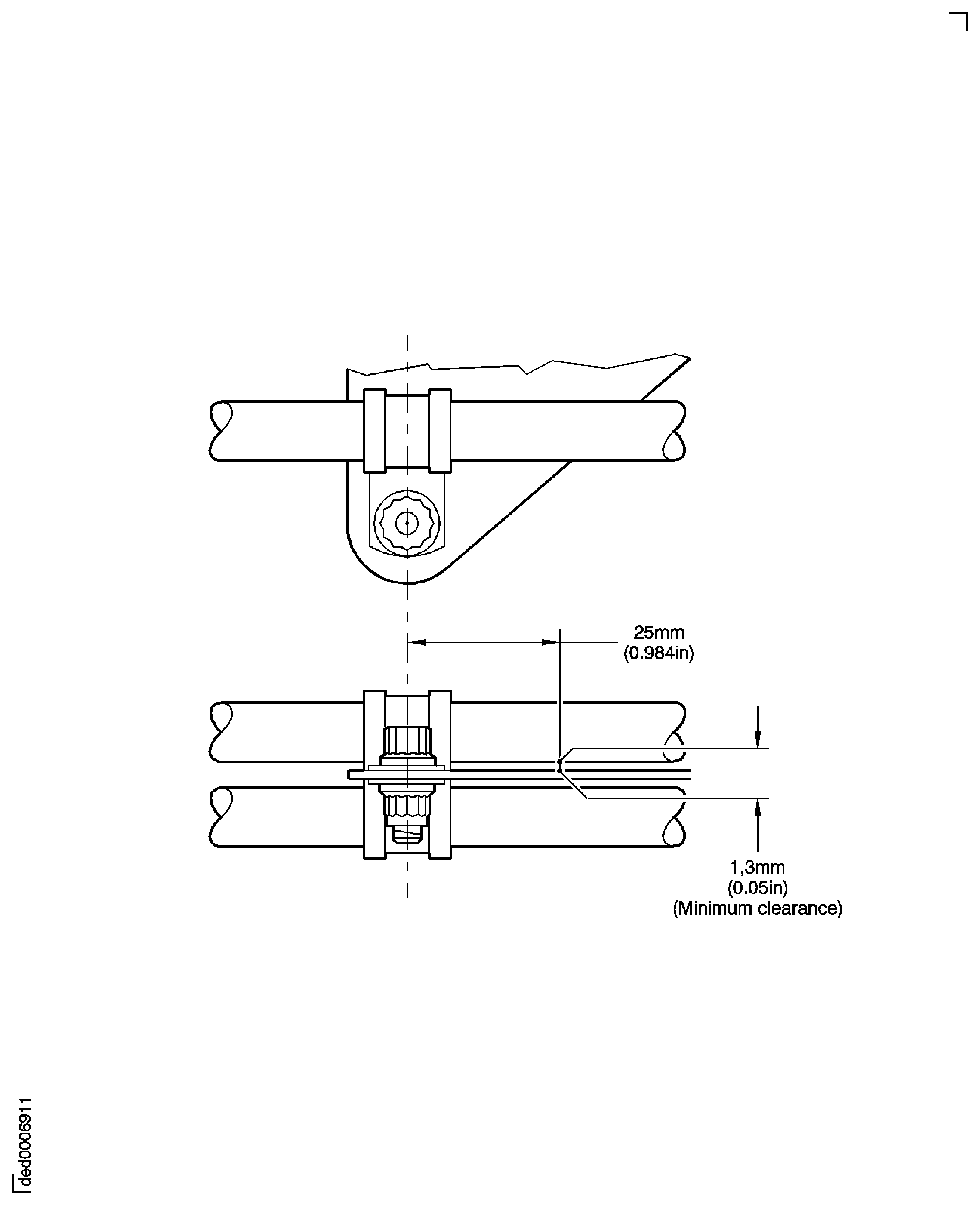

Refer to Figure.

SUBTASK 70-46-03-440-002 Check the Tube Clearance

Figure: Fig 70-46-03-990-001

Fig 70-46-03-990-001

Figure: Fig 70-46-03-990-002

Fig 70-46-03-990-002