Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-47-01-470-501 Fitting V-band Clamps

Effectivity

This procedure only applies to V-band clamps with the part numbers that follow:

6299242 - 0250

6299256 - 0400

6299257 - 0200

6299257 - 0250

6299258 - 0350

6299258 - 0400

General

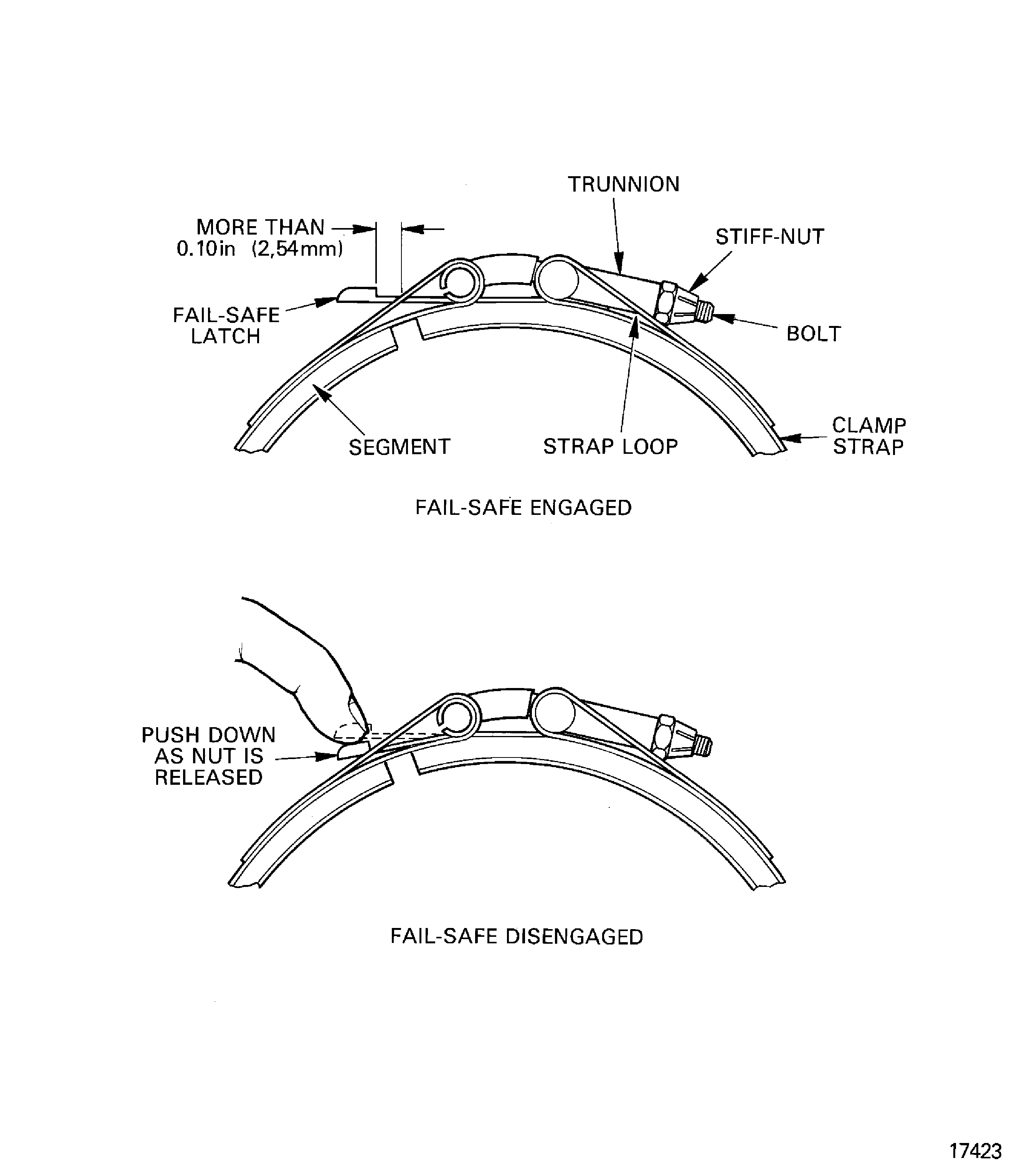

The clamps are made of three segments, each with an internal V-shape, which engage with and hold together the two mating flanges. The segments are each attached to a clamp strap, with spot welds. The clamp strap has two fork and loop-shape ends; one of which holds a trunnion assembly and the other a T-bolt assembly. A "Fail-safe" latch is located below the loop-shape ends; which is a single piece tongue, spot-welded to the clamp strap. A stiff-nut is used, together with the T-bolt assembly, to hold the clamp around the flanges.

The clamp is a quick-release device, used to attach the engine bleed air system ducts together.

Special Tools

No special tools are necessary, to install or remove the V-band clamps.

Illustrated Parts List - (IPL)

No Illustrated Parts List is supplied, for this procedure.

The only spare part necessary is one stiff-nut - (Part number 57979-4), for each V-band clamp.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

CAUTION

Procedure

Before you install the clamp, make sure that the segment and flange mating surfaces are clean and are not damaged. Lubricate the T-bolt, with a drop of engine oil.

Make sure that the mating flange faces are correctly aligned and that the position of the clamp, on the flanges, is correct.

Tighten the clamps to approximately 70 percent of their maximum tightness torque - (Refer to step 6).

If necessary, lightly hit the outer surface of the clamp, with a soft face mallet, to equally apply the band or segment tension.

Tighten the clamp stiff-nut, to the nominal torque - (Refer to step 6), with an approved and calibrated torque wrench. Make sure that the "Fail-safe" latch is correctly engaged, with the strap loop - (Refer to Figure).

Loosen the nut and make sure that the clamp is correctly attached. If the "Fail-safe" is correctly engaged, the clamp will be tight. Tighten the nut again, to the nominal torque, but do not change the position of the clamp.

The recommended procedure to release the "Fail-safe", when the clamp is to be removed, is to push the "Fail-safe" latch; to the center of the duct, when the nut is loosened - (Refer to Figure).

Installation and Removal Instructions

Life: To be in relation to the engine.

Installed check: Examine visually for tightness, cracks and defects.

The stiff-nuts can be used again, if they have the minimum torque value, after which they must be replaced. The minimum torque for a stiff-nut, with a 0.250 - 28 thread, is approximately 3.0 lbf-in (0.4 N.m). If the nut can be turned by hand, it must be replaced.

Each time the clamp is removed, make a full visual inspection; for cracks or defects. Clean the thread of the bolt and examine for too much wear.

If necessary, apply the Aeroquip Production Test Schedule - (PT207).

Servicing

Clean the V-band clamp refer to the SPM TASK 70-11-26-300-503. Remove all carbon particles, stains and color changes, with a brush. Fully flush with water, then dry with hot air.

Lubricate the bolt threads and trunnion faces, with engine oil, before they are assembled again.

Cleaning

Part number 6299242 - 0250 has a torque range of 45 to 55 lbf-in (5.1 to 6.2 N.m), with a nominal value of 50 lbf-in (5.7 N.m).

Part number 6299256 - 0400 has a torque range of 75 to 85 lbf-in (8.5 to 9.6 N.m), with a nominal value of 80 lbf-in (9.0 N.m).

Part number 6299257 - 0200 has a torque range of 45 to 55 lbf-in (5.1 to 6.2 N.m), with a nominal value of 50 lbf-in (5.7 N.m).

Part number 6299257 - 0250 has a torque range of 45 to 55 lbf-in (5.1 to 6.2 N.m), with a nominal value of 50 lbf-in (5.7 N.m).

Part number 6299258 - 0350 has a torque range of 75 to 85 lbf-in (8.5 to 9.6 N.m), with a nominal value of 80 lbf-in (9.0 N.m).

Part number 6299258 - 0400 has a torque range of 75 to 85 lbf-in (8.5 to 9.6 N.m), with a nominal value of 80 lbf-in (9.0 N.m).

Torque Values

Figure: Details of V-band clamps

Details of V-band clamps