Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-72-00-720-501 Airflow - General Information

Safety Precautions

General

Inspection of some engine parts for example, turbine cooling air ducts, air cooled turbine vanes, and air cooled turbine blades can be necessary for measurement of airflow properties. To find out if the parts agree to airflow limits, they are attached on a test stand where airflow properties can be measured.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

WARNING

Procedure

A sonic nozzle test stand.

Correlation Master Tools to calibrate the test stand.

Airflow test fixtures to adapt engine parts to the test stand.

Leak test tools to do checks for air leakage before airflow testing engine parts.

This section gives information about the equipment that is necessary to do airflow tests of engine parts. The necessary equipment are:

General

A sequence of glass tube flowmeters measures the flow of air. In general, this type of test stand is applicable only for the low volume of air used to do airflow tests of turbine blades and vanes, not for the high volume necessary to do airflow tests of turbine cooling air ducts. This type of test stand is not recommended.

Glass Tube Flowmeter Type

A sharp edged, non-adjustable orifice measures airflow. Velocity of air through the orifice is always sub-sonic. To calculate the mass or weight of airflow through the orifice, it is necessary to find the difference between pressures measured immediately upstream and immediately downstream of the orifice, the orifice area, and several other factors. The exponential relation between the weight of air and the pressure difference across the orifice makes the mathematics of the airflow calculations complex. This type of test stand is not recommended.

Orifice Type

A sonic nozzle (critical flow venturi) measures airflow. Subsequent procedures give full data on assembly and use of this type test stand. Only the sonic nozzle test stand gives all of the necessary properties of stability, durability, and easiest flow calculations. It is the only type of test stand recommended by IAE.

Sonic Nozzle Type

There are three types of airflow test stands:

Because of the accuracy that is necessary in airflow testing, it is necessary that the test stand be calibrated to find its accuracy of measurement as compared to the IAE master test stand. Calibration is done by using correlation master tools.

Correlation master tools are new engine parts, or special tools designed to copy engine parts, which have been calibrated on the IAE master test stand, and whose airflow properties have been recorded on a calibration curve and supporting data.

The operator can compare his test stand to the IAE master test stand by doing the same airflow test which was done at IAE when the master tool was calibrated.

More data on master tools is available in SPM TASK 70-72-02-720-501 Airflow Testing- Equipment.

Master Tools for Test Stand Calibration

Tool numbers and instructions of use of airflow test fixtures necessary to adapt engine parts to test stand are supplied in the Inspection procedures of the Engine manual which refers to airflow testing of the specified engine part.

Airflow test fixtures

Leak test tools are engine parts in which the air exit holes, normally open during airflow test, have been permanently sealed closed.

Since the air exit holes have been sealed closed with a leak test tool attached in the airflow test fixture (alternative of an engine part), there must be zero airflow. If airflow is there, then it is air leakage, whose source must be found and corrected before airflow testing of engine parts can be started.

More data on leak test tools is given in SPM TASK 70-72-02-720-501 Airflow Testing- Equipment.

Leak test tools

Equipment Necessary for Airflow Testing

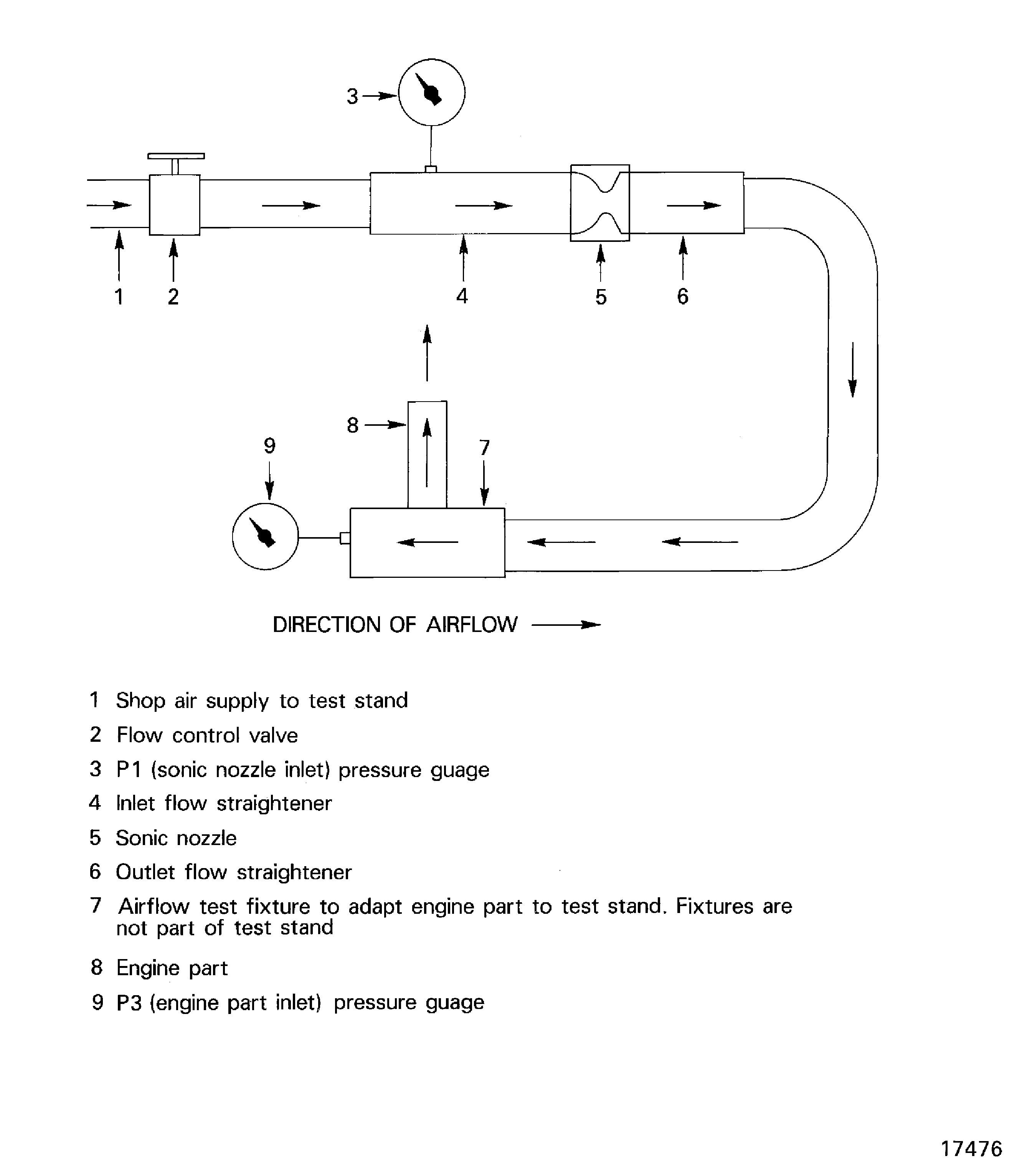

Figure is a simplified diagram which shows the primary components of a sonic nozzle test stand.

Valves, Index 2, gives means to control the flow (weight) of air entering the test stand. As valve opening is increased, the increased weight of air increases pressure throughout the system.

The inlet flow straightener, Index 4, is necessary to reduce turbulence and increase accuracy of nozzle inlet pressure. A plain metal tube does the job but, the flow straightener can have vanes or screens.

The outlet flow straightener, Index 6, is necessary to give controlled and constant expansion downstream of the sonic nozzle. A plain metal tube, without vanes or screen, is sufficient.

The fixtures also gives a plenum immediately upstream of the engine part inlet where engine part inlet (P3) pressure is kept.

Airflow test fixtures are used with test stand but are not part of the test stand. Different fixtures, each identified by a tool number, are given for each type of engine part.

Airflow test fixtures, Index 7, gives means to manually hold the engine part and hold it so that test stand air is pointed into the engine part inlet.

NOTE

Because of the short distance from the sonic nozzle to the airflow test fixture and to the large IDs in the air line or hose, it is taken that there is almost no pressure (line) loss and thus pressure measured at the plenum in the airflow test fixture is taken to be the pressure both inside the engine part and at the sonic nozzle outlet.In all systems of this type, the cross sectional area at the sonic nozzle throat must be smaller than the areas of all the air exit holes in the engine put together, i.e., the sonic nozzle must be the component which meters or controls flow.

This "sonic" condition occurs when the pressure ratio, nozzle inlet to nozzle throat, is more than 1.9, which will occur when the pressure ratio across the nozzle (P1/P3) is equal to or more than 2.0.

In some circumstances, "sonic" conditions can occur at a P1/P3 ratio that is less then 2.0.

Some nozzle attributes that contribute to a "sonic" condition at the throat at a P1/P3 ratio below 2.0 are a smooth transition from nozzle inlet to throat to exit, a very short throat section, and minimal manufacture tool marks on the inlet.

A P1/P3 ratio as low as 1.5 can be permitted if the internal condition of the nozzle is correct for this ratio.

NOTE

Sonic nozzles are calibrated in the system where air velocity at the nozzle throat is Mach 1.0 (nozzle choked) and where the relation between nozzle inlet pressure and weight of air flowing through the nozzle is linear. The linear relation is specified as the "K" factor for that specific nozzle. Each nozzle has its own "K" factor.

Critical Flow Nozzle - For correct operation, it is necessary that you use critical flow nozzles only when the gas velocity at the nozzle throat is equal to the speed of sound.

As opening of valve, Index 2, is increased, shop air pressure upstream of the valve moves an increasing weight of air through the system. Pressure and velocity of air in the system increase to a point where total pressure at the nozzle inlet, measured by P1 pressure gage, Index 3, is 1.89 times the total pressure at the nozzle outlet, measured by P3 pressure gage, Index 9. At this point, when the pressure ratio across the nozzle gets to 1.89, air velocity at the nozzle throat gets to Mach 1.0 (sonic velocity, nozzle chokes).

More opening of the valve increases nozzle inlet (P1) pressure and an increased weight of air is moved through the nozzle; but, in the system from nozzle inlet (P1) pressure, at which the nozzle chokes, on up to a nozzle inlet pressure of several hundred PSI (far more than the function of the average shop air supply), air velocity at nozzle throat stays at Mach 1.0 (nozzle choked). The relation between nozzle inlet pressure and weight of air flowing through the nozzle stays linear.

The sonic nozzle, Index 5, measures weight or mass of air flowing through the system.

An engine part, Index 8, which is necessary for airflow testing must be attached on the airflow test fixture, Index 7.

Operation of a Sonic Nozzle Test Stand

Pressure Ratio (PR) Procedure.

Flow Parameter (FP) Procedure.

The two procedures for testing airflow of engine parts, to calibrate master tools and to calibrate sonic nozzle test stands are:

If air exit holes in an engine part are too large, the pressure inside the engine part is lower than the minimum permitted limit. But, if the engine part air exit holes are too small, the pressure inside the engine part will be higher than the maximum permitted limit.

In the Pressure Ratio Procedure of testing, the test stand is used to give a specific flow (weight or mass) of air, shown by setting the P1 pressure gage to a given value. An engine part is accepted if the resulting pressure, shown by the P3 pressure gage, is in limits.

If air exit holes in an engine part are too large, flow (weight or mass) of air, will be higher than the maximum permitted limit. But, if the engine part exit holes are too small, the flow will be lower than the minimum acceptable limit.

In the Flow Parameter Procedure of testing, the test stand is used to give a specific pressure in the engine part, shown by the P3 pressure gage. An engine part is accepted, if the resulting flow (weight or mass) of air flowing through the engine part, shown by the P1 pressure gage, is in limits.

For all airflow test procedures, the weight or mass of air flowing through the engine part is always shown by P1 (sonic nozzle inlet) pressure gage and pressure inside the engine part is always shown by P3 (engine part inlet) pressure gage.

Air leakage at this interface shows up, in the airflow test results, as air which through the engine part. Thus, engine parts of which the true airflow is to the high side of the limit can be rejected for too much airflow when leakage is added to the true engine part airflow. Engine parts of which true airflow is less than the minimum limit can be accepted when air leakage is added to the true engine part airflow.

Leak test tools (engine parts with air holes permanently sealed) are given to help to check the condition of the gasket or grommet to find out if air leakage is there.

Air leakage at rubber gasket or grommet which seals the interface between the engine part air inlet and the airflow test fixture.

It is usual to find and correct external leaks when the airflow test stand is new. These leaks usually do not occur again unless you open a corrected joint for cleaning or repair of the test stand.

Internal leakage, such as at worn seals, is usually related to the age of the test stand, and to how much operation of the test stand occurs. It is necessary to continually monitor the test stand for internal leakage, specially as the age of the test stand increases.

Air leakage in the airflow test stand occurs less frequently than the air leakage at the seals between the engine part air inlet and the airflow test fixture, but is equally important.

A subsequent chapter gives procedures to examine this problem and gives instructions to cover the problem.

It is possible that when the shop introduces new engine models that have parts or assemblies for which the airflow test must use a high volume (weight) of air, the shop air system will not have sufficient capacity to supply the necessary volume (weight) of air for the necessary time.

The largest problems in airflow testing are:

Procedure for Testing Airflow

Figure: Easy diagram of sonic nozzle test stand

Easy diagram of sonic nozzle test stand