Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-72-02-720-501 Equipment And Material

General

The function of this section is to supply information about the equipment necessary to airflow test engine parts. The equipment necessary is:

A sonic nozzle test bench.

Correlation Master Tools to calibrate the test bench.

Aiflow test fixtures to adapt engine parts to the test bench.

Leak test tools to check for air leakage before you airflow test engine parts.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 6P16080 Test bench | 0AM53 | IAE 6P16080 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 02-120 APPLICATOR, COTTON-TIPPED | 0AM53 | CoMat 02-120 |

Spares

NONESafety Requirements

WARNING

Procedure

The IAE 6P16080 Test bench 1 off is used to check the airflow in the turbine blades, vanes and cooling air duct assemblies.

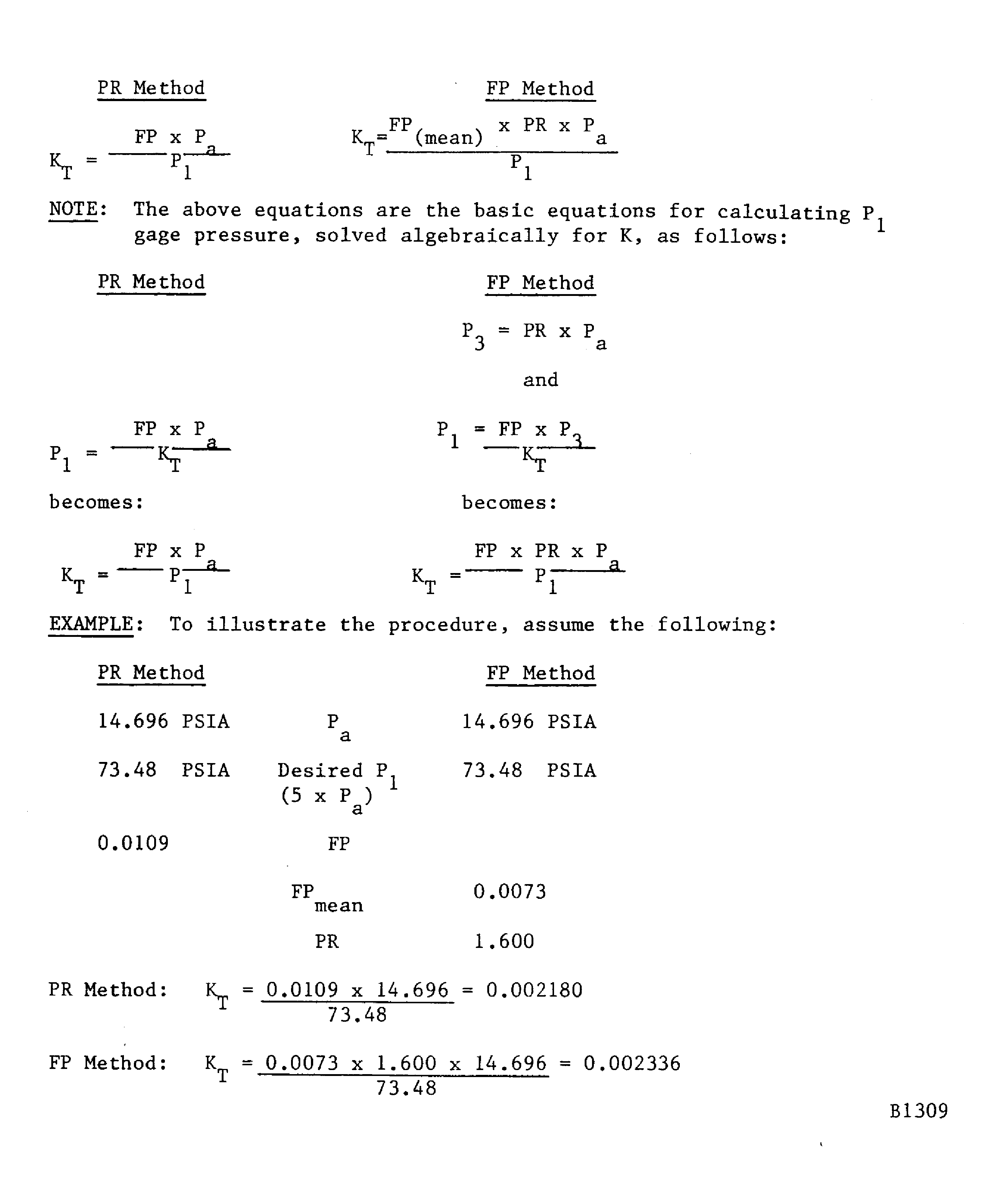

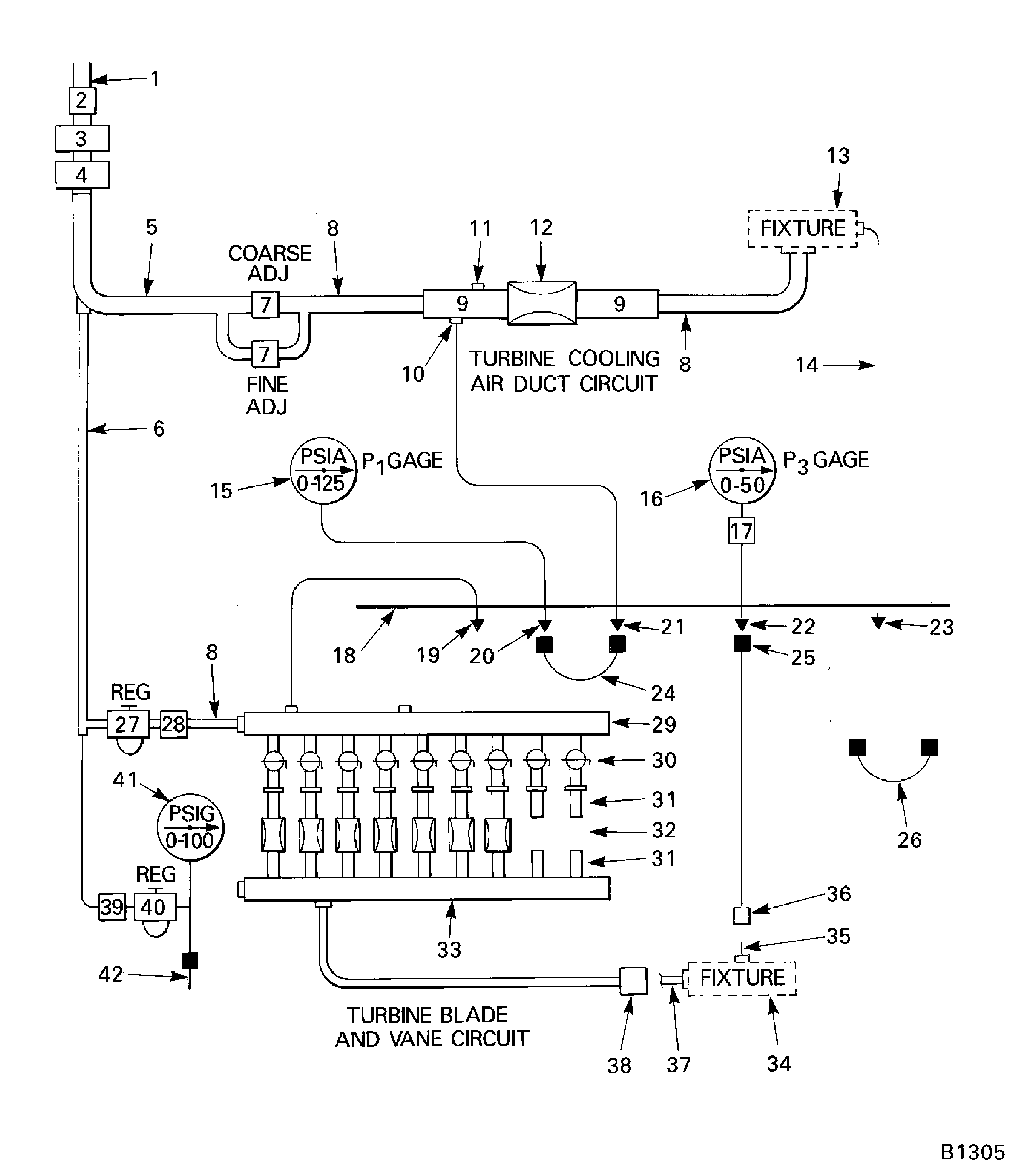

The sonic nozzle test bench is shown in schematic form in Figure and is fully specified in specifications published by IAE.

SUBTASK 70-72-02-720-001 Sonic Nozzle Test Bench

Because of the precision necessary in airflow testing, it is necessary that the persons test bench be calibrated to find how accurate it measures compared to the IAE 6P16080 Test bench 1 off. The calibration is done with the correlation master tools.

Correlation master tools are special tools made to function as engine parts. These tools are used to calibrate the IAE 6P16080 Test bench 1 off. The correlation master tools are kept with the IAE master test bench and are not available to the operators. The airflow properties have been written down on a calibration curve and support data.

The dual system of master tools is recommended because it permits the correlation master tools to be kept for controlled uses and prevents them to come into touch with dangers of daily use, such as handling damage or contamination. These would make there value unserviceable as the master to calibrate the master test bench and the work master tools.

The work master tools are used by the operator for the airflow necessary on the stage 1 turbine cooling air duct, and the stages 1 and 2 HPT blades and vanes.

SUBTASK 70-72-02-720-002 Master Tools Used for Test Bench Calibration

Descriptions of airflow test fixture installations are in SPM TASK 70-72-01-720-501.

SUBTASK 70-72-02-720-003 Fixtures to Adapt Engine Parts to Test Bench

CAUTION

ALL LEAK TEST TOOLS MUST BE CLEARLY MARKED (COLOR CODED) TO PREVENT THEM FROM BEING ACCIDENTALLY INCLUDED IN A SET OF ENGINE PARTS.The primary function of leak test tools is to check for air leakage at the rubber gasket or grommet which seals the interface between engine part air inlet and airflow test fixture. During the leak check, leakage at other locations can also be found.

SUBTASK 70-72-02-720-004 Leak Test Tools

NOTE

If the pressure measurement system is to be changed for the use of total pressure probes, after the nozzles and flow straighteners have been removed from the test bench but before they go for recalibration, install and position the probes in the inlet flow straighteners.Procedure 1. For the test benches without a total pressure pole, remove the nozzle, the inlet flow straightener, and the outlet flow straightener.

CAUTION

THE RADIAL POSITION AND THE ALIGNMENT OF THE TOTAL PRESSURE PROBE WITH RELATION TO THE AIRSTREAM ARE VERY IMPORTANT TO THE ACCURACY OF THE PRESSURE MEASUREMENT.Procedure 2. For test benches with a total pressure probe, remove the nozzle, the inlet flow straightener with the total probe installed, and the outlet flow straightener.

Remove the parts from the test bench by the applicable procedure as follows.

Recalibrate the nozzles used to test turbine cooling air ducts as follows.

As a table, for each test point, the nozzle inlet pressure in PSIA, the airflow through the nozzle in pounds/second, the calculated airflow coefficient (K-factor), the air temperature at the nozzle inlet, the ambient atmospheric pressure in PSIA at the time the test point was run, and the ambient air (room) temperature at the time the test point was run.

That the agency that does the recalibration will supply.

The purchase order which approves the nozzle recalibration must show:

Sonic nozzle - Recalibration.

CAUTION

DO NOT USE METAL OR ABRASIVES IN SONIC NOZZLES. DO NOT FORCE COTTON SWABS THROUGH NOZZLE THROATS. REMOVAL OF MATERIALS FROM A NOZZLE OR EVEN VERY SMALL SCRATCHES WITHIN A NOZZLE WILL CHANGE THE AIRFLOW PROPERTIES OF THE NOZZLE.Remove all signs of oil or contaminant from each nozzle with CoMat 02-120 APPLICATOR, COTTON-TIPPED made moist with CoMat 01-124 ISOPROPYL ALCOHOL.

At intervals of approximately six months, sonic nozzles must be removed from the test bench and cleaned.

Sonic nozzle - cleaning.

SUBTASK 70-72-02-720-005 Maintenance of Sonic Nozzle Test Stand

NOTE

This SUBTASK applies only to a sonic nozzle which has a large throat diameter, where nozzle inlet pressure is measured from a boss or port welded to the OD of the inlet flow straightener.NOTE

This SUBTASK does not apply where the nozzle inlet pressure is measured from a boss or part on a large diameter manifold.Refer to Figure.

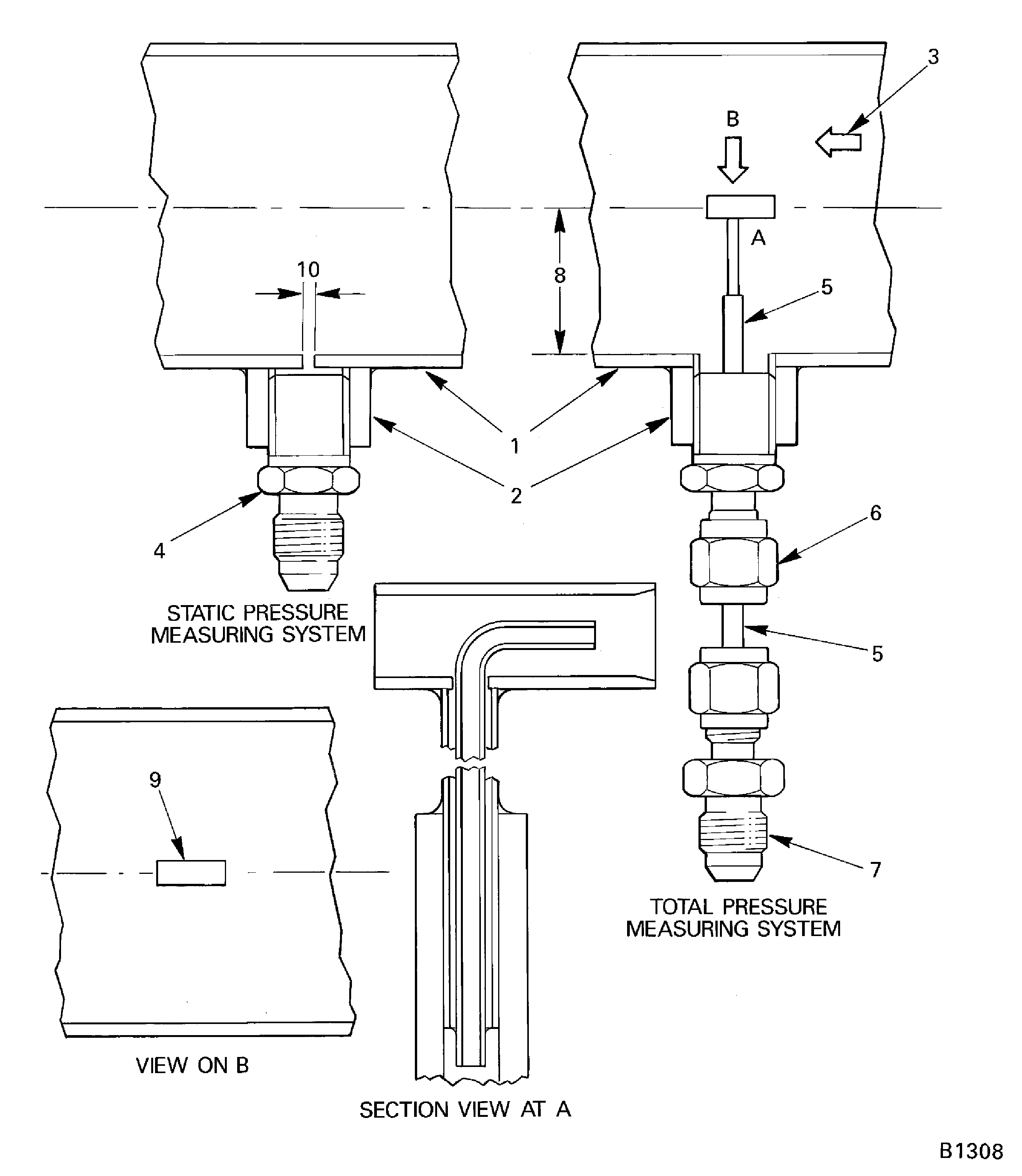

The two basic pressure measurement systems, static and total, are shown in Figure. The identity of the numbered arrows are given below.

NOTE

The inlet flow straightener used in the IAE master test bench was purchased from a nozzle manufacturer and has approximately a 1.76in. (44.70 mm) ID.The ID of the inlet flow straightener gives the velocity (Mach Number) of air in the inlet flow straightener. This is shown below.

Inlet ID (Inches)

Flow Straightener Area (Sq in)

Mach Number

1.16

1.0568

0.50

1.76

2.4328

0.19

3.30

8.5530

0.05

The chart below relates the velocity (Mach number) of air that moves past the pressure measurement port to the percentage of total pressure which would be shown or read by a static pressure measurement system.

Inlet Flow Straightener ID (Inches)

Mach Number

Total Pressure (Percentage)

1.16

0.50

84.0

1.76

0.19

97.5

3.30

0.05

99.8

When a static pressure measurement system (tap) is used, only the static component of total pressure is measured.

The steps that follow give a short description of the relation between inlet flow straightener ID and nozzle inlet pressure measurement system.

SUBTASK 70-72-02-720-006 Measuring Sonic Nozzle Inlet (P1) Pressure

Nozzle diameters and the number of nozzle positions recommended in the IAE 6P16080 Test bench 1 off specifications are general. Before the operator purchases or builds a new test bench, he must examine the airflow test needs of his fleet of engines to find the nozzle diameters applicable to his needs. An examination must also be done when a new engine model is added to the fleet.

General.

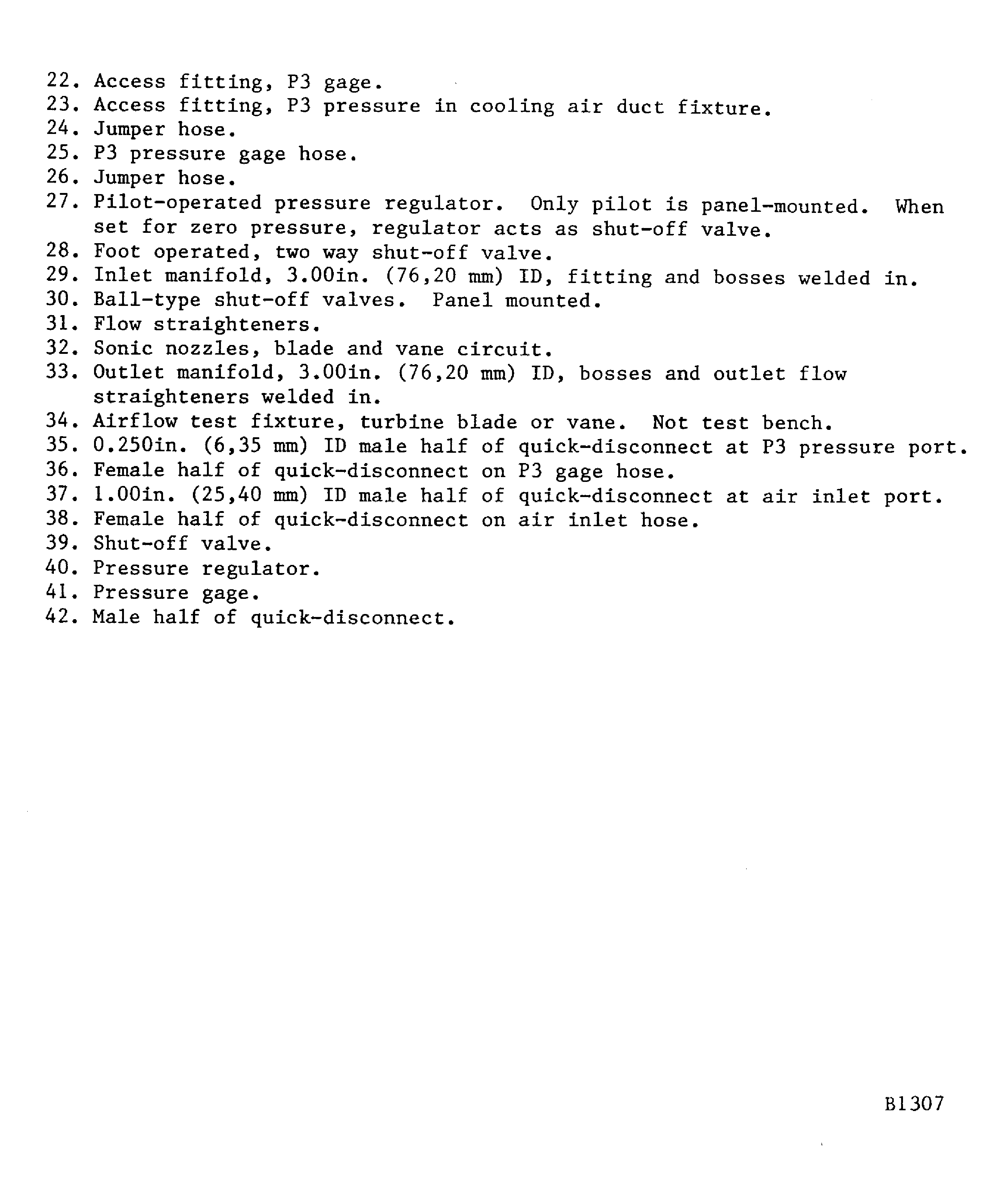

Find the total K-factor for the nozzle/nozzles necessary to test a specific engine part. Replace into the equations, refer to Figure, the values of FP or FP mean and PR from the engine part airflow test limits, the value of Pa in PSIA and a value of P1 equal to 5 x Pa. Refer to the Inspection/Check section of the Engine Manual for engine parts airflow test limits.

NOTE

Nozzle design changes nozzle discharge coefficient (nozzle efficiency). Some nozzles usually have discharge coefficiency of 0.98 or better.Sonic nozzle K-factor.

K (theoretical) = 0.532 x Throat area (sq in.).

Nozzle diameter Inches

K at CD = 0.99

1.250

0.64633

1.125

0.52353

1.000

0.41365

0.250

0.025853

0.177

0.012954

0.125

0.006463

0.088

0.003203

0.063

0.001642

0.052

0.001119

0.042

0.000730

0.021

0.000182

From a list of the actual K-factors of nozzles installed in the customers test bench, or from the list of K-factors given below, select the K-factor (nozzle diameter, or a mixture (sum) of two K-factors (two nozzle diameters)), which most carefully align the K-factor calculated in step (1).

Mathematical procedure of nozzle selection.

SUBTASK 70-72-02-720-007 Selecting Sonic Nozzles

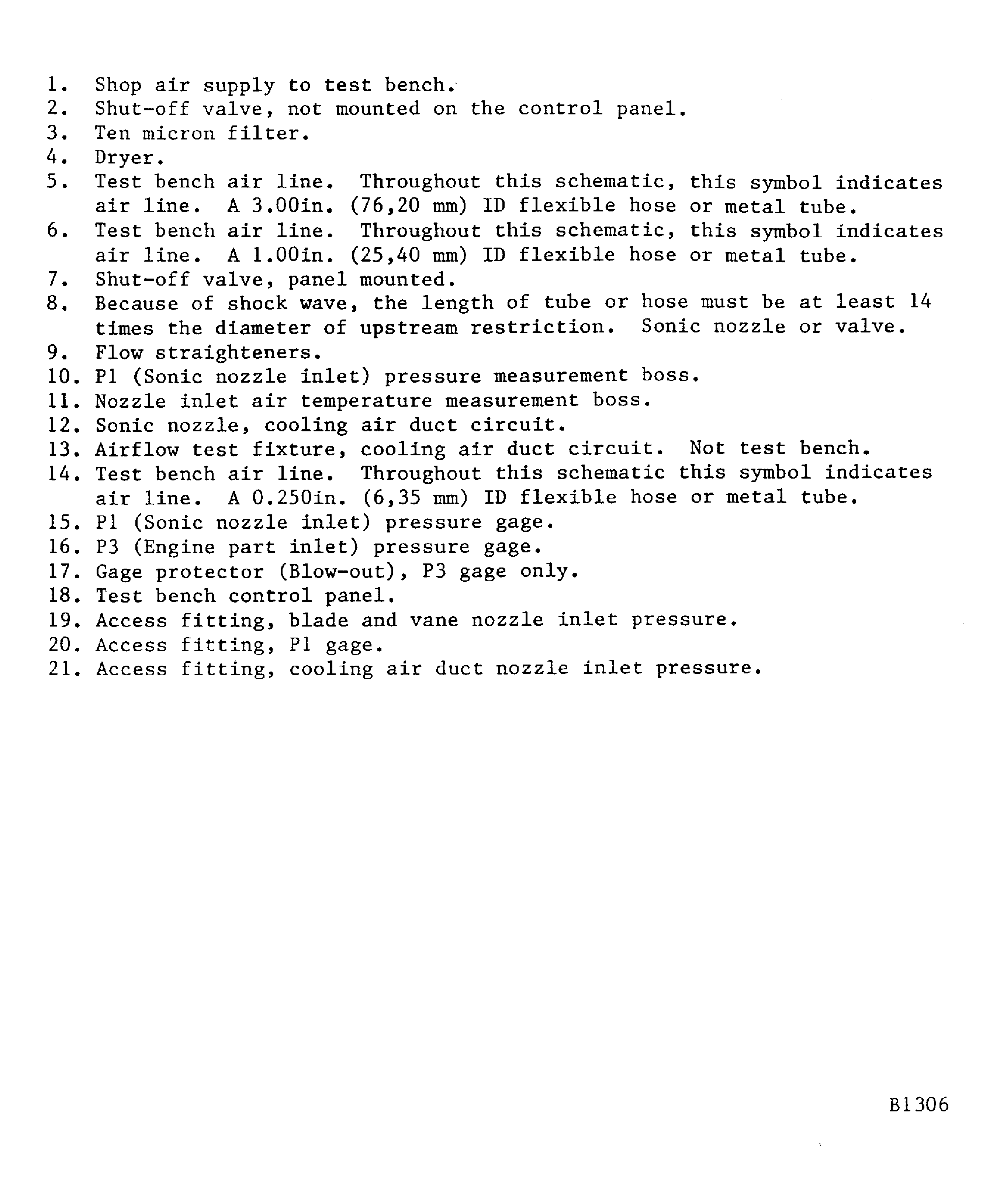

Figure: Schematic of IAE 6P16080 test bench and identification

Schematic of IAE 6P16080 test bench and identification

Figure: Schematic of IAE 6P16080 test bench and identification

Schematic of IAE 6P16080 test bench and identification

Figure: Schematic of IAE 6P16080 test bench and identification

Schematic of IAE 6P16080 test bench and identification

Figure: Pressure measurement system static against total

Pressure measurement system static against total

Figure: Calculation of total K-factor PR and FP procedures

Calculation of total K-factor PR and FP procedures