Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-00-00-810-017-B00 EGT Overtemperature, Fault Isolation-017

General

This fault isolation procedure gives the EGT overtemperature limits, inspection requirements and corrective actions for EGT overtemperature during engine start and engine run.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Correct the cause of overtemperature. Refer to Step.

If damage is seen, borescope inspect the combustion chamber, Stage 1 HP turbine vanes, Stage 1 and 2 HP turbine blades and the Stage 3 LP turbine blades. Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000) for the applicable TASK numbers.

Examine the exhaust area for signs of damage.

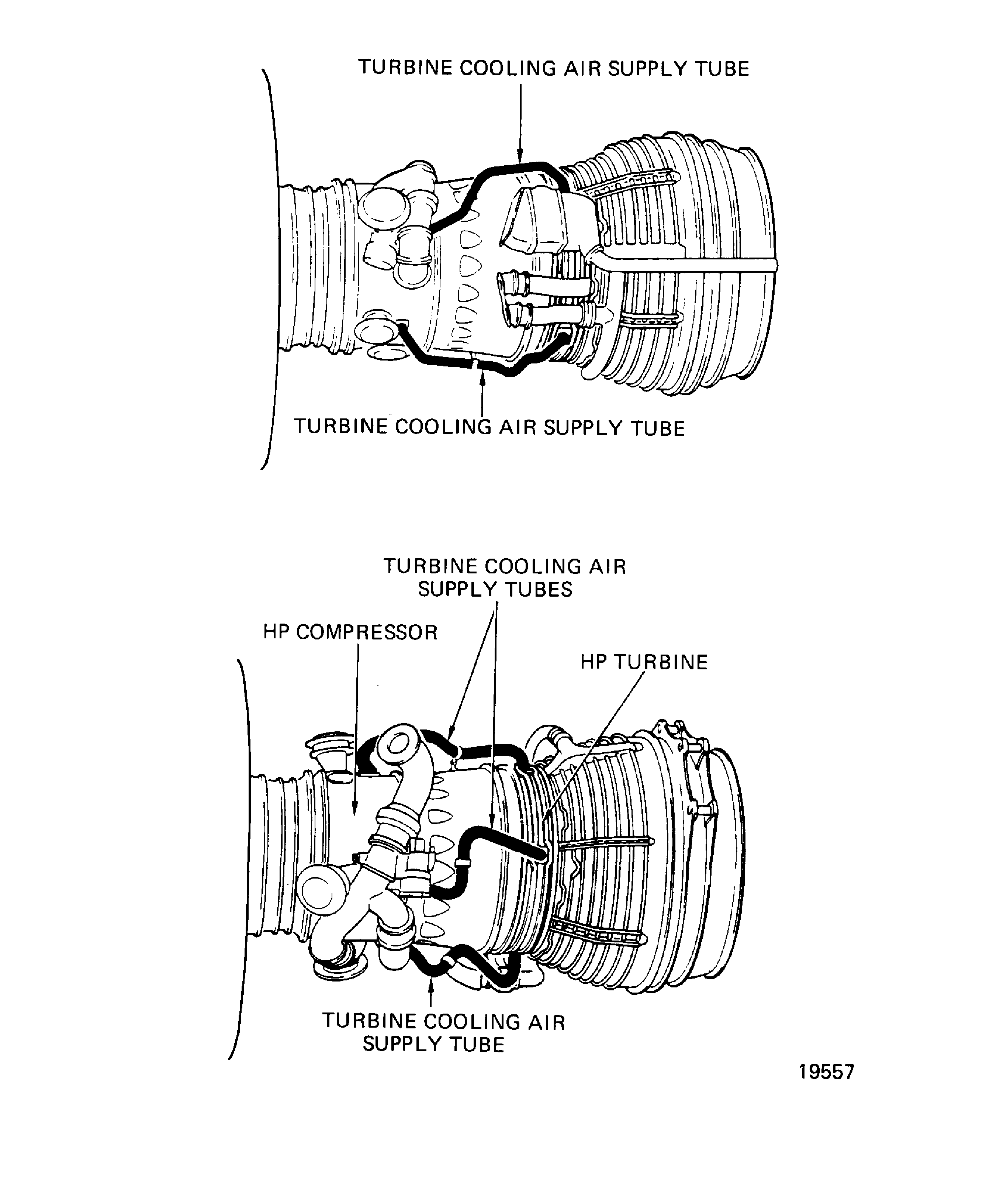

Examine for broken turbine cooling air supply tubes. Refer to Figure.

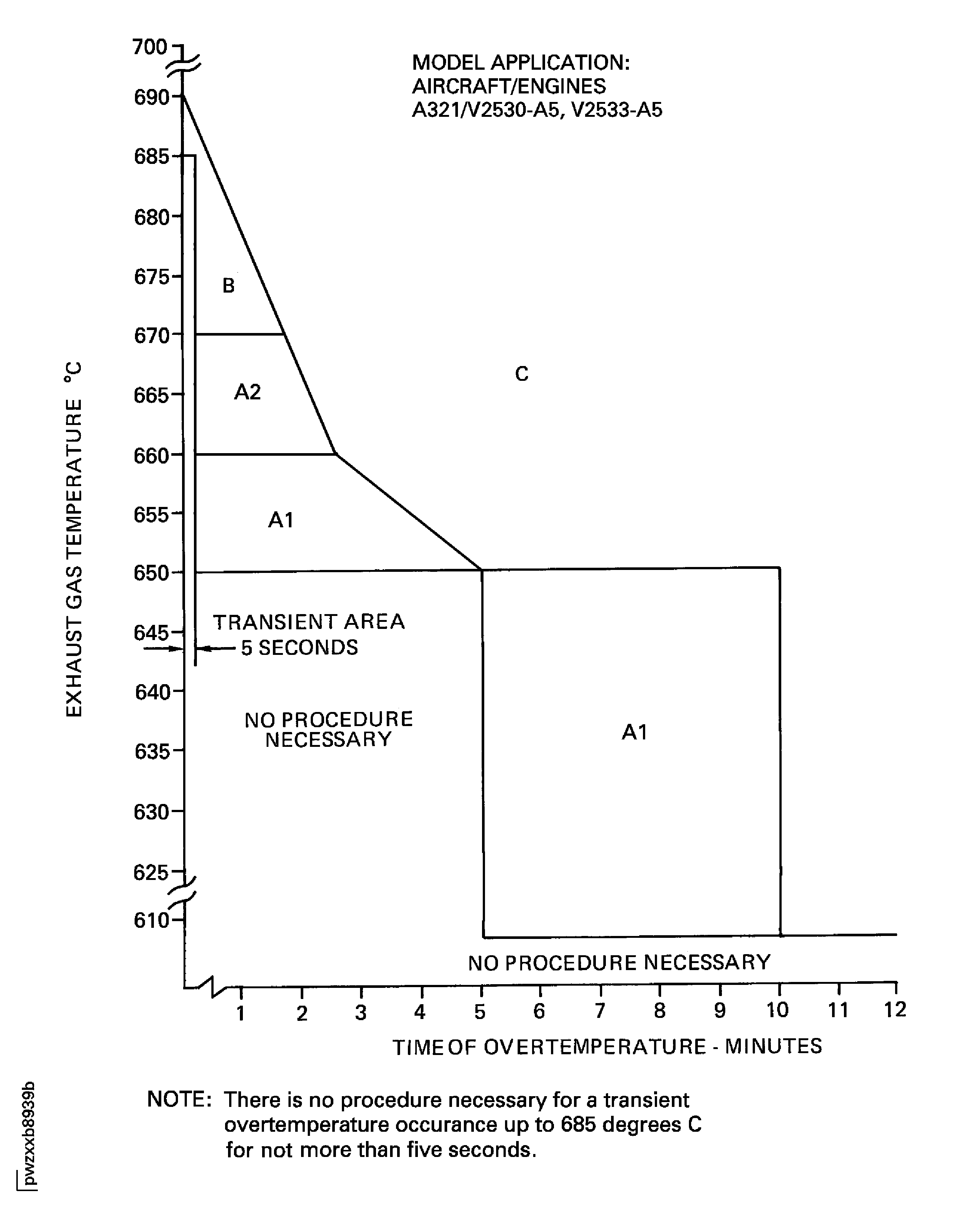

For an EGT overtemperature in Area A of the chart do the steps that follow.

Correct the cause of overtemperature. Refer to Step.

If there are no signs of damage, the engine can be started again and continue to operate. In less than 60 hours, borescope inspect the combustion chamber, Stage 1 HP turbine vanes, Stage 1 and 2 HP turbine blades and the Stage 3 LP turbine blades. Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000) for the applicable TASK number.

If damage is seen, borescope inspect the combustion chamber, the Stage 1 HP turbine vanes, Stage 1 and 2 HP turbine blades and the Stage 3 LP turbine blades. Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000) for the applicable TASK numbers.

Examine the exhaust area for signs of damage and examine for broken turbine cooling air supply tubes. Refer to Figure.

For an EGT overtemperature in Area B of the chart do the steps that follow.

Correct the cause of overtemperature. Refer to Step.

Remove the engine for hot section inspection and metallurgical analysis (Refer to SPM TASK 70-02-03-220-501) of the Stage 1 and 2 HP turbine blades.

Examine for broken turbine cooling air supply tubes. Refer to Figure.

For an EGT overtemperature in Area C of the chart do the steps that follow.

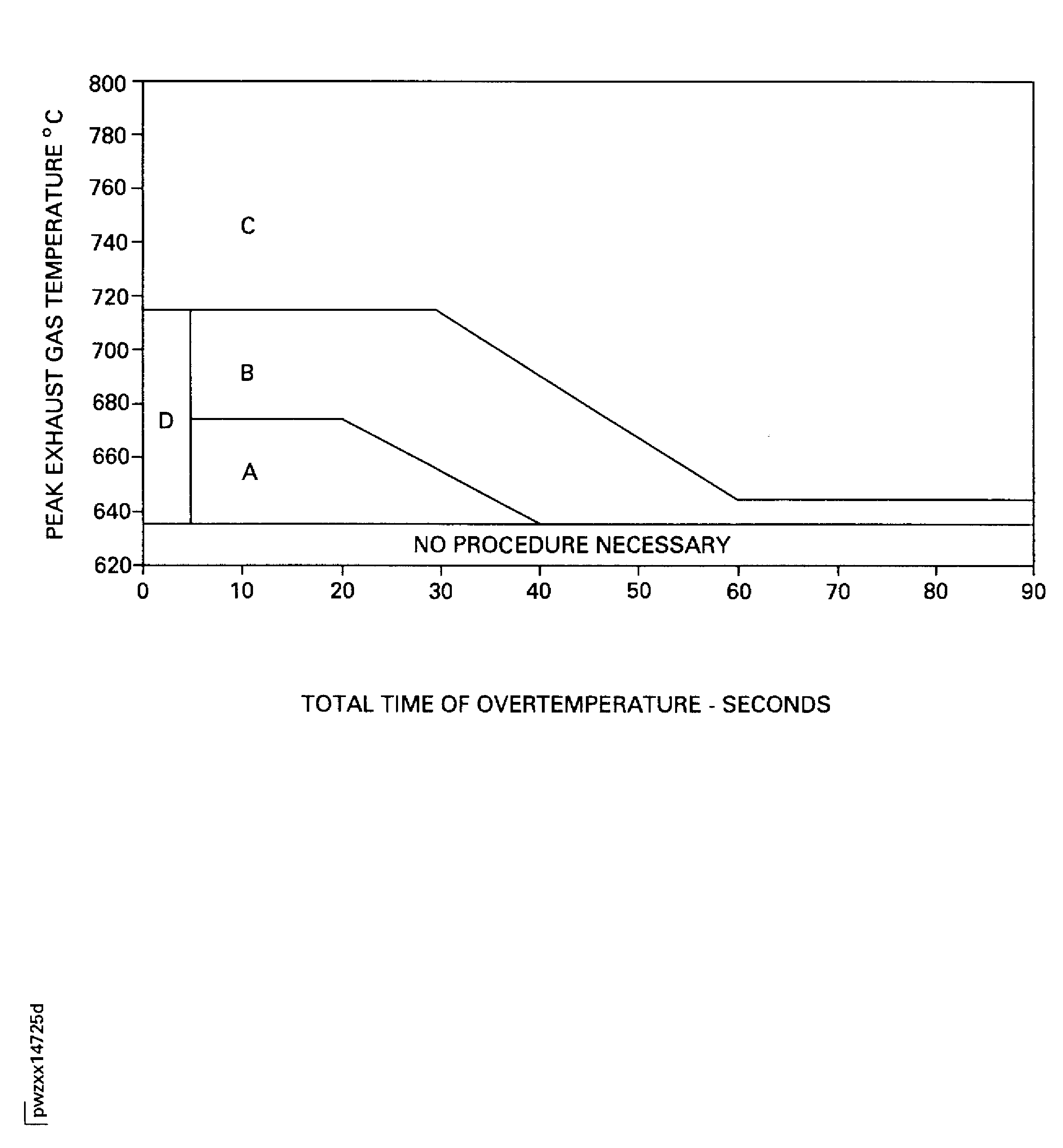

SUBTASK 71-00-00-810-051 EGT Overtemperature Limits During Engine Start and Below Idle Operation,

Correct the cause of overtemperature. Refer to Step.

If damage is seen, borescope inspect the combustion chamber, Stage 1 HP turbine vanes, Stage 1 and 2 HP turbine blades and the Stage 3 LP turbine blades. Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000) for the applicable TASK numbers.

Examine the exhaust area for signs of burning or distortion and metal particles from upstream damage.

Examine for broken turbine cooling air supply tubes. Refer to Figure.

For an EGT in Area A of the chart do the steps that follow.

Correct the cause of overtemperature. Refer to Step.

If there are no signs of damage, the engine can be started again and continue to operate. In less than 60 hours, borescope inspect the combustion chamber, Stage 1 HP turbine vanes, Stage 1 and 2 HP turbine blades and the Stage 3 LP turbine blades. Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000) for the applicable TASK numbers.

If damage is seen, borescope inspect the combustion chamber, Stage 1 HP turbine vanes, Stage 1 and 2 HP turbine blades and the Stage 3 LP turbine blades. Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000) for the applicable TASK numbers.

Examine the exhaust area for signs of burning or distortion and metal particles from upstream damage and examine for broken turbine cooling air supply tubes. Refer to Figure.

For an EGT in Area B of the chart when the overtemperature has occurred between 1 and 9 times do the steps that follow. If the overtemperature has occurred 10 times go to step E.

Correct the cause of overtemperature. Refer to Step.

Remove the engine for hot section inspection and metallurgical analysis (Refer to SPM TASK 70-02-03-220-501) of the Stage 1 and 2 HP turbine blades.

Examine for broken turbine cooling air supply tubes. Refer to Figure.

For an EGT in Area B of the chart when the overtemperature has occurred 10 times do the steps that follow.

Correct the cause of overtemperature. Refer to Step.

Remove the engine for hot section inspection and metallurgical analysis (Refer to SPM TASK 70-02-03-220-501) of the Stage 1 and 2 HP turbine blades.

Examine for broken turbine cooling air supply tubes. Refer to Figure.

For an EGT in Area C of the chart do the steps that follow.

SUBTASK 71-00-00-810-052 EGT Overtemperature Limits During Engine Run

Check the EEC fault messages and do the necessary procedures to correct the defects. Refer to TASK 71-00-00-810-000 (FAULT ISOLATION-001) for EEC fault messages.

Check the VSV mechanism. Refer to TASK 72-00-40-700-001 (TESTING-001).

SUBTASK 71-00-00-810-053 Correct the Cause of Overtemperature

Figure: EGT overtemperature limits during engine start

EGT overtemperature limits during engine start

Figure: EGT overtemperature limits during engine run

EGT overtemperature limits during engine run

Figure: Turbine cooling air supply tubes locations

Turbine cooling air supply tubes locations