Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-00-200-000 Engine General - Examine The Modular/Non-modular Interfaces, Magnetic Chip Detectors, And Borescope Examine The Engine, Inspection-000

General

The modular/non-modular interfaces must be examined before the installation of a module or a non-modular part.

The interfaces must be examined to make sure their condition is satisfactory for continued use.

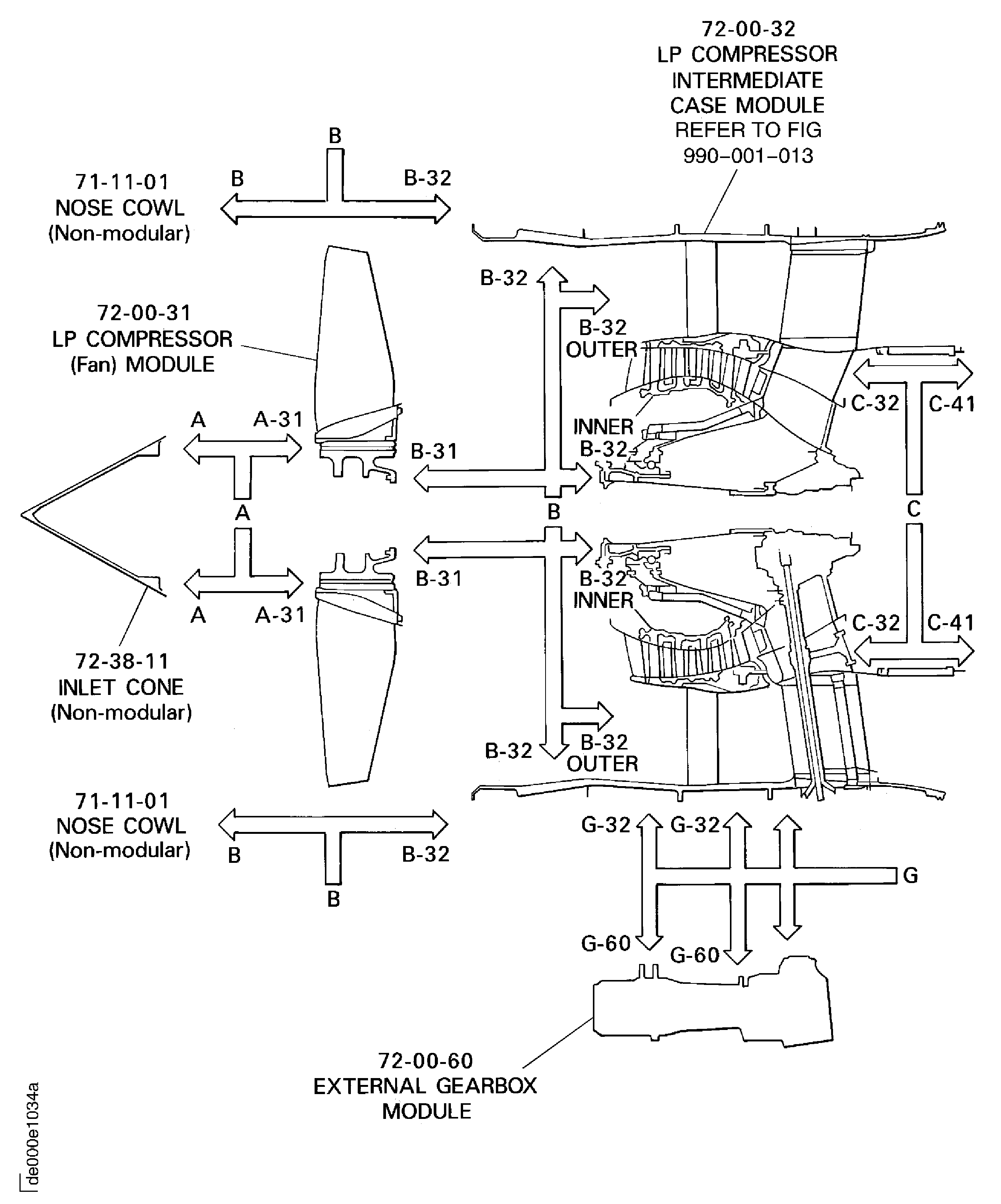

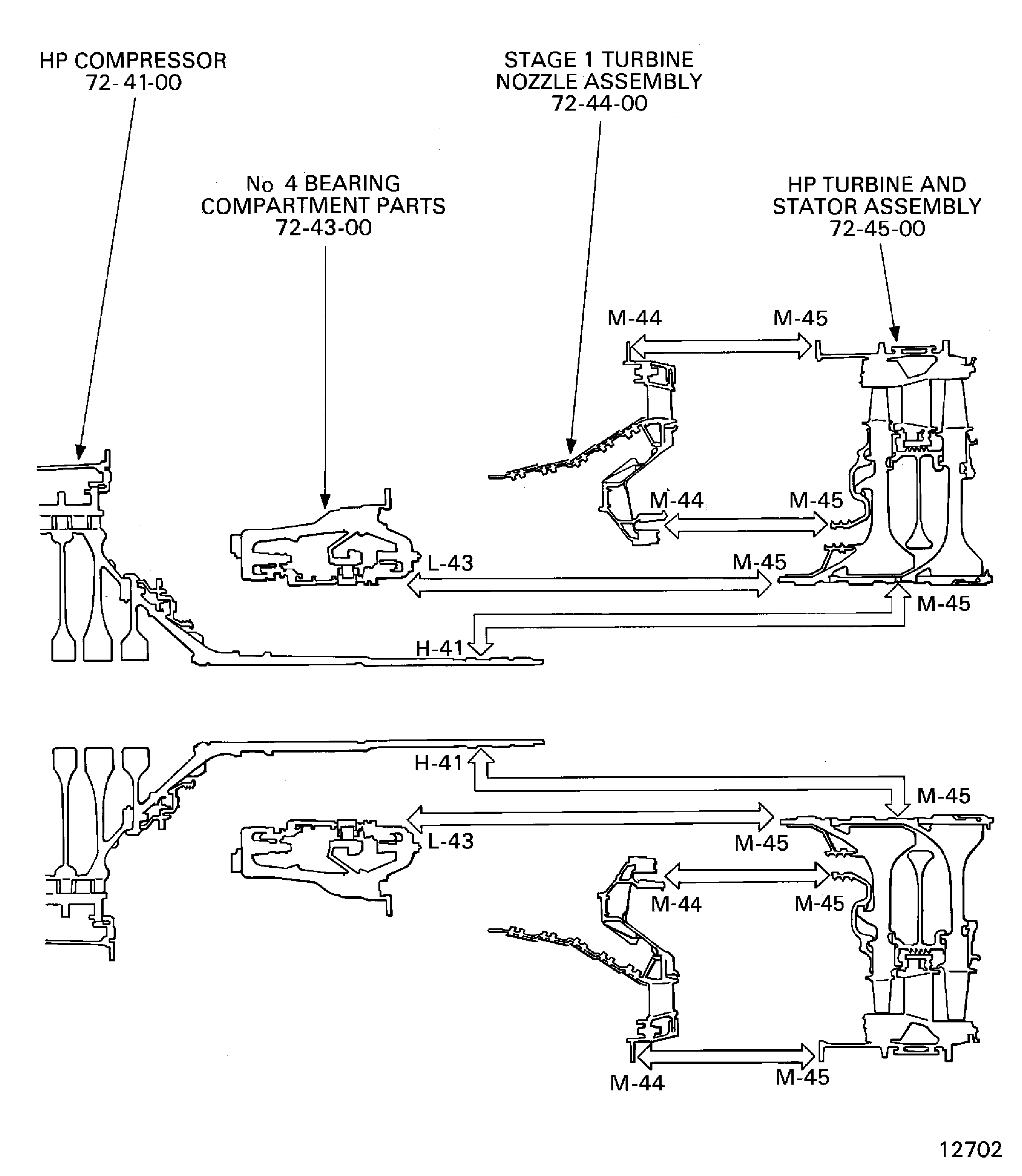

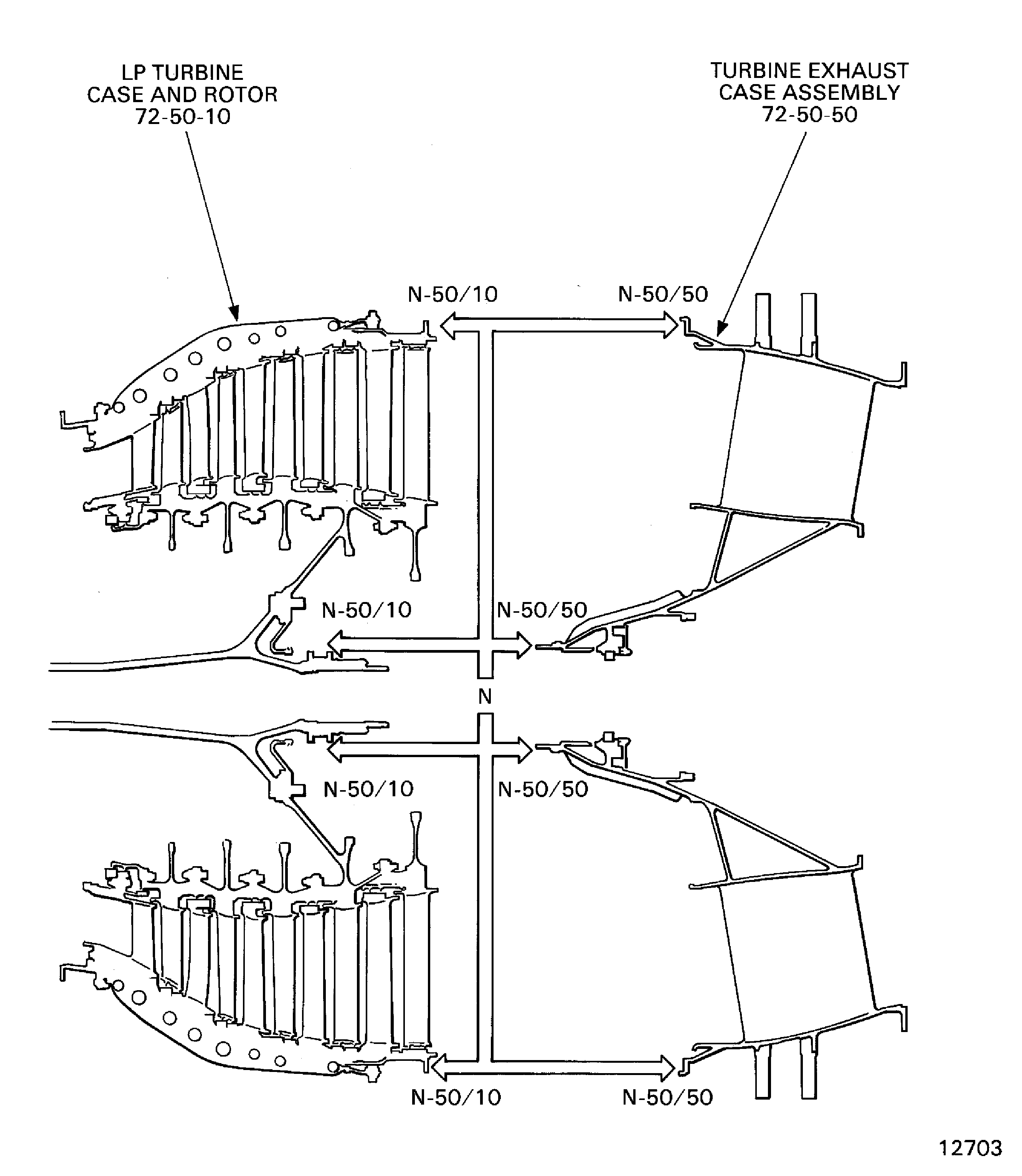

Each interface has been given an alpha identification. For example the LP compressor (fan) module and the LP compressor/intermediate case module has an interface identified as interface B. The module applicable is further identified by the module subject number as a suffix to the alpha.

Thus the rear face of the LP compressor (fan) module, (72-00-31), is identified as interface B-31.

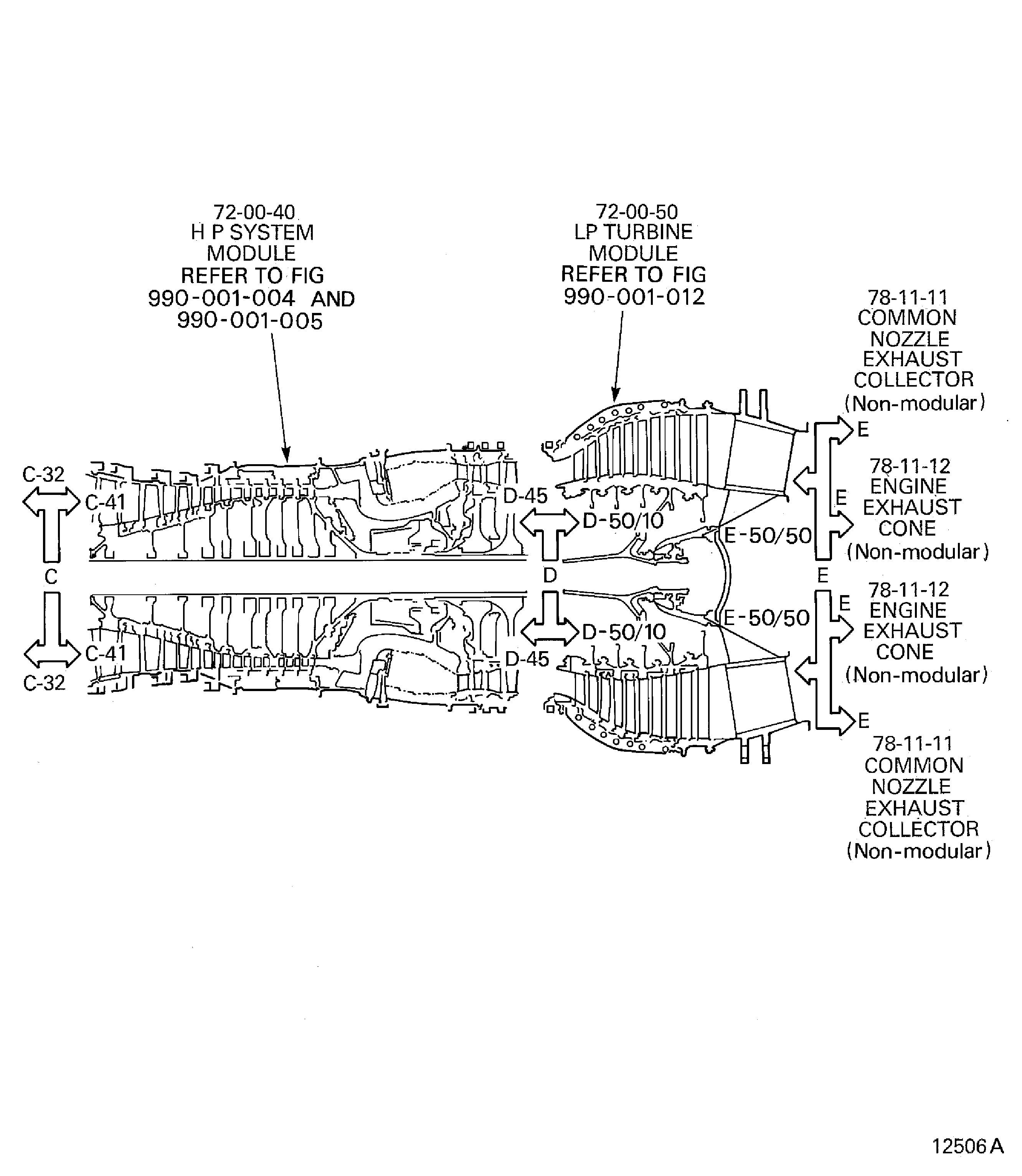

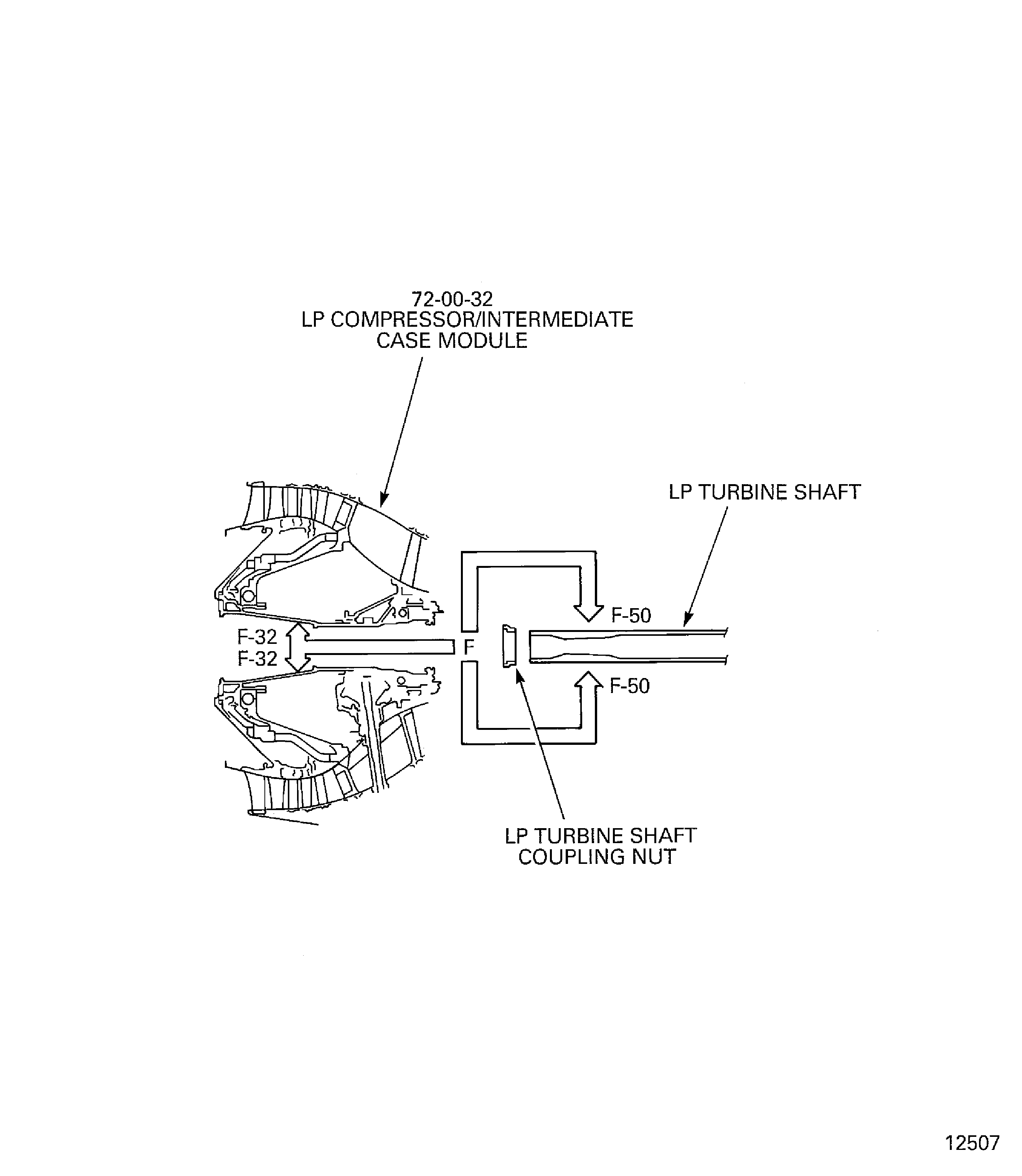

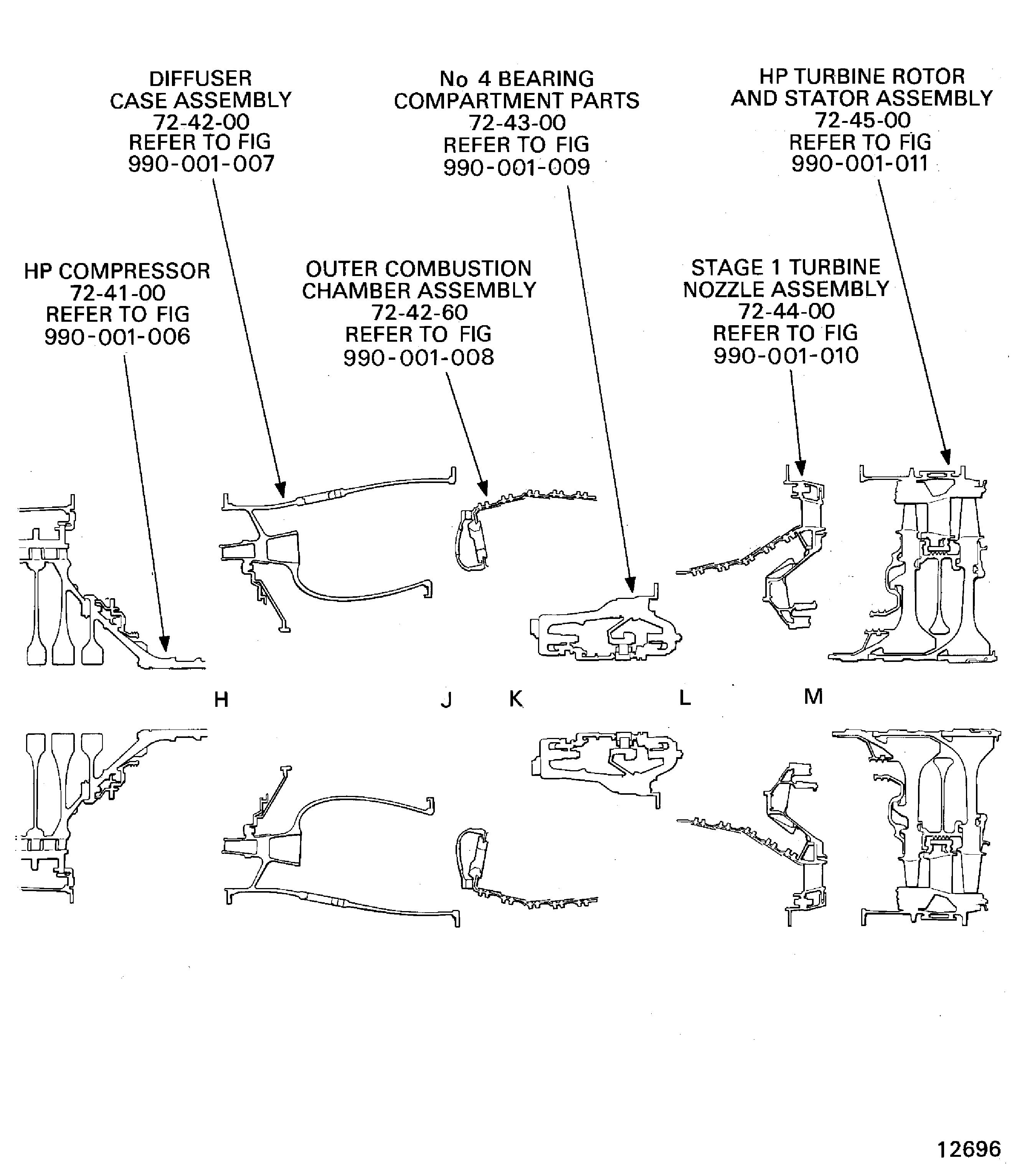

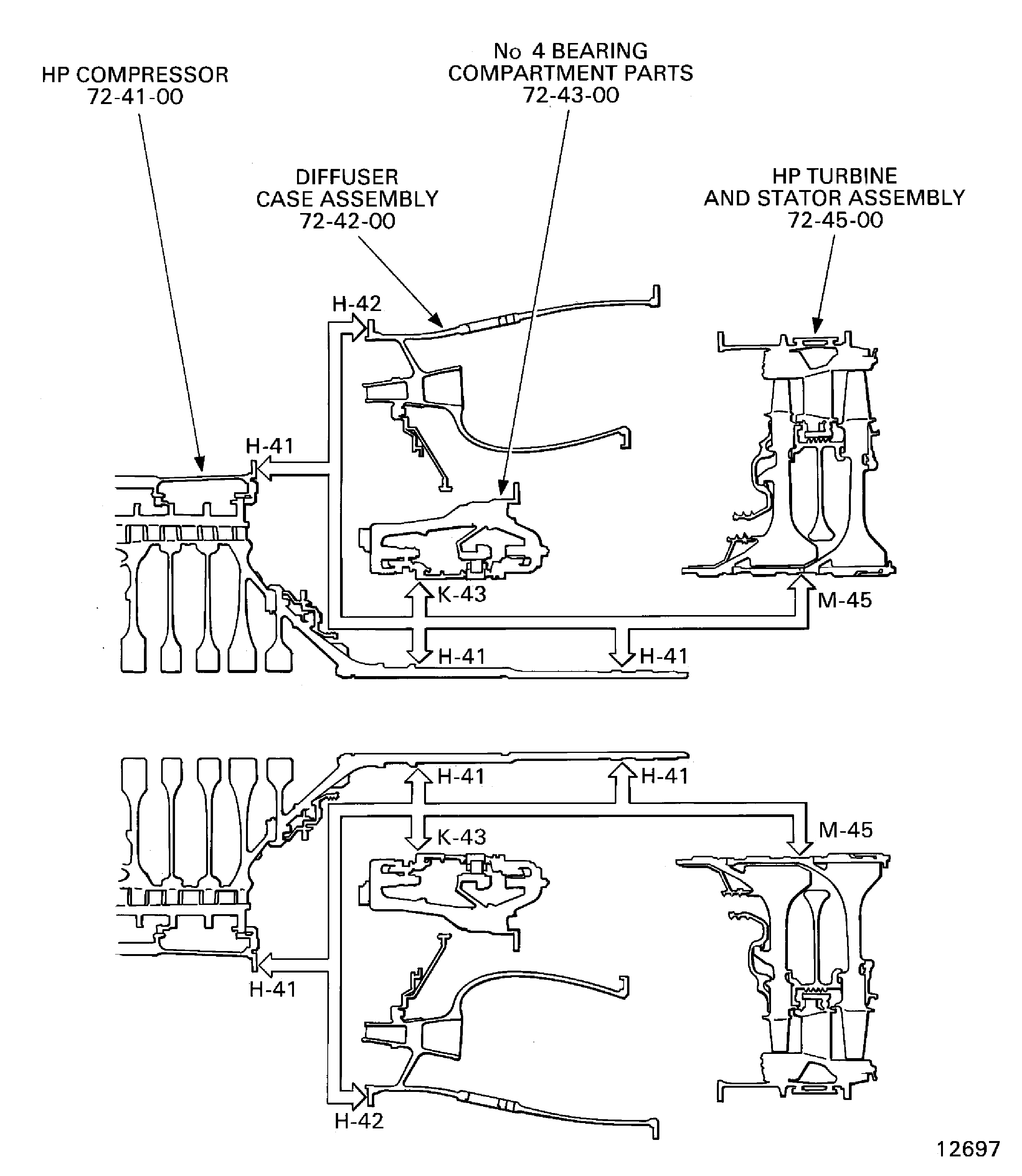

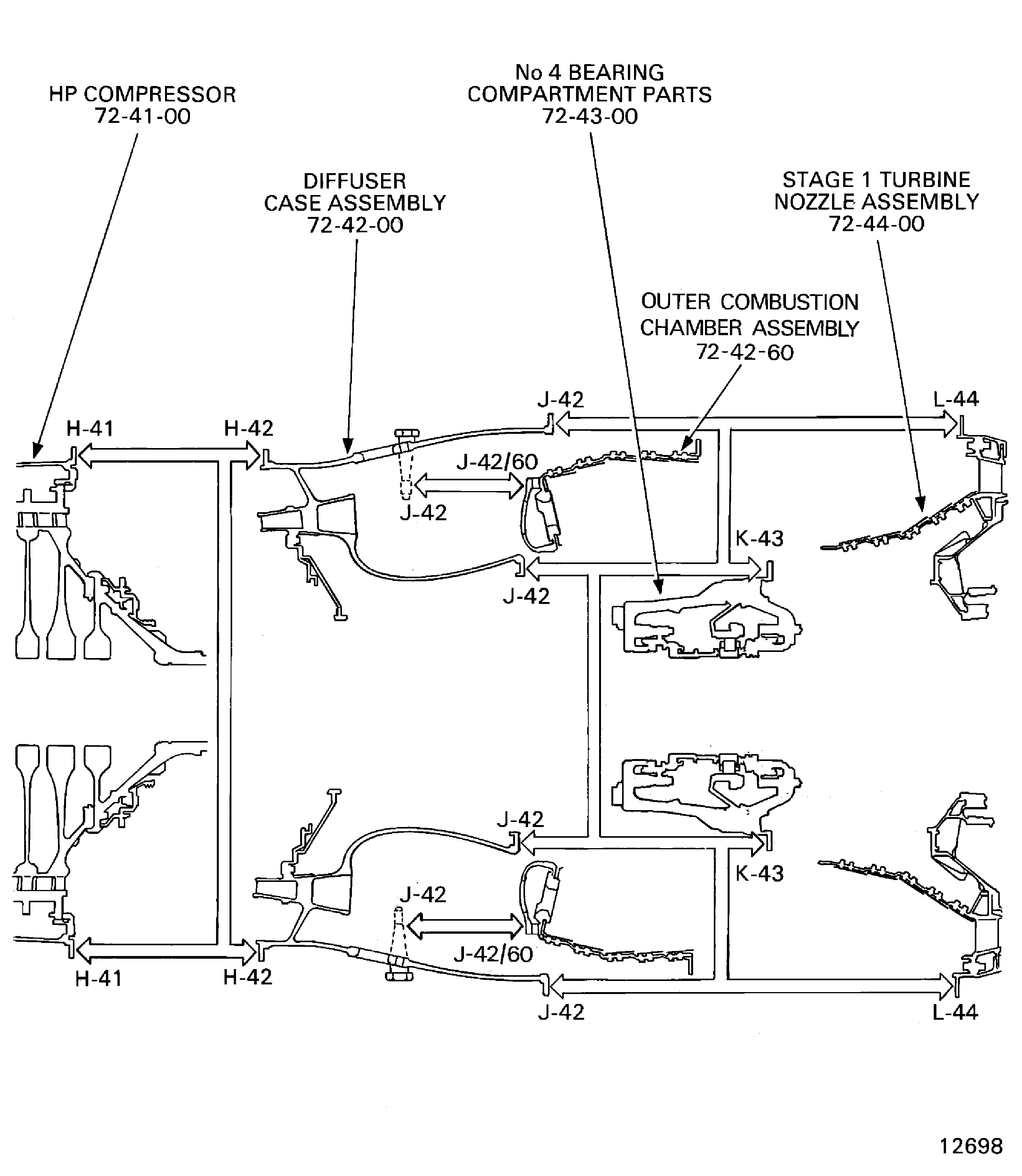

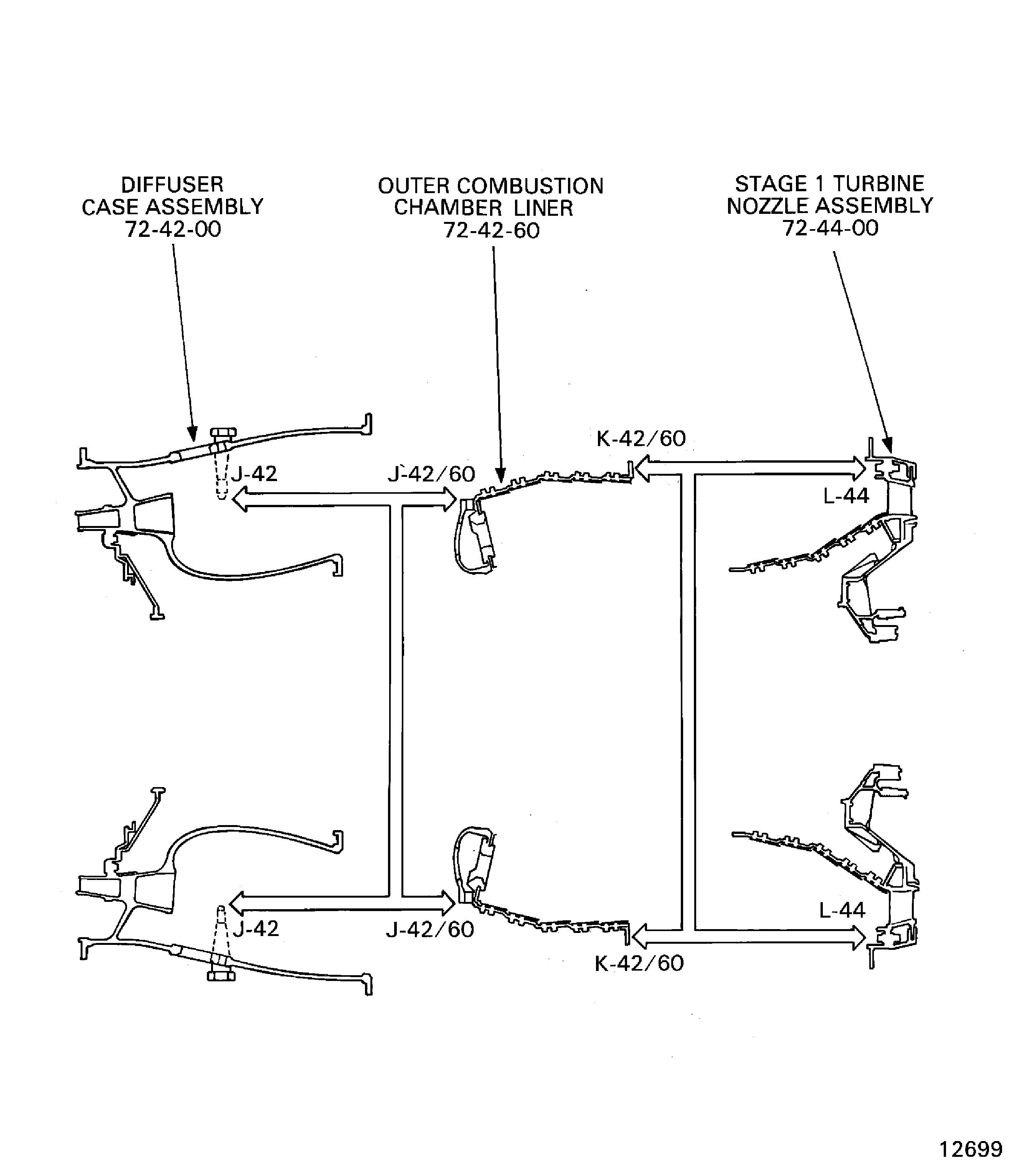

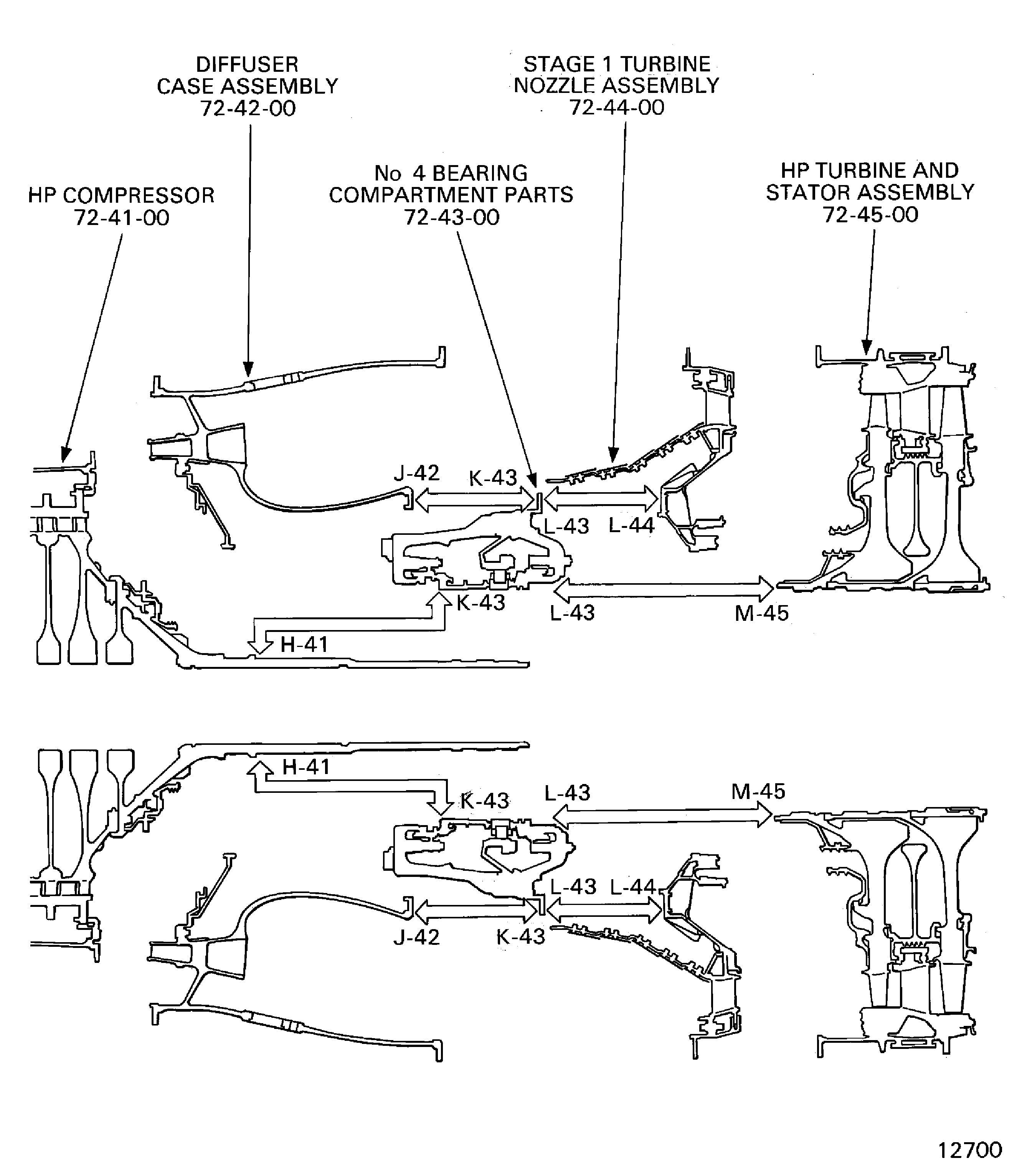

To identify each interface, refer to Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure, Figure.

The procedure to examine each interface is given in the subsequent TASKs.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

To examine the inlet cone (non-modular) at interface A refer to TASK 72-38-11-200-001 (INSPECTION-001).

To examine the air intake cowl (non-modular) at interface B refer to TASK 71-11-11-200-001 (INSPECTION-001).

To examine the LP compressor (fan) module rear face at interface B-31 refer to TASK 72-00-31-220-003 (INSPECTION-003).

To examine the No. 3 bearing, internal gearbox and support assembly inner front face at interface B-32/10 refer to TASK 72-00-32-220-006 (INSPECTION-006).

To examine the LP shaft, No. 1 and No. 2 bearing assembly rear outer face at interface B-32/50 refer to TASK 72-00-32-220-007 (INSPECTION-007).

To examine the HP system module front face at interface C-41 refer to TASK 72-00-40-220-001 (INSPECTION-001).

To examine the LP turbine module front face at interface D-50/10 refer to TASK 72-00-50-220-001 (INSPECTION-001).

To examine the LP turbine module rear face at interface E-50/50 refer to TASK 72-00-50-220-004 (INSPECTION-004).

To examine the common nozzle exhaust collector (non-modular) at interface E refer to TASK 78-11-11-220-001 (INSPECTION-001).

To examine the engine exhaust cone (non-modular) at interface E refer to TASK 78-11-12-220-001 (INSPECTION-001).

To examine the LP compressor/intermediate case module at interface F-32 refer to TASK 72-00-32-220-004 (INSPECTION-004).

To examine the LP turbine module at interface F-50 refer to TASK 72-00-50-220-005 (INSPECTION-005).

To examine the LP compressor/intermediate case module at interface G-32 refer to TASK 72-00-32-220-005 (INSPECTION-005).

To examine the external gearbox module at interface G-60 refer to TASK 72-00-60-220-001 (INSPECTION-001).

To examine the diffuser case assembly front face at interface H-42 refer to TASK 72-00-42-220-001 (INSPECTION-001).

To examine the diffuser case assembly rear face at interface J-42 refer to TASK 72-00-42-220-002 (INSPECTION-002).

To examine the outer combustion chamber assembly front face at inter-face J-42/60 refer to TASK 72-00-42-220-003 (INSPECTION-003).

To examine the outer combustion chamber assembly rear face at interface K-42/60 refer to TASK 72-00-42-220-004 (INSPECTION-004).

To examine the No. 4 bearing and rear compartment parts front face at interface K-43 refer to TASK 72-00-43-220-001 (INSPECTION-001).

To examine the No. 4 bearing and rear compartment parts rear face at interface L-43 refer to TASK 72-00-43-220-002 (72-0043, INSPECTION-002).

To examine the stage 1 turbine nozzle assembly front face at interface L-44 refer to TASK 72-00-44-220-001 (INSPECTION-001).

To examine the stage 1 turbine nozzle assembly rear face at interface M-44 refer to TASK 72-00-44-220-002 (INSPECTION-002).

To examine the LP turbine case and rotor assembly rear face at interface N-50/10 refer to TASK 72-00-50-220-002 (INSPECTION-002).

To examine the turbine exhaust case front face at interface N-50/50 refer to TASK 72-00-50-220-003 (INSPECTION-003).

Inspection TASKs applicable to both A1 and A5 models are as follows:

To examine the LP compressor (fan) module front face at interface A-31 refer to TASK 72-00-31-220-001 (INSPECTION-001).

To examine the LP compressor/intermediate case module inner front face at interface B-32 refer to TASK 72-00-32-220-001-A00 (INSPECTION-001, CONFIG-001).

To examine the LP compressor/intermediate case module outer front face at interface B-32 refer to TASK 72-00-32-220-002-A00 (INSPECTION-002, CONFIG-001).

To examine the LP compressor/intermediate case module rear face at interface C-32 refer to TASK 72-00-32-220-003-A00 (INSPECTION-003, CONFIG-001).

To examine the HP system module rear face at interface D-45 refer to TASK 72-00-45-220-001-A00 (INSPECTION-001, CONFIG-001).

To examine the HP compressor assembly rear face at interface H-41 refer to TASK 72-00-40-220-002-A00 (INSPECTION-002, CONFIG-001).

To examine the HP turbine rotor and stator assembly front face at interface M-45 refer to TASK 72-00-45-220-002-A00 (Pre SBE 72-0190) or TASK 72-00-45-220-002-B00 (SBE 72-0190), (INSPECTION-002, CONFIG-001).

Inspection TASKs applicable to A1 model only are as follows:

To examine the LP compressor (fan) module front face at interface A-31 refer to TASK 72-00-31-220-002 (INSPECTION-002).

To examine the LP compressor/intermediate case module inner front face at interface B-32 refer to TASK 72-00-32-220-001-B00 (INSPECTION-001, CONFIG-002).

To examine the LP compressor/intermediate case module outer front face at interface B-32 refer to TASK 72-00-32-220-002-B00 (INSPECTION-002, CONFIG-002).

To examine the LP compressor/intermediate case module rear face at interface C-32 refer to TASK 72-00-32-220-003-B00 (INSPECTION-003, CONFIG-002).

To examine the HP system module rear face at interface D-45 refer to TASK 72-00-45-220-001-B00 (INSPECTION-001, CONFIG-002).

To examine the HP compressor assembly rear face at interface H-41 refer to TASK 72-00-40-220-002-B00 (INSPECTION-002, CONFIG-002).

To examine the HP turbine rotor and stator assembly front face at interface M-45 refer to TASK 72-00-45-220-002-C00 (INSPECTION-002, CONFIG-002).

Inspection TASKs applicable to A5 model only are as follows:

Interface Inspection

To examine the stage 3 LP turbine blades refer to TASK 72-00-00-200-006 (INSPECTION-006).

To examine the stage 7 LP turbine blades and turbine vanes refer to TASK 72-00-00-200-007 (INSPECTION-007).

To examine the No. 4 bearing scavenge tube refer to TASK 72-00-00-200-009 (INSPECTION-009, page-801).

To examine the hydraulic pump drive gear shroud refer to TASK 72-00-00-200-012 (72-00-00 INSPECTION-12, page 801).

Borescope inspection TASKs applicable to both A1 and A5 models are as follows:

To examine the LP compressor refer to TASK 72-00-00-200-001-A00 (INSPECTION-001, CONFIG-001).

To examine the HP compressor refer to TASK 72-00-00-200-002-A00 (INSPECTION-002, CONFIG-001).

To examine the combustion chamber and the stage 1 turbine nozzle vanes refer to TASK 72-00-00-200-003-A00 (INSPECTION-003, CONFIG-001).

To examine the stage 1 HP turbine blades refer to TASK 72-00-00-200-004-A00 (INSPECTION-004, CONFIG-001).

To examine the stage 2 HP turbine blades refer to TASK 72-00-00-200-005-A00 (INSPECTION-005, CONFIG-001).

Borescope inspection TASKs applicable to A1 model only are as follows:

To examine the LP compressor refer to TASK 72-00-00-200-001-B00 (INSPECTION-001, CONFIG-002).

To examine the HP compressor refer to TASK 72-00-00-200-002-B00 (INSPECTION-002, CONFIG-002).

To examine the combustion chamber and the stage 1 turbine nozzle vanes refer to TASK 72-00-00-200-003-B00 (INSPECTION-003, CONFIG-002).

To examine the stage 1 HP turbine blades refer to TASK 72-00-00-200-004-B00 (INSPECTION-004, CONFIG-002).

To examine the stage 2 HP turbine blades refer to TASK 72-00-00-200-005-B00 (INSPECTION-005, CONFIG-002).

Borescope inspection Tasks applicable to A5 model only are as follows:

Borescope Inspection

To examine the magnetic chip detectors and the oil filters refer to TASK 72-00-00-200-008 (INSPECTION-008).

Magnetic chip detector inspection TASKs applicable to both A1 and A5 models is as follows:

Magnetic Chip Detector Inspection

Procedure for the transient acoustic propagation (TAP) test of the LP compressor (fan) blades refer to TASK 72-00-00-200-010 (INSPECTION-010).

Procedure for the ultrasonic inspection of the LP compressor (fan) blades (root debond) refer to TASK 72-00-00-200-011 (INSPECTION-011) or TASK 72-00-00-200-015 (INSPECTION-015).

Procedure for the C scan inspection of the LP compressor (fan) blades refer to TASK 72-00-00-200-013, (INSPECTION-013).

Procedure for the eddy current inspection of the LP compressor (fan) blades refer to TASK 72-00-00-200-014 (72-00-00. INSPECTION-14).

Procedure for the ultrasonic inspection of the dovetail root flanks of the LP compressor (fan) blades refer to TASK 72-00-00-200-015 (INSPECTION-015).

The LP compressor (Fan) Blades special inspection TASKS applicable to both A1 and A5 models are as follows:

LP Compressor (Fan) Blades Special Inspection

Figure: Module Split Line and Interface Identification

Sheet 1

Figure: Module Split Line and Interface Identification

Sheet 2

Figure: Module Split Line and Interface Identification

Sheet 3

Figure: Module Split Line and Interface Identification

Sheet 4

Figure: Module Split Line and Interface Identification

Sheet 5

Figure: Module Split Line and Interface Identification

Sheet 6

Figure: Module Split Line and Interface Identification

Sheet 7

Figure: Module Split Line and Interface Identification

Sheet 8

Figure: Module Split Line and Interface Identification

Sheet 9

Figure: Module Split Line and Interface Identification

Sheet 10

Figure: Module Split Line and Interface Identification

Sheet 11

Figure: Module Split Line and Interface Identification

Sheet 12

Figure: Module Split Line and Interface Identification

Sheet 13