Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-31-220-002 LPC Fan Module - Examine The LPC Fan Module Front Face at Interface A-31, Inspection-002

General

Refer to TASK 72-00-00-200-000 (Examine the modular/non modular interfaces) (INSPECTION/CHECK-000), before you do this TASK.

The policy that is necessary for inspection is given in TASK 70-20-01-200-501.

The word 'reject' is used after an interface inspection statement to show that a higher level inspection and possible repair to the damaged part is necessary. Do the higher level inspection procedure as found in the applicable Chapter/Section/Subject of this manual on the damaged part(s). It is not necessary to do the higher level inspection on parts that are serviceable to the interface inspection standard.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Repair, VRS1050 TASK 72-00-31-300-004 (REPAIR-004)

More than in Step

Nicked, dented, scored or scratched.

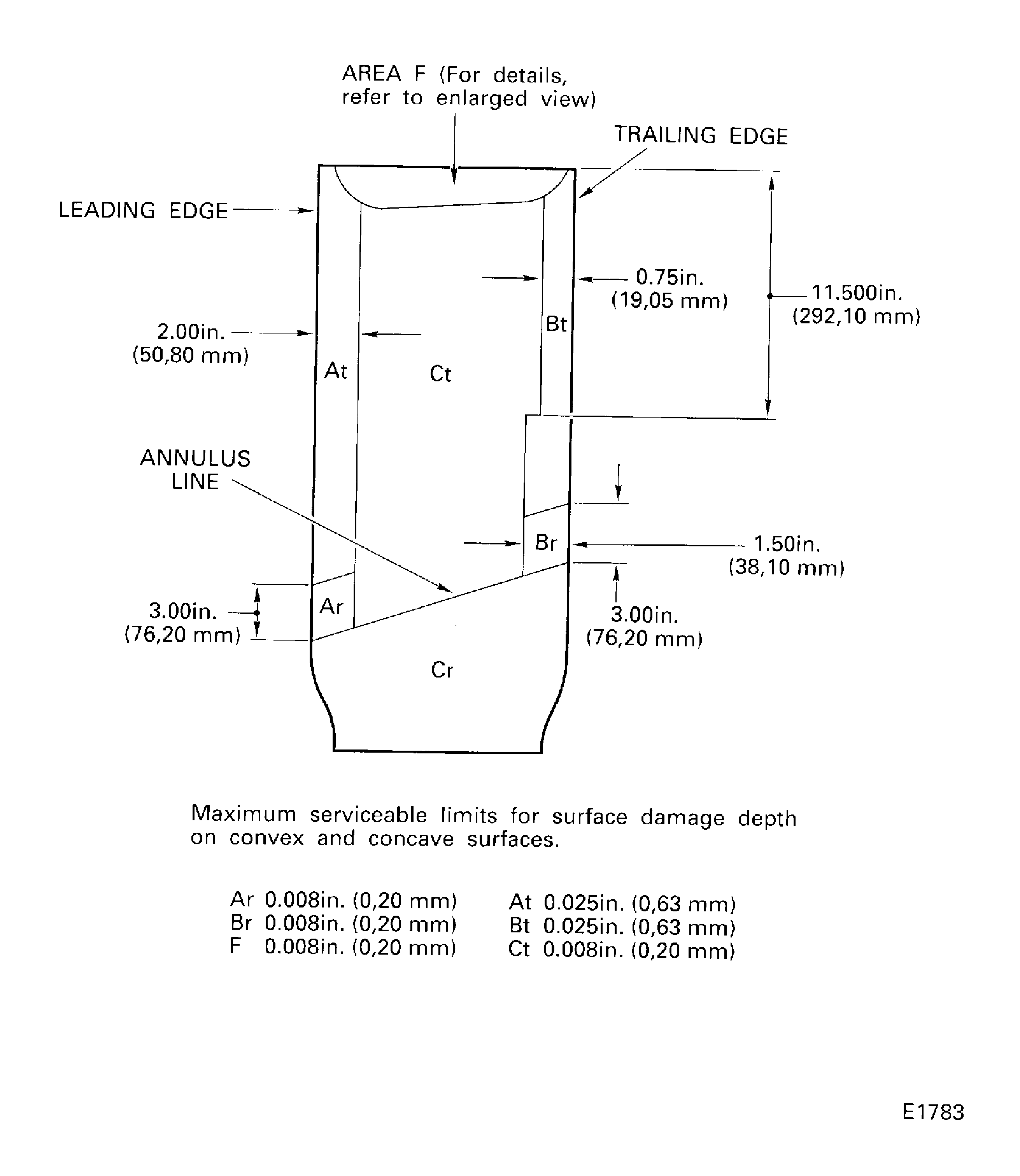

Visually examine the stage 1 fan blades at area Ar.

More than in Step

Nicked, dented, scored or scratched.

Visually examine the stage 1 fan blades at area Br.

Repair, VRS1050 TASK 72-00-31-300-004 (REPAIR-004)

More than in Step

Nicked, dented, scored or scratched.

Visually examine the stage 1 fan blades at area At.

More than in Step

Nicked, dented, scored or scratched.

Visually examine the stage 1 fan blades at area Bt.

More than in Step

Nicked, dented, scored or scratched.

Visually examine the stage 1 fan blades at area Ct.

More than in Step

Nicked, dented, scored or scratched.

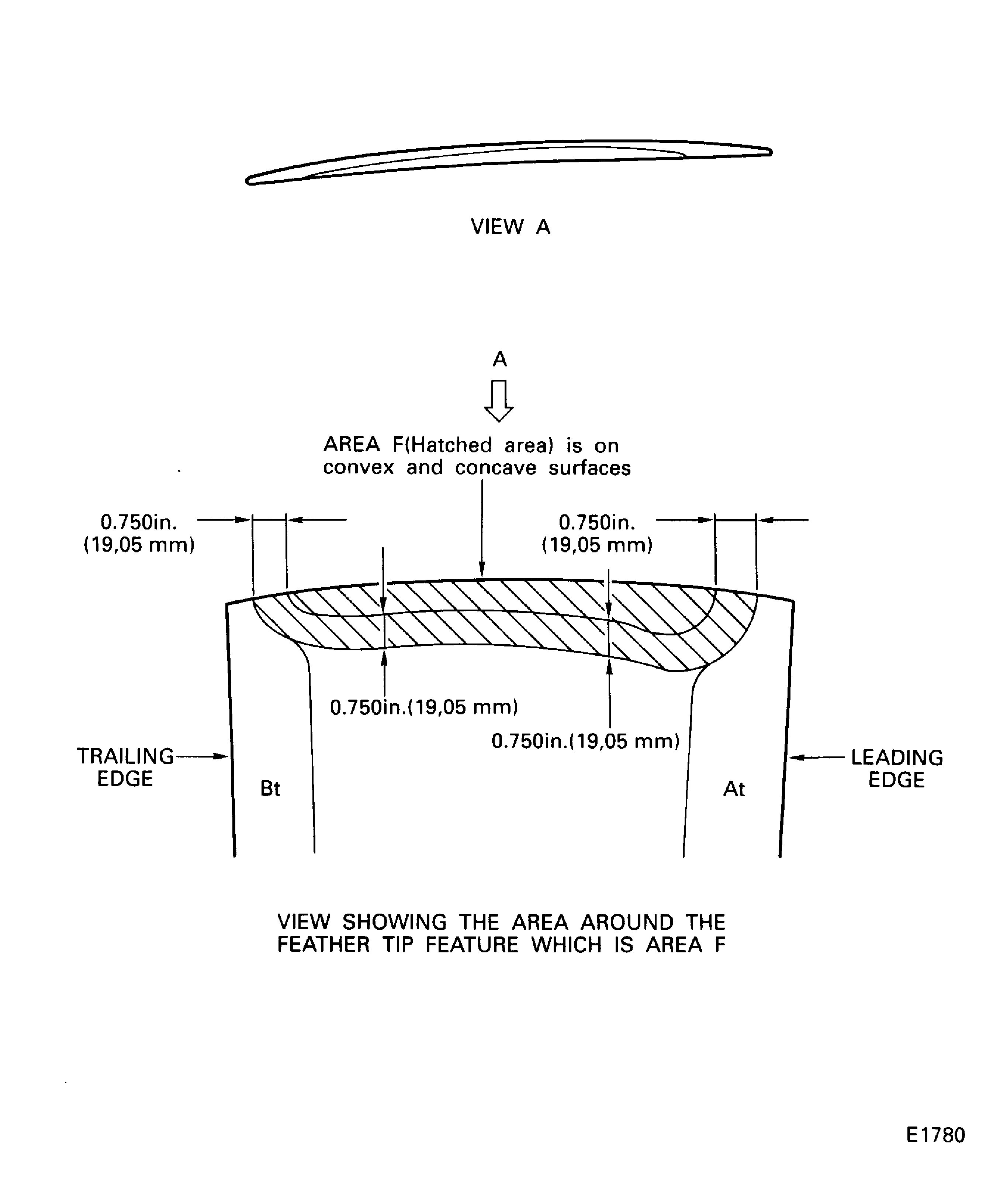

Visually examine the stage 1 fan blade tips at area F.

More than in Step

Worn.

Visually examine the stage 1 fan blades convex and concave surfaces at the annulus line areas.

SUBTASK 72-00-31-220-062 Visually Examine the Stage 1 Fan Blades at Location 1, and

Refer to TASK 72-00-00-200-010 (INSPECTION/CHECK-010)

Do a transient acoustic propagation test

SUBTASK 72-00-31-280-052 Do a Transient Acoustic Propagation Test of the Stage 1 Fan Blades

Refer to Figure.

Repair, VRS1108 TASK 72-00-31-300-003 (REPAIR-003)

Up to 6

NOTE

Only one seal per annulus fillers permitted to be partially or completely detached.More than in Step

Detached (partially or completely).

NOTE

Only one seal per annulus fillers permitted to be partially or completely detached.More than in Step

Missing (partially or completely).

Rubber seals.

SUBTASK 72-00-31-220-063 Visually Examine the LP Compressor Annulus Fillers at Location 2

Refer to Figure.

SUBTASK 72-00-31-220-064 Visually Examine the Front Retaining Ring Snap Diameter at Location 3

Refer to Figure.

SUBTASK 72-00-31-220-065 Visually Examine the Front Retaining Ring at Location 4

Refer to Figure.

SUBTASK 72-00-31-220-066 Visually Examine the Washer Plate at Location 5

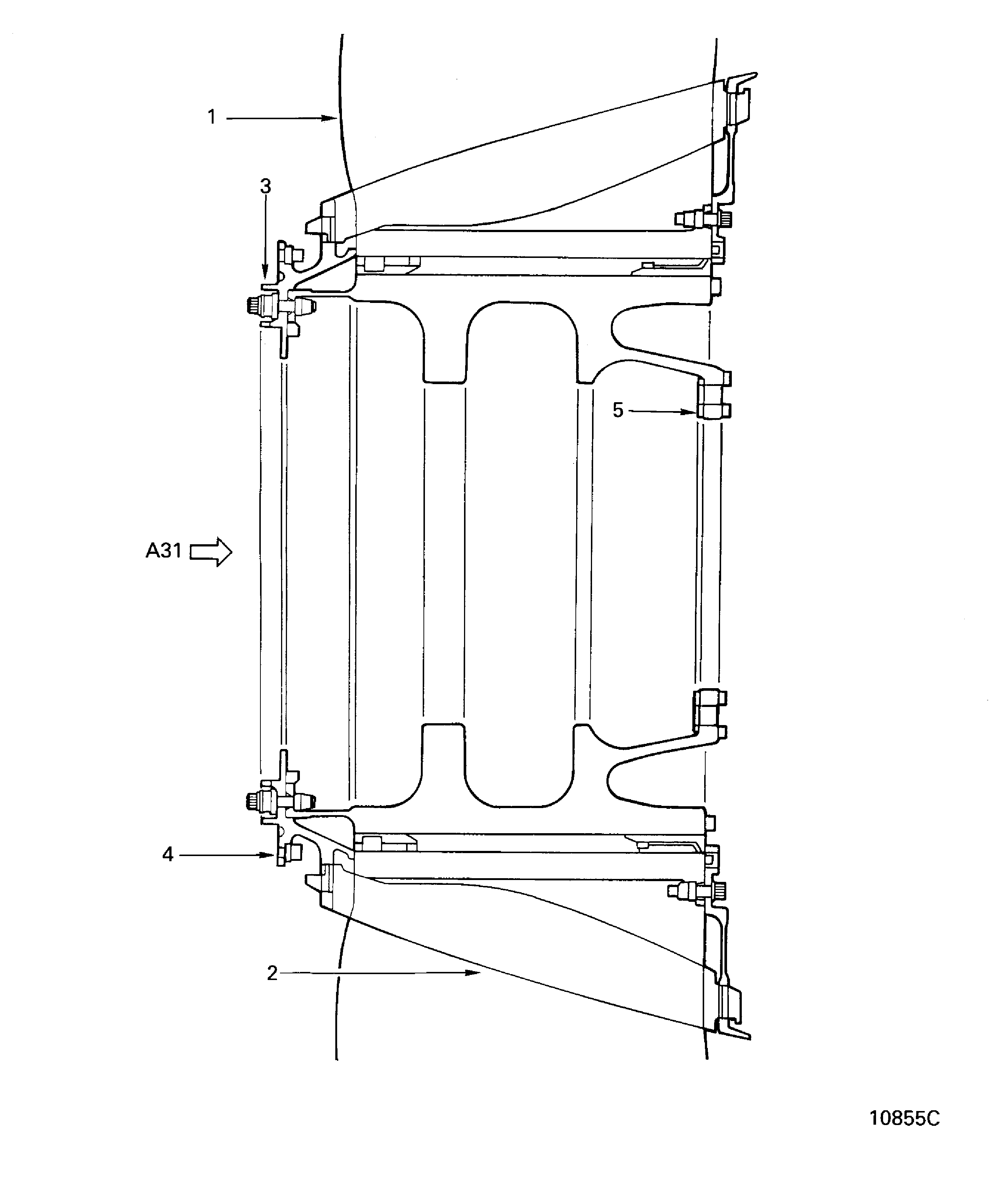

Figure: Locations at interface A-31

Locations at interface A-31

Figure: Stage 1 fan blades

Stage 1 fan blades

Figure: Stage 1 fan blades

Stage 1 fan blades

Figure: Stage 1 fan blades

Stage 1 fan blades