Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-20-01-200-501 Inspection Policy And Inspection Of Parts

General

This task gives the policy applicable to the inspection of parts.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

The instructions that follow give the policy applicable to the inspection of parts. The cleaning necessary is also given.

All special inspection instructions are given in the Engine Manual.

Instructions for the usual Standard Practice Inspection of Parts, which frequently apply to engines, are given in Part 2 - Inspection of Parts.

General:

When the module is disassembled it is necessary to do a visual inspection of all parts. Refer to SPM TASK 70-21-01-220-501.

The methods of NDT inspection - penetrant or magnetic particle inspection are given in the Engine Manual.

Removal of grease and loose carbon is usually sufficient for parts where visual or magnetic particle inspection is necessary.

Removal of paint that is not in serviceable condition, hard carbon, heat oxidation and corrosion is usually necessary for parts where penetrant inspection is specified because good surface preparation is important for this type of inspection. Refer to SPM TASK 70-23-00-230-501

NDT inspection should be carried out whenever possible on the disassembled parts. Do not remove protective layers, such as electroplating, metal/plasma spray or paint, if they are in serviceable condition, unless specified differently by applicable work instructions.

Minor parts (remaining parts) can be either visual or NDT inspected as per the Engine Manual.

Cleaning procedures that use acid or alkali etching to remove metal are specified by IAE.

Parts with easy access, when the module is disassembled:

The Repair Schemes and Modification Service Bulletins give the inspection and type of cleaning necessary for inspection.

Parts for repair or modification:

These are special procedures, which are specified when necessary.

Parts for which special inspection is necessary (because of service problems):

For parts with mandatory life limits, the inspection instructions and basic samples necessary are specified by IAE who will also make these inspections.

More inspections of parts, by operators when possible, are also necessary. This is to make sure the basic sample inspection is satisfactory. IAE will give instructions for such programs.

The inspection of other important engine parts, for which life growth sampling programs are necessary, usually follow the policy given above. Refer to SPM TASK 70-05-00-220-501 - Recording and Control of Component Lives.

Parts for which life growth sampling inspection is necessary:

Inspection Policy

The policy for the inspection of parts is given in Part 1 - Inspection Policy.

The instructions in this procedure are for the usual inspection of parts that are used through all the engine. They give a procedure to cross reference between the text and the parts illustrations.

Special instructions for the inspection of the different parts of an engine sub-assembly are given in the related part of each procedure.

General:

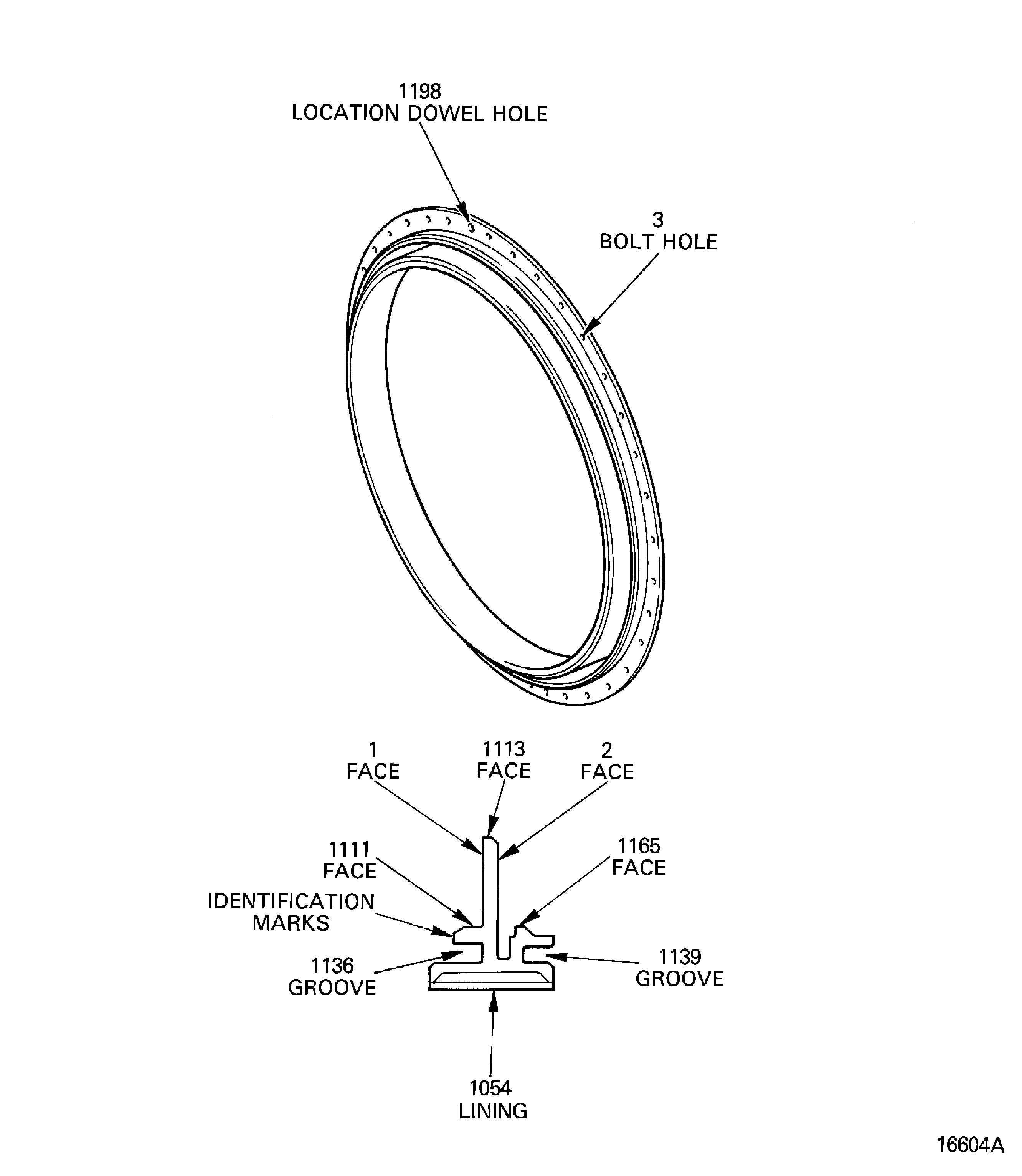

All parts are included in the related Inspection/Check page block. Each location given in the text is shown on the illustration - (For example, 2 FACE - Refer to Figure).

Where a four figure location number is used, this number also shows a fits/clearance location (For example, 1139 GROOVE - Refer to Figure).

Parts inspection:

CAUTION

THE PART NUMBER OF THE PART TO BE INSTALLED MUST AGREE WITH THE PART NUMBER SPECIFIED IN THE APPLICABLE ILLUSTRATED PARTS CATALOGUE (IPC). IF YOU DO NOT MAKE SURE THAT THE CORRECT PART IS INSTALLED FOR THE APPLICABLE ASSEMBLY, ENGINE DAMAGE CAN OCCUR.Parts that look the same can be made of different materials or can have different dimensions. Each engine part has an identified part number specified in the related Illustrated Parts Catalog (IPC).

Identification of parts:

The inspector must make sure that all important Service Bulletins are included. All Service Bulletins that are not included must be written on the Inspection Report. These are to be included during Repair, Assembly, or Installation.

The effect of a Service Bulletin on a specific engine type is given in the related Service Bulletins. Data about Service Bulletins that are included is given in the Engine Log Book and/or the Record of Accomplishment.

Service Bulletins:

To keep a record of the hours that a component has operated, and to help control its life when such records are used, all components are identified by a mark. In this mark each letter is related to a specific time. Instructions on how to apply this procedure are given in SPM TASK 70-05-00-220-501 - Recording and Control of Component Lives.

Component life marks:

All components must be examined for cracks. Examine visually, unless specified differently.

All parts with cracks for which no acceptance standards are given must be rejected. The acceptance standards for parts to be visually examined without the use of crack inspection procedures are given in the general inspection instructions of each Inspection/Check page block.

If you are not sure about a crack indication, it must be examined again by a different procedure, to make the indication more clear. Alternatively, if a penetrant inspection was done, use a more sensitive penetrant.

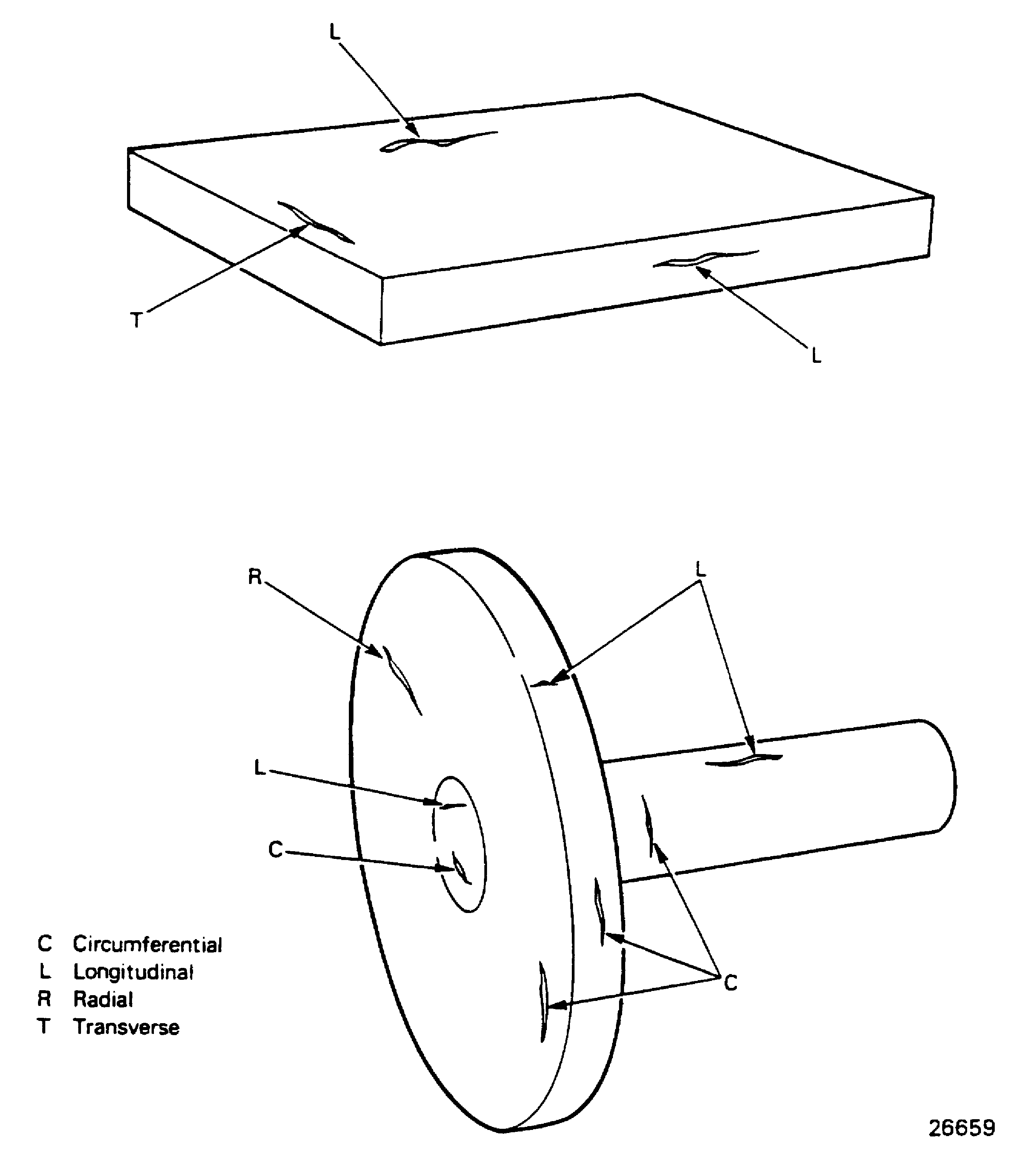

The names used to identify the directions of defects, are given in Figure.

Examine components for crack indications:

The inspection of ball and roller bearings is given in SPM TASK 70-29-01-290-501.

The cleaning and storage of ball and roller bearings is given in SPM TASK 70-53-01-620-501 and SPM TASK 70-53-02-630-501.

Ball and roller bearings:

It is not usually necessary to do a hardness test on steel components, unless there are signs that they became too hot. When parts become too hot, and a hardness test is necessary, it is specified in the related procedure.

Hardness tests:

Examine all anodized and cadmium plated parts for surface damage caused by scores.

Apply touch-up to open surfaces only.

Do not apply touch-up to the main rotating assembly, where the seal diameters align with the seal outer parts; or to surfaces which touch each other, when the parts are assembled.

Smooth areas of local surface damage, and locally touch-up the surface as given in SPM TASK 70-38-02-300-503 - Application of Chromate Conversion Coatings for Aluminium and SPM TASK 70-33-14-330-501 - Cadmium Plating on Steel.

NOTE

It is not necessary to anodize or cadmium plate this type of part again.

Anodized and cadmium plated parts:

Examine all cases for cracks, distortion, damage and corrosion; specially at joint faces.

Examine all dowel location holes for extension and damage.

Examine all threads for damage. The installation of wire thread inserts to repair damaged threads is given in SPM TASK 70-35-08-300-501.

CAUTION

IF YOU APPLY MECHANICAL FORCE TO STUDS OR INSERTS AS A TIGHTNESS CHECK, OR TRY TO LOOSEN THEM, DAMAGE TO THE ASSEMBLY CAN OCCUR.Examine all studs and inserts for thread damage and tightness. Inserts can be accepted if they are tight and correctly installed. Visually examine to make sure that the top faces of the inserts are below, and clear of, the case joint faces.

Make a mark on all bent or damaged studs to identify them for replacement.

Cases:

Galling is usually identified by a change in the color of the surfaces that touch each other. It is not necessary to remove the galling, unless it prevents the crack inspection procedure. Very fine abrasive paper or metal polish can be used to remove the galling, but it is not permitted to use emery cloth.

Do not fully remove heavy galling marks because their removal will increase the clearance between the mating parts. High points must be removed with a fine abrasive stone.

Galling:

Examine all ring nuts for damage, specially in the spanner slots.

Examine all threads for signs of pick-up.

Examine the mating faces and threads of all silver plated nuts. If the plate has become flaked, cracked, or very black, it must be replaced as given in TASK 70-33-16-330-501 - Silver Plating on Steel, Stainless Steel and Nickel Base Alloys.

NOTE

Nuts that are in good condition must be examined, to make sure they fit their related mating parts.

Ring nuts:

NOTE

Before a magnetic particle inspection of a cup washer, it is necessary to remove the lock marks as given in SPM TASK 70-35-04-350-501.Apply a magnetic particle inspection to the cup washers. Carefully examine the parts of the rim used to lock the cup washer.

Cup washers with permitted rim cracks must be repaired by scalloping as given in SPM TASK 70-35-04-350-501.

Only one scallop is permitted on cup washers used on the engine main rotating assembly.

It is permitted to use a cup washer again if it has two opposite 60 degree lengths of arc that are not used or scalloped.

Do not use cup washers with cracks parallel to the axis of the washer. This is because the hoop strength is not sufficient.

Cup washers used on compressor and turbine shafts can have small circumferential cracks between the washer skirt and the backplate. These cracks must be no longer than 0.125 in. (3.175 mm), and there must not be more than four cracks in a cup washer.

Circumferential cracks are not permitted in other cup washers.

All cup washer mating faces must be smooth, flat, and parallel to less than 0.001 in. (0.025 mm).

Cup washers (steel):

Two types of light weight, 12-point, self-locking nuts are used which are almost the same. One type is magnetic and cadmium-plated, and has a black molybdenum disulfide coating. The other type is not magnetic, and is silver-plated. The instructions on how to identify the different types are given in SPM TASK 70-42-02-220-501.

Nuts with damaged mating faces, spanner serrations or threads must be discarded.

Make sure that all nuts that are to be used again have sufficient plating and/or molybdenum disulfide coating on their threads and mating surfaces. This is so that they can not become seized.

A table of the permitted locking torque loads is given in SPM TASK 70-41-02-400-501. The locking torque load is the torque necessary to turn the nut. This is with the full chamfer of the bolt or stud locked, and with no axial load on the nut.

Reject all nuts with a minimum or maximum locking torque limit outside that given in SPM TASK 70-41-02-400-501. Below the minimum limit, the grip load is not sufficient; while above the maximum limit, the nut lock device is stressed too much. In time, it is possible for a person to feel, then make an accurate estimate of, the permitted locking torque. If it is possible to install a nut along the full length of an external thread by hand, then that nut must be discarded.

NOTE

Do not change the locking torque of a nut mechanically (for example, do not crimp a lock device to tighten it; or loosen it with a tap).

Self-locking nuts:

All used flexible seals and seal rings must be discarded; the time that the engine has run is not important.

Used parts:

On some small parts (for example, turbine blades), there is not sufficient space to engrave the numbers of the repairs included. Because of this, special code symbols are used. These symbols are identified as numbers in a triangle. Reference to the List of Repairs, for the Chapter/Section/Subject of the related component, will show the repair numbers related to the code symbols.

During inspection before the components are repaired, the code symbols must be examined. This is to make sure that repairs, that can only be done one time, are not done again.

During inspection, all items and details included when the repairs were done must be examined. This is to make sure that they are satisfactory for continued use. Also, all related crack tests and/or dimension checks must be done when necessary.

Repaired part inspection:

Inspection of Parts

Figure: Parts Inspection Locations - (Example Only)

Parts Inspection Locations - (Example Only)

Figure: Names Used To Show Direction Of Defects

Names Used To Show Direction Of Defects