Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-35-04-350-501 Repair And Install Cupwashers

General

This repair is applicable to cupwashers that are used in all areas of the engine.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop tools | LOCAL | Standard workshop tools |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-24-01-240-501, Magnetic Particle Inspection and TASK 70-20-01-200-501, Inspection of Parts (cupwasher).

Magnetically crack test the cupwasher.

SUBTASK 70-35-04-240-001 Inspect the Cupwasher for Cracks

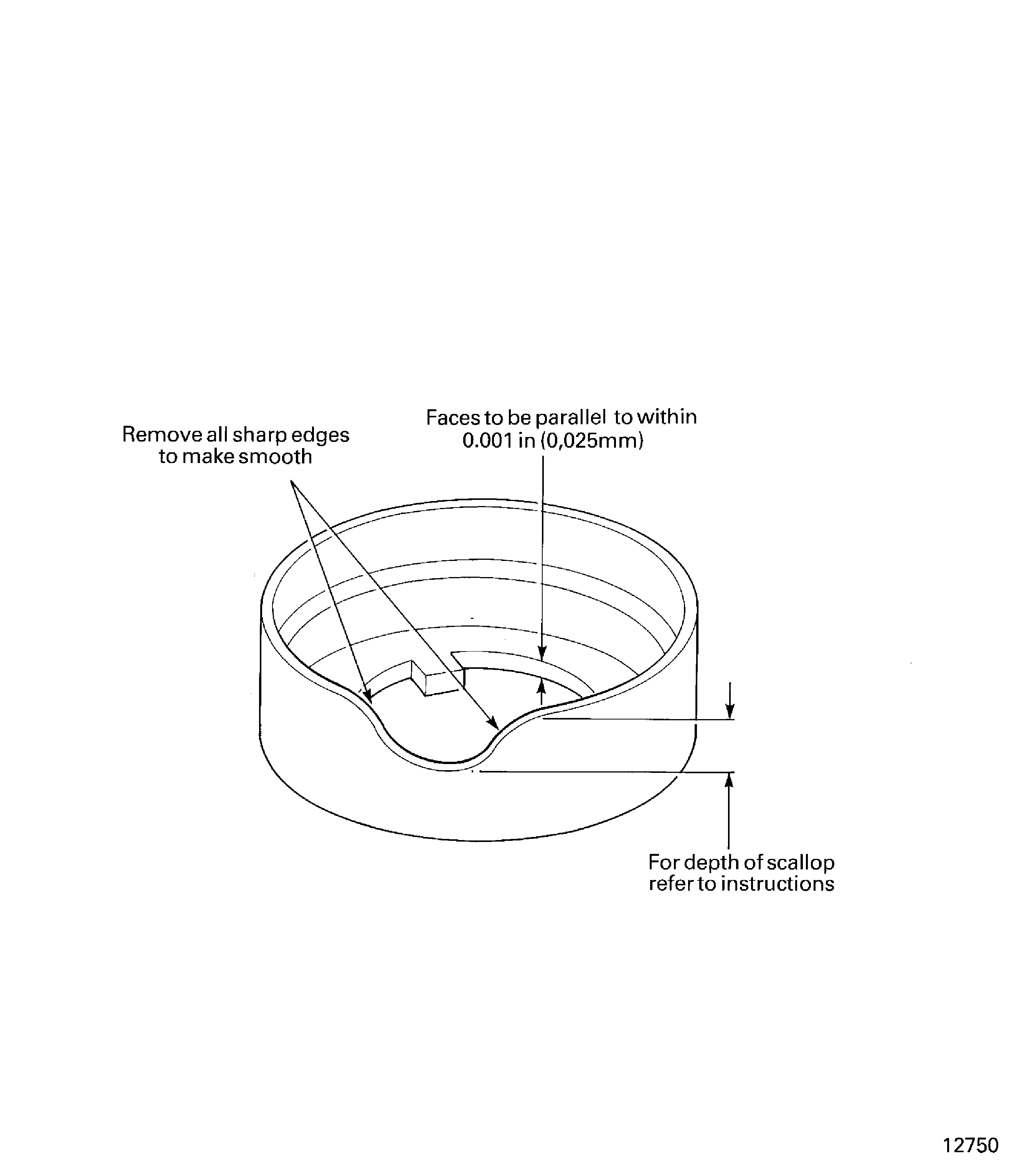

Remove all of the sharp edges from the scallop to make it smooth. Refer to Figure.

Scallop depth must not be more than 0.125 in. (3.17 mm) on cupwashers with a thickened section between the lock rim and the backplate. Cupwashers with an equal rim thickness must not be scalloped more than 50 percent of the rim depth.

SUBTASK 70-35-04-350-002 Remove Cracks From the Rim With a Small Scallop to the Specified Depth

Refer to the SPM TASK 70-24-01-240-501, Magnetic Particle Inspection and 70-20-01-200-501, Inspection of Parts (cupwashers).

For magnetic materials, magnetically crack test the cupwasher.

Refer to the SPM TASK 70-23-01-230-501, Fuorescent Penetrant Inspection and SPM TASK 70-20-01-200-501, Inspection of Parts (cupwasher).

For non-magnetic materials, fluorescent pentrant crack test the cupwasher.

SUBTASK 70-35-40-240-002 Examine the Cupwasher for Cracks After Small Scallop

Remove all of the sharp edges from the scallop to make it smooth. Refer to Figure.

On cupwashers with a thickened section between the rim and the backplate, the scallop must not go further than the thickened section of the cupwasher. Cupwashers with an equal rim thickness must not be scalloped more than two thirds of the rim depth.

SUBTASK 70-35-04-350-003 Remove Cracks From the Rim With a Large Scallop to the Specified Depth

Refer to the SPM TASK 70-24-01-240-501, Magnetic Particle Inspection and TASK 70-20-01-200-501, Inspection of Parts (cupwashers).

For magnetic materials, magnetically crack test the cupwasher.

Refer to the SPM TASK 70-23-01-230-501, Fuorescent Penetrant Inspection and SPM TASK 70-20-01-200-501, Inspection of Parts (cupwasher).

For non-magnetic materials, fluorescent pentrant crack test the cupwasher.

SUBTASK 70-35-04-240-003 Examine the Cupwasher for Cracks After Large Scallop

Figure: Repair cupwasher with a scallop

Repair cupwasher with a scallop