Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-42-220-001 Combustion System - Examine The Diffuser Case Assembly Front Face at Interface H-42, Inspection-001

General

The word 'reject' after an interface inspection statement requires that further detailed inspection or repair as applicable, of the affected area be accomplished using data in the applicable ATA section of the part in question. Contact IAE for FAA approved data if the referenced TASK is not in the manual.

Refer to TASK 72-00-00-200-001 (examine the modular/non-modular interfaces) before you do this TASK.

The policy that is necessary for inspection is given in the SPM TASK 70-20-01-200-501.

Interface limit definitions

Nick | - | A small area of local displacement of metal usually caused by contact with another object. There is no distortion to the adjacent metal. |

Dent | - | A surface depression made by contact with another object and can possibly have local distortion of the adjacent metal. |

Warp | - | A local area of metal twisted or damaged from it's original shape. For this applicable function, warps cause metal movement of less than 0.050in. (0.270 mm). |

Distortion | - | An area (larger than a warp) of metal damaged from it's original shape. For this applicable function, distortion can cause metal movement more than 0.050in. (0.270 mm). |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

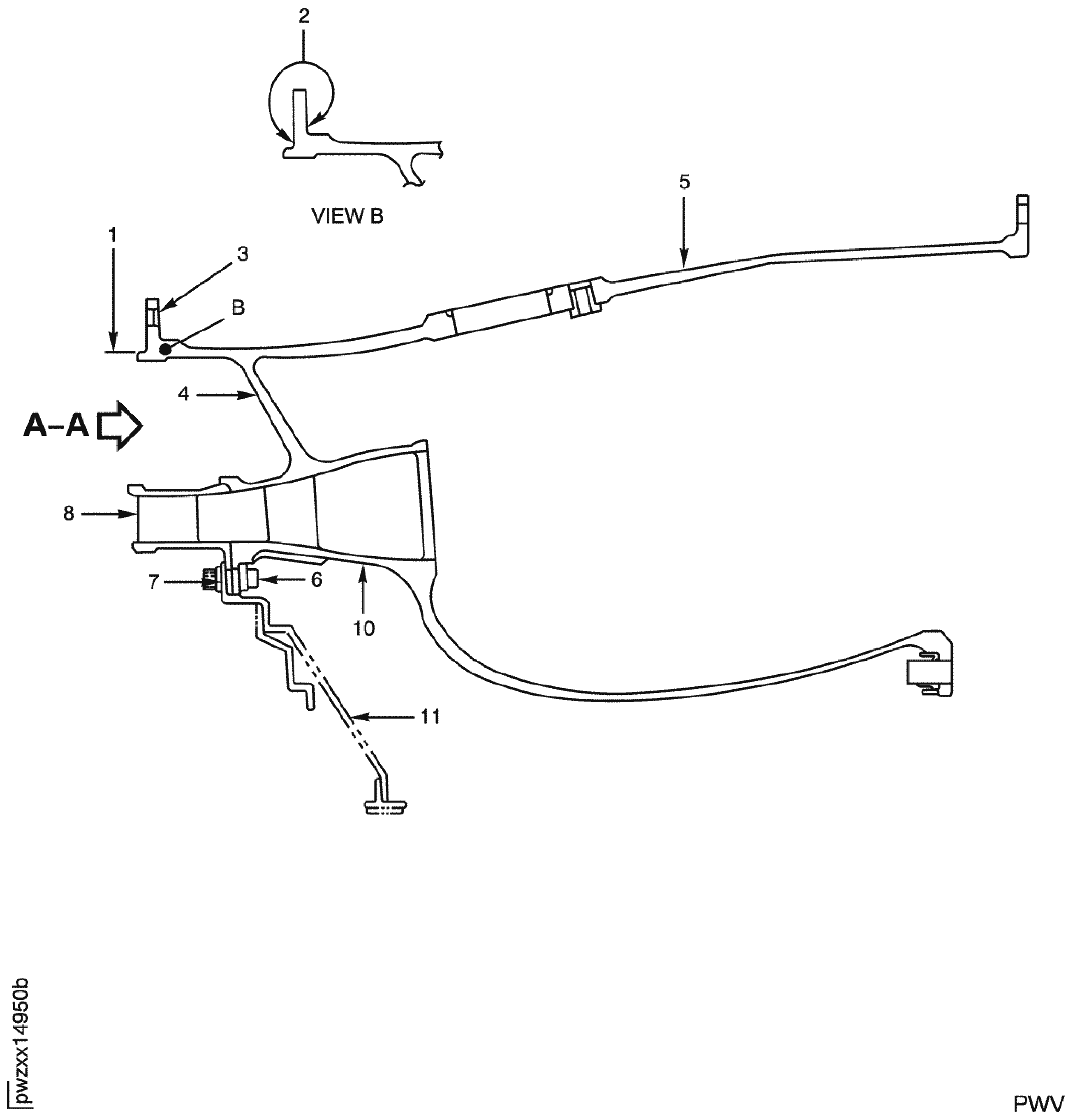

SUBTASK 72-00-42-220-053 Visually Examine the Flange of the Diffuser Case Assembly at Location 2

Refer to Figure.

SUBTASK 72-00-42-220-054 Visually Examine the Flange Dowel Pin and the Bolt Holes on the Diffuser Case Assembly at Location 3

Refer to Figure.

SUBTASK 72-00-42-220-055 Visually Examine the Inner Surface of the Diffuser Case Assembly at Location 4

Refer to Figure.

SUBTASK 72-00-42-220-056 Visually Examine the Outer Surface of the Diffuser Case Assembly at Location 5

Refer to Figure.

SUBTASK 72-00-42-220-057 Visually Examine the Front Inner Flange Flare Nuts of the Diffuser Case Assembly at Location 6

Refer to Figure.

SUBTASK 72-00-42-220-058 Visually Examine the Inner Front Flange Face of the HPC Outlet Guide Vanes at Location 7

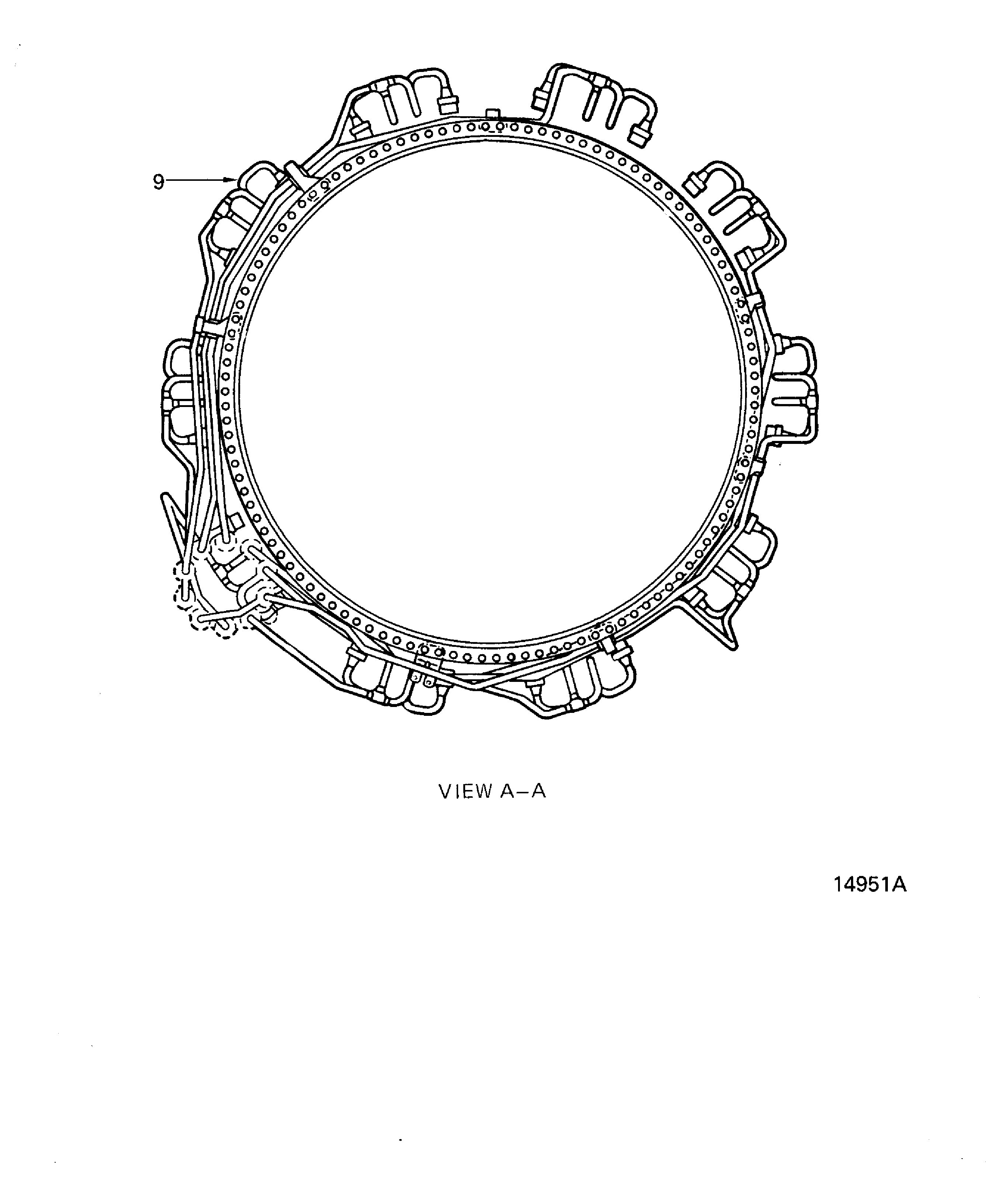

Figure: Locations at Interface H-42

Locations at Interface H-42

Figure: Locations at Interface H-42

Locations at Interface H-42