DMC:V2500-A5-72-00-4000-00B-300A-B|Issue No:004.00|Issue Date:2018-02-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991:

SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.

Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021)

The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).

Common Information

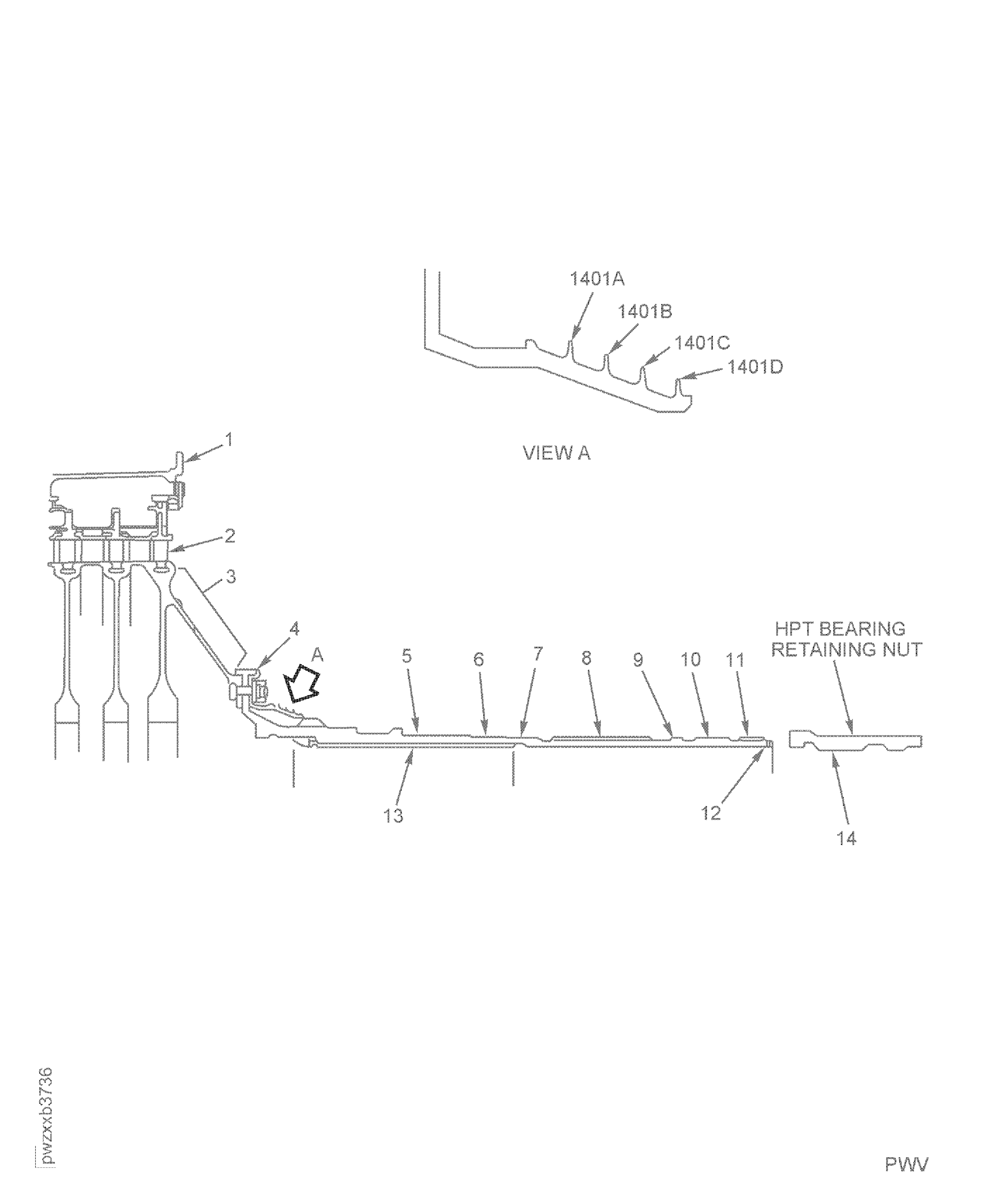

TASK 72-00-40-220-002-B00 HP System Module - Examine The HP Compressor Rotor Assembly At Interface H-41, Inspection-002

General

Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-001), (Examine the modular/non-modular interfaces), before you do this TASK.

The policy that is necessary for inspection is given in the SPM TASK 70-20-01-200-001.

A ** following repair referenced in this inspection indicates that the repair is not yet published in the current revision of the manual and the part must be rejected. Contact IAE for additional information concerning FAA approved repair date.

The word 'reject' after an interface inspection statement requires that further detailed inspection or repair, as applicable, of the affected area be accomplished using data in the applicable ATA section of the part in question. Contact IAE for FAA approved data if the referenced TASK is not in the manual.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

SUBTASK 72-00-40-220-117 Examine the Rear Flange of the HP Compressor Rear Outer Case at Location 1

SUBTASK 72-00-40-220-118 Examine the Stage 12 HP Compressor Blades at Location 2

Nicked up to 0.030 in. (0.76 mm) in depth in the first 0.250 in. (6.35 mm) along the blade length (when measured from the blade tip).

Nicked in the first 0.250 in. (6.35 mm) along the blade length (when measured from the root).

Nicked up to 0.015 in. (0.38 mm) in depth in the area remaining.

Dents that are not related to nicks.

Dents that are related to nicks.

Missing piece (not related to tip rub).

Discoloration (related to tip rub).

Bent or curled (not related to cracks or tears) not more than 5 percent of the blade length or width.

Tip rub (not related to cracks or tears).

Light deposits of abradable/atmospheric contamination.

SUBTASK 72-00-40-220-119 Examine the Stage 12 HP Compressor Disk at Location 3

Up to 0.003 in. (0.076 mm) in depth.

Up to 0.003 in. (0.076 mm) in depth.

SUBTASK 72-00-40-220-120 Examine the HP Compressor Rotating Seal at Location 4

Chipped up to 10 percent of total width, 25 percent of the circumference and 0.004 in. (0.10 mm) in depth along the edges.

Pitted in brush seal rub track.

Scattered pits in other areas up to 0.025 in. (0.64 mm) in diameter and 0.004 in. (0.10 mm) in depth.

Scratched in brush seal rub track.

Scratched in other areas up to 0.002 in. (0.05 mm) in depth and 0.250 in. (6.35 mm) in length.

Up to 0.002 in. (0.05 mm) smooth constant wear in brush rub track.

SUBTASK 72-00-40-220-121 Examine the HP Compressor Rotating Air Seals at Locations 1401A, 1401B, 1401C and 1401D

Do an 8 point check at locations 1401A, 1401B, 1401C and 1401D. Calculate the average diameters and make sure they are in the limits that follow.

If the diameter is between 7.539 and 7.546 in. (191.49 and 191.67 mm).

Less than 7.539 in. (191.49 mm).

If the diameter is between 7.326 and 7.333 in. (186.08 and 186.27 mm).

Less than 7.326 in. (186.08 mm).

If the diameter is between 7.113 and 7.121 in. (180.67 and 180.87 mm).

Less than 7.113 in. (180.67 mm).

If the diameter is between 6.901 and 6.908 in. (175.28 and 175.47 mm).

Less than 6.901 in. (175.28 mm).

NOTE

One of the seal fin diameters can be less than the limit given in

Step,

Step,

Step, or

Stepif the other seal fins are within the limits.

SUBTASK 72-00-40-220-122 Examine the HP Compressor Shaft Location Diameter at Location 5

Repair, VRS6088 TASK 72-41-13-300-019 (REPAIR-019).

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Up to 0.003 in. (0.076 mm) in depth.

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Do an 8 point check and calculate the average diameter.

If the diameter is between 5.127 and 5.129 in. (130.23 and 130.28 mm).

Less than 5.127 in. (130.23 mm).

SUBTASK 72-00-40-220-123 Examine the HP Compressor Shaft Bearing Location Diameter at Location 6

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Up to 0.003 in. (0.076 mm) in depth.

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Do an 8 point check and calculate the average diameter.

If the diameter is between 5.1184 and 5.1191 in. (130.007 and 130.025 mm).

Less than 5.1184 in. (130.007 mm).

SUBTASK 72-00-40-220-124 Examine the HP Compressor Shaft Snap Diameter at Location 7

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Up to 0.003 in. (0.076 mm) in depth.

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Do an 8 point check and calculate the average diameter.

If the diameter is between 5.107 and 5.108 in. (129.72 and 129.74 mm).

Less than 5.107 in. (129.72 mm).

SUBTASK 72-00-40-220-125 Examine the HP Compressor Shaft Splines at Location 8

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

SUBTASK 72-00-40-220-126 Examine the HP Compressor Shaft Snap Diameter at Location 9

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Up to 0.003 in. (0.076 mm) in depth.

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Do an 8 point check and calculate the average diameter.

If the diameter is between 4.841 and 4.842 in. (122.96 and 122.99 mm).

Less than 4.841 in. (122.96 mm).

SUBTASK 72-00-40-220-127 Examine the HP Compressor Shaft Diameter at Location 10

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

Up to 0.003 in. (0.076 mm) in depth.

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

SUBTASK 72-00-40-220-128 Examine the HP Compressor Shaft Threads at Location 11

SUBTASK 72-00-40-220-129 Examine the HP Compressor Shaft Slots at Location 12

Repair, VRS6088 TASK 72-41-13-300-019 (72 -41-13, REPAIR 019).

SUBTASK 72-00-40-220-130 Examine the HP Compressor Shaft Heatsheild at Location 13

SUBTASK 72-00-40-220-131 Examine the HPT Bearing Retaining Nut (ATA 72-40-00, 04-020) at Location 14

If the HPT Bearing Retaining Nut is to be reinstalled, silver plate must be replaced before installing. Refer to Repair, VRS3011 TASK 72-40-00-300-006 (REPAIR-006).

Requirements After Job Completion

Follow-On Conditions

NONE