Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-00-200-003-A00 Engine General - Examine (Borescope) The Combustion Chamber And The HPT Stage 1 Vanes, Inspection-003

General

All Fig/item numbers in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Assembly tolerances are included in this procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

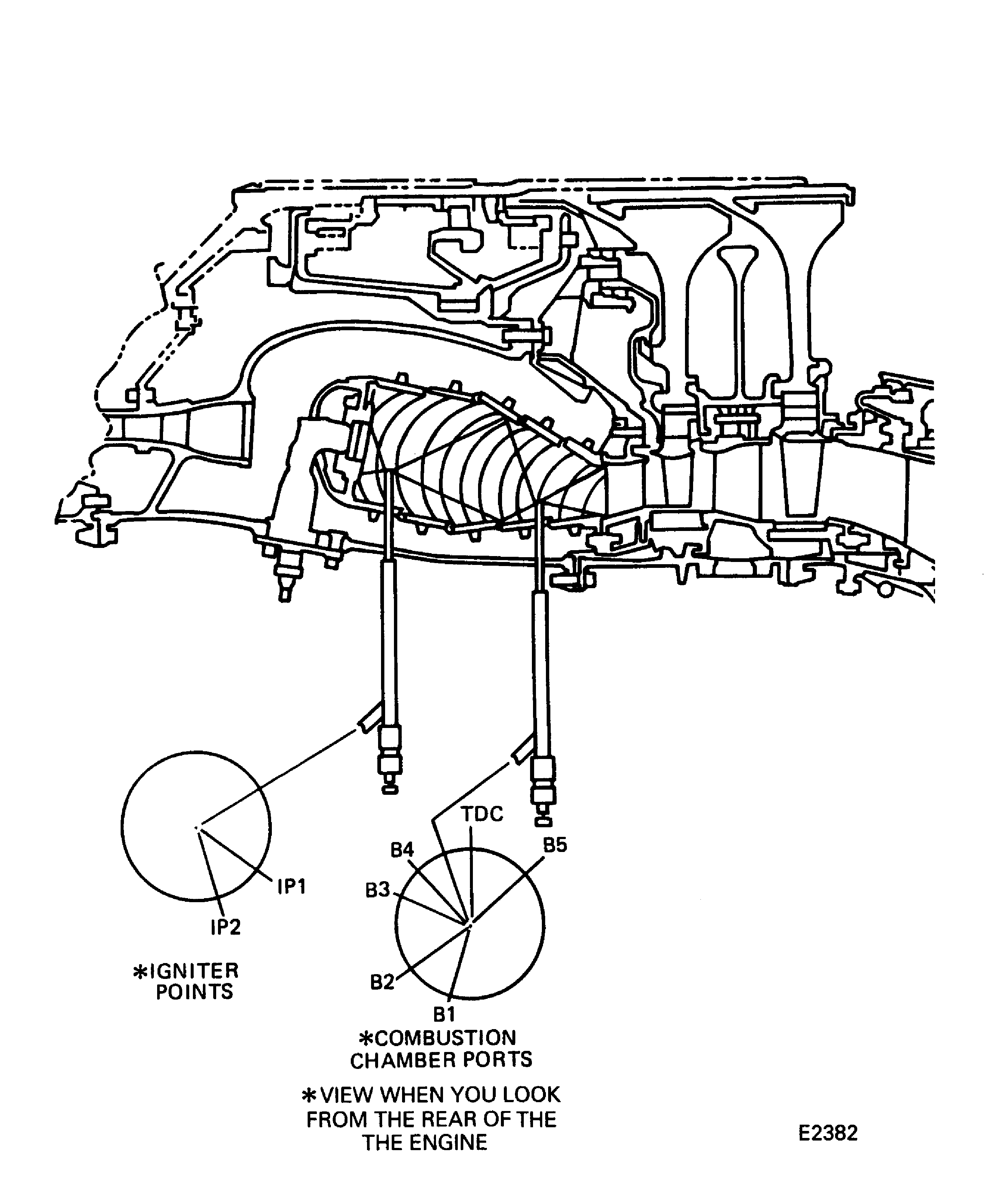

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Definitions and General Information

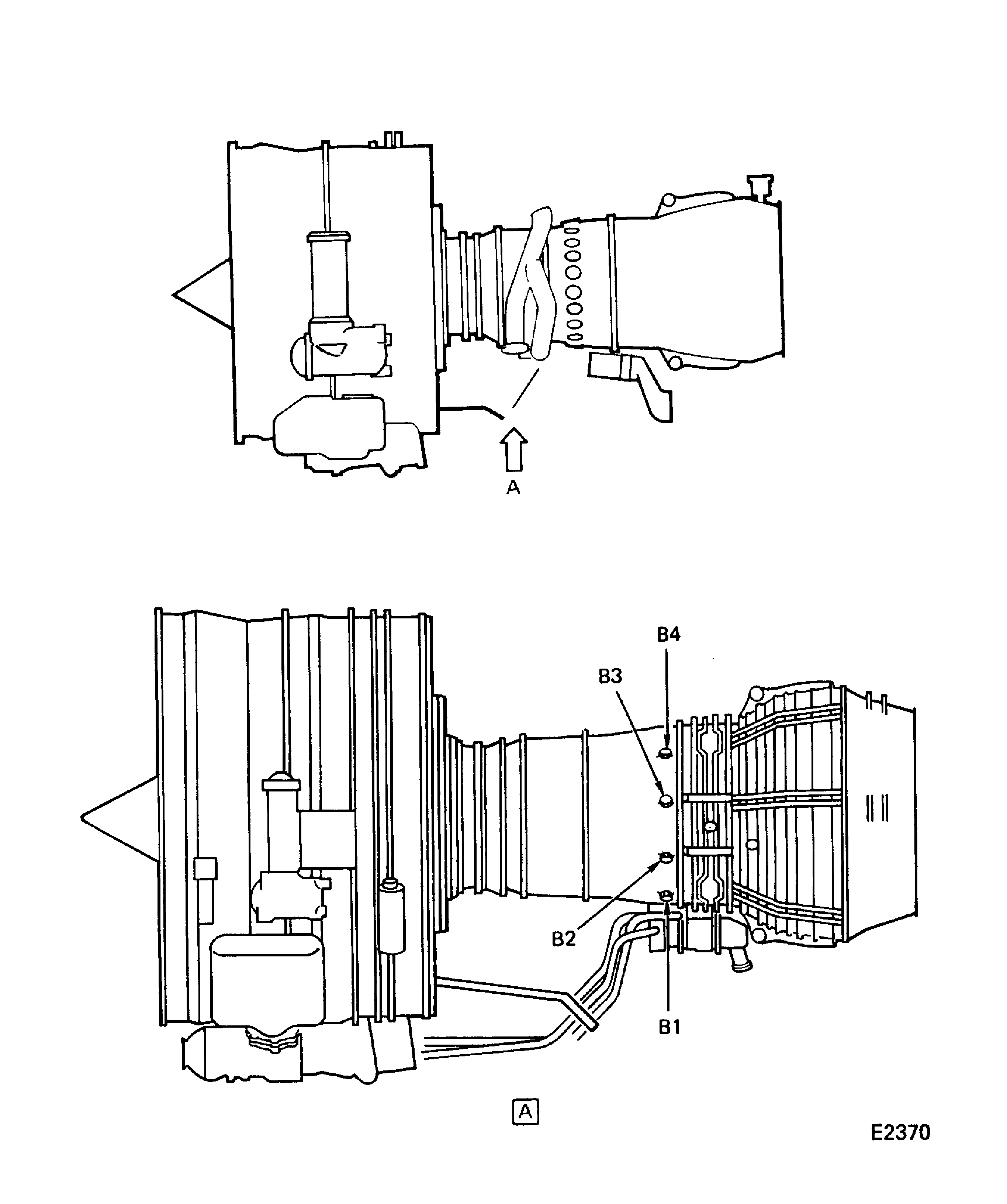

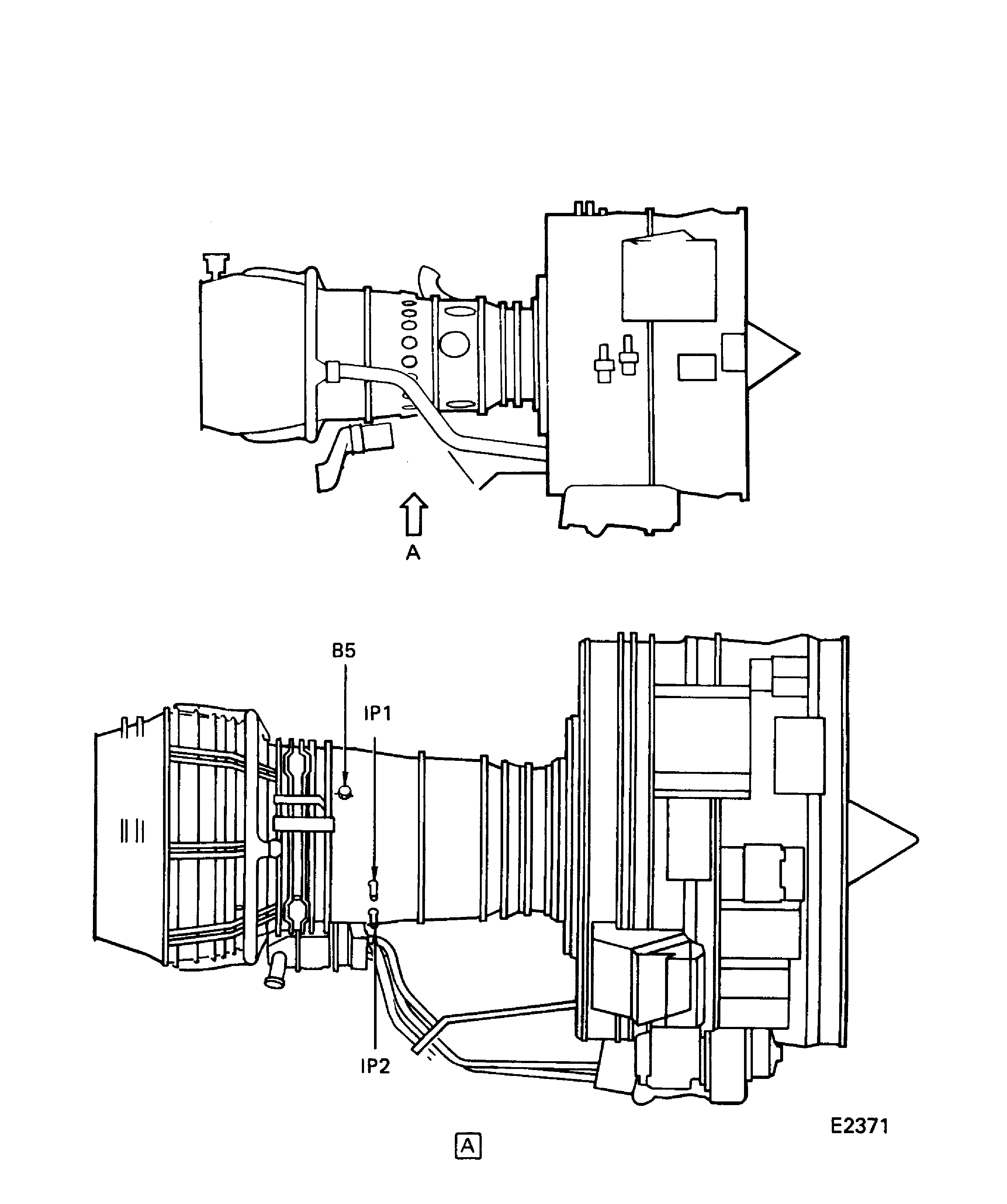

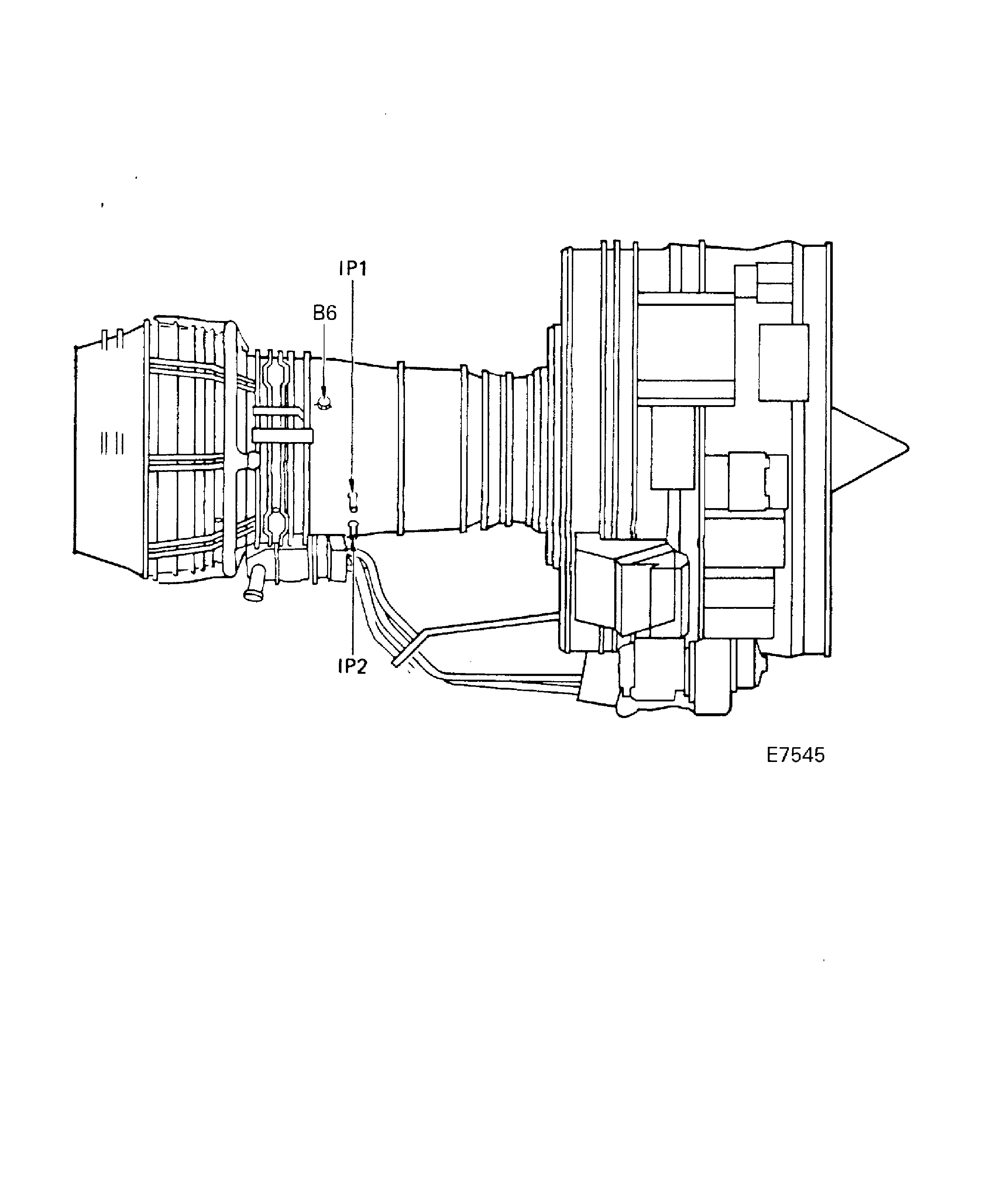

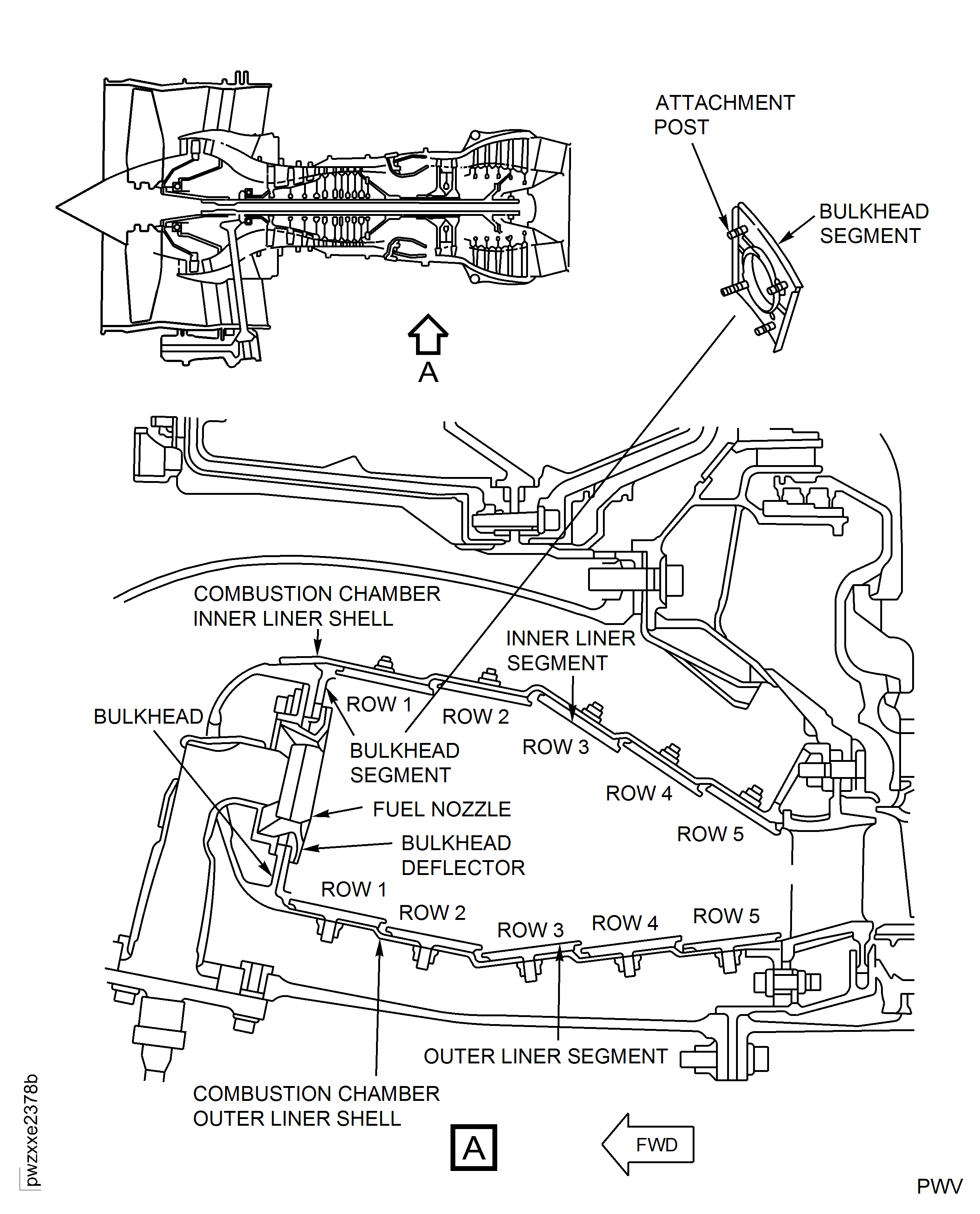

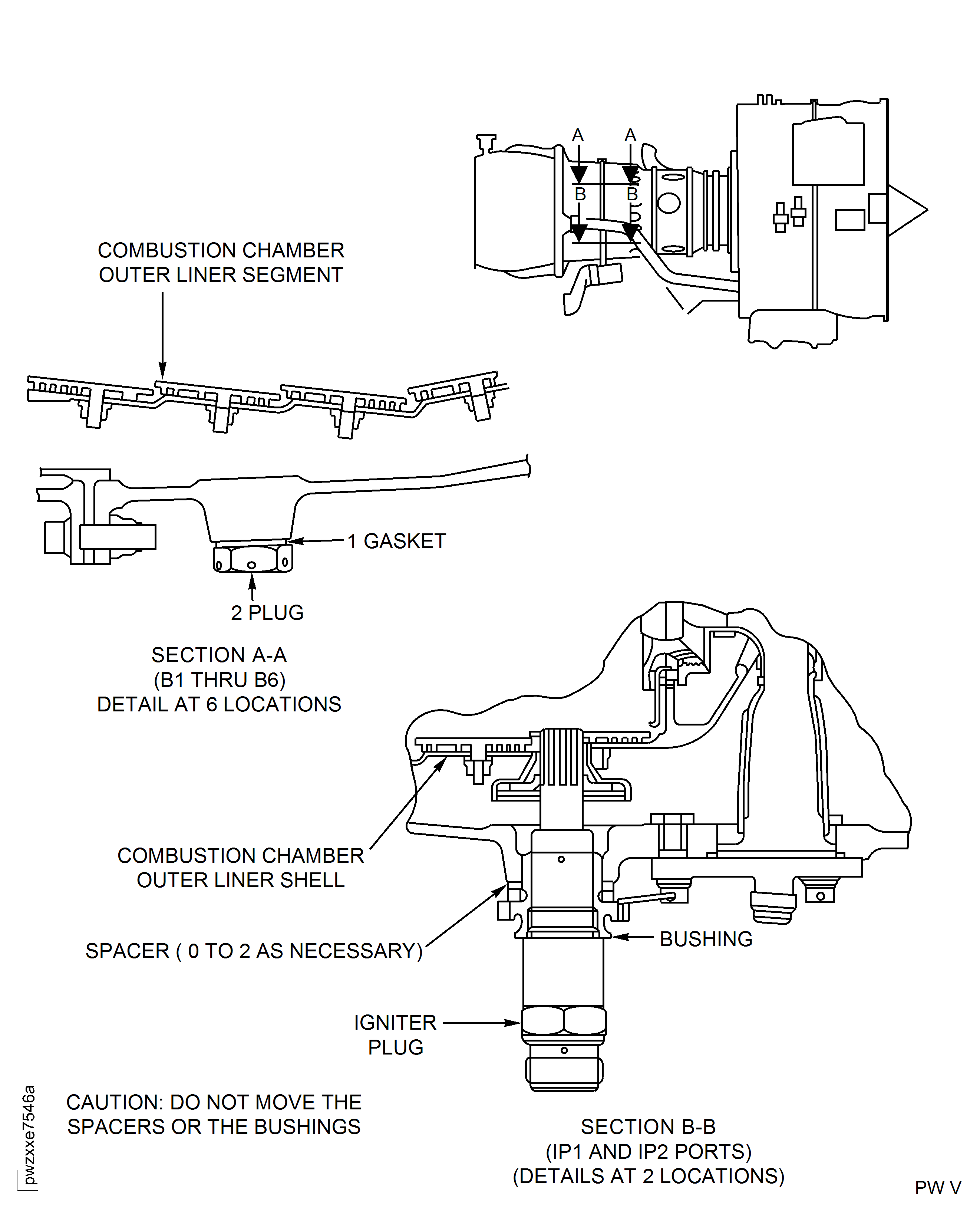

Pre SBE 72- 0221: Five borescope ports and two igniter ports give access to the combustion chamber and the Stage 1 HPT vanes Figure, Figure, Figure and Figure.

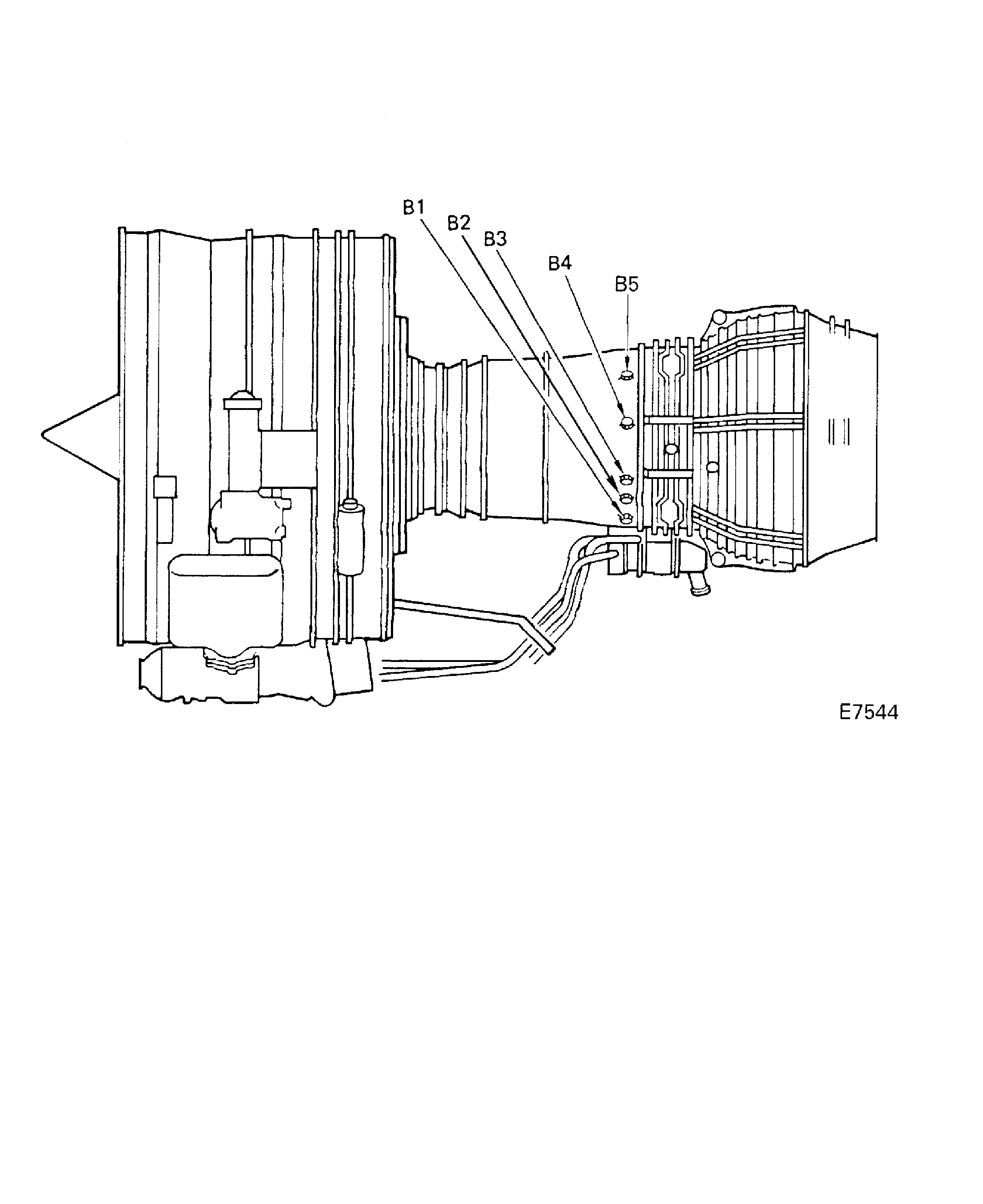

SBE 72- 0221: Six borescope ports and two igniter ports give access to the combustion chamber and stage 1 HPT vanes, Figure, Figure, Figure and Figure.

Use the terms which follow when you identify a combustion chamber condition seen during borescope inspection:

BURN: A local area of burner liner segment surface that has changed colour, has a rough surface texture or shows thinner material because of high temperatures. Burns can be located all around but more are found downstream of combustion holes in the burner liner segments.

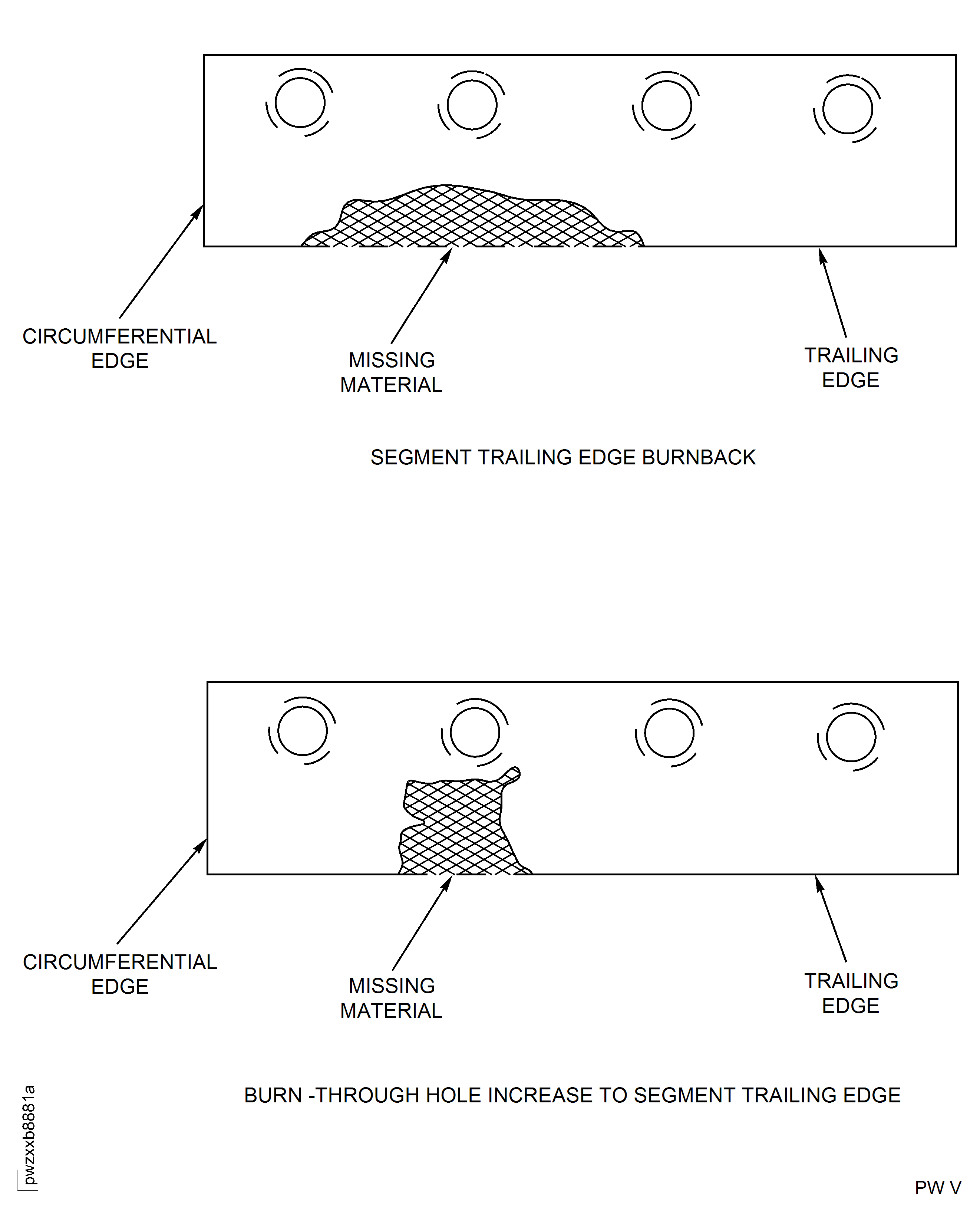

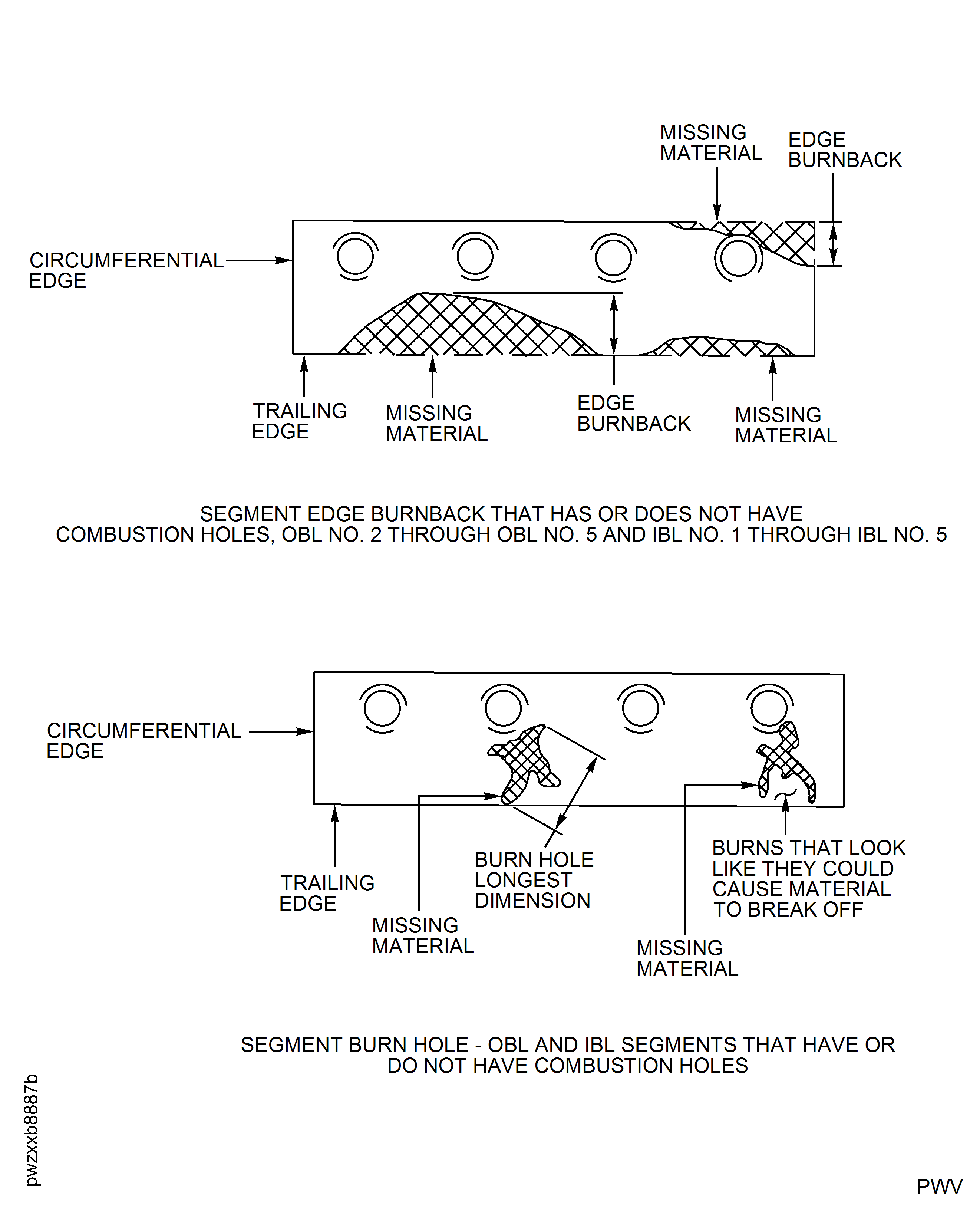

BURN HOLE: A local burn area that has continued to a segment hole and does not extend to the leading or trailing edge of the segment. Figure.

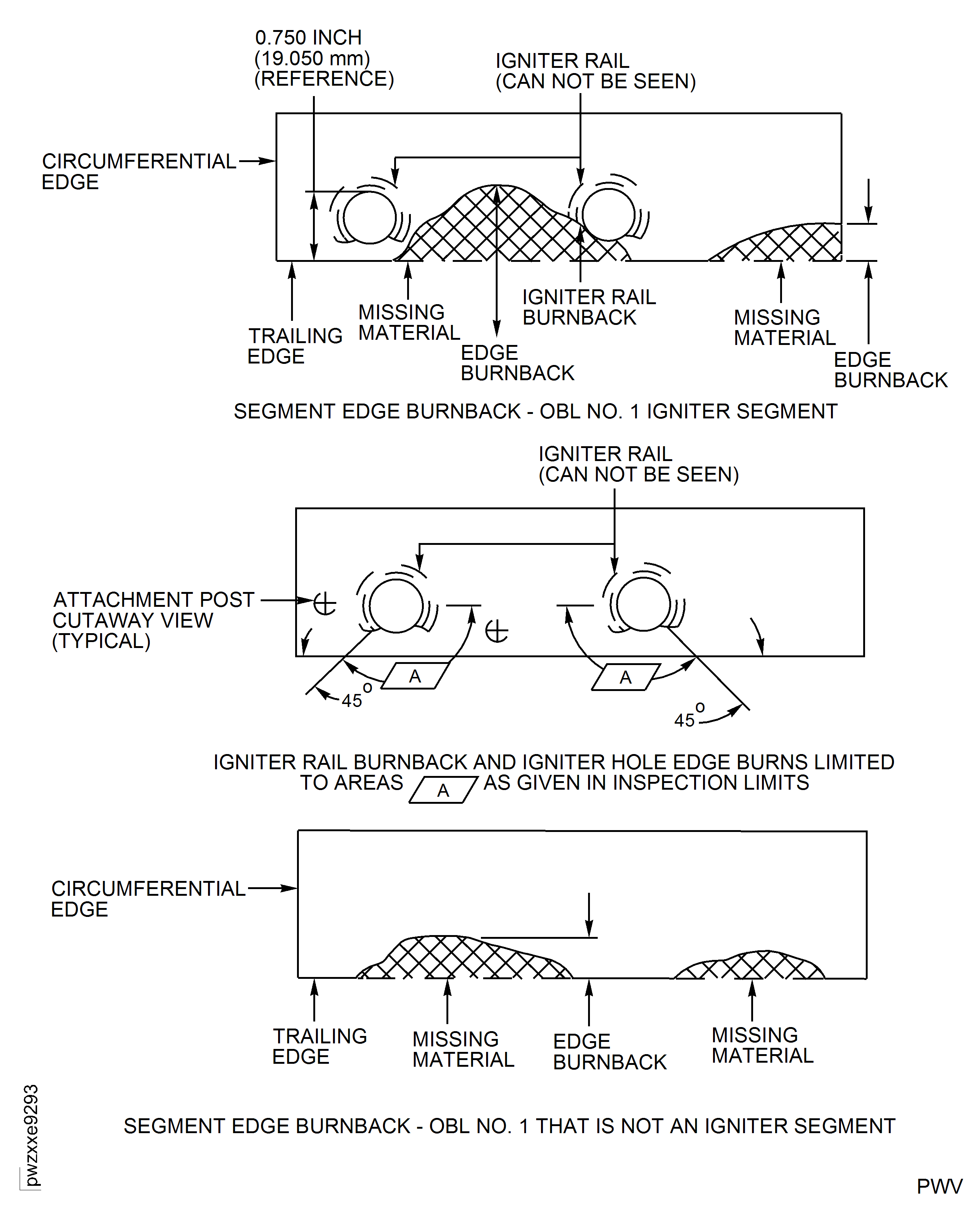

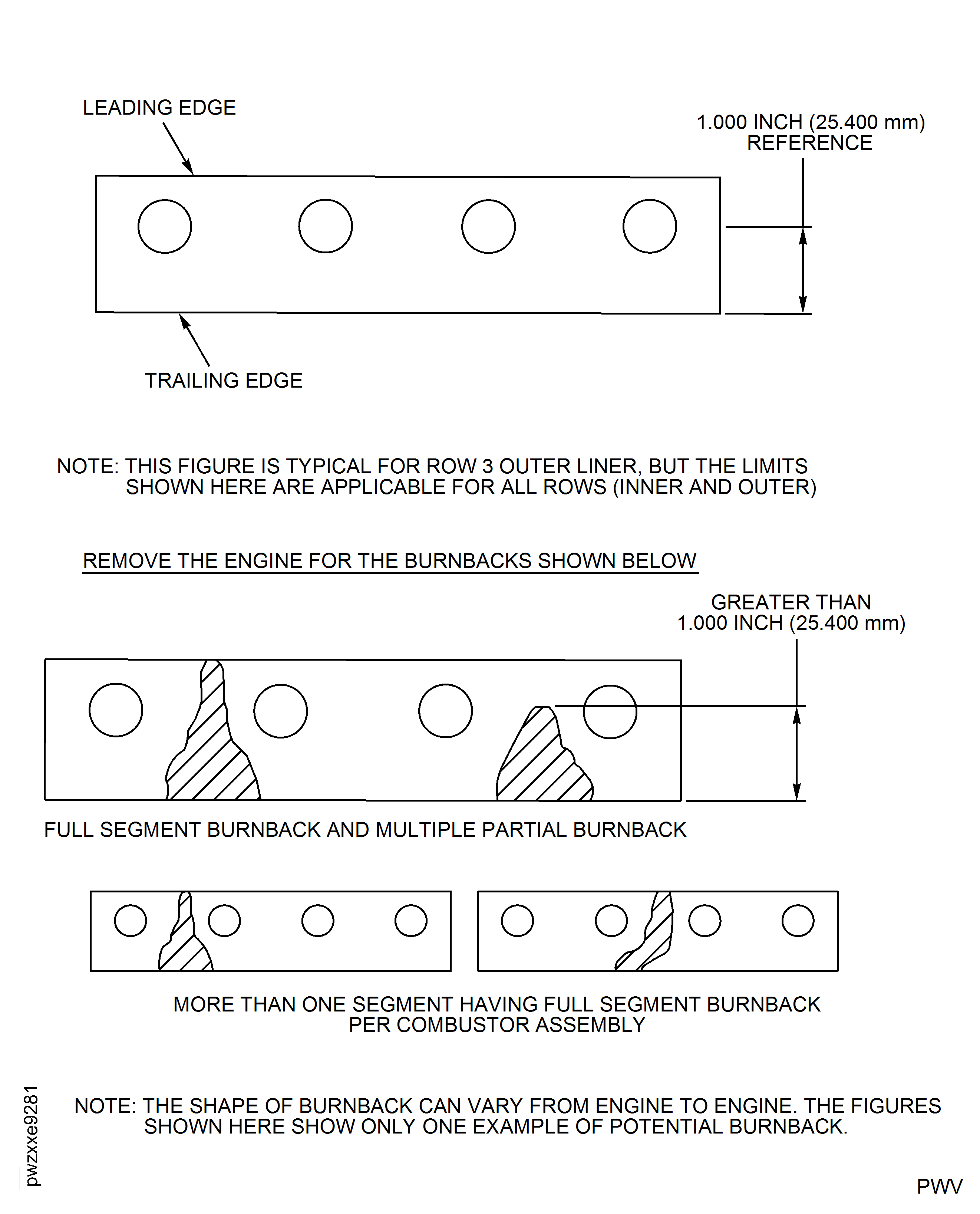

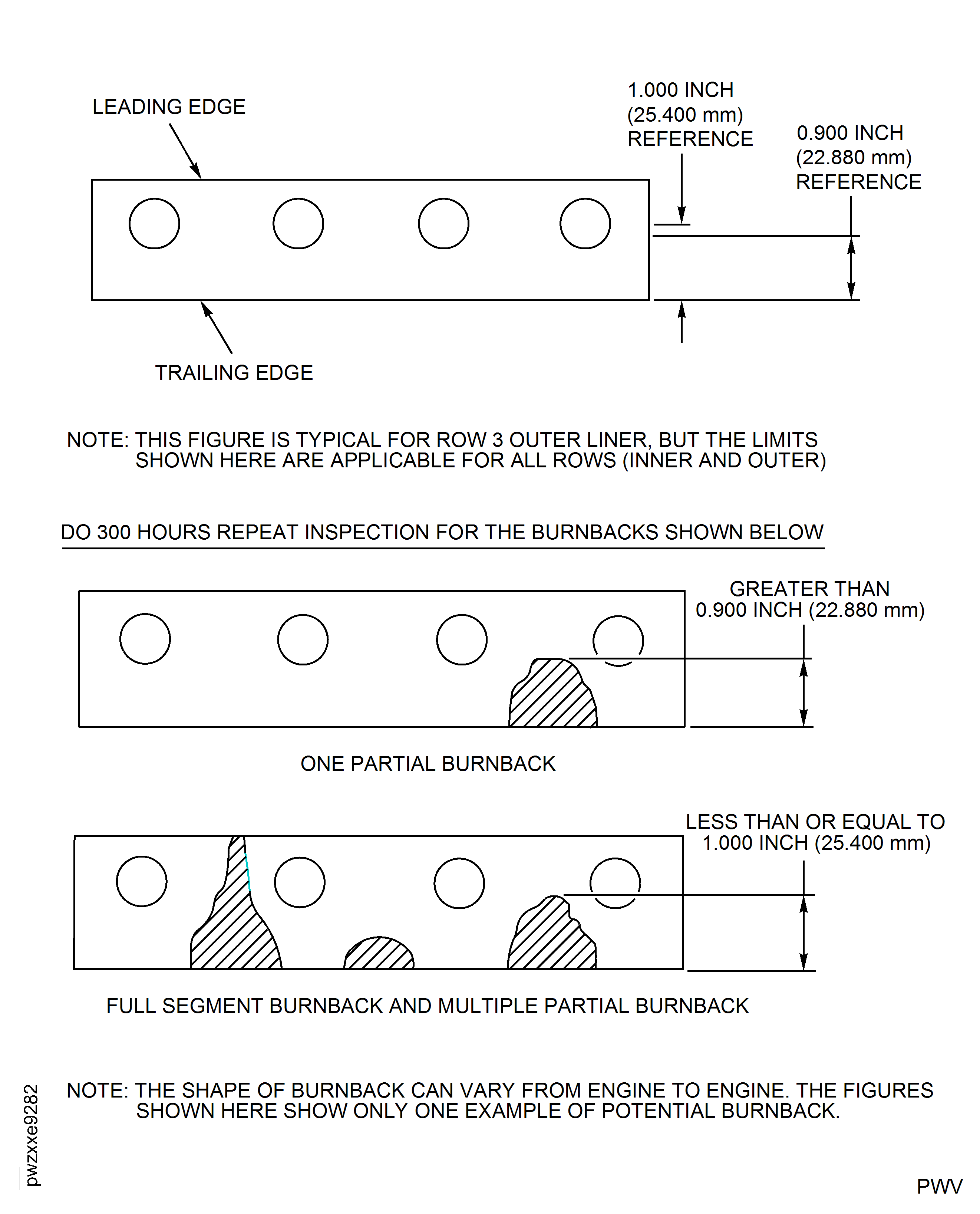

EDGE BURNBACK: Full thickness segment burns that start at an edge, occur more at the segment trailing edge location but have also occurred at the leading edge. Burnback is segment material that is missing. Complete edge burnback is when segment material is missing from the trailing edge to the leading edge. Figure.

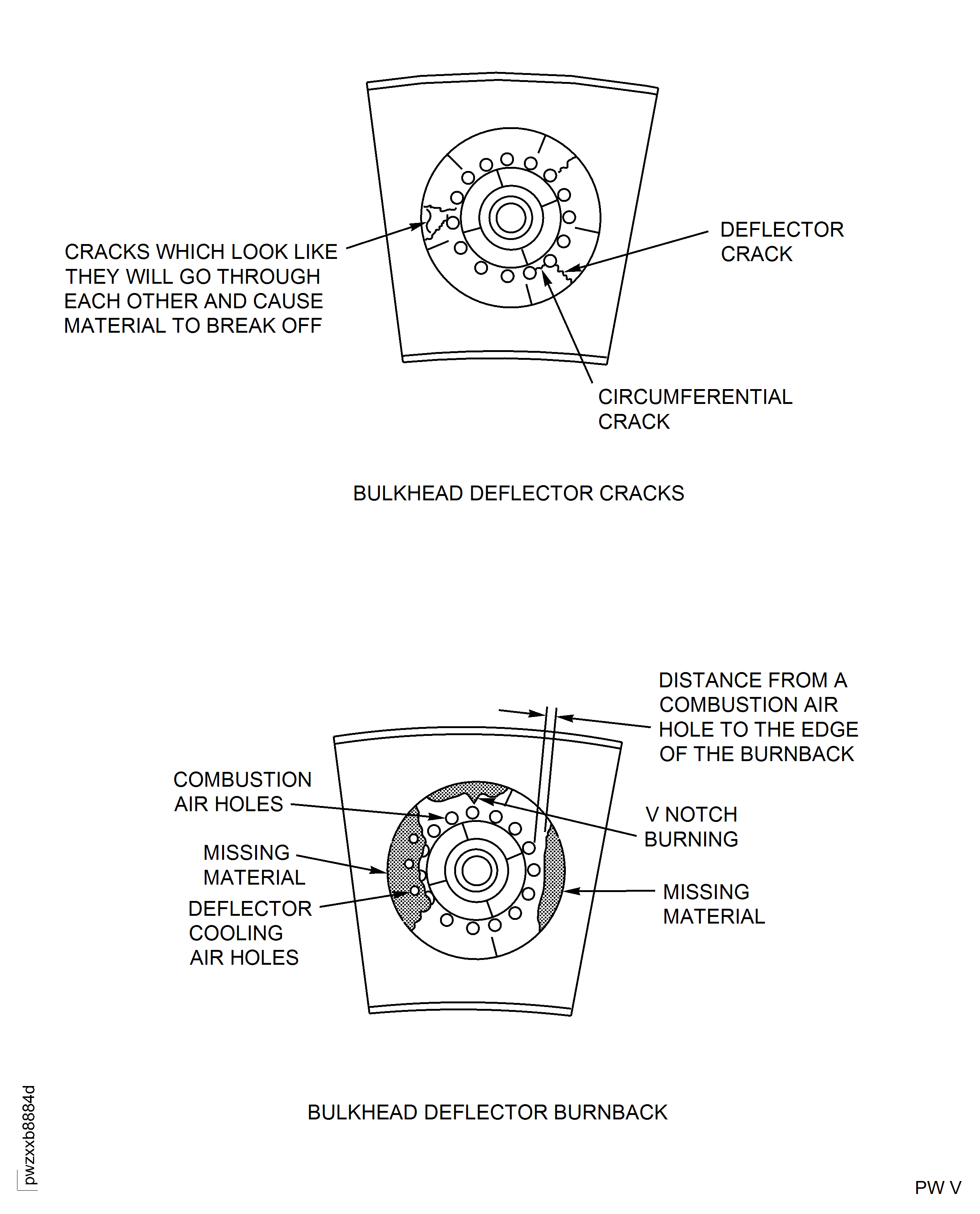

RADIAL BURNBACK: Full thickness burning on deflector edge continuing radially inward toward the fuel nozzle.

THROUGH CRACK: A crack on the surface of the segment material that has penetrated beyond the surface into and past the parent material. Typically the crack will be black in color and liner segment separation will be visible at the crack location.

NON-THROUGH CRACK: An indication/crack on the segment material which does not extend beyond segment material. Non-through cracks are acceptable as-is and should not be added to the measurement of the through crack.

General inspection guidelines:

Give the results of decreased time inspections to your IAE representative.

If a piece of combustion chamber materials breaks off between inspection times, a borescope inspection of the high pressure turbine is necessary. If the high pressure turbine is not damaged after the material breaks off you can continue the combustion chamber borescope inspections at the times given by other limits.

All spalled ceramic coating on the combustor segments, the bulkhead segments or the bulkhead deflectors is acceptable without a decreased borescope inspection time.

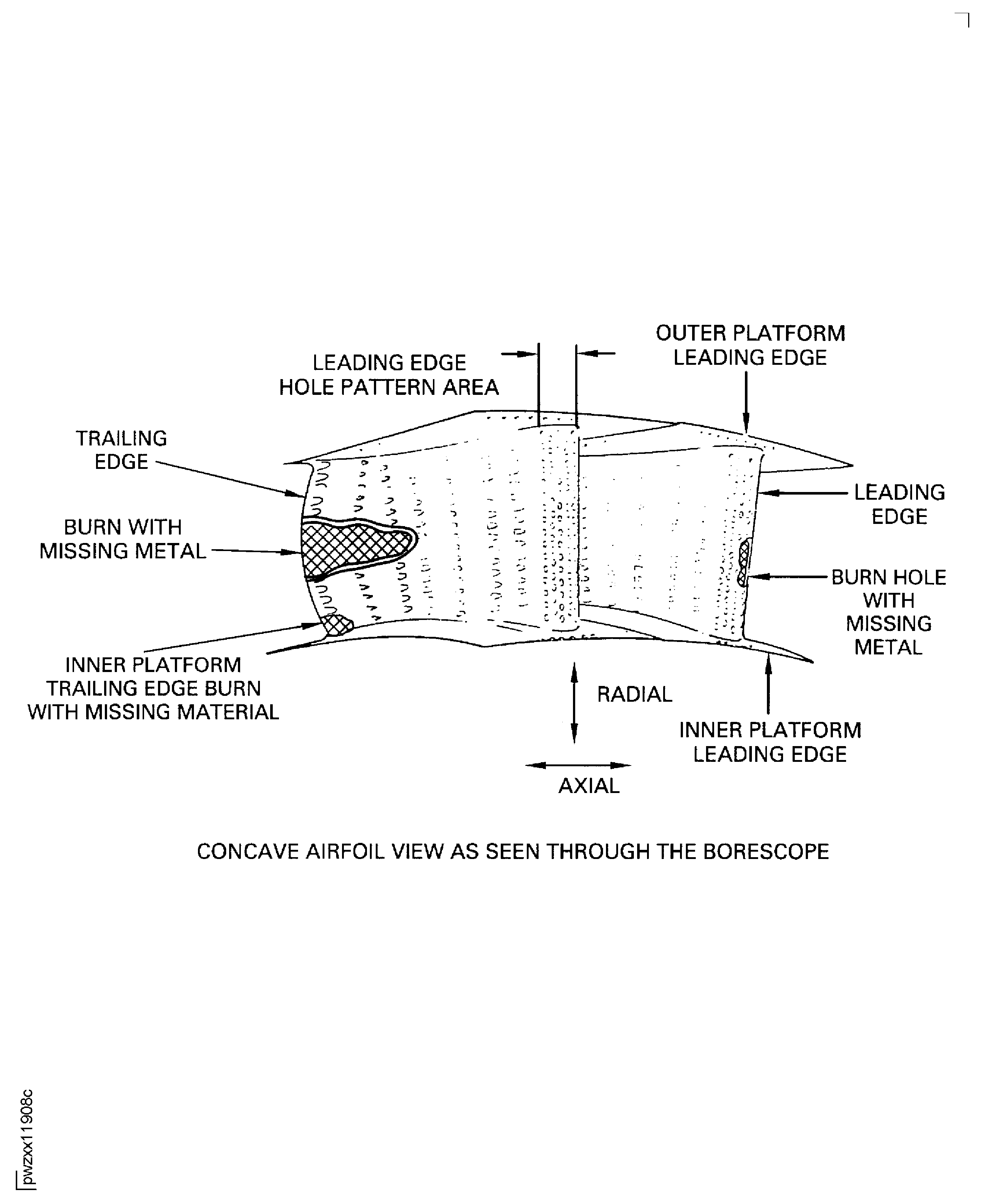

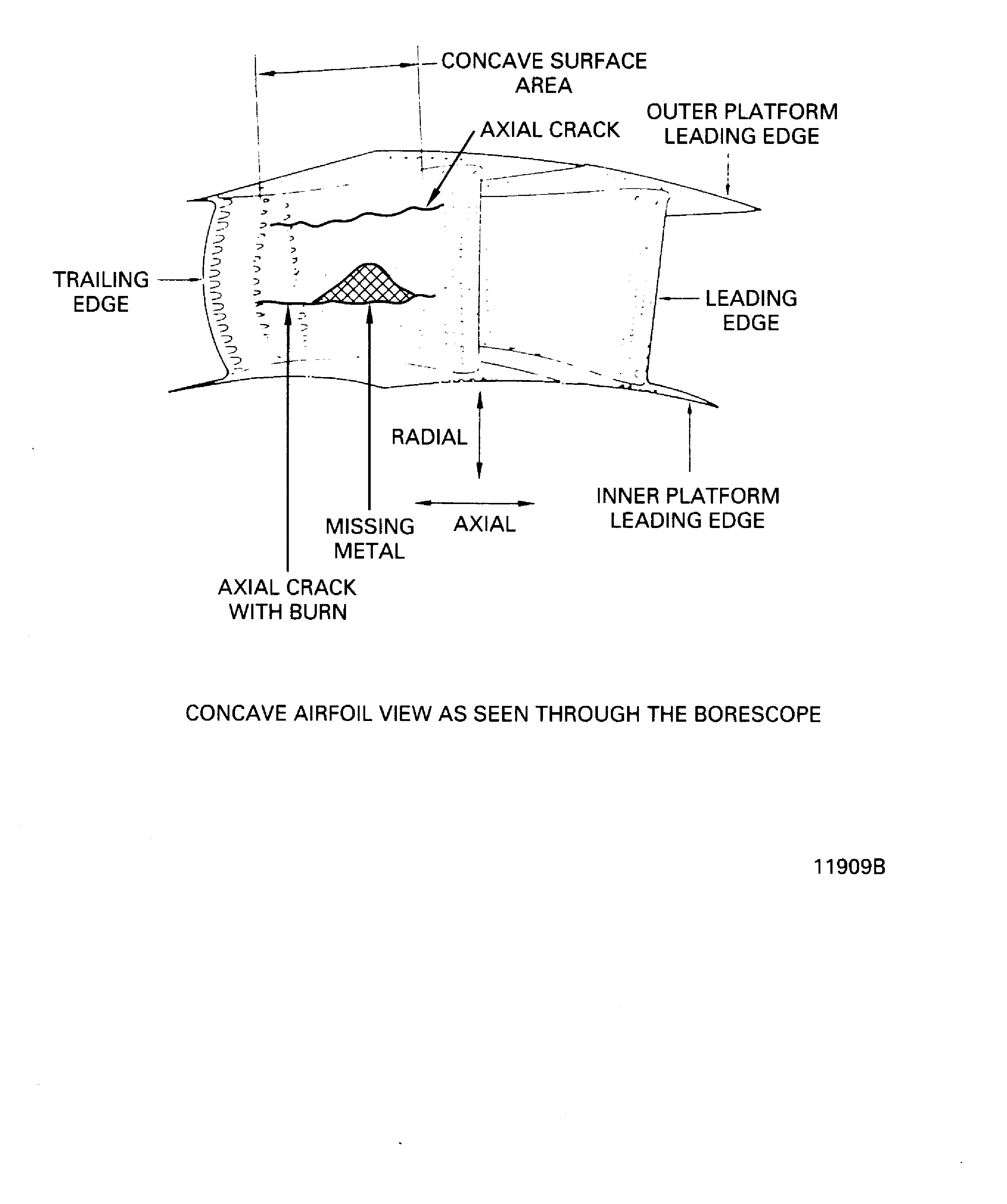

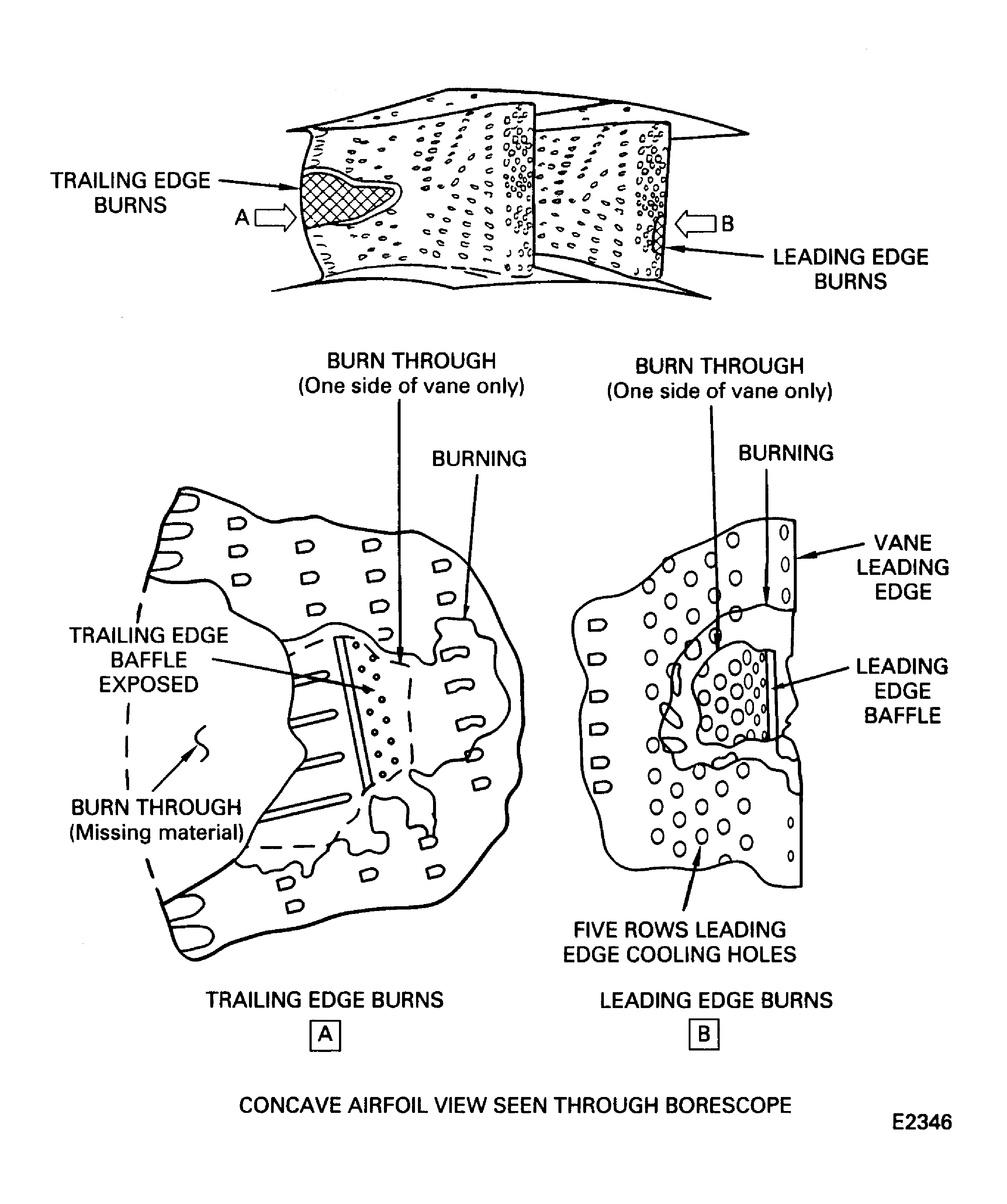

Use these terms when you identify an HPT 1st stage vane condition seen during borescope inspection:

BURNS: A local area of 1st stage vane surface that has changed colour, has a rough surface texture or shows thinner material because of high temperature. Burns can be located all around.

BURN-THROUGH: A local burn area that has continued through the airfoil surface. Cracks that have burned to more than 0.050 in. (1.269 mm) separation are also burn-through.

TRAILING EDGE BURNS: Burns or burn-through that start at the airfoil trailing edge and continue forward to the airfoil leading edge.

LIFT UP: An area where the surface on one side of a crack is higher than the surface on the other side of the crack.

COATING DAMAGE: Chips, spalling, flakes, blisters, peeling or oxidation that is confined to the coating.

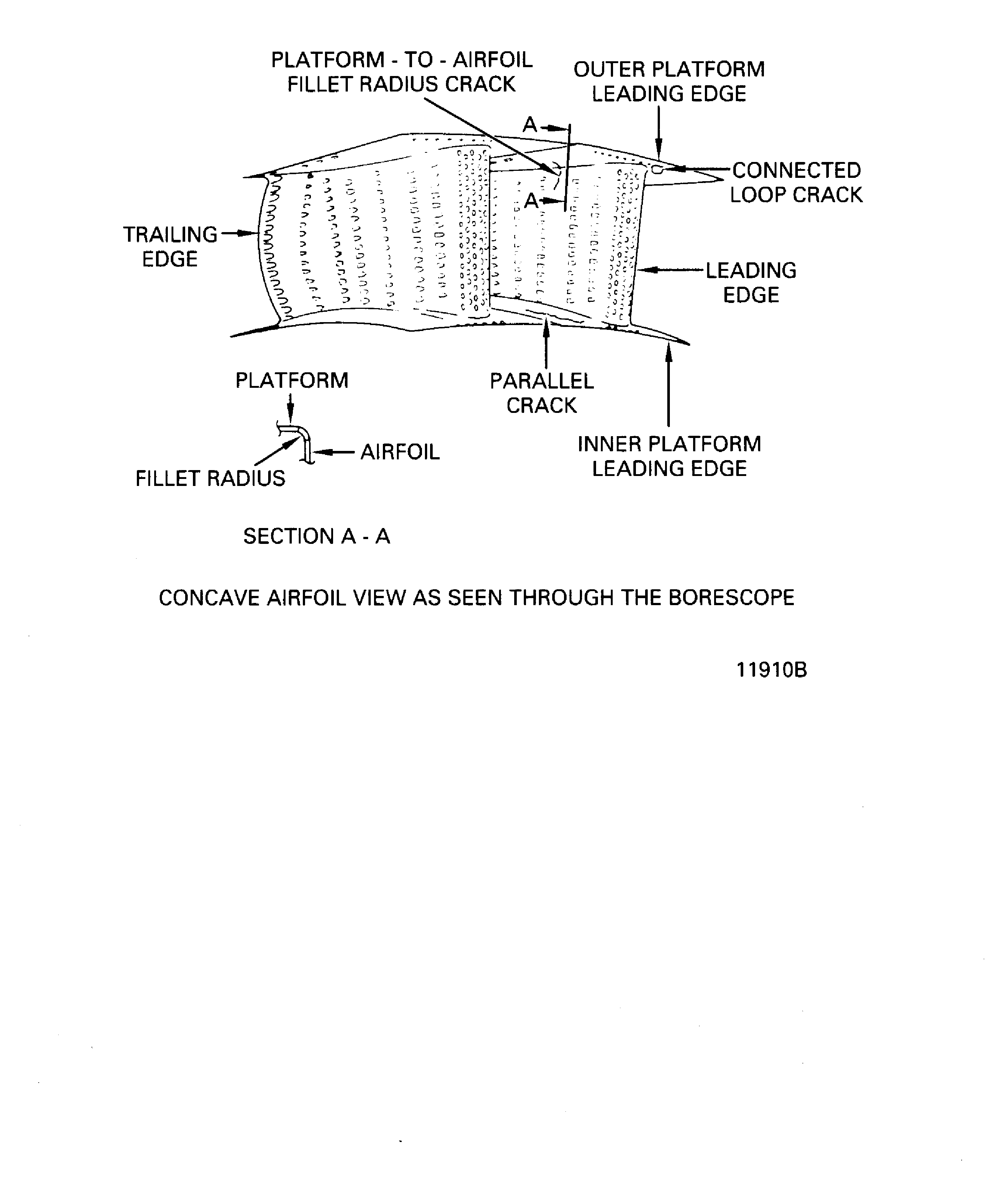

CONNECTED LOOP CRACK: A crack or a group of cracks that show an isolated area of vane metal.

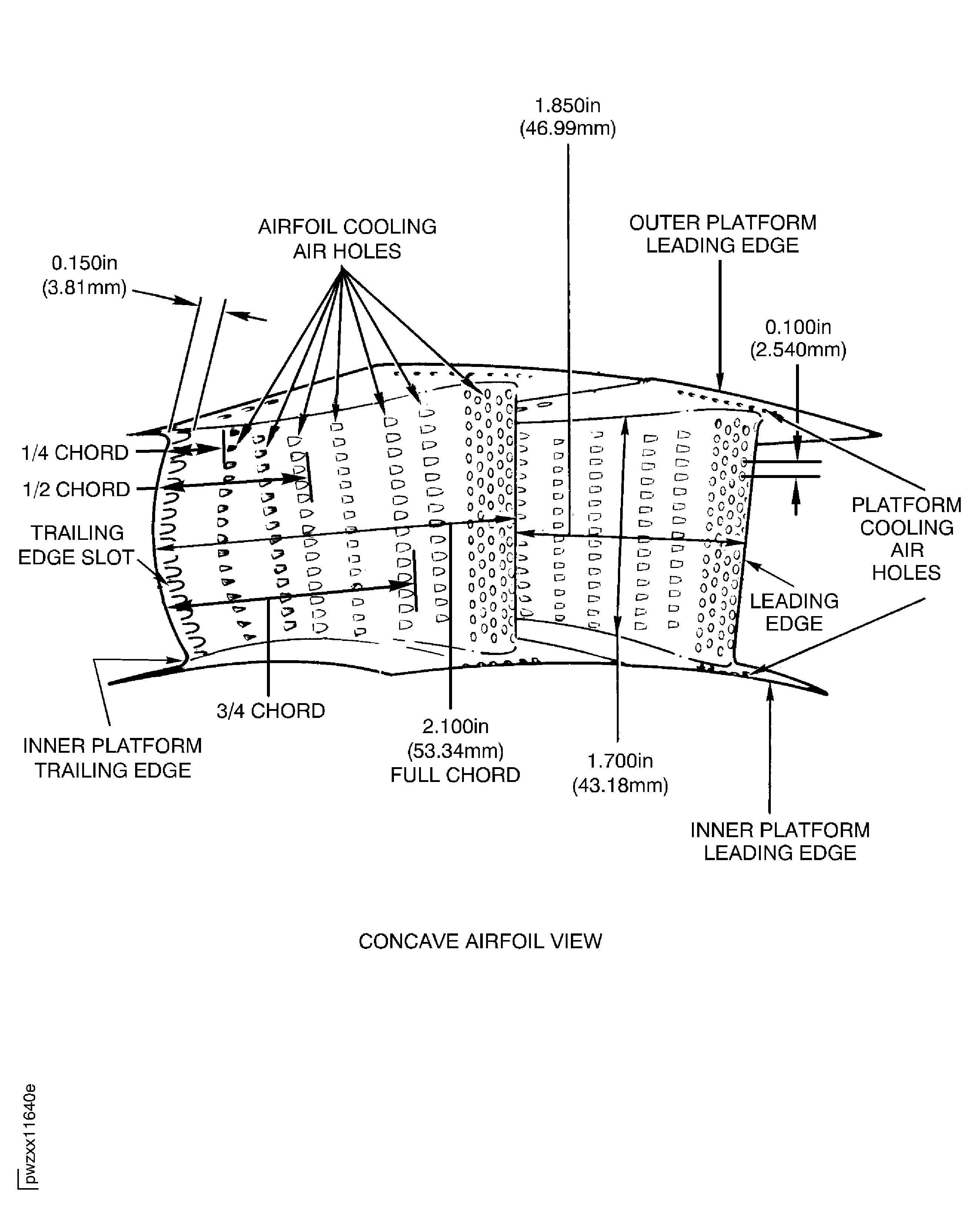

LEADING EDGE: The area from the first row of cooling holes on the concave side of the vane to the first row of cooling holes on the convex side of the vane.

ONE QUARTER CORD LENGTH: The length from the trailing edge to the second row of cooling holes or 0.50 in. (12.7 mm).

ONE HALF CORD LENGTH: The length from the trailing edge to the fifth row of cooling holes or 1.00 in. (25.4 mm).

THREE QUARTER CORD LENGTH: The length equal to 1.50 in. (38.1 mm).

General inspection guidelines:

Give the results of decreased time inspections to your IAE representative.

All ceramic coating damage is acceptable without a decreased borescope inspection time. Extended operation with a large quantity of ceramic coating not there can possibly cause the vane to be out of limits and cannot be repaired at overhaul.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Cover (eye) | LOCAL | Cover (eye) | ||

| Flexible boroscope (6 or 8 mm) | LOCAL | Flexible Boroscope | ||

| Rigid boroscope (6 or 8 mm) | LOCAL | Rigid boroscope (6 or 8 mm) | ||

| Tap 0.5625-18 UNJF-3B | LOCAL | Tap 0.5625-18 UNJF-3B | ||

| Torque Wrench - 0 to 1000 lbf.in range | LOCAL | Torque Wrench |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL | LOCAL | CoMat 10-094 | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 |

Safety Requirements

CAUTION

Procedure

SUBTASK 72-00-00-020-055-B00 Get Access to the Combustion Chamber and the Stage 1 Turbine Vanes through the B1 to B6 and IP1 and IP2 Ports (SBE 72-0221)

Refer to Figure.

CAUTION

THE LIMITS THAT FOLLOW ARE APPLICABLE ON A CONTINUE IN SERVICE BASIS ONLY. EACH LIMIT IS BASED ON WHAT THE STRUCTURE OF THE VANE MUST BE AND DOES NOT INDICATE THAT THERE WILL NOT BE DETERIORATION OF THE ENGINE PERFORMANCE, STABILITY, OPERATING LIMITS OR PART REPAIRABILITY.Put the borescope into the ports and examine the combustion chamber and the Stage 1 HPT vanes for damage.

NOTE

A cover for the eye which is not used will decrease eye tension.

SUBTASK 72-00-00-220-054- A00 Examine the Combustion Chamber and the Stage 1 HPT Vanes for Damage (Pre SBE 72- 0221)

Refer to Figure.

CAUTION

THE LIMITS THAT FOLLOW ARE APPLICABLE ON A CONTINUE IN SERVICE BASIS ONLY. EACH LIMIT IS BASED ON WHAT THE STRUCTURE OF THE VANE MUST BE AND DOES NOT INDICATE THAT THERE WILL NOT BE DETERIORATION OF THE ENGINE PERFORMANCE, STABILITY, OPERATING LIMITS OR PART REPAIRABILITY.Put the Rigid boroscope (6 or 8 mm) into the ports and examine the combustion chamber and the stage 1 HPT vanes for damage.

NOTE

A cover for the eye which is not used will decrease eye tension.

SUBTASK 72-00-00-220-054- B00 Examine the Combustion Chamber and the Stage 1 HPT Vanes for Damage (SBE 72- 0221)

There is axial or radial crack lift up of more than 0.050 in. (12.7 mm).

There are connected loop cracks that show a piece of vane metal that is calculated to be more than 0.500 in. (12.7 mm) in length.

There Is a crack that is three-quarters of a cord length long or longer that also goes into a leading edge or a convex surface burn-through.

There is a burn that has caused a burn-through that is more than 0.300 in. (7.620 mm) at its shortest dimension.

Reject if:

SUBTASK 72-00-00-220-055 Convex and Concave Surface Cracks/Burns

NOTE

All cracks or sections of cracks burned to a width of more than 0.050 in. (1.270 mm) are burn holes. Use the applicable burn limits.NOTE

If a convex or a concave burn extends to the leading edge, you must use leading edge criteria.Refer to Figure.

There is leading edge burn-through that is less than 0.250 in. (6.35 mm) beyond the first row of cooling holes and the total length of the burn-through is less than 0.650 in. (16.51 mm) axially and 0.850 ln. (21.59 mm) radically.

Accept with an inspection each 75 hours if:

There is leading edge burn-through that extends more than 0.250 in. (6.35 mm) beyond the first row of cooling holes on either the convex or concave surfaces.

Radial leading edge burning extends beyond 0.850 in. (21.59 mm).

Axial leading edge burning extends beyond 0.650 in. (16.51 mm).

On any vane, the total length of bum-through from the leading edge plus a crack and/or bum-through from the trailing edge is more than three-quarters of the chord length.

There is baffle bum-through.

There is baffle cracking.

Reject if:

SUBTASK 72-00-00-220-056 Leading Edge Cracks and Leading Edge Burns

NOTE

There is no limit to the number of leading edge tight cracks permitted without decreased inspection times.Refer to Figure.

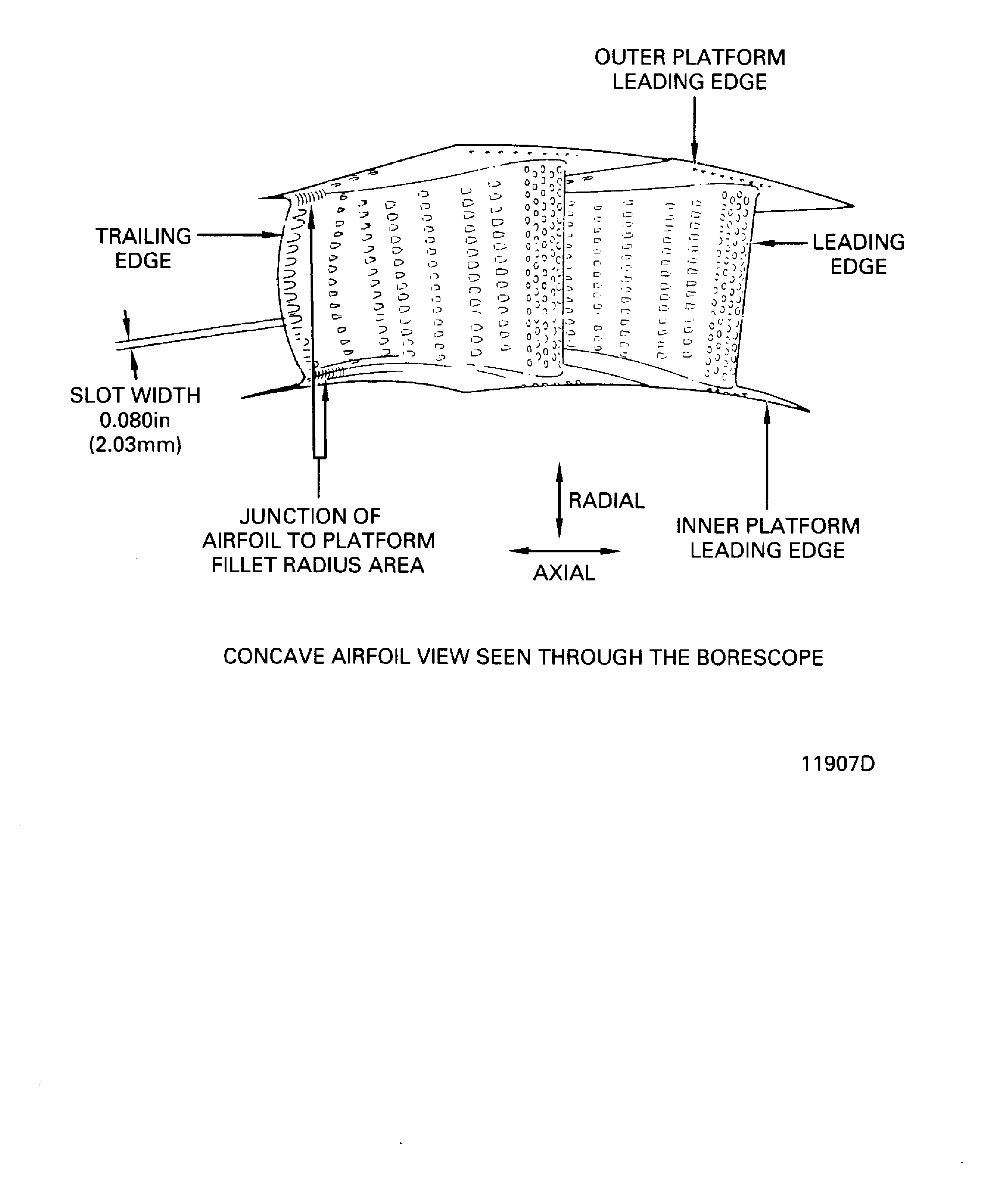

SUBTASK 72-00-00-220-058 Cracks on the Inner and Outer Platform

Refer to Figure.

There is a crack that Is more than 1.000 in. (25.4 mm) in length and part of the length is eroded to a width of more than 0.030 in. (0.76 mm).

There is a crack in the fillet radius that Is more than 1.500 in. (38.1 mm) in length and that goes around to the airfoil leading edge.

Reject if:

SUBTASK 72-00-00-220- 059 Cracks on the Inner and Outer Platform Airfoil Fillet Radii

Refer to Figure.

There are burns that have caused a burn-through that is more than 0.250 in. (6.35 mm) in length.

Reject if:

SUBTASK 72-00-00-220-060 Burns on the Inner and Outer Platform

Accept burner liner segment that have combustion holes with an inspection each 300 hours if:

NOTE

You must also do a borescope Inspection of the Stage 1 HPT Blades TASK 72-00-00-200-004-A00 (Inspection-004) each 300 hours of liner segments are on a 300 hour repeat borescope inspection for segment cracking.One crack is completely through the segment and is more than 0.700 in. (17.780 mm) from a circumferential edge.

No other crack is more than two thirds the axial length of the segment or nearer than 0.700 in. (17.780 mm) to a circumferential edge.

There are two or more axial cracks and the following requirements are met:

Accept burner liner segments that do not have combustion holes with an inspection each 300 hours if:

NOTE

You must also do a borescope inspection of the Stage 1 HPT Blades TASK 72-00-00-200-004-A00 (Inspection-004) each 300 hours of liner segments are on a 300 hour repeat borescope inspection for segment cracking.There are cracks that can cause a piece of segment material more than 0.25 in.2 (161.29 mm2 ) in area to break off.

Reject if:

SUBTASK 72-00-00-220-061 Burner Liner Segment Cracks

There is no liner shell damage (burn-through or cracks).

There is damage to the rails around the igniter holes on the Row 1 igniter segment less than 135 degrees.

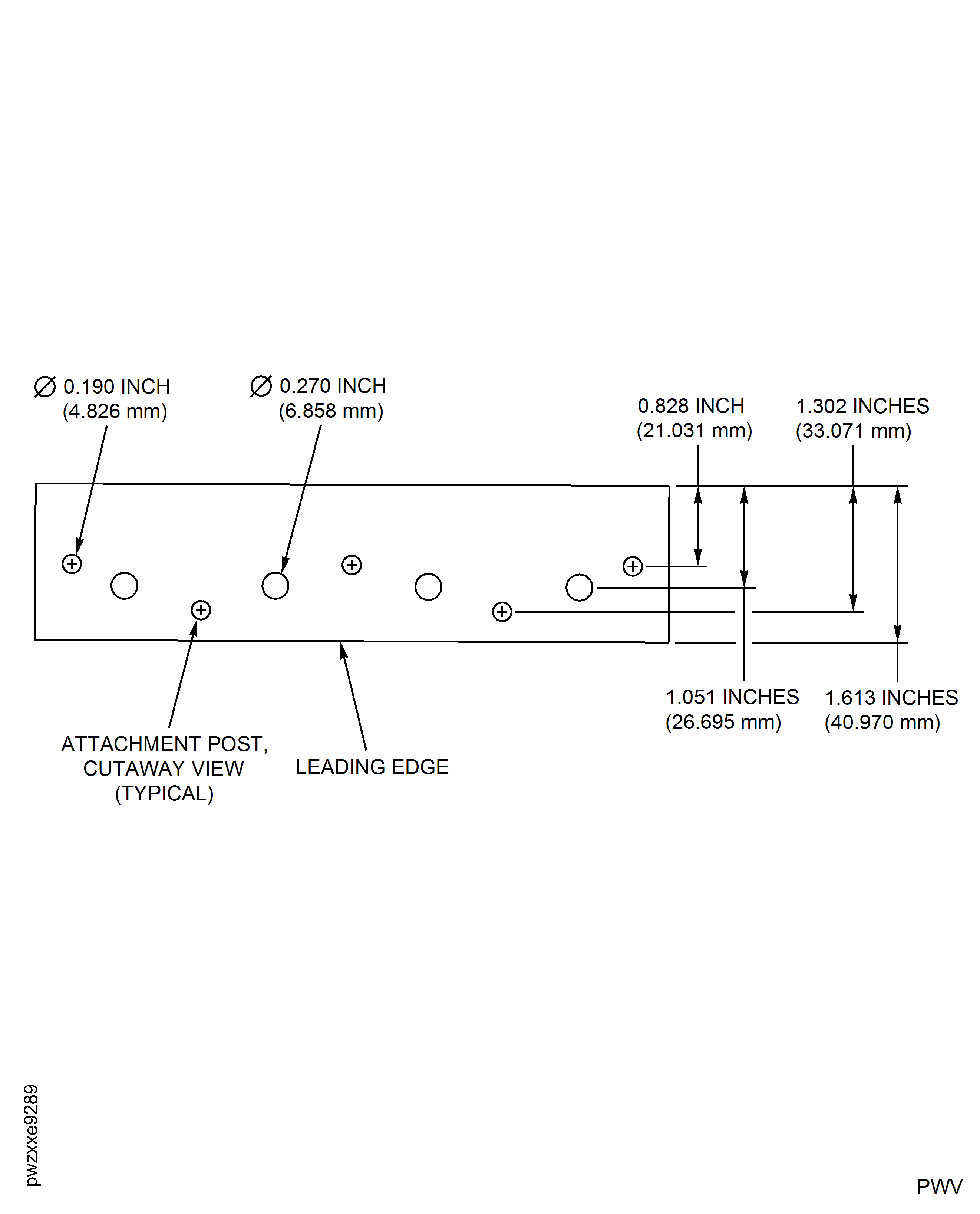

You must not be able to see an attachment post.

There is trailing edge burnback less than 0.70 in (17.78 mm) and the following conditions are met:

Accept burner liner segments without a decreased borescope inspection if:

There is no liner shell damage (burn-through or cracks).

There is damage to the rails around the igniter holes on the row 1 igniter segment less than 135 degrees.

You must not be able to see an attachment post.

The trailing edge burnback is between 0.70 in. (17.78 mm) and 0.90 in. (22.86 mm) and the following conditions are met:

Accept burner liner segments with an inspection 600 hours if:

Liner shell damage (burn-through or cracks) must not have an area of more than 0.50 in.2 (322.58 mm2).

There is damage to the rails around the igniter holes on the row 1 igniter segment less than 135 degrees.

You must not be able to see an attachment post.

NOTE

A maximum of three liner shell damage locations for each burner assembly is allowed.

The trailing edge burnback is more than 0.90 in. (22.86 mm) and the following conditions are met:

Accept burner liner segments with an inspection each 300 hours if:

There is complete edge burnback on one segment and another area of edge burnback more than 1.00 in. (25.4 mm) on the same segment.

There are two or more segments with complete edge burnback. Refer to Figure.

There is damage to the rails around the Igniter holes on the Row 1 igniter segment more than 135 degrees.

There is trailing edge burnback that shows an attachment post or an attachment post is missing.

There is liner shell damage (burn-through or cracks) that is more than 0.500 in.2 (322.58 mm2 ) in area or there are more than three locations of liner shell damage less than 0.500 in.2 (322.58 mm2 ) in all the burner assembly.

Reject if:

SUBTASK 72-00-00-220-062 Segment Edge Burnback

There must be no liner shell damage (burn-through or cracks).

There is damage to the rails around the Igniter holes on the row 1 igniter segment less than 135 degrees.

You must not be able to see an attachment post.

There are segment burn-through holes that are less 0.350 in. (8.890 mm) in length and the following conditions are met:

Accept segments (with or without combustion holes) without a decreased borescope inspection time if:

There must be no liner shell damage (burn-through or cracks).

There is damage to the rails around the Igniter holes on the row 1 igniter segment less than 135 degrees.

You must not be able to see an attachment post.

There is a segment burn-through hole that is between 0.350 and 0.650in. (8.890 and 16.510 mm) in length and the following conditions are met:

Accept segments (with or without combustion holes) with an inspection each 600 hours if:

Liner shell damage (burn-through or cracks) must not have an area of more than 0.50 in.2 (322.58 mm2).

Liner shell damage (burn-through or cracks) must not occur in more than three locations.

There is damage to the rails around the igniter holes on the row 1 igniter segment less than 135 degrees.

You must not be able to see an attachment post.

There is a segment burn-through hole that is between 0.650 and 1.000in. (16.51 0 and 25.400 mm) in length and the following conditions are met:

There are segment burns or cracks that can cause a piece of segment material more than 0.50 in. (12.70 mm) In length to break off.

Accept segments (with or without combustion holes) with an inspection each 300 hours if:

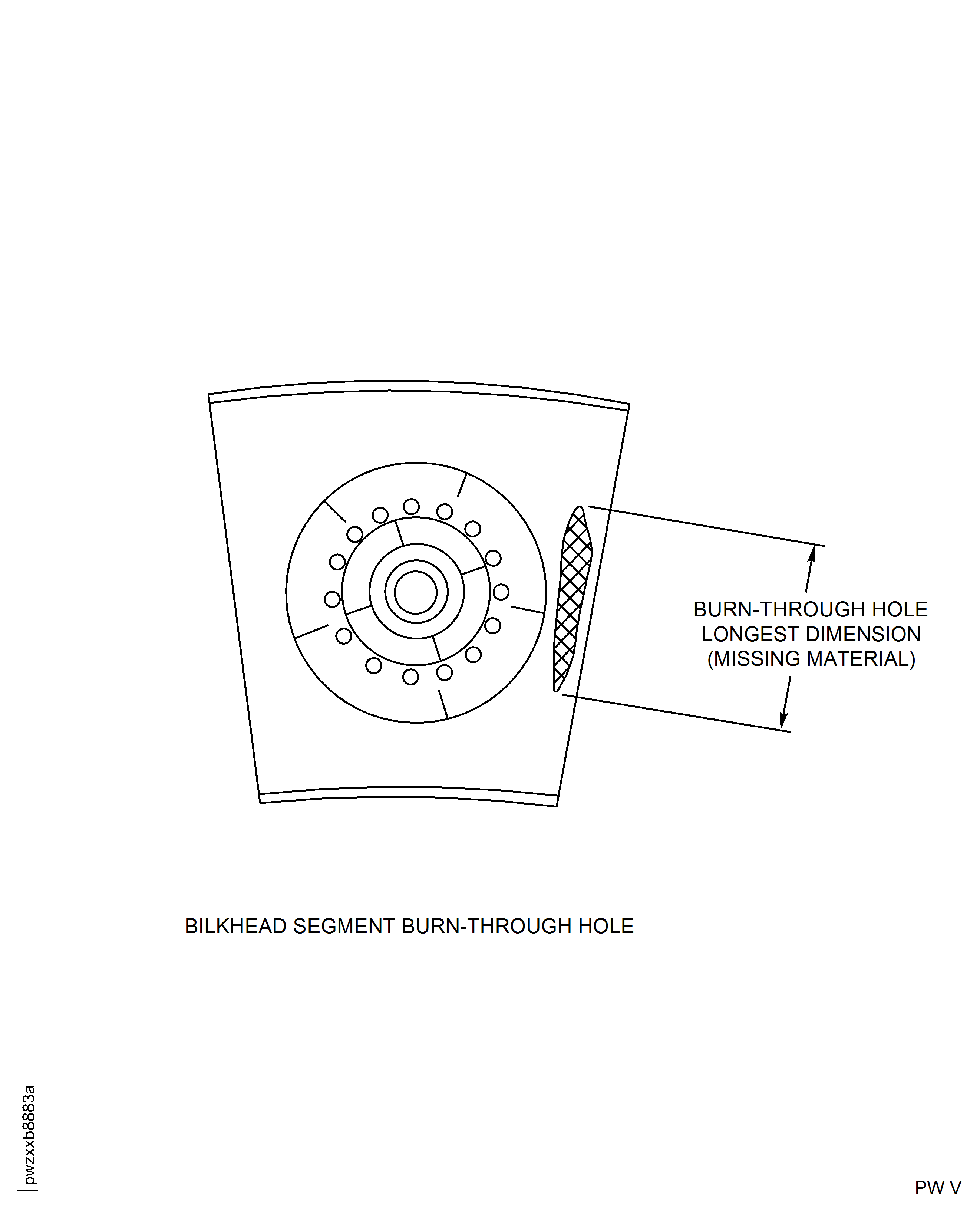

There is a segment burn-through hole that is more than 1.00 in. (25.4 mm) in length.

There is damage to the rails around the igniter holes on the row 1 igniter segment more than 135 degrees.

There are segment burn-through holes that show an attachment post.

There is liner shell damage (burn-through or cracks) that is more than 0.500 in.2 (322.58 mm2) in area or occurs in more than three locations that are less than 0.500 in.2 (322.58 mm2) in area.

Reject if:

SUBTASK 72-00-00-220- 063 Surface Burns and Burn-Through Holes in Liner Segments

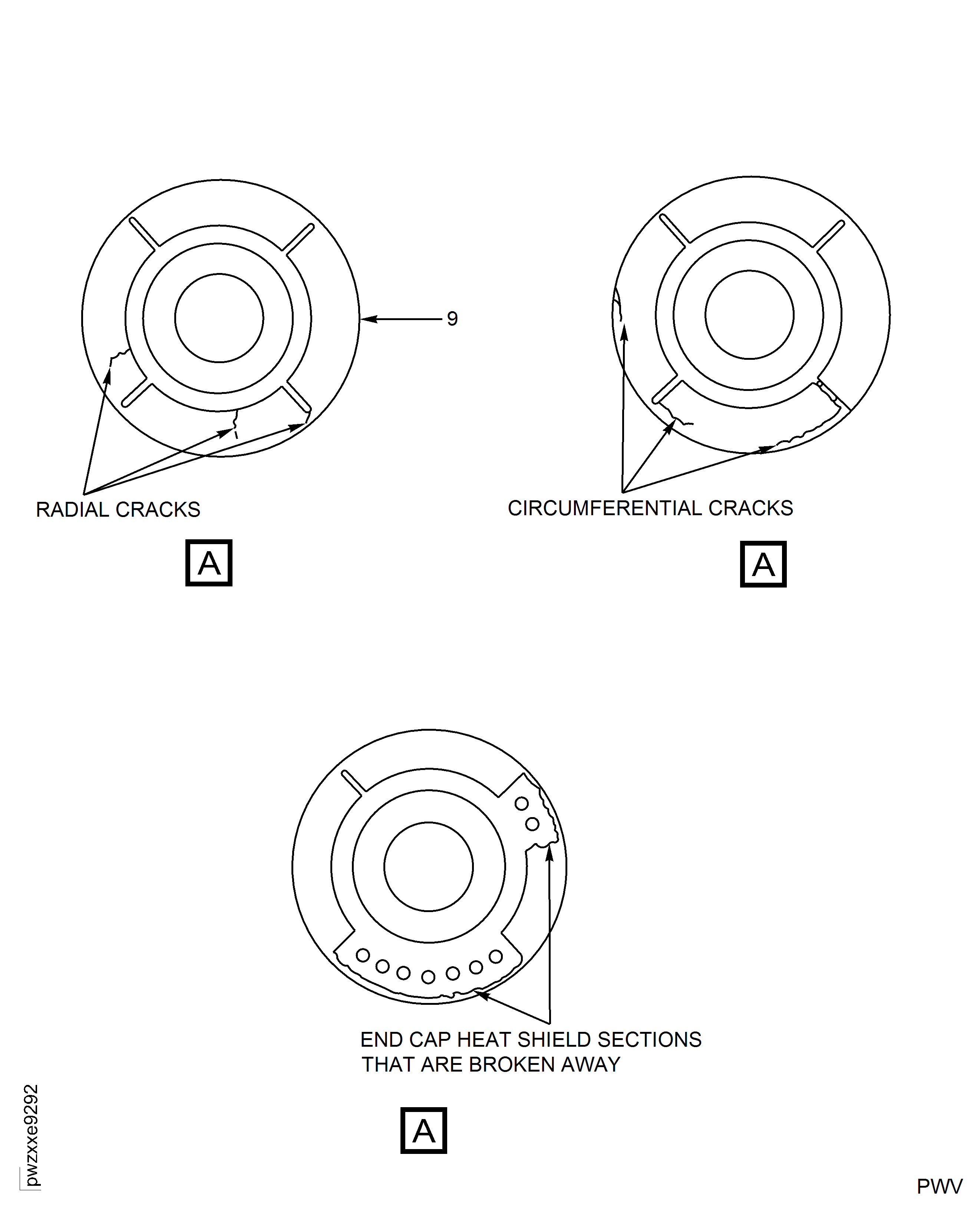

Refer to Figure.

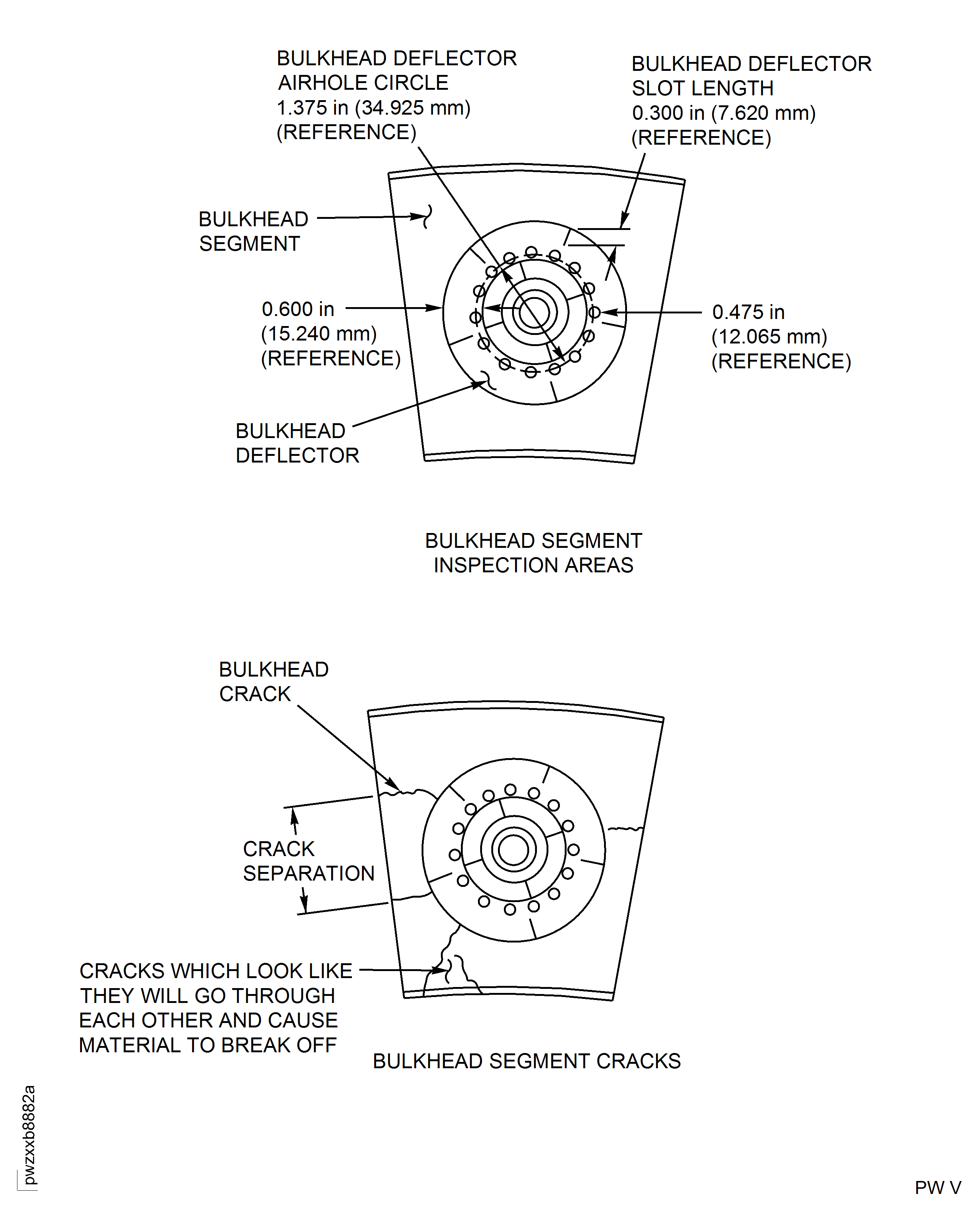

There are two or more cracks on the same side of one or more bulkhead segments. At least two cracks of each bulkhead segment extend from the edge of the bulkhead segment under the fuel nozzle guide. These cracks must be separated by less than 0.50 in. (12.70 mm).

Accept all bulkhead segments with a 300 hour repeat borescope inspection if:

NOTE

You must also do a borescope inspection of the Stage 1 HPT Blades TASK 72-00-00-200-004-A00 (Inspection-004) each 300 hours if the combustor is on a 300 hour repeat borescope inspection for bulkhead segment cracking.There are cracks that may liberate a piece of material more than 0.25 in.2 (161.29 mm2 ).

There are two or more cracks on the same side of a bulkhead segment. At least one crack extends from the edge of the bulkhead segment under the fuel nozzle guide. These cracks are separated by more than 0.50 inch (12.70 mm).

Reject if:

SUBTASK 72-00-00-220-064 Bulkhead Segment Cracks

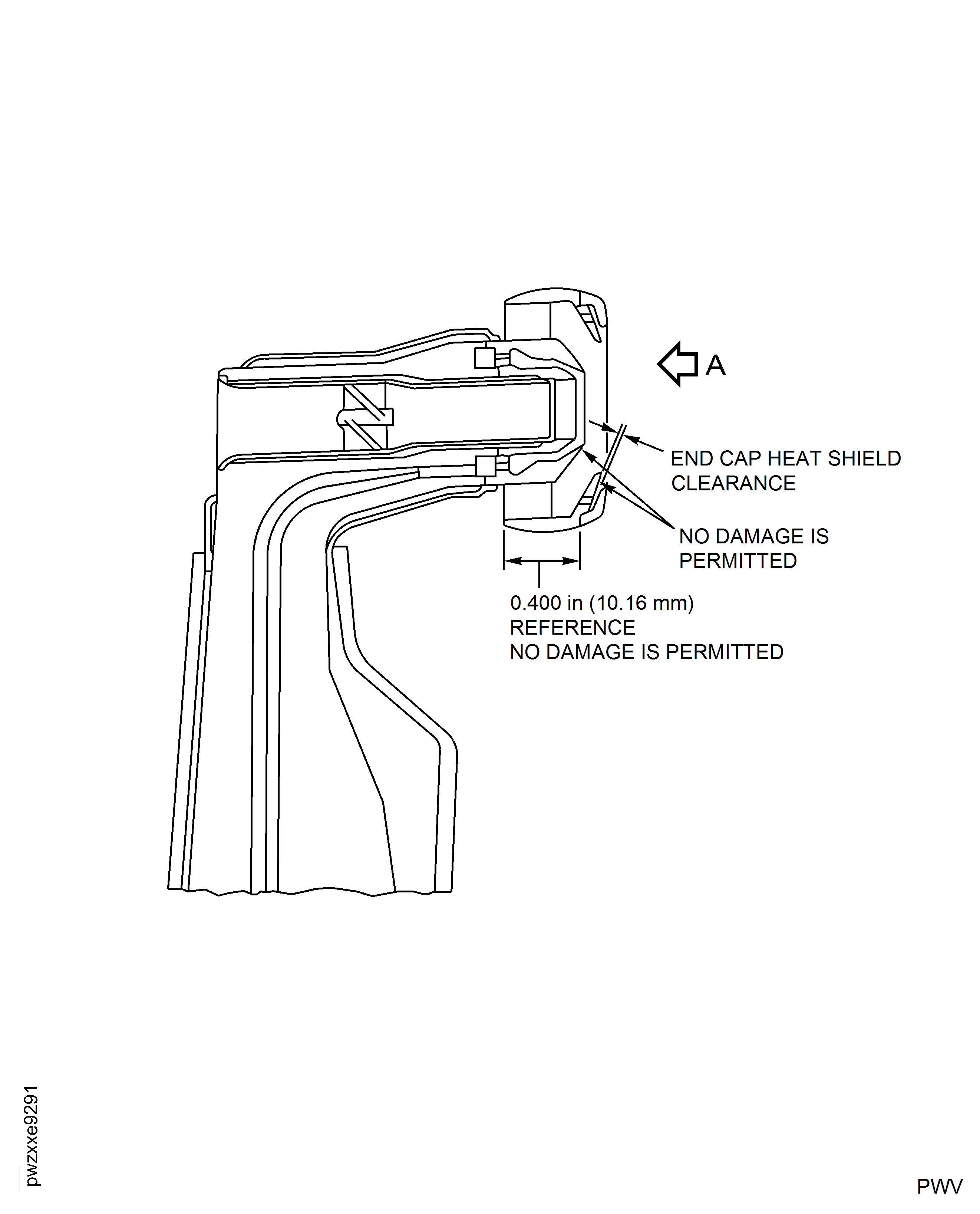

There must be no damage to the bulkhead liner below.

A bulkhead segment attachment post must not be visible.

There is one bulkhead segment burn-through hole less than 2.00 in. (50.8 mm) in length and the following conditions are met:

There must be no damage to the bulkhead liner below.

A bulkhead segment attachment post must not be visible.

There are multiple bulkhead segment burn-through holes less than 1.00 in. (25.4 mm) in length and the following conditions are met:

Accept all bulkhead segments without a decreased borescope inspection time if:

There must be no damage to the bulkhead liner below.

A bulkhead segment attachment post must not be visible.

There is one bulkhead segment bum-through hole more than 2.00 in. (25.4 mm) but less than 3.00 in. in length and the following conditions are met:

Accept all bulkhead segments with an inspection each 600 hours if:

SUBTASK 72-00-00-220- 065 Bulkhead Segment Burns and Burn-Through Holes

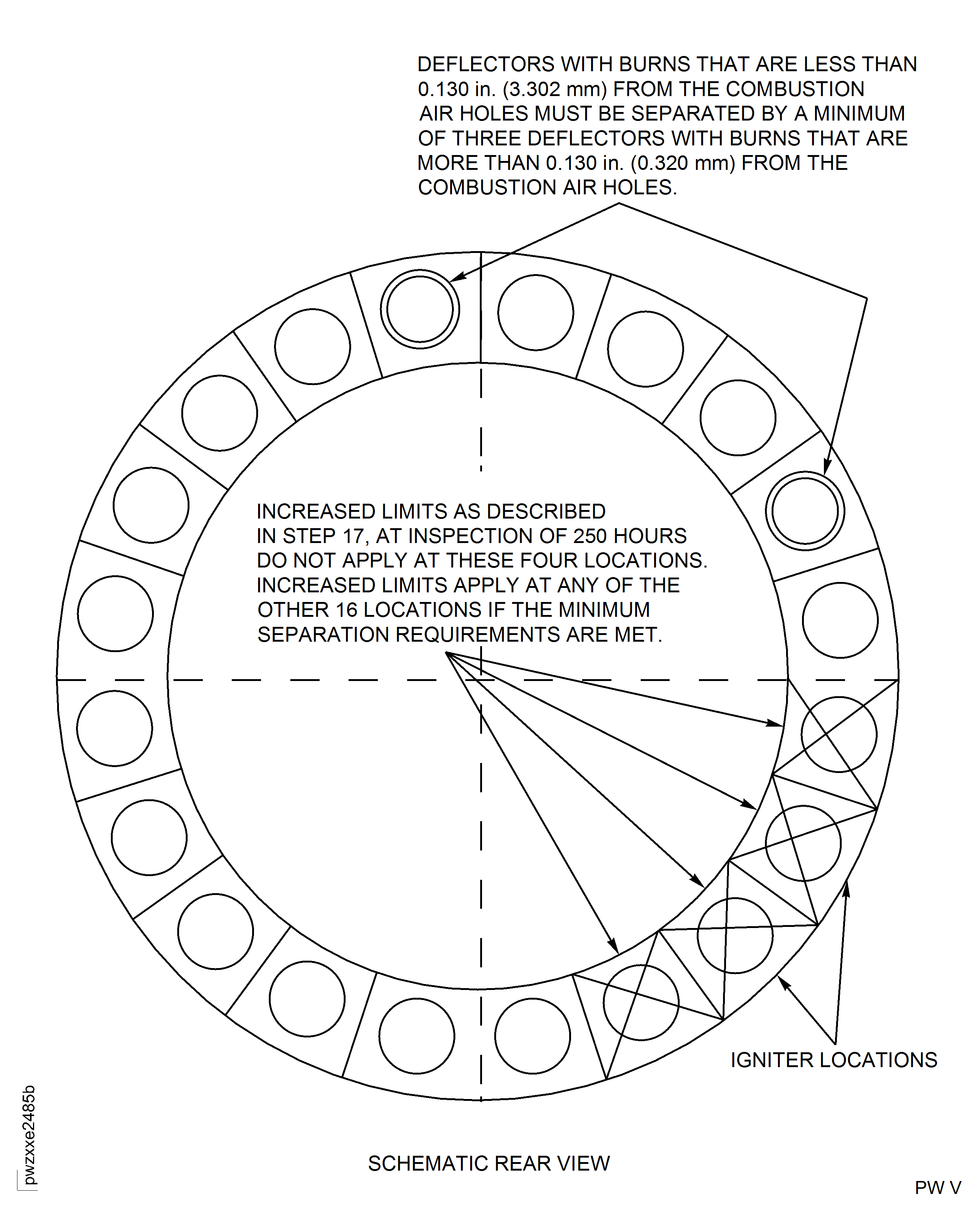

There are full material thickness burns that are less than 0.130 in. (3.30 mm) from the combustion air holes but do not break into the combustion air holes. This burning can extend for a maximum of 180 degrees around the circumference of the deflector. This is acceptable at a maximum of four locations around the circumference of the combustor. Deflectors with this condition must be separated by a minimum of three deflectors with full material thickness burns that are more than 0.130 in. (3.30 mm) from the combustion air holes. It is not acceptable at the igniter locations or the locations adjacent to the igniters.

Accept all bulkhead deflectors with an inspection each 300 hours if:

SUBTASK 72-00-00-220-067 Bulkhead Deflector Burns

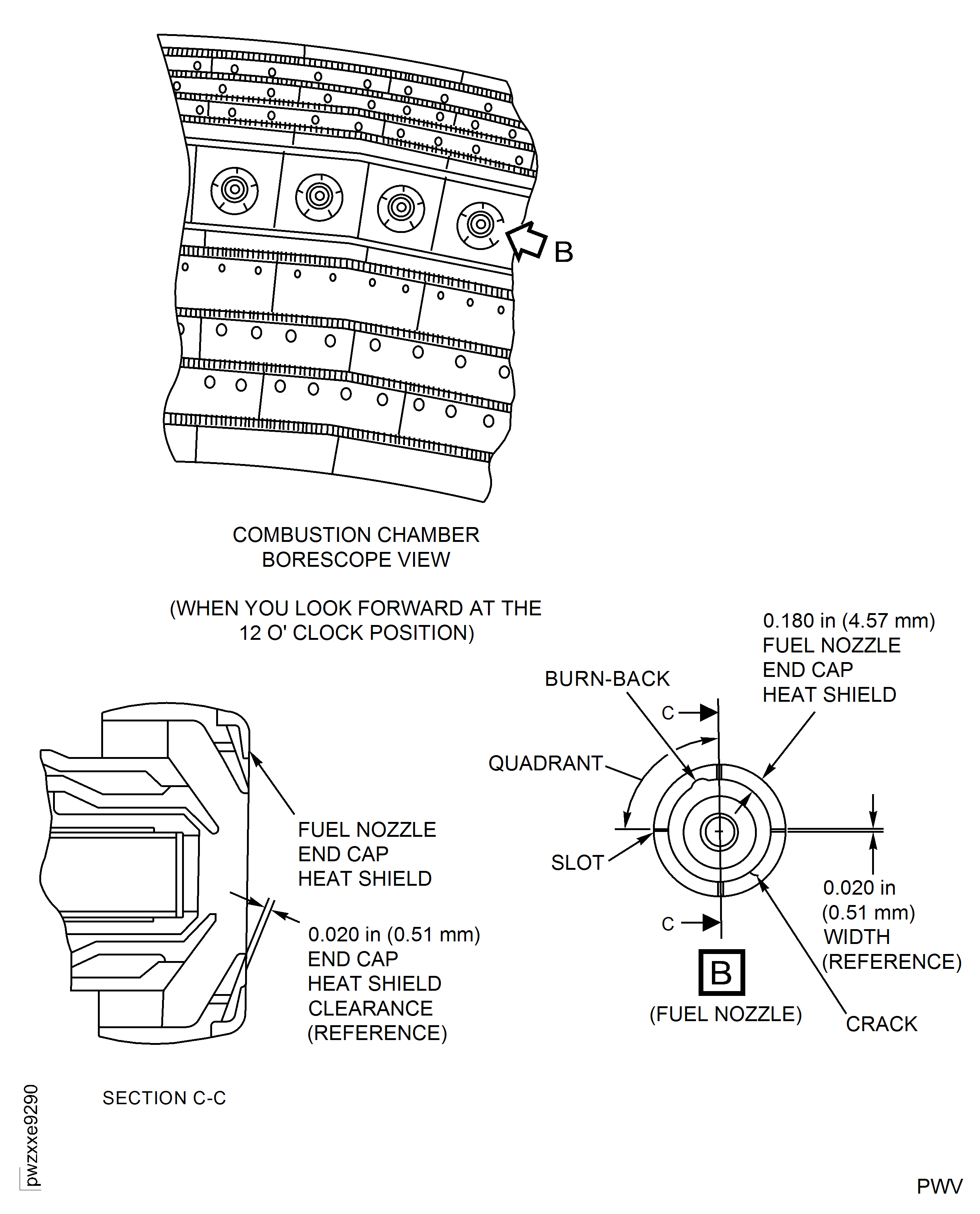

The clearance between the end cap and the nozzle is fully closed.

There is no limit to the number of radial circumferential cracks in the end cap heatshield.

Some or all of the end cap segments are broken away.

Accept the nozzle if:

There are cracks, distortion, erosion or other damage on the areas adjacent to the end cap heatshleld.

Replace the fuel nozzle if:

SUBTASK 72-00-00-220-068 End Cap Heatshield Damage on the Fuel Nozzles

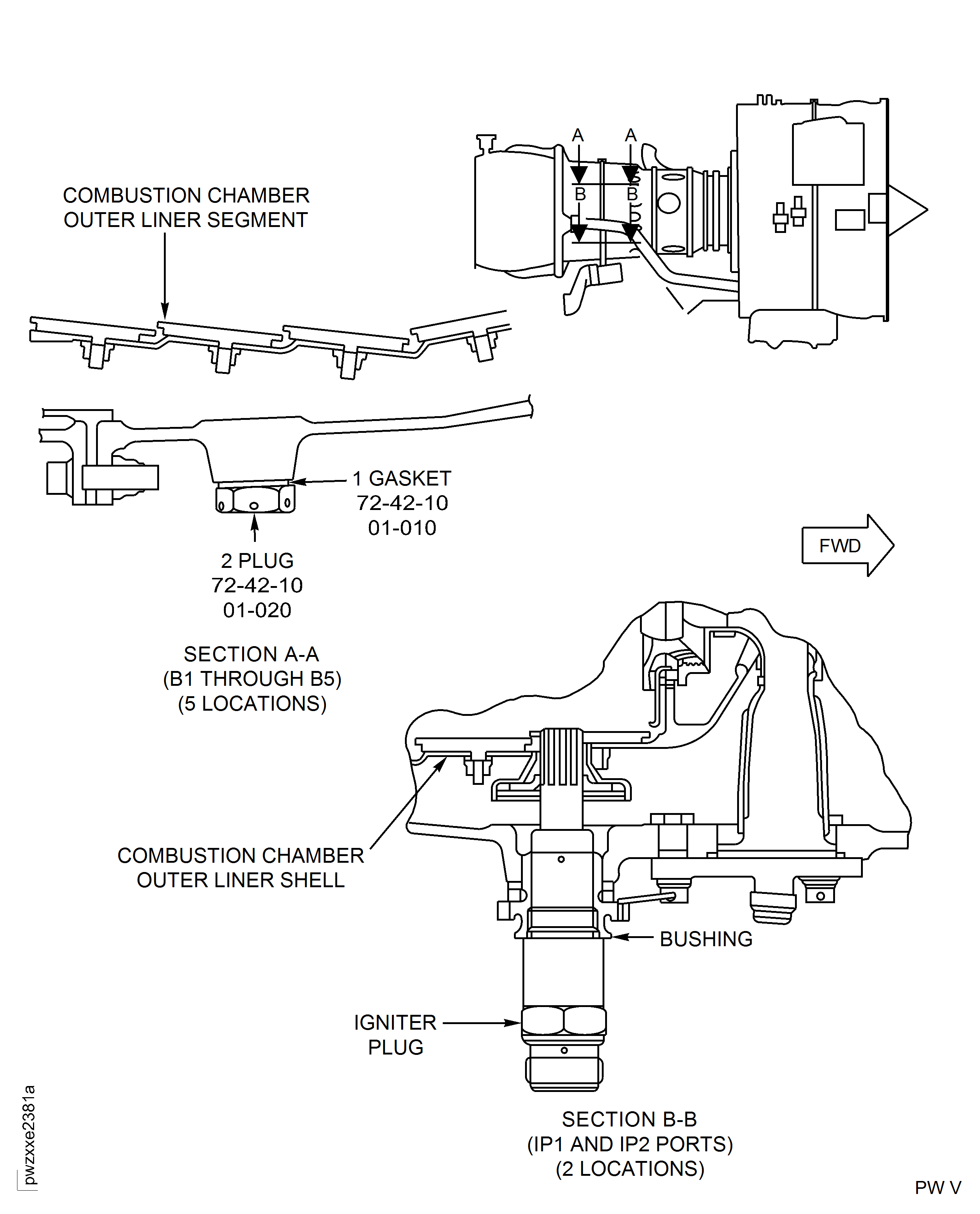

Lubricate the plug ENGINE-DIFFUSER CASE ASSEMBLY AND FITTINGS (72-42 -10, 01-020) threads with CoMat 10-129 ANTI-SEIZE PASTE or CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL.

NOTE

It is permissible to correct minor thread damage to a threaded hole with a Tap 0.5625-18 UNJF-3B.Install the plugs and the ENGINE-DIFFUSER CASE ASSEMBLY AND FITTINGS (72-42-10, 01-010) gaskets 5 off, Figure. Wipe off excess paste.

Safety the plugs with CoMat 02-141 LOCKWIRE.

For the B1 through B5 ports:

SUBTASK 72-00-00-420-056- A00 Close the Borescope Inspection Ports, after the Borescope Inspection is Completed, as follows: (Pre SBE 72- 0221)

SBE 72- 0221: Introduce a new diffuser case

Lubricate the plug ENGINE-DIFFUSER CASE ASSEMBLY AND FITTINGS (72-42 -10, 01-020) threads with CoMat 10-129 ANTI-SEIZE PASTE or CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL.

NOTE

It is permissible to correct minor thread damage to a threaded hole with a tap 0.5625 - 18 UNJF-3B.Install the plugs and the ENGINE-DIFFUSER CASE ASSEMBLY AND FITTINGS (72-42-10, 01-010) gaskets 6 off, Figure. Wipe off excess paste.

Safety the plugs with CoMat 02-141 LOCKWIRE.

For the B1 to B6 ports:

SUBTASK 72-00-00-420-056- B00 Close the Borescope Inspection Ports after the Borescope Inspection is Completed, as follows: (SBE 72- 0221)

Figure: Pre SBE 72-0721: Borescope Ports for Inspection of the Combustion Chamber Liners and the Stage 1 HPT Vanes (Left Side)

Pre SBE 72-0721: Borescope Ports for Inspection of the Combustion Chamber Liners and the Stage 1 HPT Vanes (Left Side)

Figure: SBE 72-0221: Borescope Ports for the Inspection of the Combustion Chamber Liners and First Stage Vanes (Left Side)

SBE 72-0221: Borescope Ports for the Inspection of the Combustion Chamber Liners and First Stage Vanes (Left Side)

Figure: Pre SBE 72-0221: Borescope Ports for Inspection of the Combustion Chamber Liners and the Stage 1 HPT Vanes (Right Side)

Pre SBE 72-0221: Borescope Ports for Inspection of the Combustion Chamber Liners and the Stage 1 HPT Vanes (Right Side)

Figure: SBE 72-0221: Borescope Ports for Inspection of the Combustion Chamber Liners and first Stage Vanes (Right Side)

SBE 72-0221: Borescope Ports for Inspection of the Combustion Chamber Liners and first Stage Vanes (Right Side)

Figure: Stage 1 HPT Vane Area Names and Dimensional References

Stage 1 HPT Vane Area Names and Dimensional References

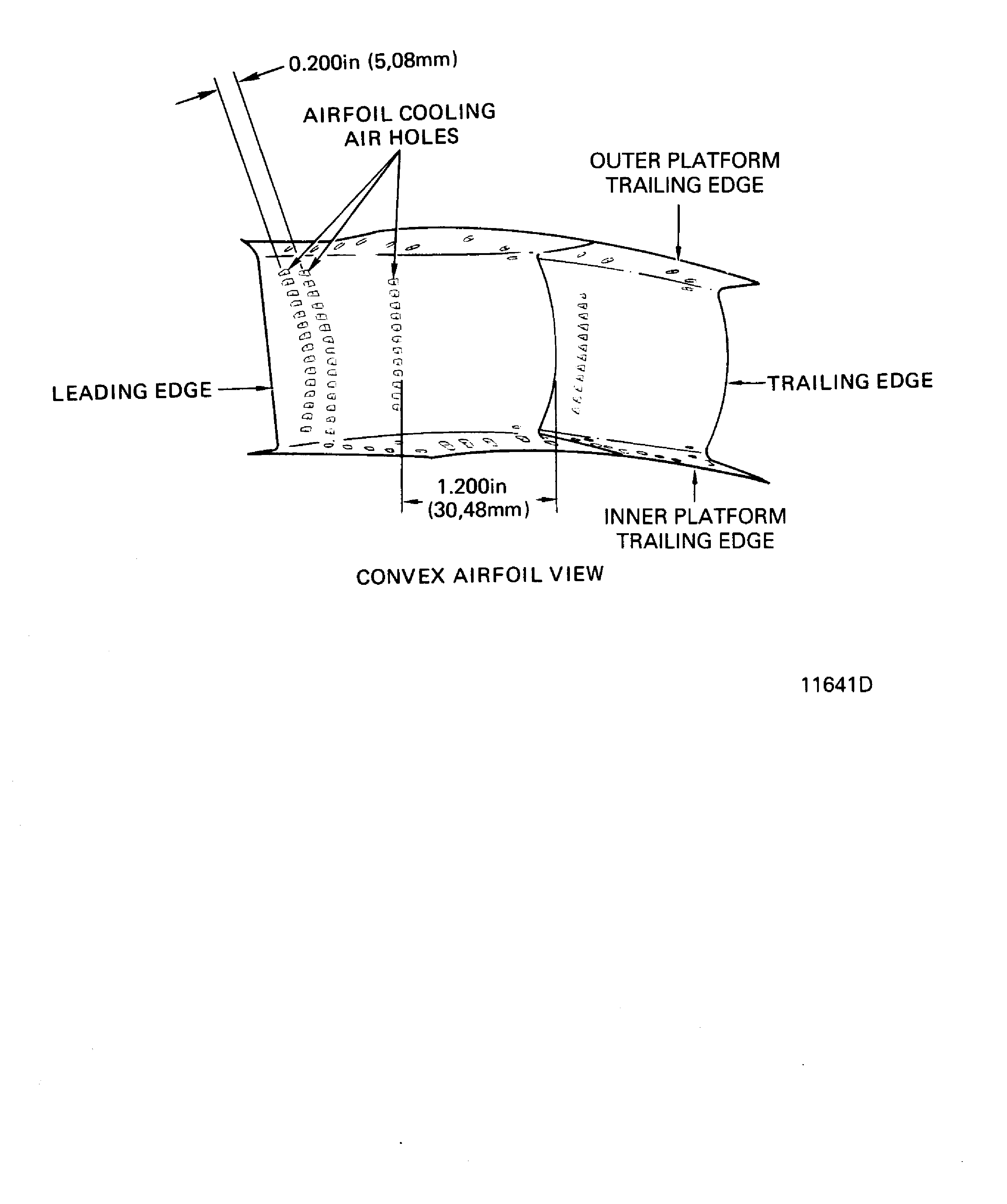

Figure: Stage 1 HPT Vane Area Names

Stage 1 HPT Vane Area Names

Figure: Stage 1 HPT Vane Area Names and Dimensional References

Stage 1 HPT Vane Area Names and Dimensional References

Figure: Stage 1 HPT Vane Area Names and Types of Damage

Stage 1 HPT Vane Area Names and Types of Damage

Figure: Stage 1 HPT Vane Area Names and Types of Damage

Stage 1 HPT Vane Area Names and Types of Damage

Figure: Stage 1 HPT Vane Area Names and Dimensional References

Stage 1 HPT Vane Area Names and Dimensional References

Figure: Stage 1 HPT Vane Area Names and Types of Damage

Stage 1 HPT Vane Area Names and Types of Damage

Figure: Combustion Chamber Area Names

Combustion Chamber Area Names

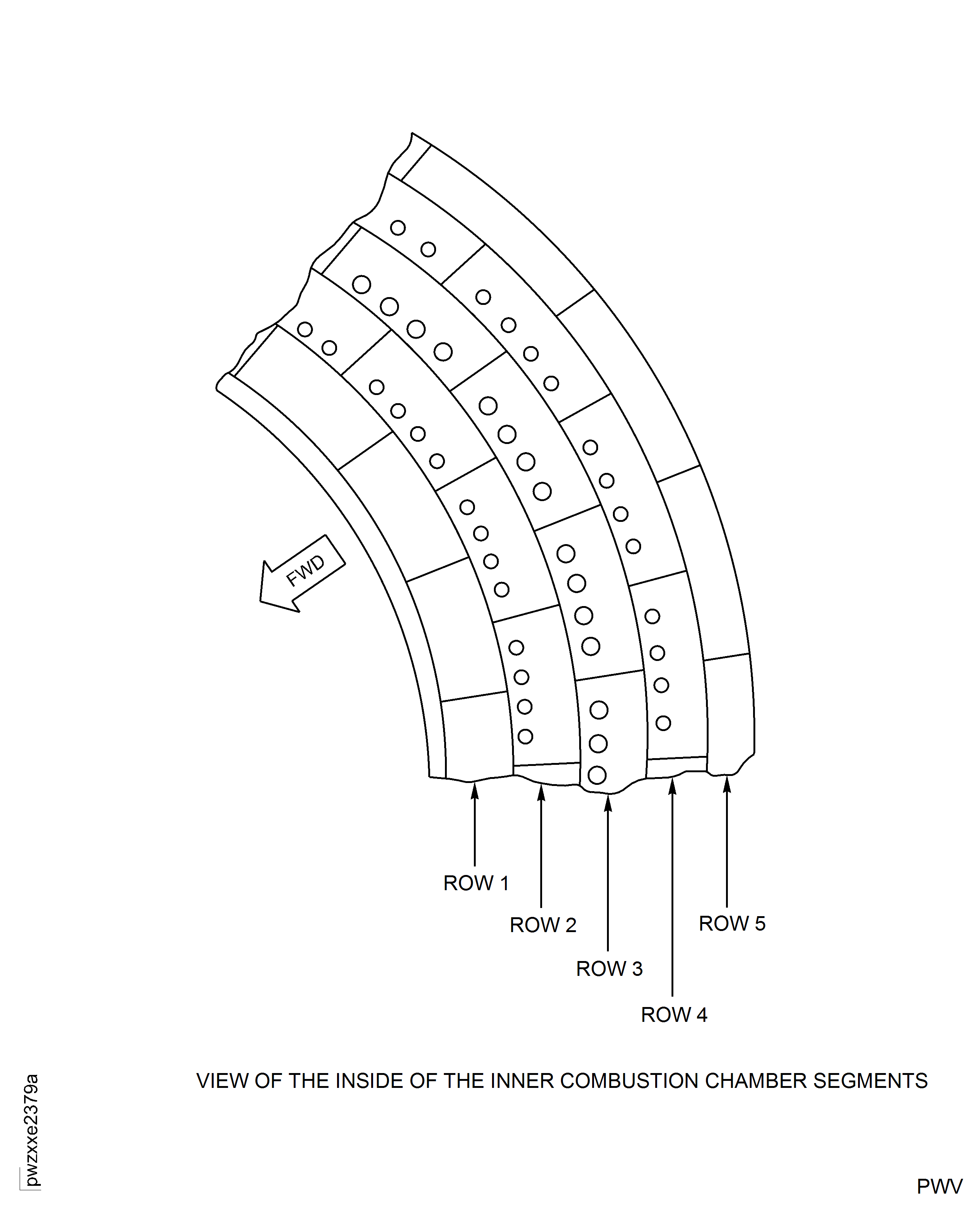

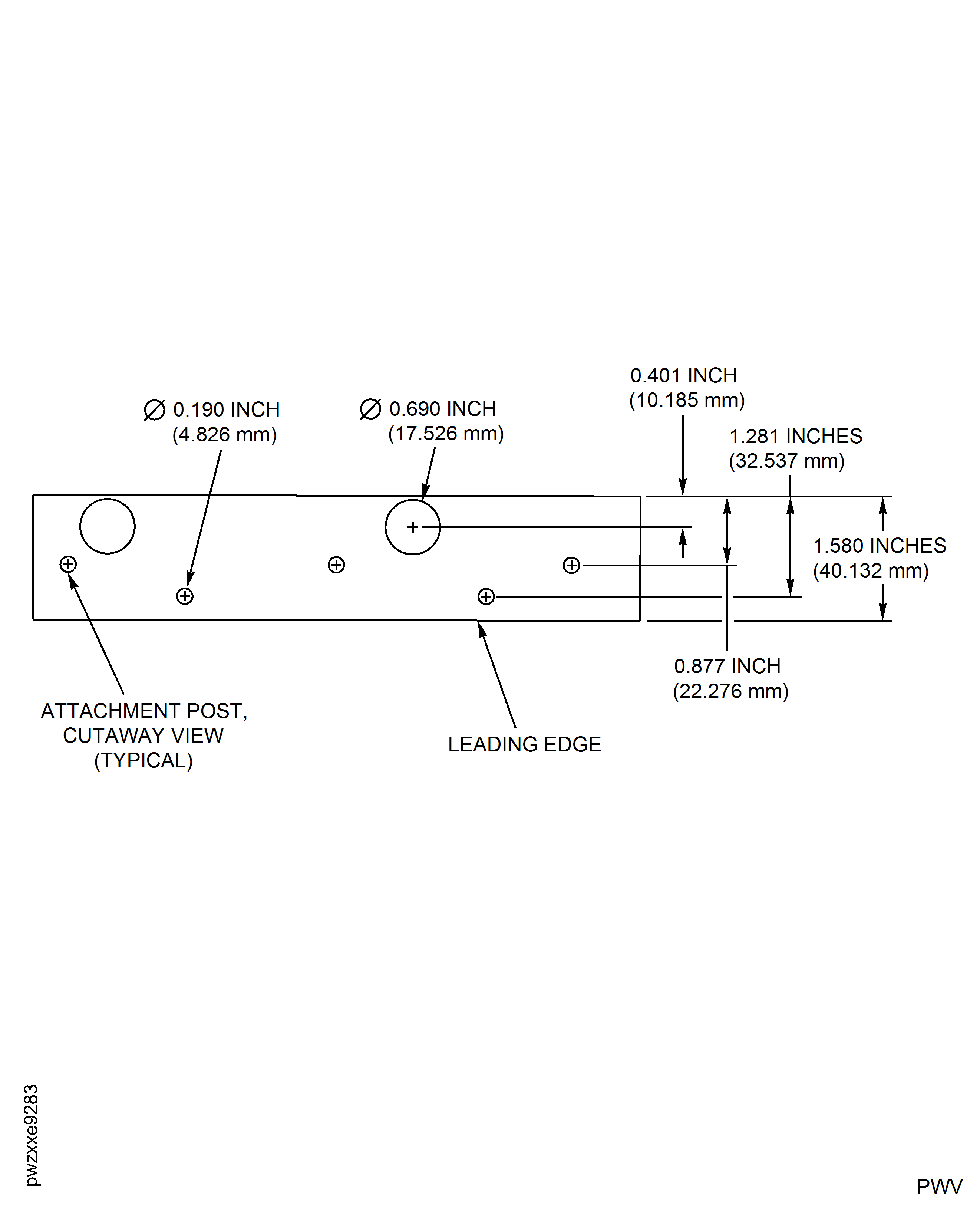

Figure: Inner Combustion Chamber Liner Dimensions References

Inner Combustion Chamber Liner Dimensions References

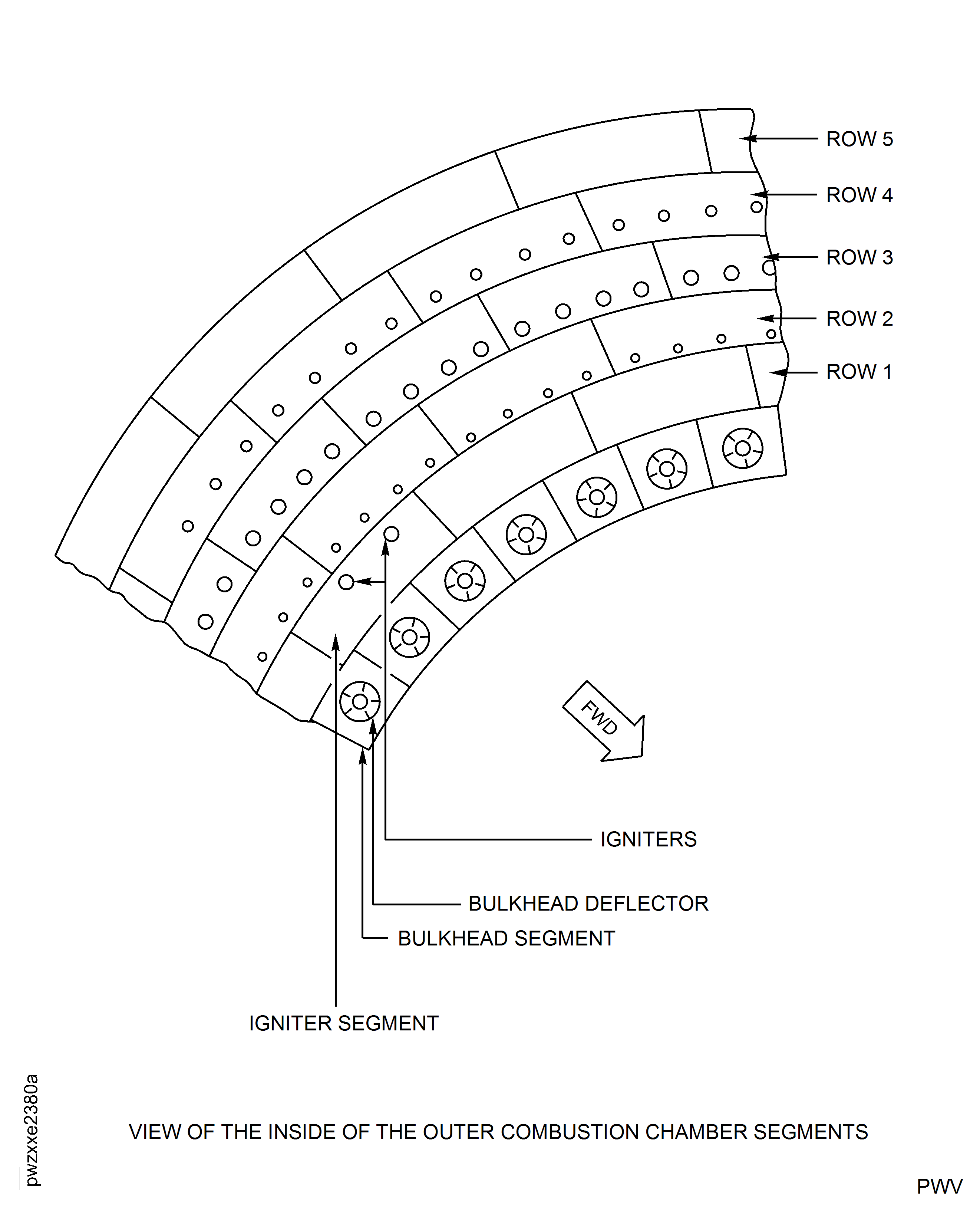

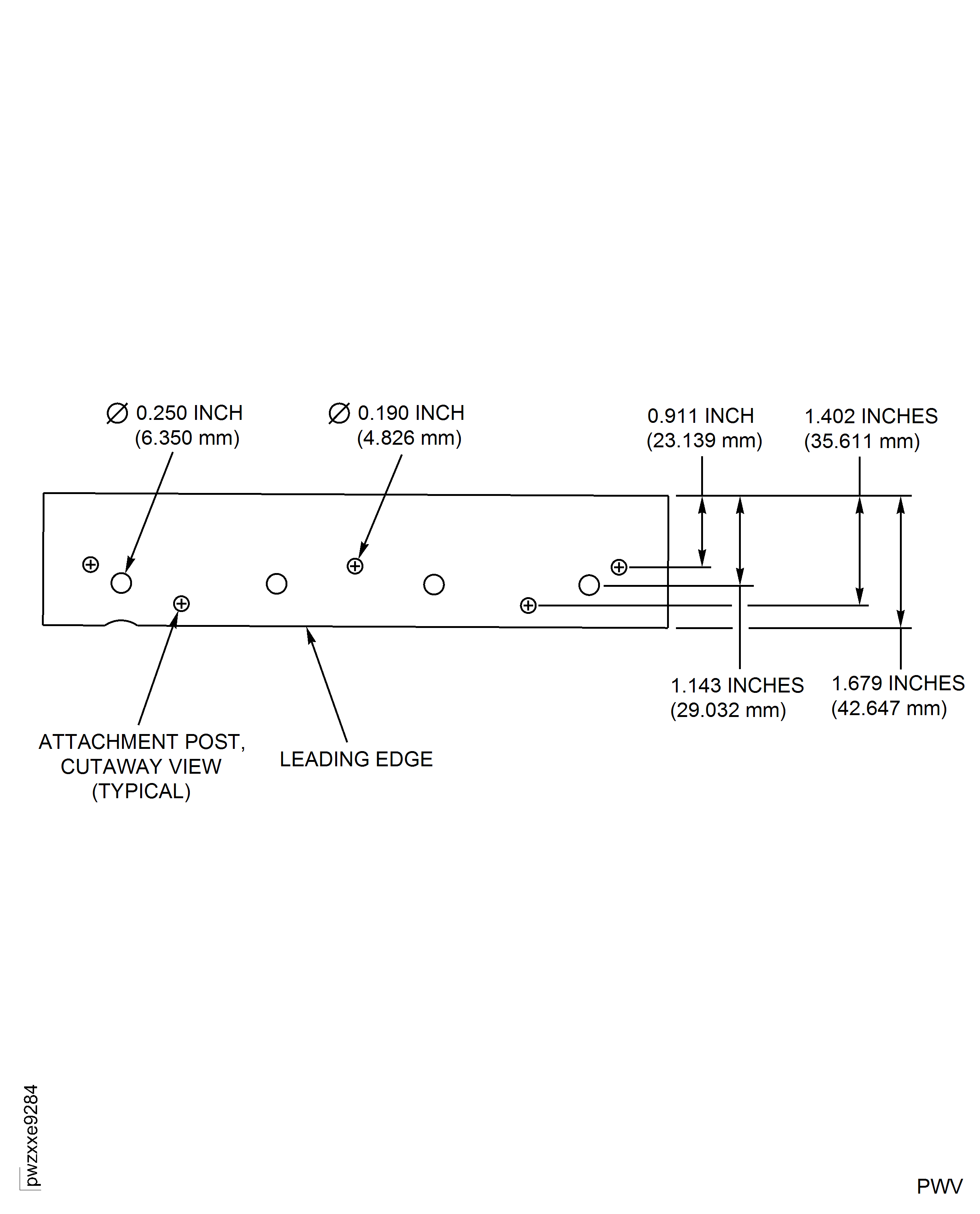

Figure: Outer Combustion Chamber Liner Dimensions References

Outer Combustion Chamber Liner Dimensions References

Figure: Pre SBE 72-0221: Borescope Parts

Pre SBE 72-0221: Borescope Parts

Figure: SBE 72-0221: Borescope Parts

SBE 72-0221: Borescope Parts

Figure: Pre SBE 72-0221: Borescope Inspection Ports for the Stage 1 HPT Vanes and the Combustion Chamber Liner

Pre SBE 72-0221: Borescope Inspection Ports for the Stage 1 HPT Vanes and the Combustion Chamber Liner

Figure: SBE 72-0221: Borescope Inspection Ports for the First Stage Vanes and the Combustion Chamber Liner

SBE 72-0221: Borescope Inspection Ports for the First Stage Vanes and the Combustion Chamber Liner

Figure: Combustion Chamber Liner Segments Borescope Inspection Guide Lines

Combustion Chamber Liner Segments Borescope Inspection Guide Lines

Figure: Combustion Chamber Liner Segment Burn Limits

Combustion Chamber Liner Segment Burn Limits

Combustion Chamber Liner Segment Burn Limits

Figure: Liner (Bulkhead) Segment Inspection Areas and Cracks

Liner (Bulkhead) Segment Inspection Areas and Cracks

Figure: Combustion Chamber Bulkhead Segment Burn-Through Hole

Combustion Chamber Bulkhead Segment Burn-Through Hole

Figure: Combustion Chamber Bulkhead Deflector Cracks and Burnback

Combustion Chamber Bulkhead Deflector Cracks and Burnback

Figure: Burnback limits for combustion chamber rejection

Burnback limits for combustion chamber rejection

Figure: Burnback Limits for 300 Hour Inspection

Burnback Limits for 300 Hour Inspection

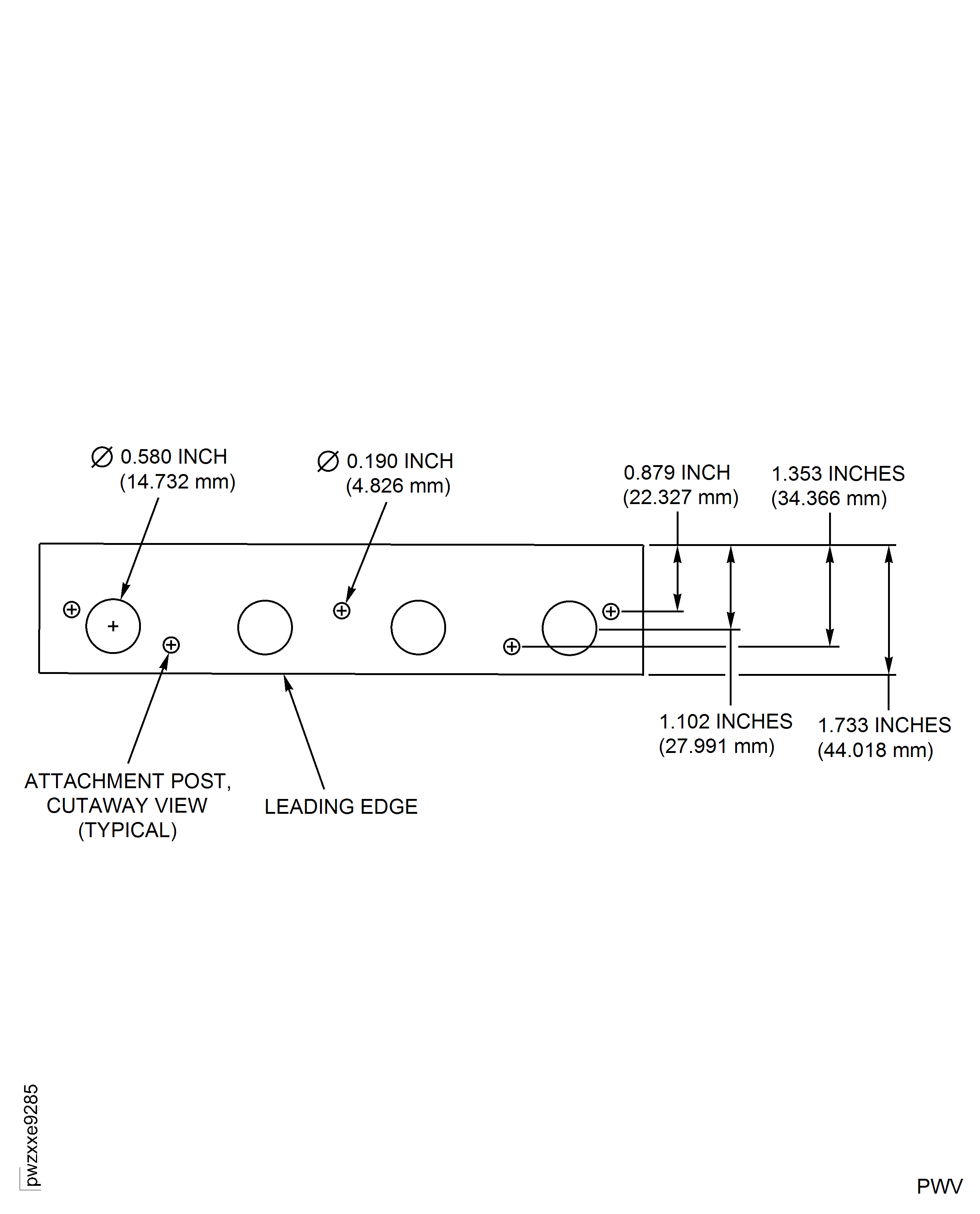

Figure: Combustion Chamber Outer Liner Row 1 (with Igniter Holes)

Combustion Chamber Outer Liner Row 1 (with Igniter Holes)

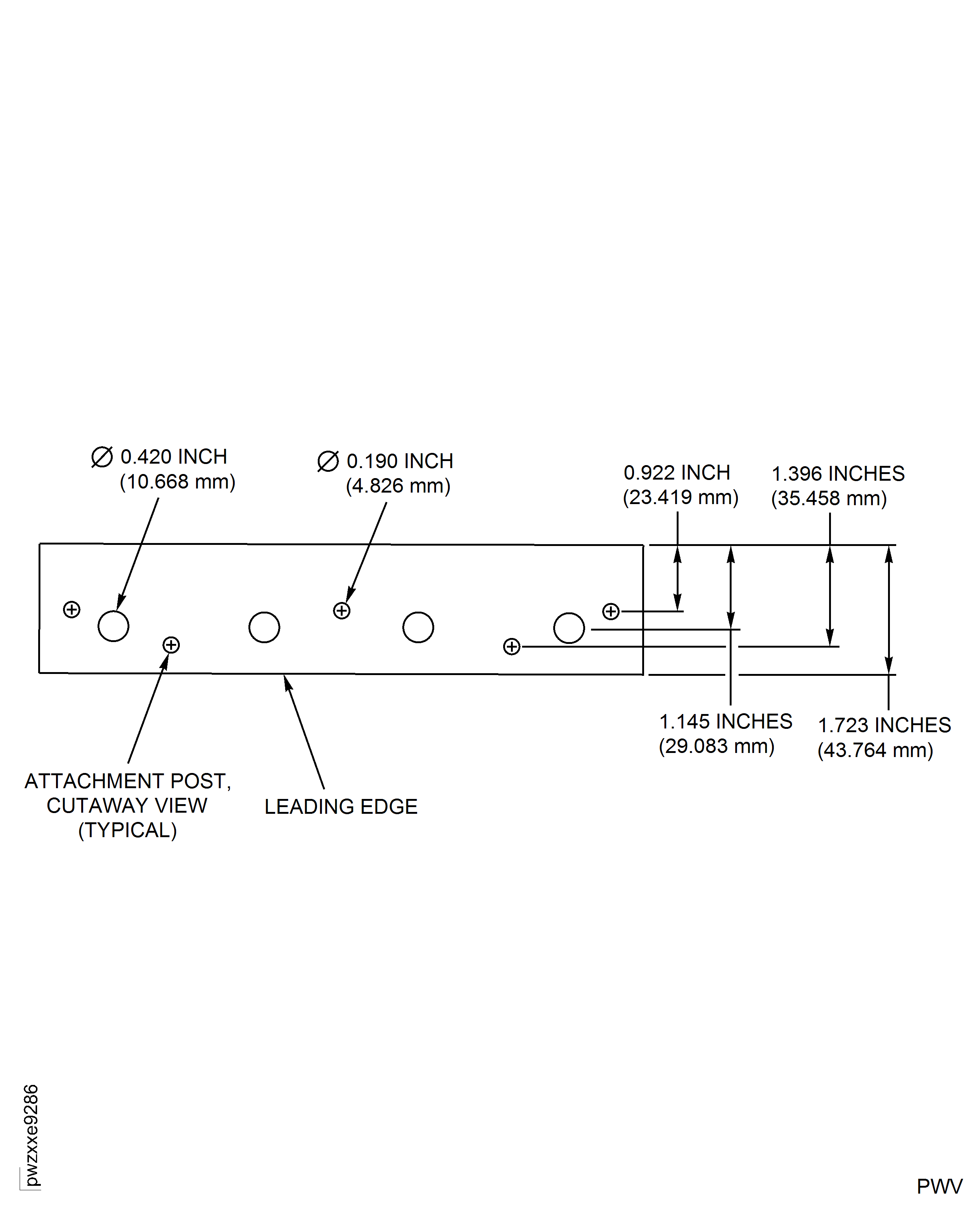

Figure: Combustion Chamber Outer Liner Row 2

Combustion Chamber Outer Liner Row 2

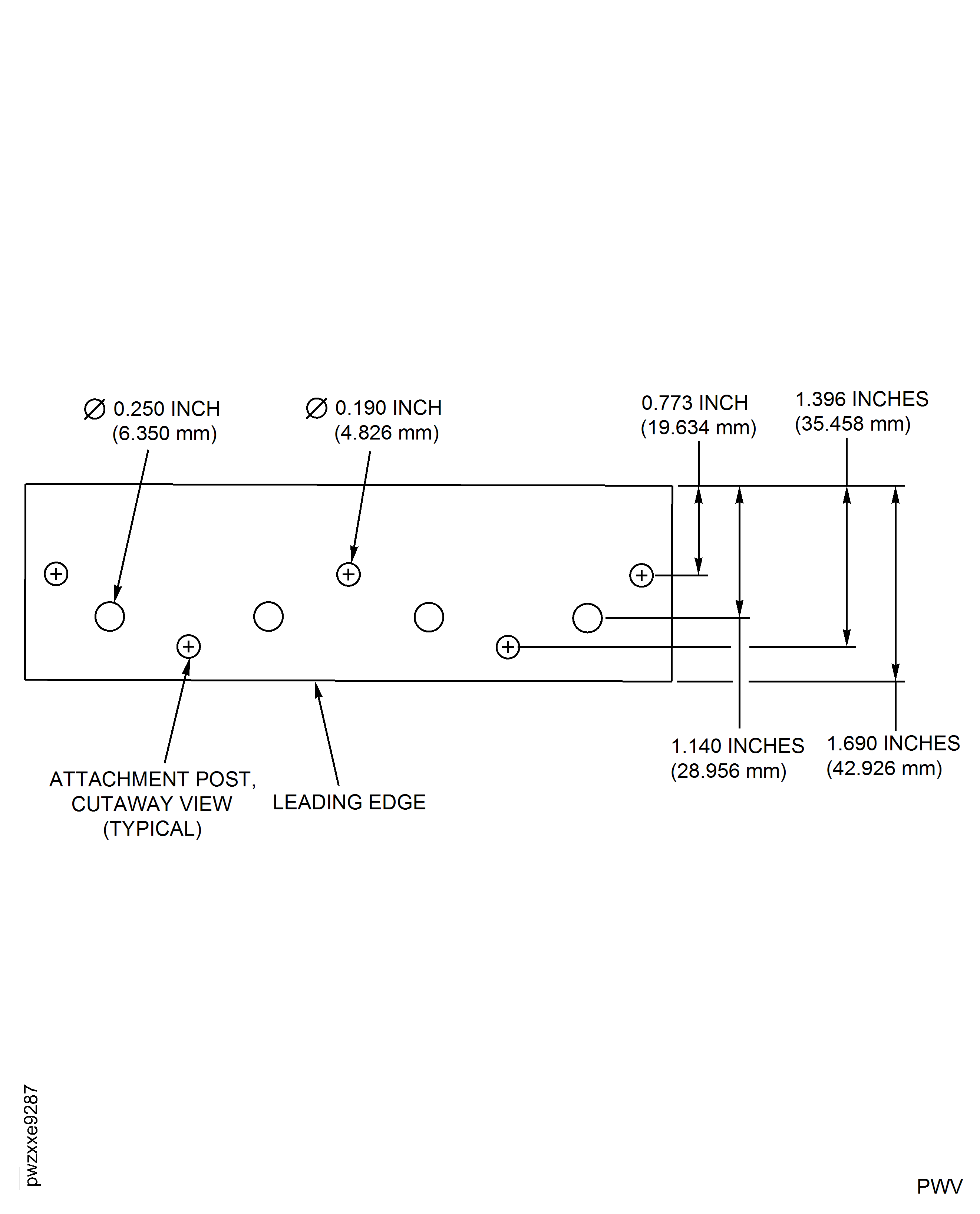

Figure: Combustion Chamber Outer Liner Row 3

Combustion Chamber Outer Liner Row 3

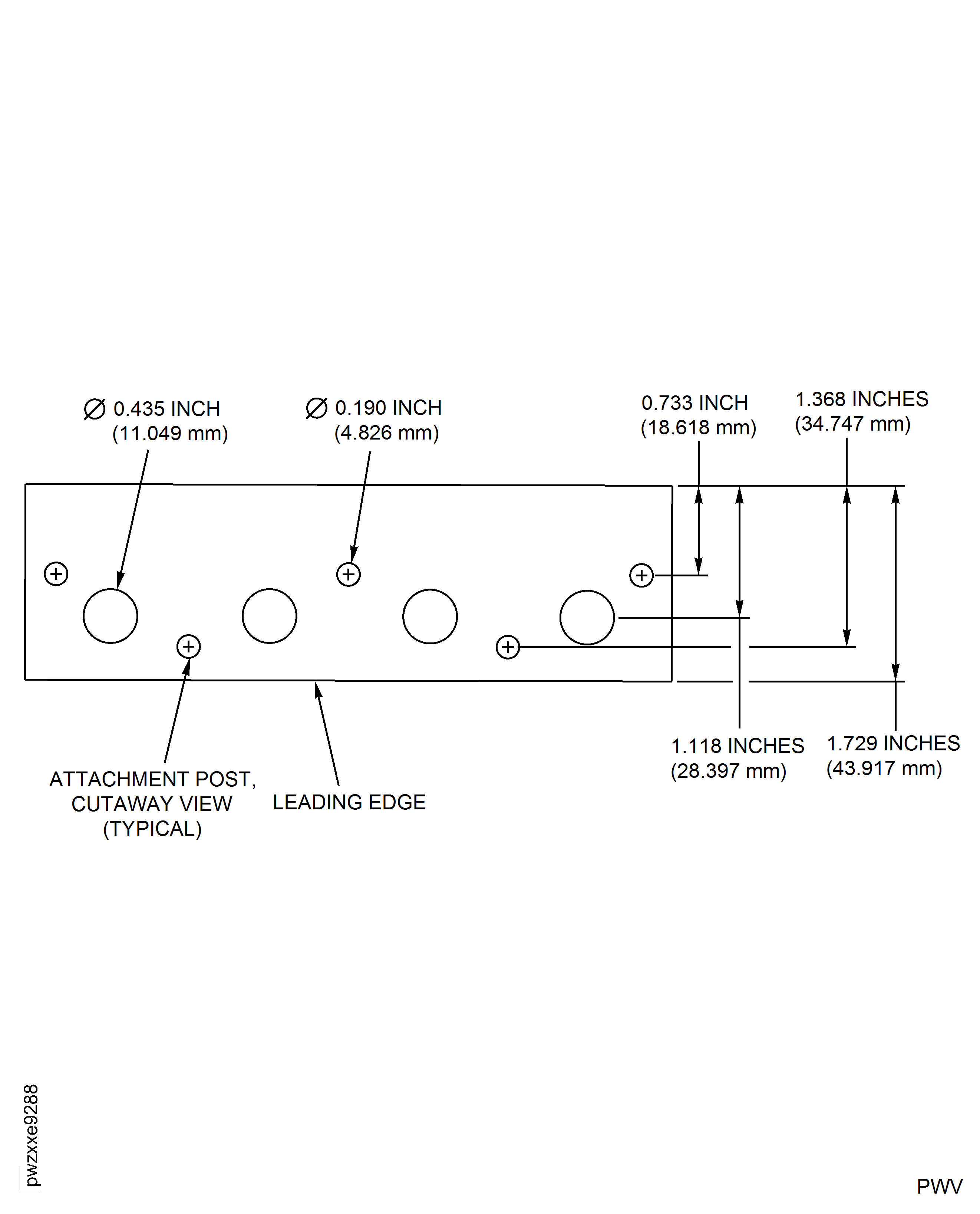

Figure: Combustion Chamber Outer Liner Row 4

Combustion Chamber Outer Liner Row 4

Figure: Combustion Chamber Inner Liner Row 2

Combustion Chamber Inner Liner Row 2

Figure: Combustion Chamber Inner Liner Row 3

Combustion Chamber Inner Liner Row 3

Figure: Combustion Chamber Inner Liner Row 4

Combustion Chamber Inner Liner Row 4

Figure: Fuel Nozzle Types of Damage

Fuel Nozzle Types of Damage

Figure: Fuel Nozzle End Cap Inspection area

Fuel Nozzle End Cap Inspection area

Figure: Fuel Nozzle End Cap Inspection Area

Fuel Nozzle End Cap Inspection Area

Figure: Combustion Chamber Bulkhead Deflector Burns

Combustion Chamber Bulkhead Deflector Burns