Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-00-200-002-A00 Engine General - Examine (Borescope) The HP Compressor (HPC), Inspection-002

General

Nicks and dents on airfoils, 0.005 in. (0.127 mm) or less, are considered minor. Minor nicks and dents are acceptable. There is no limit to the number of minor nicks and dents allowed.

This TASK gives the procedure for the borescope inspection of HP compressor rotor blades and rotor ceramic lining and measure stage 6 VSV bushing wear.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

A ** following repair referenced in this inspection indicates that the repair is not yet published in the current revision of the manual and the part must be rejected. Contact IAE for additional information concerning FAA approved repair date.

For all the parts identified in a different Chapter/Section/Subject the applicable Chapter/Section/Subject comes before the Fig/item number.

For the torque tightening procedures refer to SPM TASK 70-41-01-400-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| ACR Torq-Set bit 212-1/4-ACR | LOCAL | Torq-Set | ||

| IAE 2F10057 Rotator Kit | 0AM53 | IAE 2F10057 | ||

| IAE 6F10408 Borescope | 0AM53 | IAE 6F10408 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-003 SOLVENT, DELETED | X111X | CoMat 01-003 | ||

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 04-011 JOINTING COMPOUND | LOCAL | CoMat 04-011 | ||

| CoMat 10-070 ANTI-SEIZE COMPOUND | X222X | CoMat 10-070 | ||

| CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) | K6835 | CoMat 10-072 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

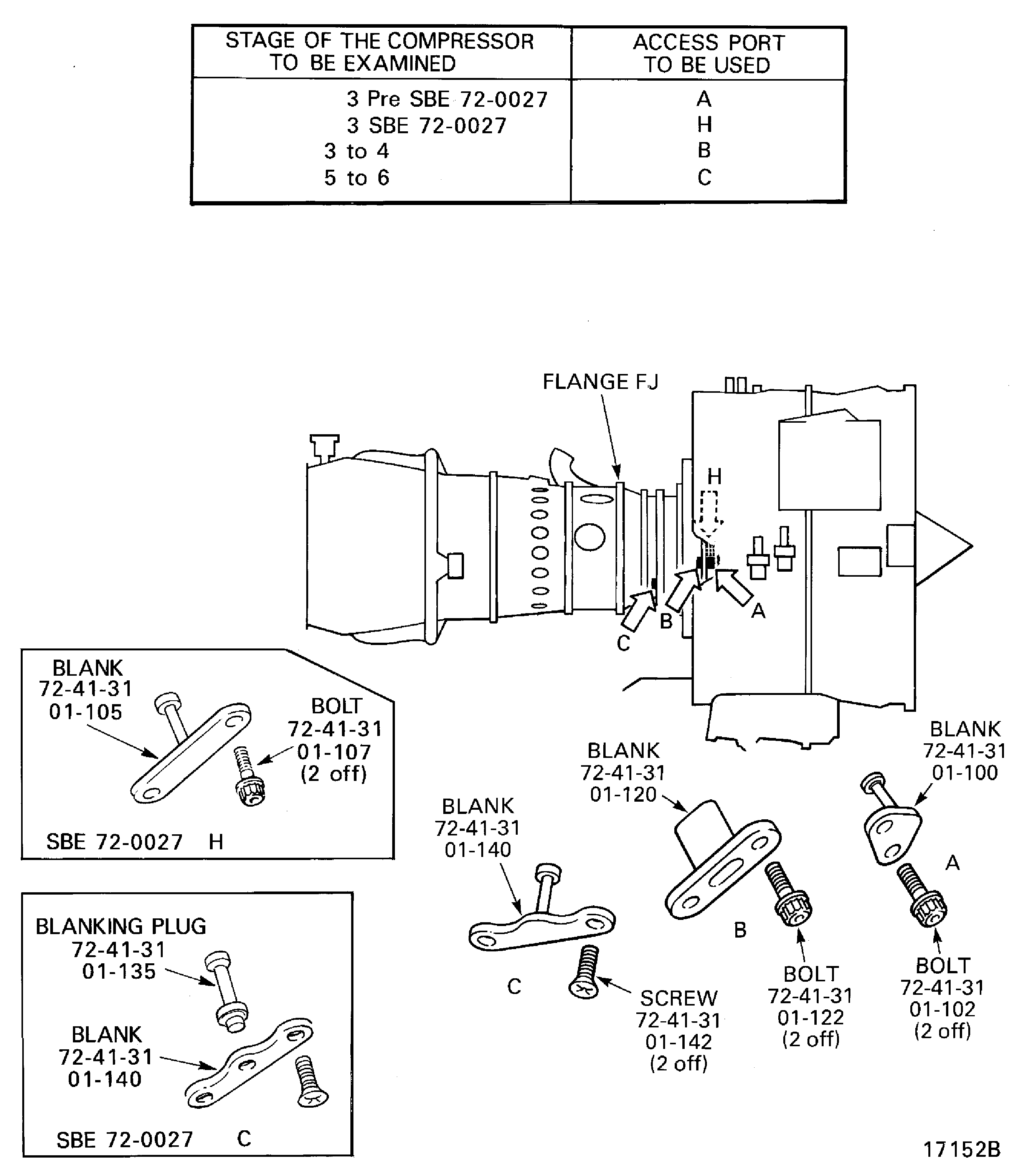

Remove the two bolts that attach the blank A ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-100) to the compressor case at the 4 o'clock position, forward of the stage 3 unison ring. Remove the blank.

Remove the two bolts that attach the blank B ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-120) to the compressor case at the 4 o'clock position, to the rear of the stage 3 unison ring. Remove the blank.

Remove the stage 3 borescope blanks (A and B).

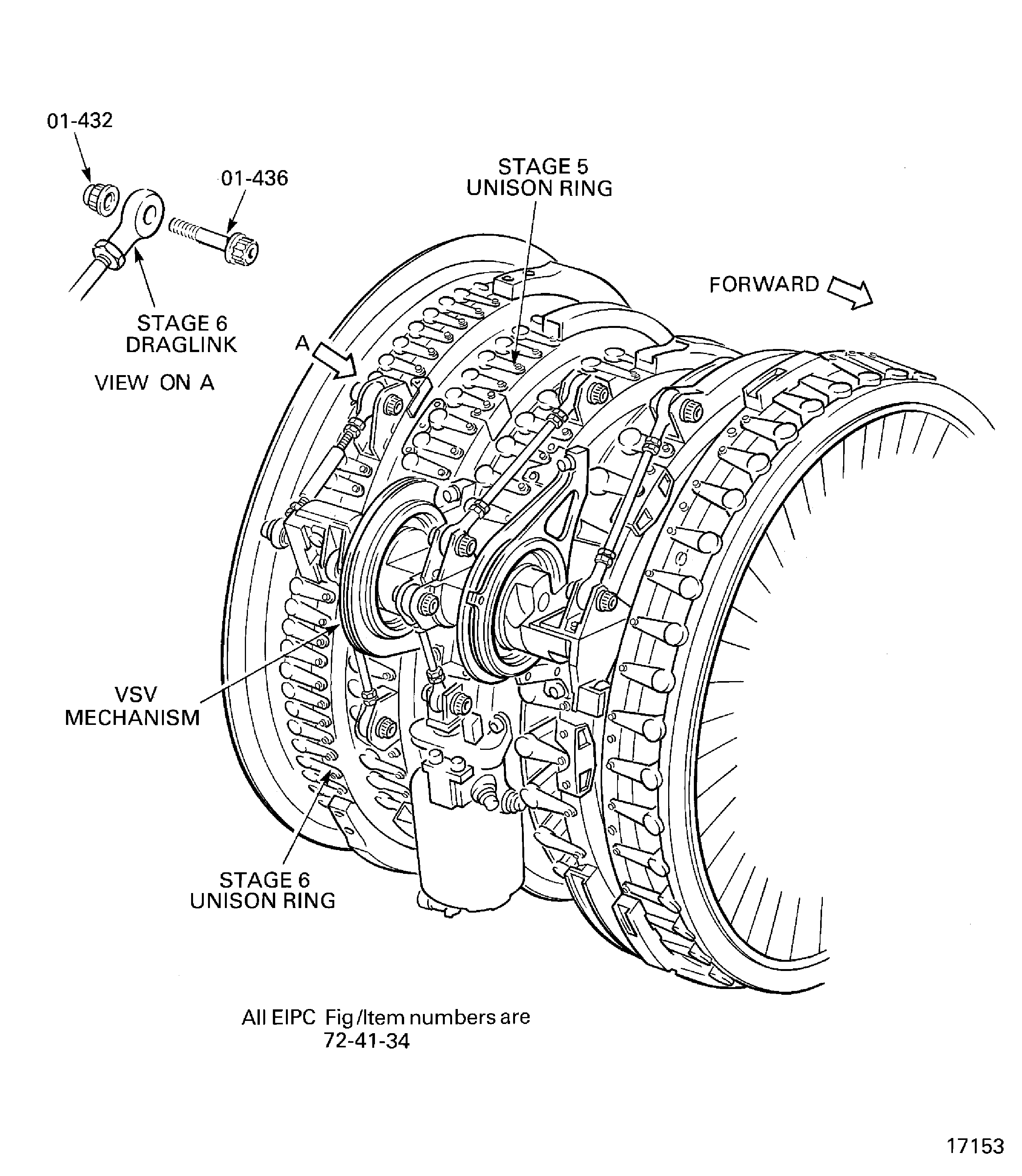

Remove the bolt that attaches the stage 6 drag link to the unison ring bracket (refer to Figure).

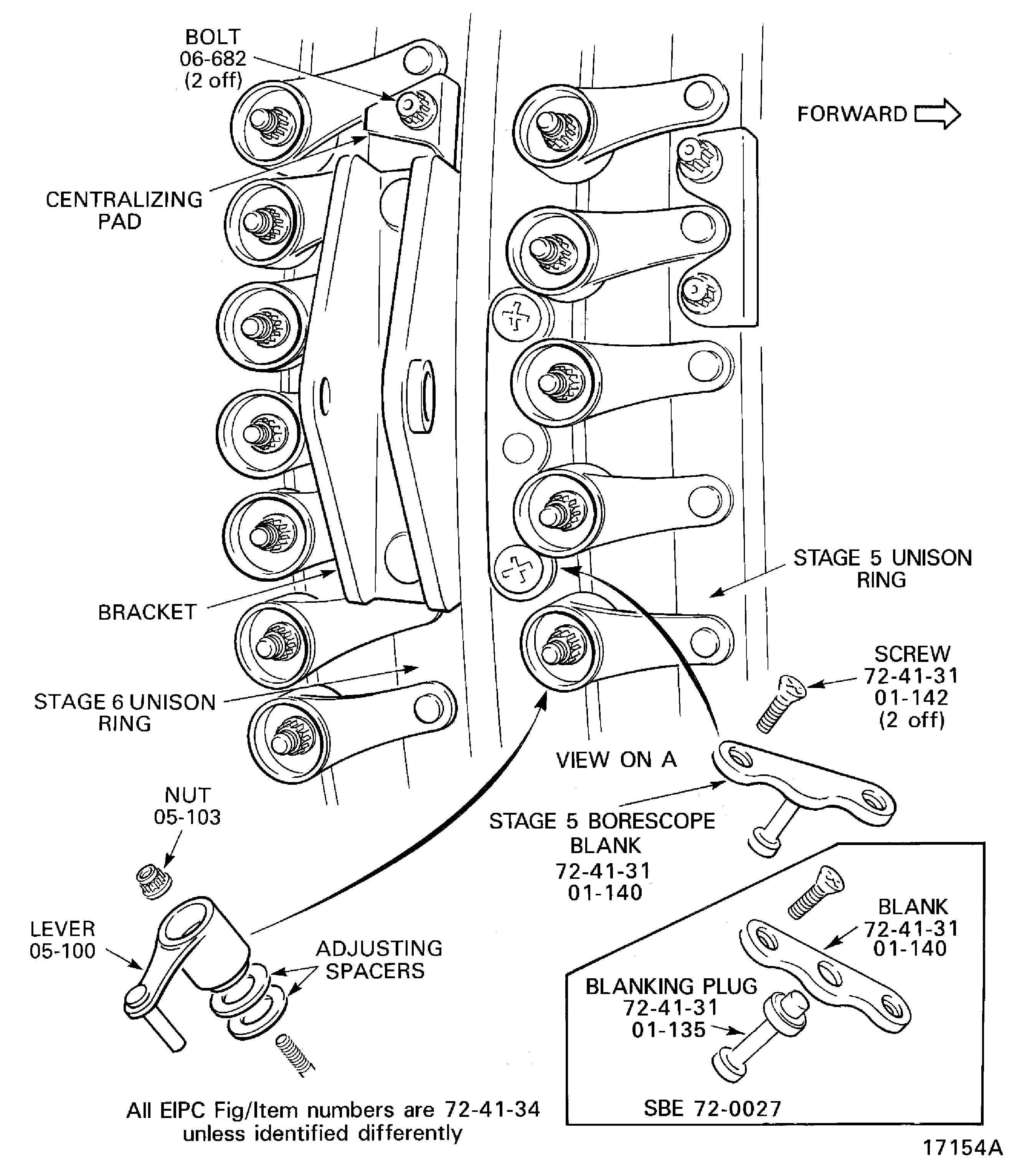

Loosen, but do not remove, the two bolts that attach the centralizing pad to the stage 6 unison ring (refer to Figure).

Remove the nuts from each of the two stage 5 levers, adjacent to the borescope blank (refer to Figure).

With the ACR Torq-Set bit 212-1/4-ACR 1 off remove the two screws that attach the borescope blank C ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-140) to the compressor case and remove the blank.

Remove the stage 5 borescope blank (C).

Remove the borescope access port blanks (refer Figure).

SUBTASK 72-00-00-020-053-A00 Remove the Stage 3 and 5 Borescope Access Port Blanks (Pre SBE 72-0027)

Remove the two bolts that attach the blank A ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-100) to the compressor case at the 4 o'clock position, forward of the stage 3 unison ring. Remove the blank.

Remove the two bolts that attach the blank B ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-120) to the compressor case at the 4 o'clock position, to the rear of the stage 3 unison ring. Remove the blank.

Remove the two bolts that attach the blank H ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-105) to the compressor case at the 8 o'clock position, forward of the stage 3 unison ring. Remove the blank.

Remove the stage 3 borescope blanks (A, B and H).

With the ACR Torq-Set bit 212-1/4-ACR 1 off remove the two screws that attach the borescope blank C ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-140) to the compressor case and remove the blank and the blanking plug.

Remove the stage 5 borescope blank (C).

Remove the borescope access port blanks.

SUBTASK 72-00-00-020-053-B00 Remove the Stage 3 and 5 Borescope Access Port Blanks (SBE 72-0027)

Refer to Figure.

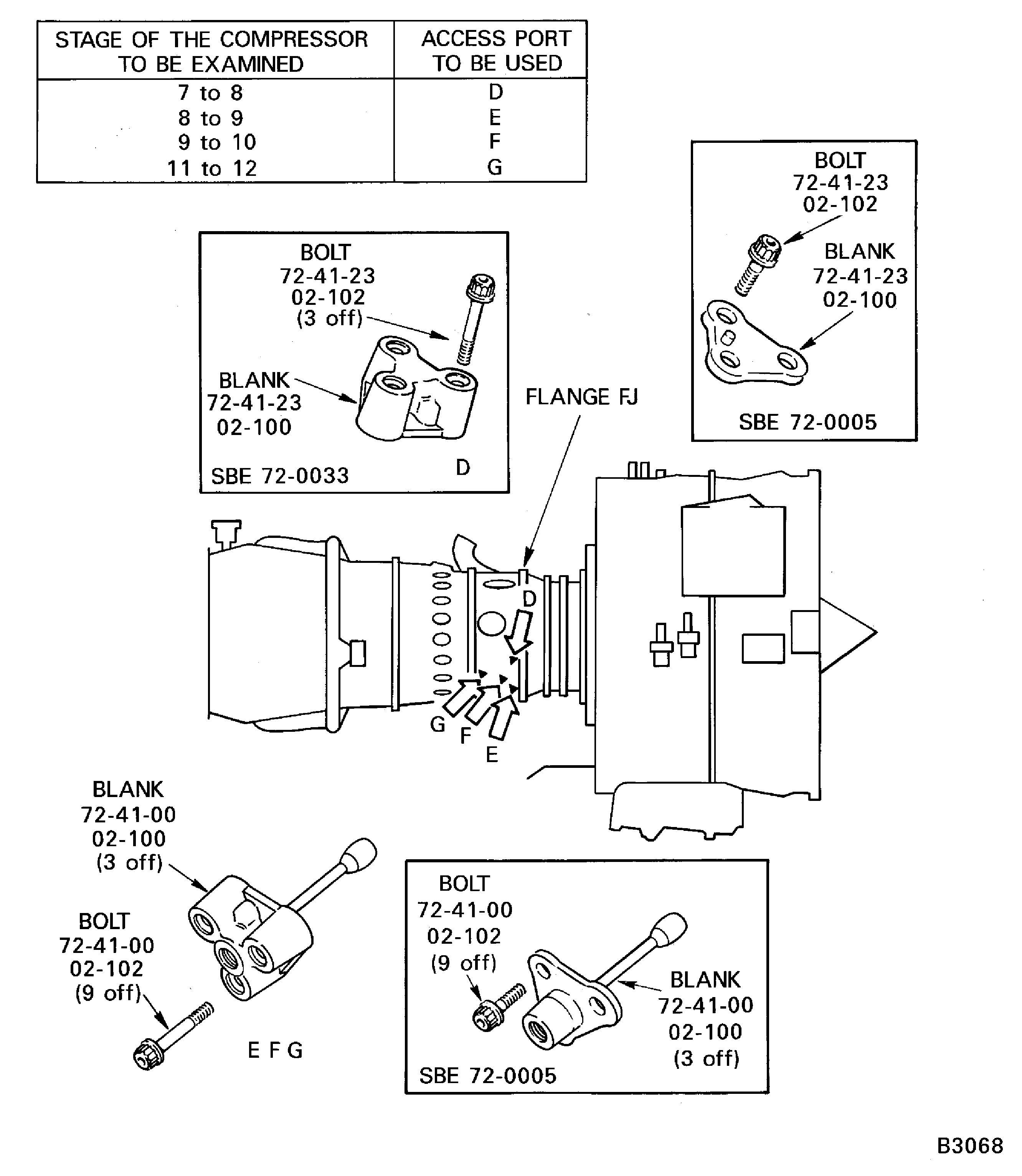

Remove the three bolts that attach the borescope blank E ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank.

Remove the three bolts that attach the borescope blank F ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank.

Remove the three bolts that attach the borescope blank G ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank.

Remove the three stage 8 to 12 borescope blanks (E, F and G).

SUBTASK 72-00-00-020-066-A00 Remove the Stage 8 to 12 Borescope Access Port Blanks (Pre SBE 72-0033 and Pre SBE 72-0100)

Remove the three bolts that attach the borescope blank D ENGINE-HP COMPRESSOR REAR OUTER CASE (72-41-23, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank.

Remove the three bolts that attach the borescope blank E ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank.

Remove the three bolts that attach the borescope blank F ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank.

Remove the three bolts that attach the borescope blank G ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank.

Remove the four stage 7 to 12 borescope blanks (D, E, F and G).

SUBTASK 72-00-00-020-066-B00 Remove the Stage 7 to 12 Borescope Access Port Blanks (SBE 72-0033 and Pre SBE 72-0100)

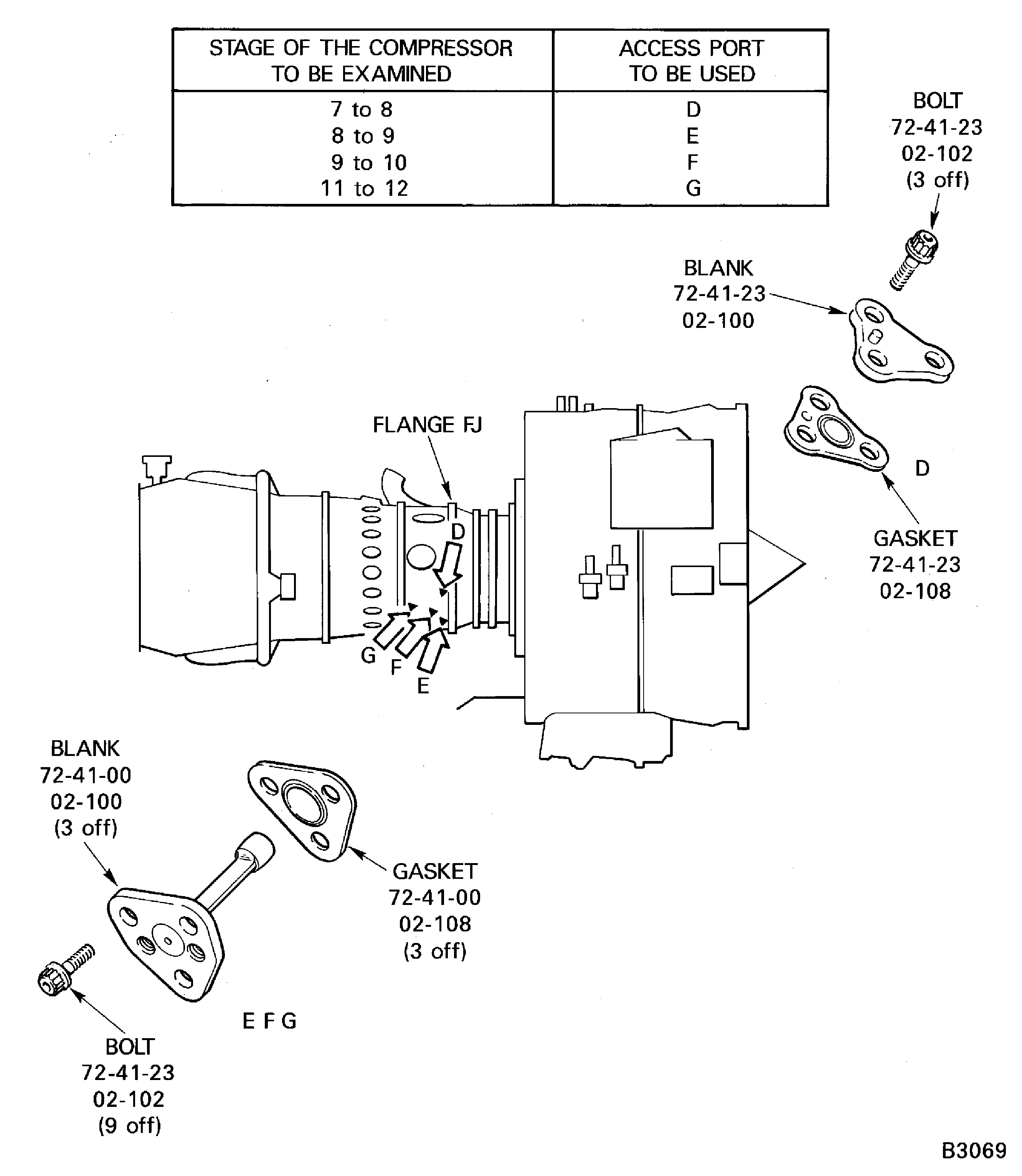

Refer to Figure.

Remove the three bolts that attach the borescope blank D ENGINE-HP COMPRESSOR REAR OUTER CASE (72-41-23, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank and discard the gasket.

Remove the three bolts that attach the borescope blank E ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank and discard the gasket.

Remove the three bolts that attach the borescope blank F ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank and discard the gasket.

Remove the three bolts that attach the borescope blank G ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case at the 4 o'clock position, to the rear of flange FJ. Remove the blank and discard the gasket.

Remove the four stage 7 to 12 borescope blanks (D, E, F and G) (refer to Figure).

SUBTASK 72-00-00-020-066-C00 Remove the Stage 7 to 12 Borescope Access Port Blanks (SBE 72-0100)

Repair, VRS9170 TASK 72-00-00-300-013 (REPAIR-013) with KEENSERTS or Repair, VRS6518 TASK 72-00-41-300-001 (REPAIR-001) with thinwall inserts. KEENSERTS must be replaced at next HPC overhaul.

Broken, loose, worn, crossed threaded or stripped thread.

Accept, until next HPC overhaul.

Inspect for installed KEENSERTS.

SUBTASK 72-00-00-220-178 Examine the HP Compressor Rear Case Screw Thread Inserts

Use a non metallic scraper and a lint free cloth made moist with CoMat 01-003 SOLVENT, DELETED 1.1.2 trichloroethylene (inhibited and stabilized) or CoMat 01-076 METHYL ETHYL KETONE. Remove all the used jointing compound from around the access ports.

Remove the used jointing compound from the access ports.

SUBTASK 72-00-00-160-051 Clean the Borescope Access Ports

WARNING

WHEN YOU USE CoMat 01-076 METHYL ETHYL KETONE METHYL ETHYL KETONE OR CoMat 01-003 SOLVENT, DELETED 1.1.2 TRICHLOROETHYLENE (INHIBITED AND STABILIZED) YOU MUST MAKE SURE THERE IS SUFFICIENT VENTILATION. YOU MUST USE THE CORRECT PROTECTIVE CLOTHING. YOU MUST NOT SMOKE AND DO NOT PUT THE SOLVENT NEAR A SOURCE OF HEAT AS THE VAPOR CHANGES AND BECOMES TOXIC.

CAUTION

DO NOT LET JOINTING COMPOUND GET IN TO THE ENGINE THROUGH THE ACCESS PORTS, CONTAMINATION OF HP COMPRESSOR AND COMPONENT DAMAGE CAN OCCUR.Refer to Figure.

NOTE

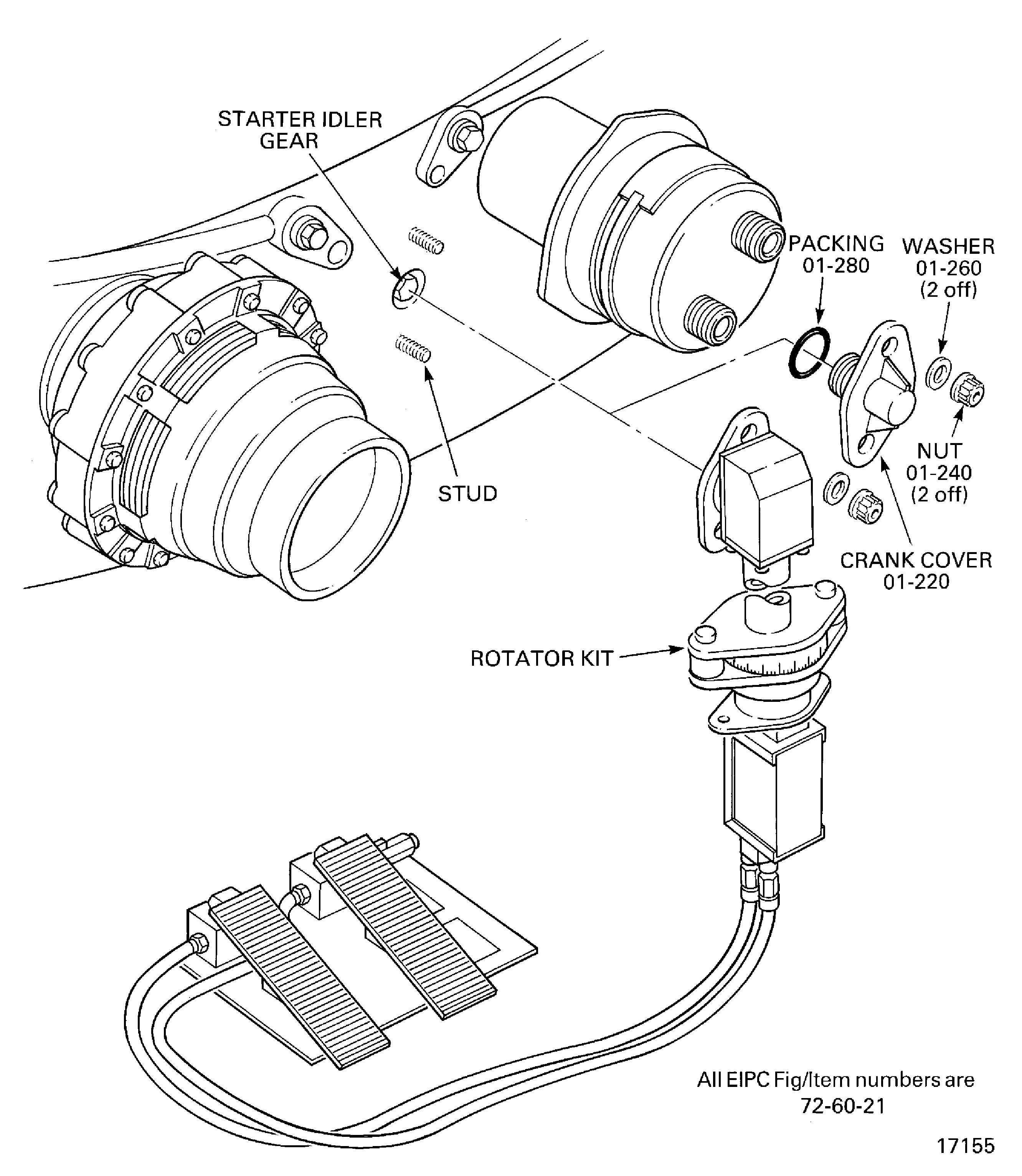

The crank cover is on the front face of the external gearbox between the dedicated alternator and the pneumatic starter.Remove the crank cover ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-220) from the external gearbox.

Install the two washers ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-260) and the two bolts ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-240). Tighten the two nuts.

Install the IAE 2F10057 Rotator Kit 1 off.

SUBTASK 72-00-00-420-053 Install the Rotator Kit

NOTE

Use a 0.32 in. (8.0 mm) borescope probe.Install the IAE 6F10408 Borescope 1 off in the access port to the stage of the compressor you want to examine.

SUBTASK 72-00-00-420-054 Install the Borescope Probe Stages 3 to 6

NOTE

Use a 0.22 in. (5.5 mm) borescope probe.Install the IAE 6F10408 Borescope 1 off in the access port of the stage 7 compressor.

SUBTASK 72-00-00-420-069 Install the Borescope Probe Stage 7 (SBE 72-0033)

NOTE

Use a 0.22 in. (5.5 mm) borescope probe.Install the IAE 6F10408 Borescope 1 off in the access port of the stage of the compressor you want to examine.

SUBTASK 72-00-00-420-071 Install the Borescope Probe Stages 8 to 12

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.200 in. (5.08 mm).

More than in Step.

Nicked and torn (not related to cracks).

Zone A.

Reject.

More than Step Step.

Nicked.

Zone B.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Nicks more than in Step but not more than 0.200 in. (5.08 mm).

More than in Step.

Nicked and torn.

Zone C.

SUBTASK 72-00-00-220-150 Examine the Stage 3 HP Compressor Rotor Blades

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.180 in. (4.57 mm) in depth.

More than in Step.

Nicked and torn (not related to cracks).

Zone A - All stages.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.180 in (4.57 mm) in depth.

More than in Step.

Nicked (not related to cracks or tears).

Zone B - All stages.

SUBTASK 72-00-00-220-151 Examine the Stage 4 and 5 HP Compressor Rotor Blades

More than in Step.

Nicked and torn (not related to cracks).

Zone A - Stage 6 Rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.075 in. (1.90 mm).

More than in Step.

Nicked and torn (not related to cracks).

Zone A - Stage 7 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.067 in. (1.70 mm).

More than in Step.

Nicked and torn (not related to cracks).

Zone A - Stage 8 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.060 in. (1.52 mm).

More than in Step.

Nicked and torn (not related to cracks).

Zone A - Stage 9 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.050 in. (1.27 mm).

More than in Step.

Nicked and torn (not related to cracks).

Zone A - Stage 10 to 12 rotor blades.

More than in Step.

Nicked (not related to cracks or tears).

Zone B - Stage 6 Rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.075 in. (1.90 mm) in depth.

More than in Step.

Nicked (not related to cracks or tears).

Zone B - Stage 7 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.067 in. (1.70 mm) in depth.

More than in Step.

Nicked (not related to cracks or tears).

Zone B - Stage 8 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.060 in. (1.52 mm) in depth.

More than in Step.

Nicked (not related to cracks or tears).

Zone B - Stage 9 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

More than in Step but not more than 0.050 in. (1.27 mm) in depth.

More than in Step.

Nicked (not related to cracks or tears).

Zone B - Stage 10 to 12 rotor blades.

Reject.

Missing piece - Stage 6, 7, 9, 10, 11 and 12 rotor blades.

Repair, VRS9653 TASK 72-00-00-300-004 (REPAIR-004).

Not more than 0.060 in. (1.524 mm).

Reject.

More than Step.

Missing piece - Stage 8 rotor blades only.

Blade tips.

SUBTASK 72-00-00-220-152 Examine the Stage 6 to 12 HP Compressor Rotor Blades

Lightly lubricate a new ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-280) packing1 off with CoMat 10-077 APPROVED ENGINE OILS and install it on the crank cover ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-220).

Attach the crank cover on the external gearbox with the two washers ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-260) and the two nuts ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-240). Torque the nuts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Remove the rotator kit from the external gearbox.

SUBTASK 72-00-00-020-054 Remove the Support Equipment

Use a lint free cloth made moist with CoMat 01-003 SOLVENT, DELETED or CoMat 01-076 METHYL ETHYL KETONE. Remove all the used jointing compound from the mating faces of the blanks.

Remove the used jointing compound from the mating faces of the access port blanks.

SUBTASK 72-00-00-160-052 Clean the Borescope Access Port Blanks

WARNING

WHEN YOU USE CoMat 01-076 METHYL ETHYL KETONE OR CoMat 01-003 SOLVENT, DELETED YOU MUST MAKE SURE THERE IS SUFFICIENT VENTILATION. YOU MUST USE THE CORRECT PROTECTIVE CLOTHING. YOU MUST NOT SMOKE AND DO NOT PUT THE SOLVENT NEAR A SOURCE OF HEAT AS THE VAPOR CHANGES AND BECOMES TOXIC.

CAUTION

DO NOT LET JOINTING COMPOUND GET IN TO THE ENGINE THROUGH THE ACCESS PORTS, CONTAMINATION OF HP COMPRESSOR AND COMPONENT DAMAGE CAN OCCUR.Refer to Figure.

Apply a thin layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the mating faces of the access ports and the access port blanks with a stiff bristle brush. Do not apply jointing compound nearer than 0.12 to 0.16 in. (3 to 4 mm) to the access port.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-102) which hold the borescope access port blank A to the compressor case.

Attach the access port blank A ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-100) to the compressor case with the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-102). Torque the screws to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-122) which hold the borescope access port blank B to the compressor case.

Attach the access port blank B ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-120) to the compressor case with the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-122). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two screws ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-142) which hold the borescope access port blank C to the compressor case.

Attach the access port blank C ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-140) to the compressor case with the two screws ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-142). Use theACR Torq-Set bit 212-1/4-ACR to torque the screws to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Install the two levers ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-100) with their applicable spacers. Install each of the two nuts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 05-103) and torque to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Tighten the two bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-682) that attach the centralizing pad to the stage 6 unison ring. Torque the bolts to 36 lbf.in to 45 lbf.in (4 Nm to 5 Nm).

CAUTION

YOU MUST INSTALL THE VSV LEVERS CORRECTLY OR THE COMPRESSOR CAN BE DAMAGED.Connect the stage 5 and 6 unison rings.

Install the borescope access port blanks A, B and C.

SUBTASK 72-00-00-420-055-A00 Install the Borescope Access Port Blanks Stage 3 and 5 (Pre SBE 72-0027)

Refer to Figure.

Apply a thin layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the mating faces of the access ports and the access port blanks with a stiff bristle brush. Do not apply jointing compound nearer than 0.12 to 0.16 in. (3 to 4 mm) to the access port.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-102) which hold the borescope access port blank A to the compressor case.

Attach the access port blank A ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-100) to the compressor case with the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-102). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-122) which hold the borescope access port blank B to the compressor case.

Attach the access port blank B ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-120) to the compressor case with the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-122). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two screws ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-142) which hold the borescope access port blank C to the compressor case.

Attach the access port blank C ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-140) blank and ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-135) blanking plug to the compressor case with the two screws ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-142). Use the ACR Torq-Set bit 212-1/4-ACR 1 off to torque the screws to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-107) which hold the borescope access port blank H to the compressor case.

Attach the access port blank H ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-105) to the compressor case with the two bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-107). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Tighten the two bolts ACTUATING MECHANISM HP COMPRESSOR VARIABLE VANES (72-41-34, 06-682) that attach the centralizing pad to the stage 6 unison ring. Torque the bolts to 36 lbf.in to 45 lbf.in (4 Nm to 5 Nm).

Connect the stage 5 and 6 unison rings.

Install the borescope access port blanks A, B, C and H.

SUBTASK 72-00-00-420-055-B00 Install the Borescope Access Port Blanks Stage 3 and 5 (SBE 72-0027)

Refer to Figure.

Apply a thin layer of CoMat 04-011 JOINTING COMPOUND to the mating faces of the access ports and access port blanks with a stiff bristle brush or pallet knife. Do not apply jointing compound nearer than 0.12 to 0.16 in. (3 to 4 mm) around the access port.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the nine bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102) which hold the borescope access port blanks E, F and G to the compressor case.

Attach the access port blanks E, F and G ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case with the nine bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Install the three borescope access port blanks E, F and G.

SUBTASK 72-00-00-420-071-A00 Install the Stage 8 to 12 Borescope Access Port Blanks (Pre SBE 72-0033 and Pre SBE 72-0100)

Refer to Figure.

Apply a thin layer of CoMat 04-011 JOINTING COMPOUND to mating surfaces of the access ports and access port blanks with a stiff bristle brush or pallet knife. Do not apply jointing compound nearer than 0.12 in. to 0.16 in. (3 mm to 4 mm) around the access ports.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the three bolts ENGINE-HP COMPRESSOR REAR OUTER CASE (72-41-23, 02-102) which hold the borescope access port blank D to the compressor case.

Attach the access port blank D ENGINE-HP COMPRESSOR REAR OUTER CASE (72-41-23, 02-100) to the compressor case with the three bolts ENGINE-HP COMPRESSOR REAR OUTER CASE (72-41-23, 02-102). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the nine bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102) which hold the borescope access port blanks E, F and G to the compressor case.

Attach the access port blanks E, F and G ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case with the nine bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

SUBTASK 72-00-00-420-071-B00 Install the Stage 7 to 12 Borescope Access Port Blanks (SBE 72-0033 and Pre SBE 72-0100)

Refer to Figure.

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the three bolts ENGINE-HP COMPRESSOR REAR OUTER CASE (72-41-23, 02-102) which hold the borescope access port blank D to the compressor case.

Attach the access port blank D ENGINE-HP COMPRESSOR REAR OUTER CASE (72-41-23, 02-100) to the compressor case with the ENGINE-HP COMPRESSOR REAR OUTER CASE (72-41-23, 02-108) gasket 1 off and the three bolts ENGINE-HP COMPRESSOR REAR OUTER CASE (72-41-23, 02-102). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Apply CoMat 10-072 ANTISEIZE COMPOUND (MoDISULFIDE) or CoMat 10-070 ANTI-SEIZE COMPOUND to the nine bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102) which hold the borescope access port blanks E, F and G to the compressor case.

Attach the access port blanks E, F and G ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-100) to the compressor case with the ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-108) gaskets 3 off and the nine bolts ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 02-102). Torque the bolts to 85 lbf.in to 105 lbf.in (10 Nm to 12 Nm).

Install the four stage 7 to 12 borescope blanks (D, E, F and G).

SUBTASK 72-00-00-420-071-C00 Install the Stage 7 to 12 Borescope Access Port Blanks (SBE 72-0100)

Other than in Step.

Amount of movement in stator vanes.

SUBTASK 72-00-00-220-149 Measure the Stage 6 VSV Bushing Wear

SUBTASK 72-00-00-220-172 Examine the HP Compressor Stage 6 Rotor Path Coating

Reject.

Damper wire visible.

SUBTASK 72-00-00-220-173 Stages 6, 7 and 8 Front and Rear Damper Wires

Figure: HP Compressor Borescope Access Ports

HP Compressor Borescope Access Ports

Figure: HP Compressor Borescope Access Ports

HP Compressor Borescope Access Ports

Figure: HP Compressor Borescope Access Ports

HP Compressor Borescope Access Ports

Figure: HP Compressor Borescope Access Ports

HP Compressor Borescope Access Ports

Figure: HP Compressor Borescope Access Ports

HP Compressor Borescope Access Ports

Figure: Install the Rotator Kit

Install the Rotator Kit

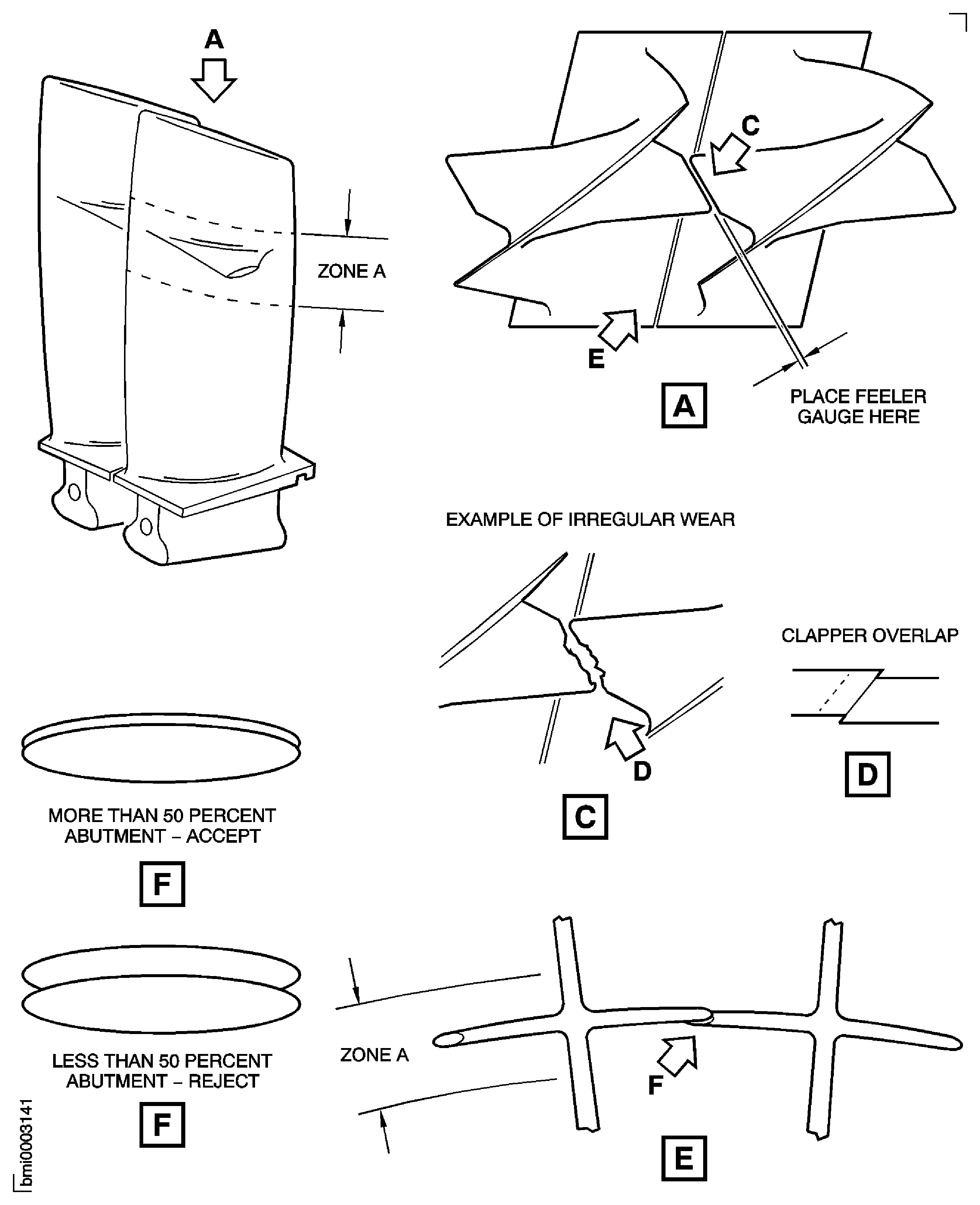

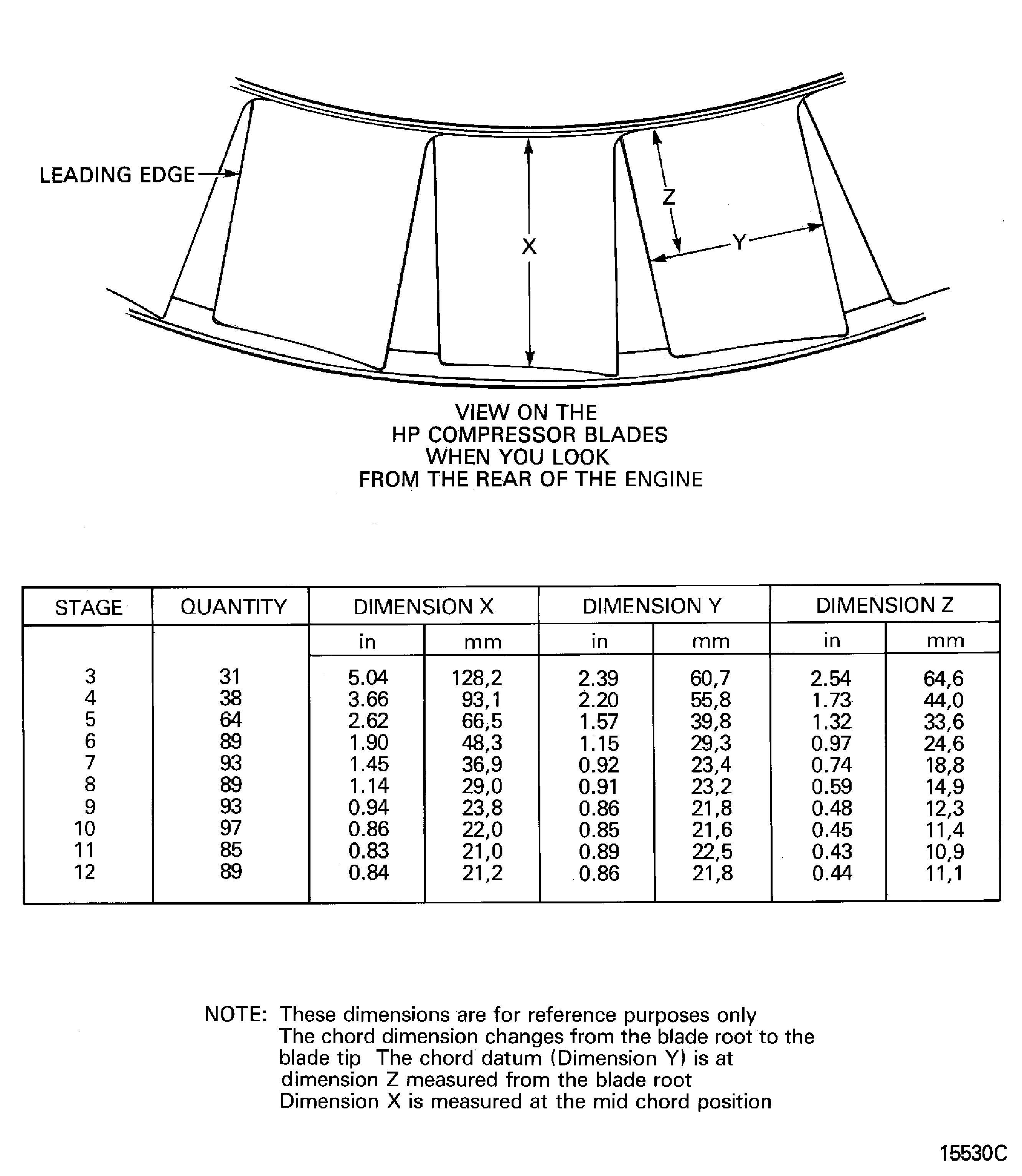

Figure: HP Compressor Blades

HP Compressor Blades

Figure: HP Compressor Blades

HP Compressor Blades

Figure: HP Compressor Blades

HP Compressor Blades