Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-00-300-013 Repair Damaged Thinwall Insert(s) In The HP Compressor, Rear Outer Case Assembly, With Oversized Insert (KEENSERTS Inserts), Repair-011 (VRS9170)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-400 | 6A2949 |

02-400 | 6A3557 |

02-400 | 6A4154 |

02-400 | 6A5495 |

02-400 | 6A5682 |

02-400 | 6A8162 |

02-400 | 6B1427 |

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor, Rear Outer Case Assembly | EEJ or ENH | Corrosion resistant steel Chrome cobalt molybdenum electro flux remelted steel |

General

This repair must only be done when the instruction is given in the relevant inspection procedures (identified by the applicable part number) located in section 72-00-00.

This repair is to replace the thinwall insert(s) with Self-Broaching KEENSERTS when they are broken, worn, cross threaded or missing.

For price and availability, Refer to International Aero Engines (IAE).

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Approved workshop equipment | LOCAL | Approved workshop equipment | AR | |

| Basic Power Unit | LOCAL | 70951-6 | AR | |

| Broaching Tool | LOCAL | B397-2 | AR | Use this tool for insert MS51831CA202L |

| Broaching Tool | LOCAL | B453-4 | AR | Use this tool for insert MS51832CA202L |

| Broaching Tool | LOCAL | B543-4 | AR | Use this tool for insert MS51831CA203L |

| Installation Tool | LOCAL | THD 428L | AR | Use this tool for insert MS51831CA202L |

| Installation Tool | LOCAL | THXHD428L | AR | Use this tool for insert MS51832CA202L |

| Installation Tool | LOCAL | THD524 | AR | Use this tool for insert MS51831CA203L |

| Nose Assembly | LOCAL | 70947ASBK-202H | AR | |

| Tang Removal Tool | LOCAL | 2R19618 | AR |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | X222X | CoMat 06-064 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| INSERT | 0AM53 | KU37022 | AR | |

| INSERT | 96906 | MS51831CA202L | AR | KEENSERTS |

| INSERT | 96906 | MS51832CA202L | AR | KEENSERTS |

| INSERT | 96906 | MS51831CA203L | AR | KEENSERTS |

Safety Requirements

NONEProcedure

Refer to Figure.

Ensure that the condition is as reported.

Examine the damaged area.

SUBTASK 72-00-00-220-176 Examine the Damaged Area

Mask and cover all holes and openings to the inner side of the case which need to be repaired. Prepare inner-free area of the hole(s) by placing a clean cloth over hole(s) such that no cutting debris can fall into the engine; mask the holes by taping the cloth, use CoMat 02-001 ADHESIVE TAPE (MASKING).

Mask all open holes adjacent to the repair area, use CoMat 02-001 ADHESIVE TAPE (MASKING) or CoMat 02-005 ADHESIVE TAPE (MASKING).

Mask the repair area.

NOTE

This step is to prevent foreign objects falling into the engine.

SUBTASK 72-00-00-350-053 Mask the Repair Area

Refer to SPM TASK 70-35-26-300-501.

Discard the insert and continue with Step.

Remove the damaged thinwall insert(s).

SUBTASK 72-00-00-350-054 Remove the Damaged Thinwall Insert(s)

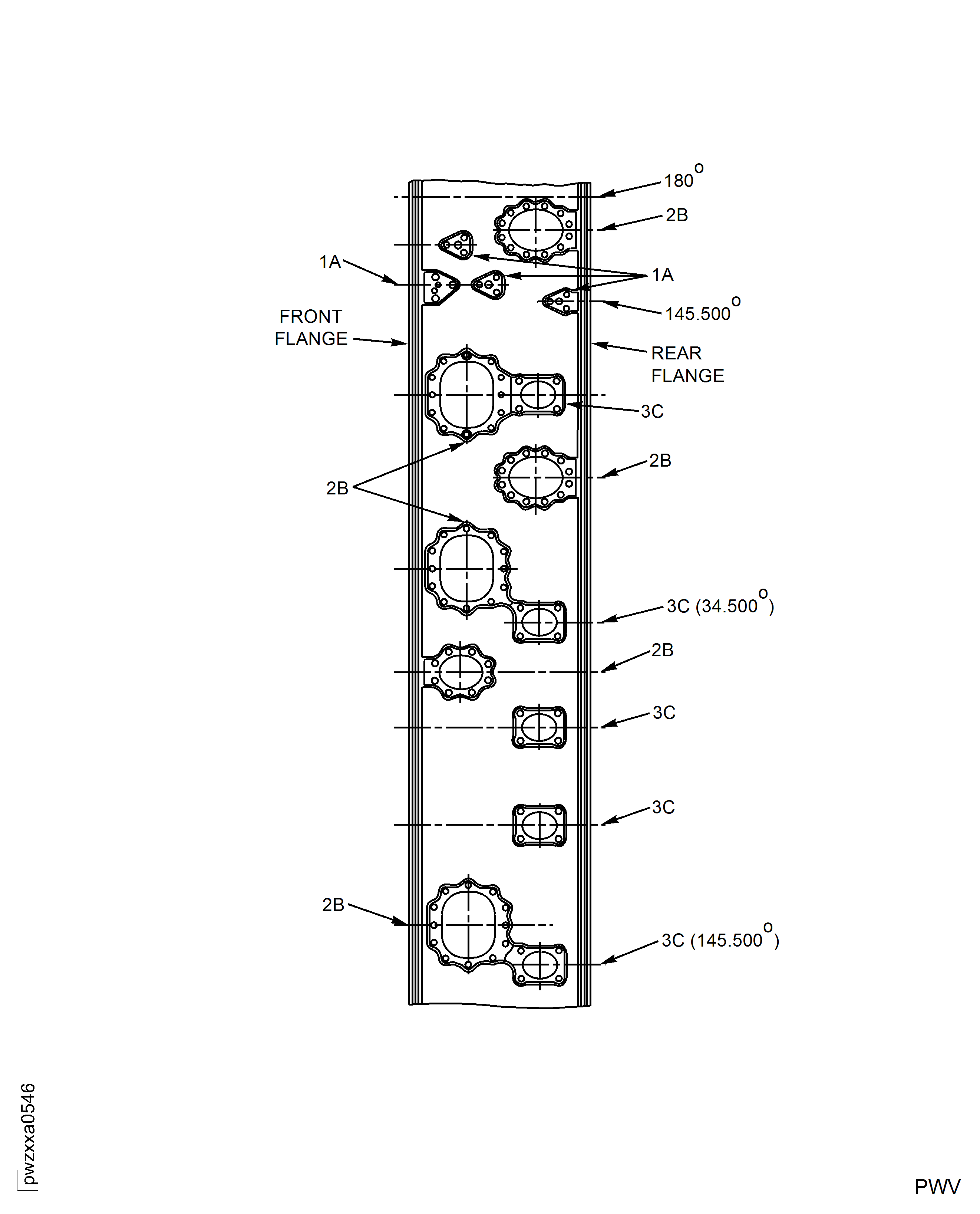

Refer to Figure.

Use a vacuum cleaner.

All the debris must be removed from the hole.

Clean the hole.

SUBTASK 72-00-00-110-058 Clean the Hole

Refer to Figure.

Use KU37022 INSERT for holes identified as 1A.

Use MS51831CA202L INSERT for holes identified as 2B; if a bleed port hole requires a 0.25 - 28 internal thread for the screw use MS51832CA202L INSERT.

Use MS51831CA203L INSERT for holes identified as 3C.

Refer to Figure.

Refer to Figure.

Refer to Figure.

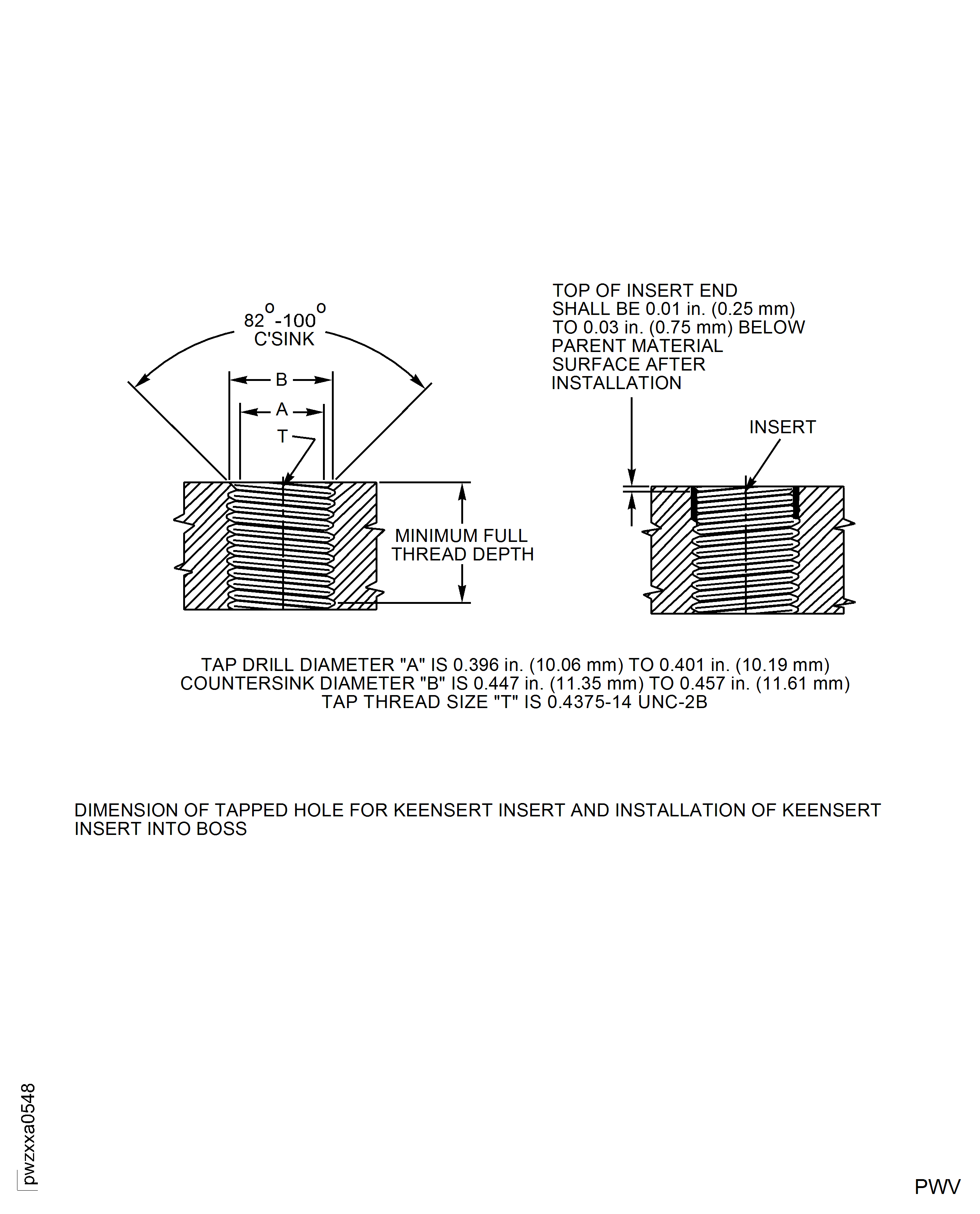

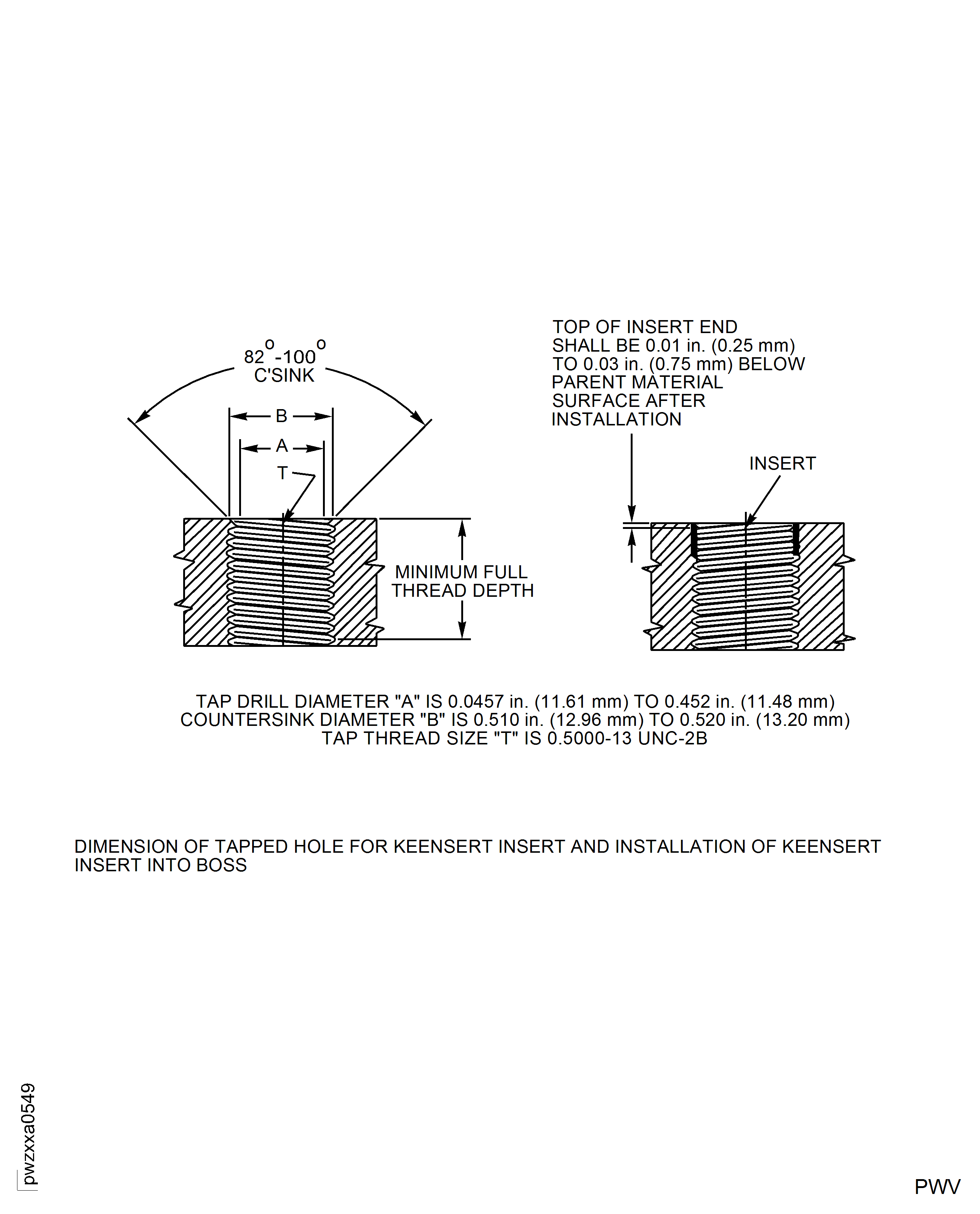

For MS51831CA202L INSERT, MS51832CA202L INSERT or MS51831CA203L INSERT use drilling machine, standard drill, standard countersink (82 deg to 100 deg) and standard unified thread series tap.

Refer to Figure.

Refer to Figure.

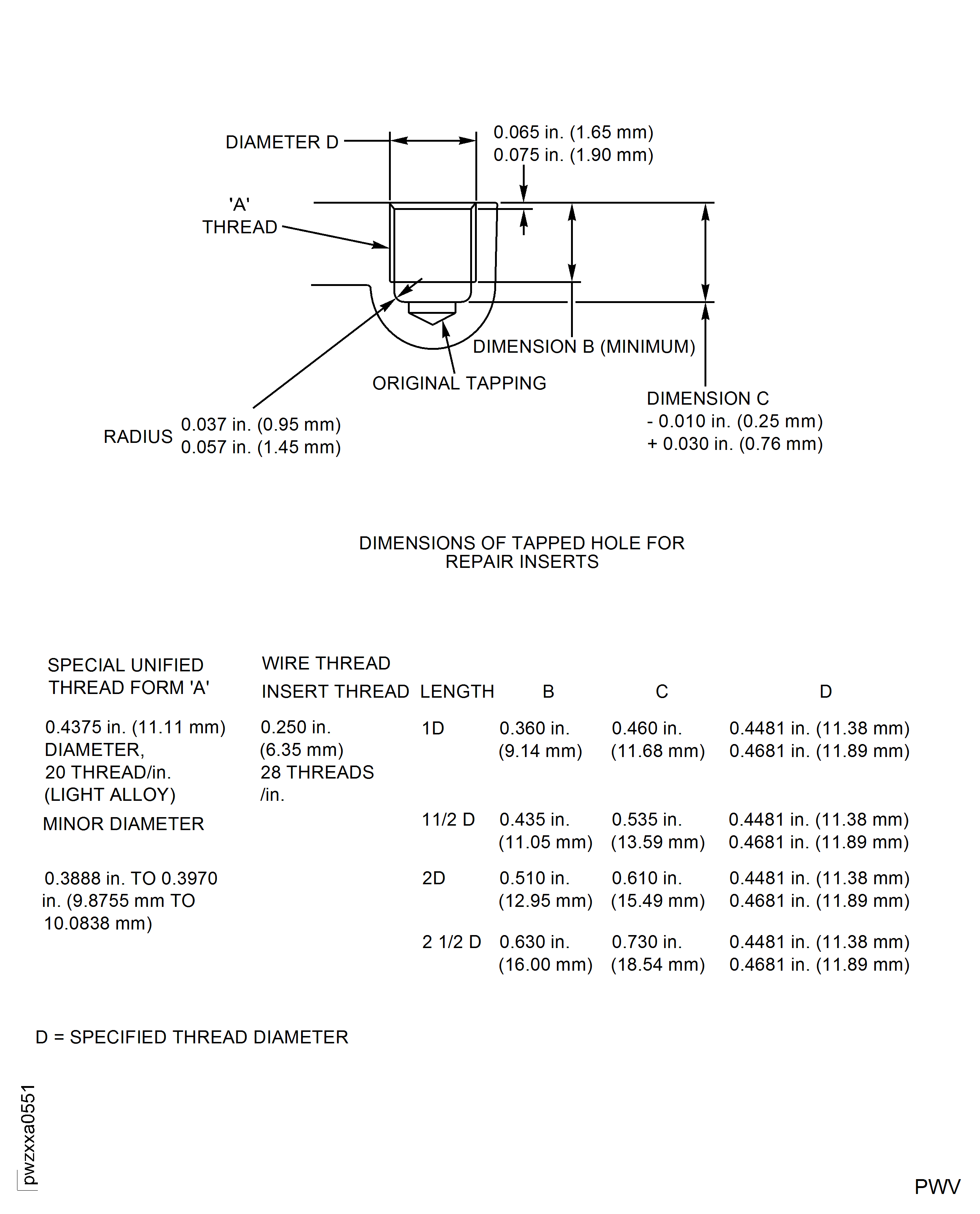

For KU37022 INSERT drill the hole for repair insert then tap the hole for repair insert.

CAUTION

BE CAREFUL TO ALIGN THE DRILL WITH THE HOLE SO THE RESULTANT TAPPED HOLE WILL NOT BE OFF IN AN ANGLE.Determine the proper oversize insert required for replacement. The size required can be determined by using standard equipment for measuring diameters.

Drill, counterbore and tap the insert hole for fitment of Self-Broaching KEENSERTS Insert.

SUBTASK 72-00-00-350-055 Drill, Counterbore and Tap the Insert Hole

Remove unwanted material from the machined Self-Broaching KEENSERTS insert hole. All the debris must be removed from the tapped hole to permit the correct installation of the insert.

Use a vacuum cleaner.

Chemically clean the Self-Broaching KEENSERTS insert hole. Refer to SPM TASK 70-11-26-300-503.

Clean the KEENSERTS insert hole to remove debris.

Clean the Self-Broaching KEENSERTS insert hole.

SUBTASK 72-00-00-110-059 Clean the Self-Broaching KEENSERTS Insert Hole

Refer to SPM TASK 70-23-05-230-501.

Locally clean and fluorescent penetrant inspect the repair area.

Use CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) with a clean paint brush. If cracks are found the part is to be rejected.

Do a local fluorescent penetrant inspection of the repair area.

Do a crack test.

SUBTASK 72-00-00-230-053 Do a Crack Test

Make sure that there are no burrs, unwanted particles, grease or oil.

Use visual inspection equipment, 10X Magnification.

Do a visual inspection of the tapped hole.

Do a visual inspection of the Self-Broaching KEENSERTS insert hole.

SUBTASK 72-00-00-220-177 Do a Visual Inspection

Use CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE. Air-dry the jointing compound to the manufacturer's instructions before installing the insert.

Use a clean paint brush.

Before the installation of Self-Broaching KEENSERTS insert apply a thin layer of jointing compound to the internal threads and to the external surface of the Self-Broaching KEENSERTS insert.

Refer to the manufacturer's instructions.

Use Basic Power Unit and Nose Assembly.

Use Self-Broaching KEENSERTS insert.

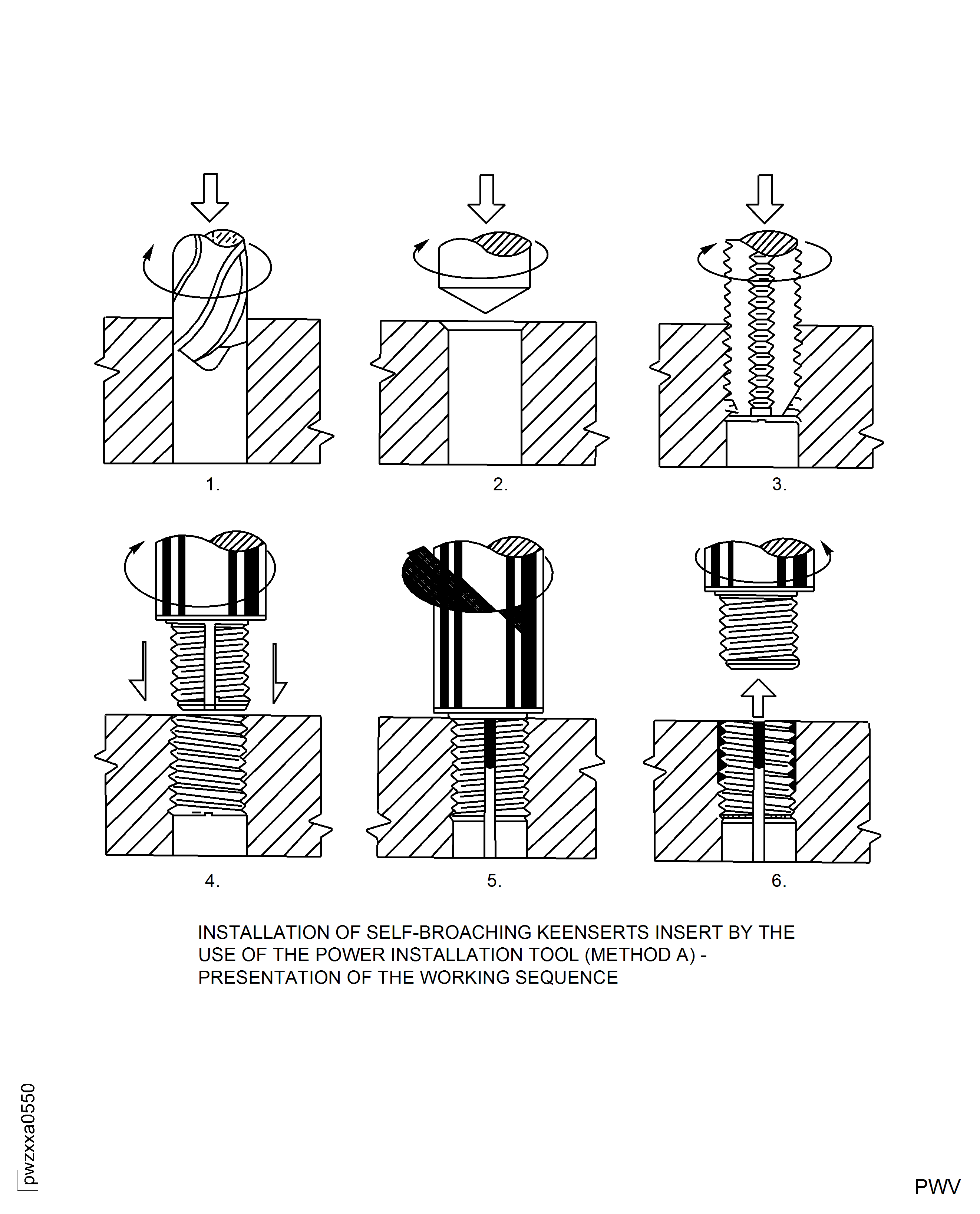

Screw in the Self-Broaching KEENSERTS insert using the power installation tool.

Refer to the manufacturer's instructions. The Self-Broaching KEENSERTS insert should be positioned with KEENSERTS maximum offset from flange edge.

Drive KEENSERTS into position.

Remove the power installation tool.

Install the Self-Broaching MS51831CA202L INSERT, MS51832CA202L INSERT or MS51831CA203L INSERT - Power Installation Tool (Method A).

NOTE

If only KU37022 INSERT is required skip to Step.NOTE

The power installation tool is composed of a power unit and a nose assembly. Refer to Support Equipment section.NOTE

Take care to align the power installation tool with the axis of the insert hole.

SUBTASK 72-00-00-350-056 Install the Self-Broaching KEENSERTS (Method A)

Use Self-Broaching KEENSERTS insert.

Use the Installation Tool, Installation Tool or Installation Tool.

Install the Self-Broaching KEENSERTS insert using fingers or installation tool.

NOTE

Insert is designed to stop at the correct depth below the surface.The Self-Broaching KEENSERTS insert should be positioned with KEENSERTS maximum offset from flange edge.

Mark the location of the KEENSERTS stopped on the port flange material.

Remove the Self-Broaching KEENSERTS insert.

Remove the Self-Broaching KEENSERTS Insert - Hand Tools Installation (Method B).

Use Broaching Tool, Broaching Tool or Broaching Tool.

Insert the pilot of the Broaching Tool, Broaching Tool or Broaching Tool into the insert hole aligning the blades with the location markings of the KEENSERTS.

Use a hammer and the Broaching Tool, Broaching Tool or Broaching Tool.

Use a vacuum cleaner.

NOTE

Ensure the blades in the Broaching Tool, Broaching Tool or Broaching Tool are sharp. Replace as required.Cut the KEEways into the port flange material by strike a blow to the top of the broach tool.

NOTE

To complete the broaching process likely several cuts are necessary.Remove the Broaching Tool, Broaching Tool or Broaching Tool.

Cut the KEEways - Hand Tools Installation (Method B).

Use Standard Unified Thread Series Tap.

Remove the burrs in the Self-Broaching KEENSERTS insert hole by using the tap.

Remove unwanted Material - Hand Tools Installation (Method B).

Remove unwanted material. All the debris must be removed from the tapped hole to permit the correct installation of the insert.

Use a vacuum cleaner.

Clean the Self-Broaching KEENSERTS insert hole to remove debris.

Refer to SPM TASK 70-11-26-300-503.

Chemically clean the Self-Broaching KEENSERTS insert hole.

Clean the Self-Broaching KEENSERTS insert hole - Hand Tools Installation (Method B).

Use CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE. Air-dry the jointing compound to the manufacturer's instructions before installing the insert.

Use a clean paint brush.

Before the installation of Self-Broaching KEENSERTS insert apply a thin layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the internal threads and to the external surface of the Self-Broaching KEENSERTS insert.

Use Self-Broaching KEENSERTS insert.

Use the Installation Tool, Installation Tool or Installation Tool. Refer to the manufacturer's instructions.

Install the Self-Broaching KEENSERTS insert using fingers or Installation Tool, Installation Tool or Installation Tool.

Immediately align the KEENSERTS to the keyways.

Use a hammer and the Installation Tool, Installation Tool or Installation Tool.

Tap down the KEENSERTS using the Installation Tool, Installation Tool or Installation Tool.

Remove the Installation Tool, Installation Tool or Installation Tool.

Install the Self-Broaching KEENSERTS insert - Hand Tools Installation (Method B).

NOTE

Replace the blades in the Broaching Tool, Broaching Tool or Broaching Tool as required (one or three cut per blade are allowed in rear case).Make sure the insert is correctly installed.

Make sure that there are no burrs, unwanted particles, grease or oil.

Use visual inspection equipment, 10X Magnification.

Do a visual inspection of the repair area.

Install the Self-Broaching MS51831CA202L INSERT, MS51832CA202L INSERT or MS51831CA203L INSERT - Hand Tools Installation (Method B).

NOTE

If only KU37022 INSERT is required skip to Step.NOTE

This hand tools installation is an alternative method to Step. Method A (Install the Self- Broaching KEENSERTS Insert - Power Installation Tool) is the preferred insert installation procedure. If necessary, Method B (Install the Self-Broaching KEENSERTS Insert- Hand Tools Installation) may be used.

SUBTASK 72-00-00-350-057 Install the Self-Broaching KEENSERTS (Method B)

Apply a layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to newly tapped threads and repair insert outer threads.

Use repair KU37022 INSERT.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to threads.

Refer to Figure.

Ensure repair insert is fitted under flush to internal counterbore (i.e. below the damaged broached serrations).

Visually inspect the repair inserts.

Apply a layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to repair insert threads and wire thread insert outer threads.

Use wire thread insert AGS3707.

Apply CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to threads.

Refer to Figure.

Install the wire insert thread.

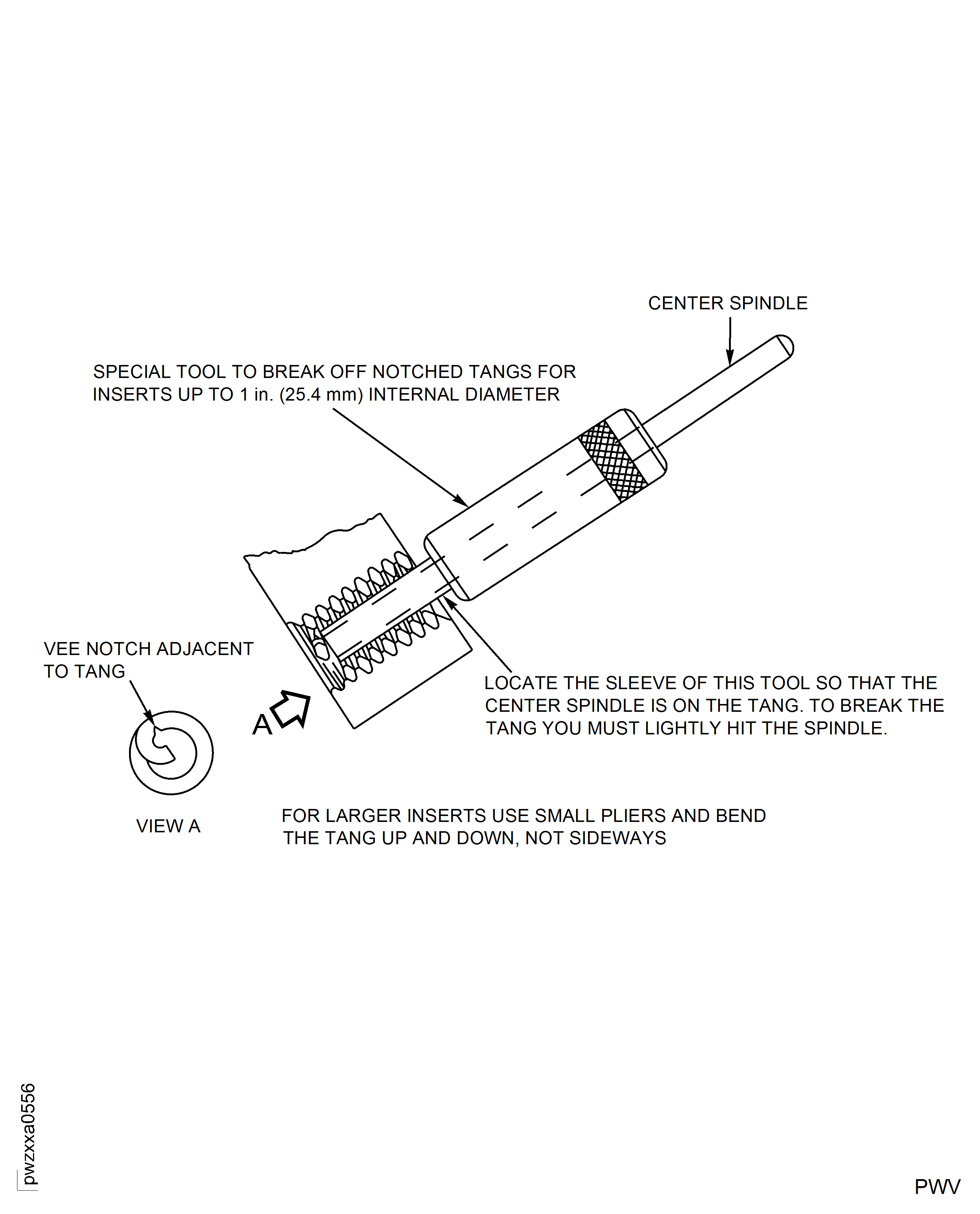

Refer to Figure and Figure for proper thread Tang Removal Tool.

Remove the tang on the wire thread insert.

Ensure wire thread insert is fitted slightly under flush to repair insert.

Inspect wire thread insert.

Install the Self-Broaching KU37022 INSERT if required.

SUBTASK 72-00-00-350-058 Install the Self-Broaching KEENSERTS Insert KU37022 (If Required)

Remove the cloth and masking from the repair area.

Wipe the area clean of tape residue. Refer to SPM TASK 70-11-26-300-503.

SUBTASK 72-00-00-350-059 Remove the Cloth and Masking

Make a record of VRS9170 in the relevant engine documentation.

SUBTASK 72-00-00-350-060 Make a Record of the Repair

Figure: Repair Details

Repair Details

Figure: Dimensions for the Tapped Insert Hole using MS51831CA202L

Dimensions for the Tapped Insert Hole using MS51831CA202L

Figure: Dimensions for the Tapped Insert Hole using MS51832CA202L or MS51831CA203L

Dimensions for the Tapped Insert Hole using MS51832CA202L or MS51831CA203L

Figure: Installation Sequence

Installation Sequence

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Approved Hand Tools

Approved Hand Tools

Figure: Installation of Repair Inserts

Installation of Repair Inserts

Figure: Installation Procedure

Installation Procedure

Installation Procedure

Figure: Removal of Insert Tag

Removal of Insert Tag

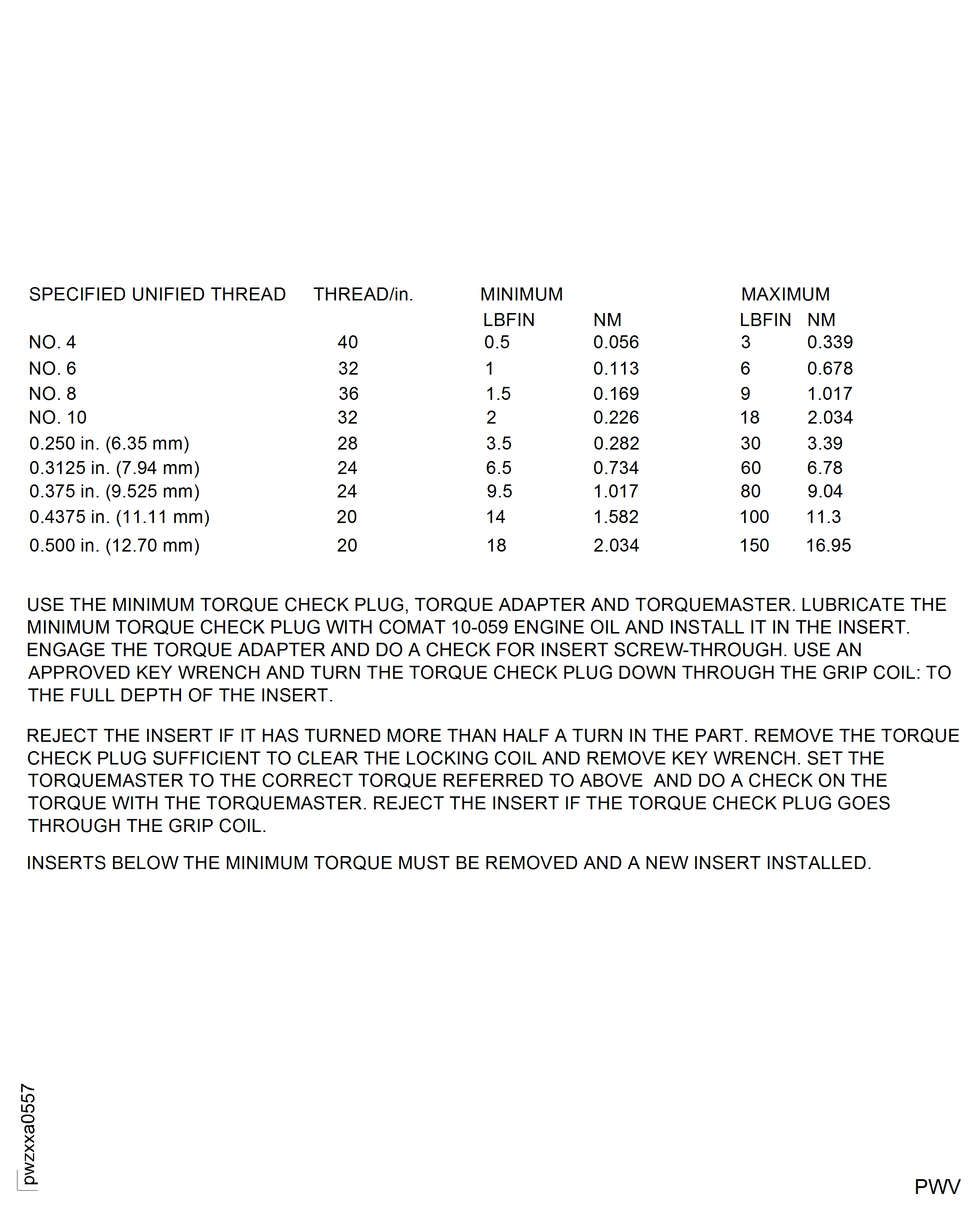

Figure: Torque Check of Screw Lock Inserts

Torque Check of Screw Lock Inserts