Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-00-200-012 Engine General - Examine (Borescope) The Hydraulic Pump Drive Gear Shroud, Inspection-012

General

This TASK gives the procedure for the borescope inspection of the hydraulic pump drive gear shroud. For the other inspections of the engine, refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000).

For standard torque data and procedure refer to TASK 70-41-00-400-501 and TASK 70-41-02-400-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

For lockwire data and procedures, refer to TASK 70-42-05-400-501.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

References

Refer to the SPM for data on these items.

Definition of Damage, TASK 70-02-02-350-501

Record and Control of the Lives of the Parts, TASK 70-05-00-220-501

Inspection of Parts, TASK 70-20-00-200-501

Some data on these is contained in this TASK. For more data on these items refer to the SPM.

Surface protection

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Flexible borescope (probe dia. 0.24 to 0.31 in. (6.0 to 8.0 mm) with view capability of 180 degrees up and down) | LOCAL | Flexible Borescope |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

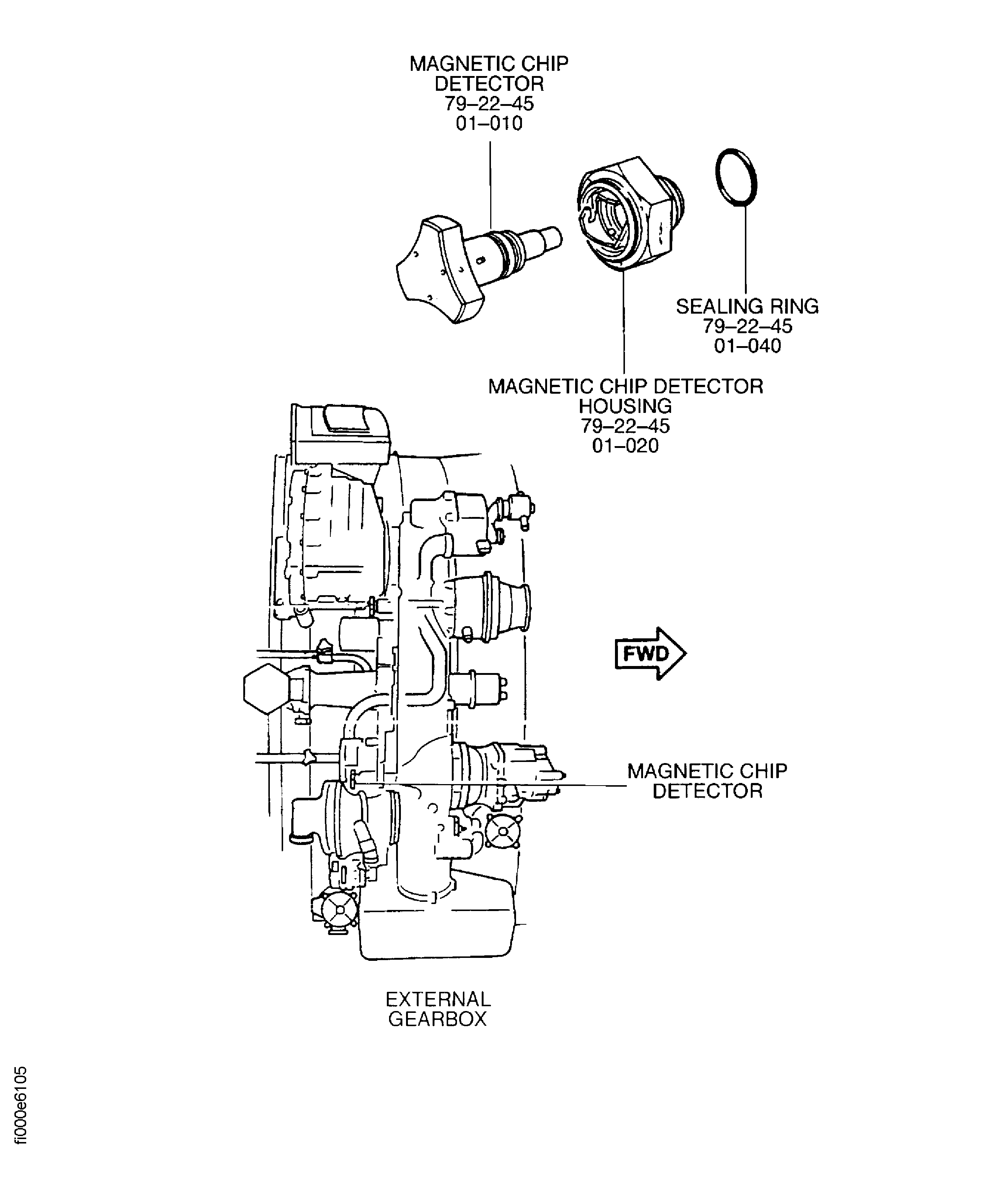

Remove the magnetic chip detector (MCD). Refer to TASK 72-00-00-050-001 (REMOVAL-001).

Remove and discard the seal ring Magnetic Chip Detector (79-22-45, 01-040) from the MCD housing.

Remove the MCD housing Magnetic Chip Detector (79-22-45, 01-020).

SUBTASK 72-00-00-610-051 Drain the External Gearbox

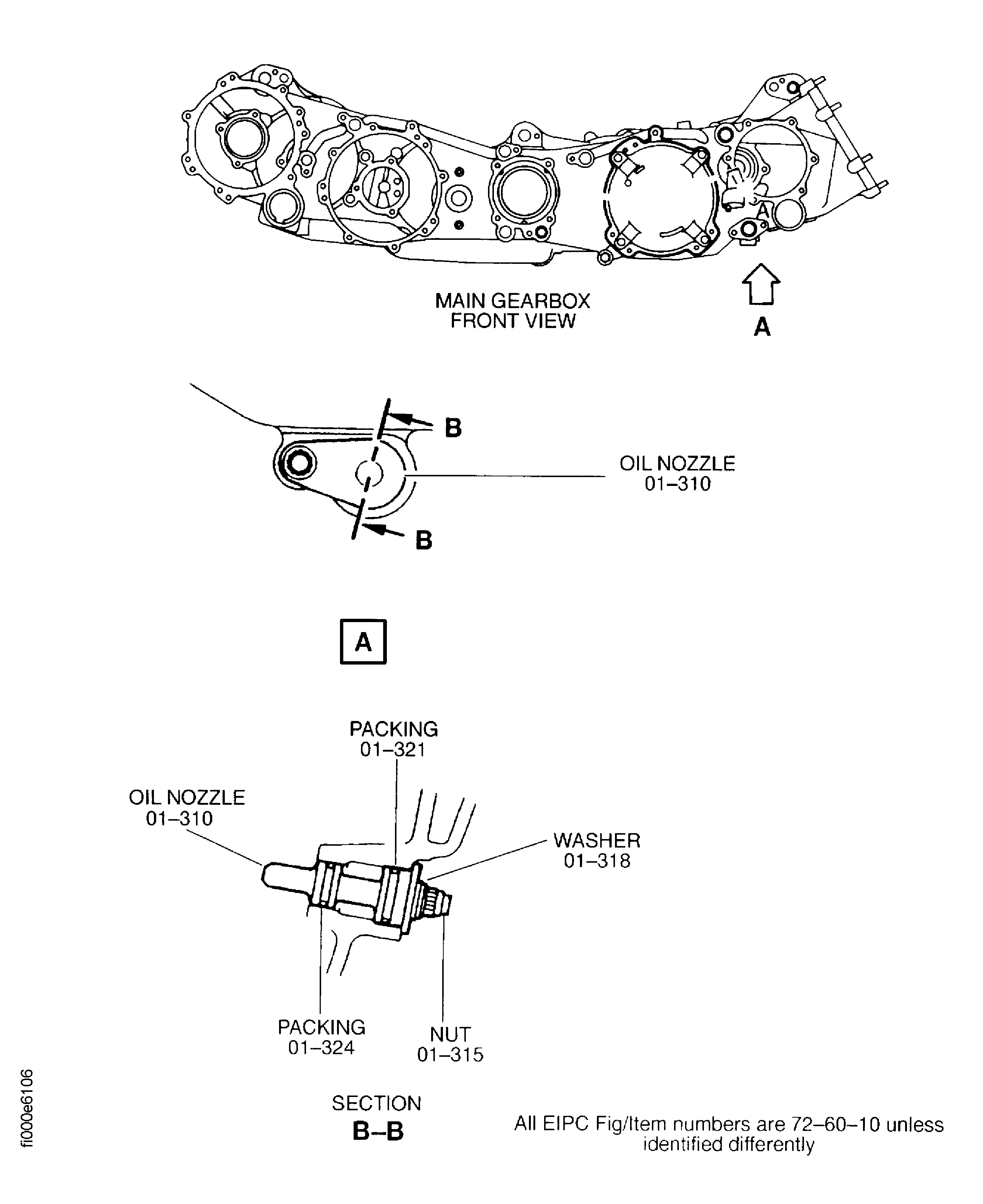

Refer to Figure.

Remove the nut and the washer which attach the oil nozzle Main Gearbox Assembly (72-60-10, 01-310) to the gearbox casing. Remove the oil nozzle from the seal below the mounting flange of the fuel pump. Remove and discard the packings.

SUBTASK 72-00-00-040-051 Remove the Oil Nozzle

Refer to Figure.

Engage the Flexible borescope (probe dia. 0.24 to 0.31 in. (6.0 to 8.0 mm) with view capability of 180 degrees up and down) 1 off probe through the oil nozzle port.

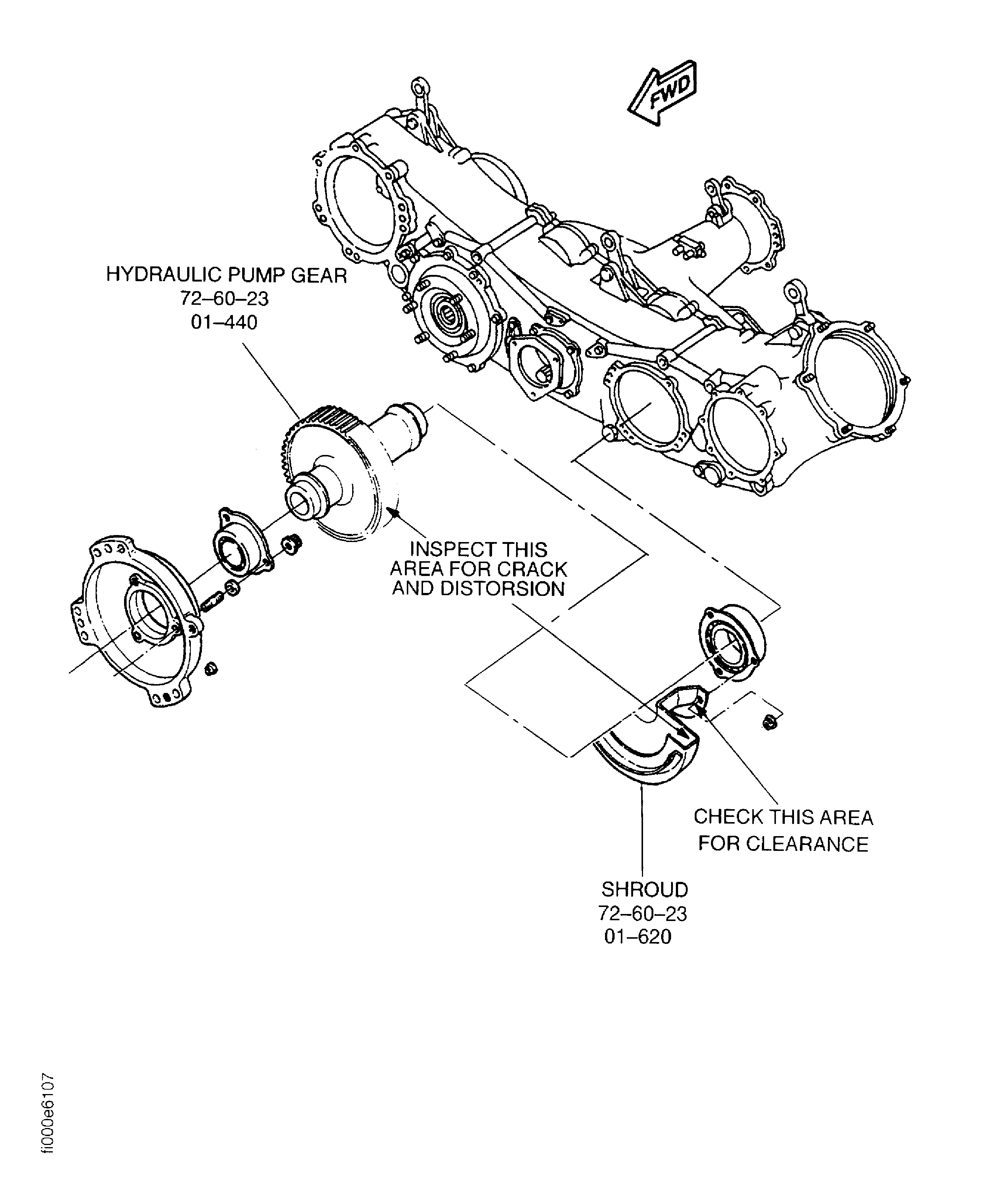

SUBTASK 72-00-00-220-051 Do a Borescope Inspection of the Hydraulic Pump Gear Shroud

Refer to: Figure.

Install one of each Main Gearbox Assembly (72-60-10, 01-321 and Main Gearbox Assembly 72-60-10, 01-324) packing 1 off into the grooves of the oil nozzle.

SUBTASK 72-00-00-220-052 Install the Oil Nozzle

Refer to Figure.

Install the new sealing ring Magnetic Chip Detector (79-22-45, 01-040) to the MCD housing.

Lubricate the sealing ring, the mating face and the threads of the housing with CoMat 10-077 APPROVED ENGINE OILS.

Install the MCD housing Magnetic Chip Detector (79-22-45, 01-020).

Safety the MCD housing with CoMat 02-126 LOCKWIRE.

Install the MCD. Refer to TASK 72-00-00-450-001 (INSTALLATION-001).

SUBTASK 72-00-00-440-051 Install the MCD Housing

Fill the oil tank. Refer to TASK 71-00-00-600-002 (SERVICING-002).

SUBTASK 72-00-00-640-052 Fill the Oil Tank

Do a dry motor leak check. Refer to TASK 71-00-00-700-001 (TESTING-001).

SUBTASK 72-00-00-790-051 Do a Dry Motor Leak Check

Figure: Magnetic chip detector

Magnetic chip detector

Figure: Oil nozzle

Oil nozzle

Figure: Inspect the hydraulic pump gear shroud

Inspect the hydraulic pump gear shroud