Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-00-00-700-001 Test No. 1 - Dry Motor Leak Check, Testing-001

V2500-A1: General

Instructions to operate the engine, engine safety precautions and other general information are found in Engine Safety Precautions and Engine Operation Limits, Guidelines and Special Precautions. Refer to TASK 71-00-00-700-050-A00 (TESTING-000, CONFIG-001) and TASK 71-00-00-700-051-A00 (TESTING-000, CONFIG-001).

You can use this test to do a check of the fuel and oil system for leaks after you replace or repair a component.

V2500-A5: General

Instructions to operate the engine, engine safety precautions and other general information are found in Engine Safety Precautions and Engine Operation Limits, Guidelines and Special Precautions. Refer to TASK 71-00-00-700-050-B00 (TESTING-000, CONFIG-002) and TASK 71-00-00-700-051-B00 (TESTING-000, CONFIG-002).

You can use this test to do a check of the fuel and oil system for leaks after you replace or repair a component.

NOTE

Run the engine at Approach Idle for 20 minutes

Inspect the No. 4 bearing compartment weep tube exit at the bottom of the turbine exhaust case for signs of oil. If you see wetness, contact IAE for instructions

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

CAUTION

Procedure

Do the necessary steps by the instructions in Pre-Rig the Engine for Testing. Refer to TASK 71-00-00-700-020 (TESTING-020).

V2500-A1: Do the Oil and Fuel System Priming Procedure, as necessary. Refer to TASK 71-00-00-700-061-A00 (TESTING-000, CONFIG-001).

V2500-A5: Do the Oil and Fuel System Priming Procedure, as necessary. Refer to TASK 71-00-00-700-061-B00 (TESTING-000, CONFIG-002).

Open the slave nacelle system ducts and make sure they are held open during engine operation.

Make sure that the ignition is OFF.

Make sure that the fuel is in the FUEL OFF mode.

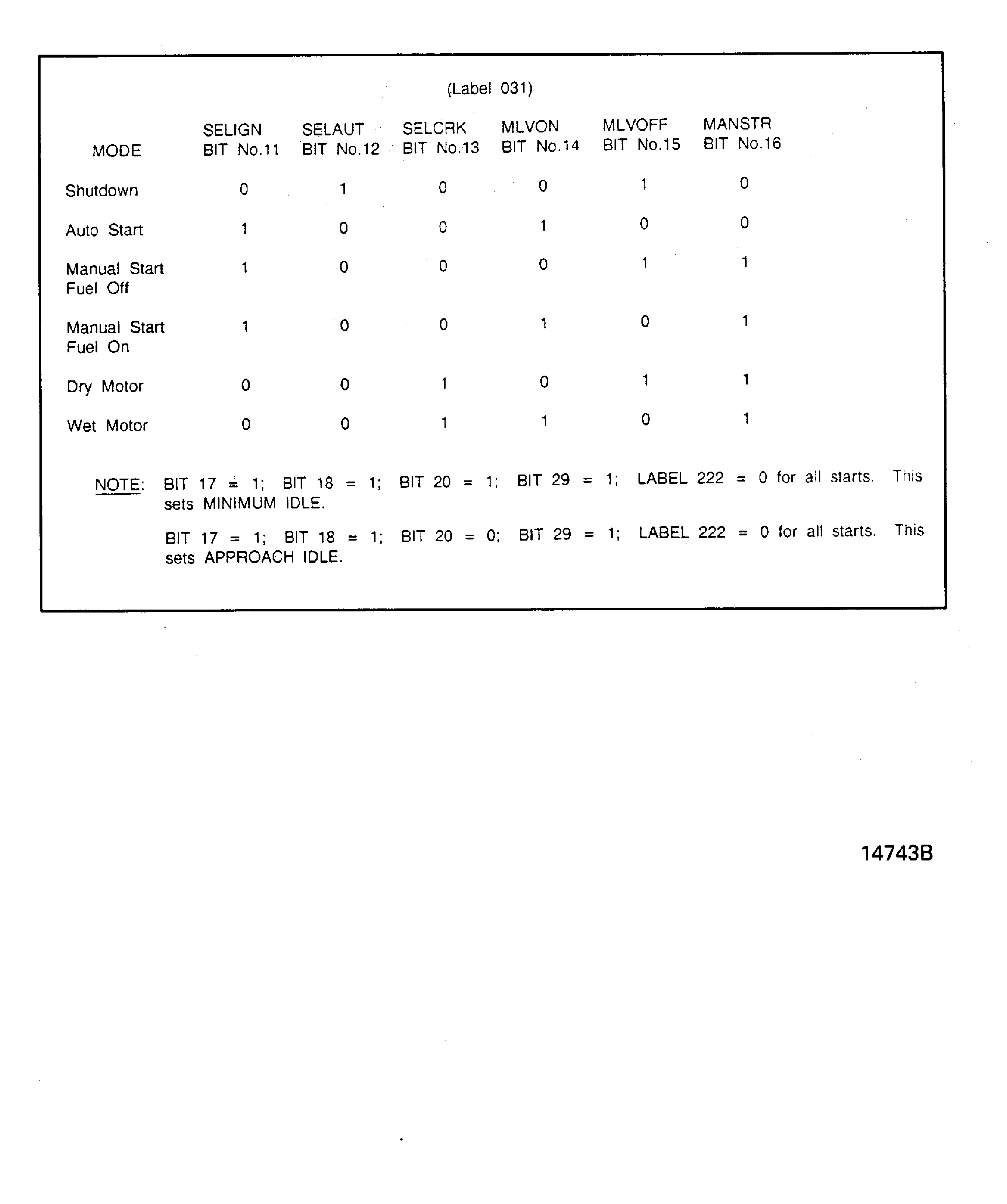

Set the Engine Interface Unit (EIU) inputs for the dry motor mode. Refer to Figure.

Look for an indication of positive oil pressure, N1 and N2.

Do not continue to motor the engine if there is not an indication of positive oil pressure.

Do not motor the engine for more than two minutes.

Motor the engine with the starter.

While you motor the engine do an inspection for leaks.

Stop the engine.

Do an inspection of the engine for leaks.

Correct the cause of the leaks. Do a test again as necessary.

If more tests are to be done, close the slave nacelle system ducts.

Do the necessary steps by the instruction in De-Rig the Engine after testing. Refer to TASK 71-00-00-700-021 (TESTING-021).

Dry Motor the Engine and Check for Leaks

Figure: EIU inputs

EIU inputs