Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 71-00-00-700-051-A00 Engine Operation Limits, Guidelines, And Special Procedures, Testing-000

Engine Operation Limits

Exhaust gas temperature (EGT) limits

Take-off

Duration of 5 minutes

EGT limit of 1175 deg F (635 deg C)

Maximum continuous

Duration unlimited

EGT limit of 1130 deg F (610 deg C)

Starting

Duration of 2 minutes

EGT limit of 1175 deg F (635 deg C)

Transient

Duration unlimited

EGT limit of 1175 deg F (635 deg C)

Oil pressure limits

During operation in cold weather, the scavenge oil filter differential pressure switch warning is inhibited until the main oil temperature gets to approximately 90 deg F (32 deg C) in order to prevent false indication of a clogged filter due to cold oil.

Make sure at all running conditions that the No. 4 Bearing compartment scavenge pressure is not more than the limits that follow:

Maximum Allowable Transient Limit: All testing conditions: 205 psig (1413.4 kPa) Maximum Allowable Steady-State Limit (3 Minutes Stabilization or More): Idle and Approach Idle: 9 psig (62.1 kPa) |

Band A: Band B and C: Band D: | Minimum: 55 psig (379.2 kPa) Maximum: 145 psig (999.7 kPa) 145 psig (999.7 kPa) 17 psig (117.2 kPa) |

If the scavenge pressure limit is exceeded at any time, you must shut down the engine as given in TASK 71-00-00-700-054-A00 (TESTING-000, CONFIG-001)

Do the checks that follow if the P4SCAV limit is exceeded:

Inspect the gasket for leaks at the interface between the No. 4 Bearing compartment external scavenge elbow and internal scavenge line. (This potential cause more likely will increase P4SCAV in between 130 psig to 160 psig (896.3 kPa to 1103.2 kPa).

Disconnect the No. 4 Bearing compartment external scavenge elbow.

Check and record signs of leaks from the gasket.

Replace the gasket. Refer to TASK 72-42-00-430-001 (ASSEMBLY-001).

Do the Performance Test again to check for correct No. 4 Bearing compartment scavenge pressure. Refer to TASK 71-00-00-700-010-A00 (TESTING-010, CONFIG-001) or TASK 71-00-00-700-010-A01 (TESTING-010, CONFIG-002).

If the scavenge pressure is still not normal, do a No. 4 Bearing Compartment Vacuum Check. Refer to TASK 72-00-43-420-001 (INSTALLATION).

If the vacuum check is more than 17 pph, disassemble, inspect and reassemble No. 4 Bearing compartment.

If the vacuum check is less than 17 pph, contact IAE Technical Services for instructions.

Oil temperature limits

The maximum oil temperature is 311 deg F (155 deg C) when the operation is stabilized for a minimum of three minutes. If the oil temperature is higher than 311 deg F (155 deg C), find the cause of the high temperature as soon as possible. Refer to the fault isolation TASK 71-00-00-810-015 (FAULT ISOLATION-015).

The maximum transient temperature is 329 deg F (165 deg C) for 15 minutes after any high power operation. If the temperature is higher than 329 deg F (165 deg C), shut down the engine and find the cause of the high temperature. Refer to the fault isolation TASK 71-00-00-810-015 (FAULT ISOLATION-015).

Minimum Oil Temperatures are shown in the table below:

Oil Temperature - °C | V2500- A1 | |||

|---|---|---|---|---|

Minimum starting | -40 | |||

Minimum prior to exceeding idle | -10 | |||

Prior to takeoff | FSII not used | IDG engaged | OAT>-45°C | 50 |

-54°C<OAT<-45°C | Not allowed | |||

IDG disconnected (no heat addition from IDG) | OAT>-40°C | 50 | ||

-40°C>OAT>-45°C | 50 | |||

-54°C<OAT<-45°C | Not allowed | |||

FSII used | Whatever IDG condition (engaged or disconnected) | OAT>-45°C | 50 | |

-54°C<OAT<-45°C | Not allowed | |||

Maximum Continuous | 155 | |||

Maximum Transient (15 Minutes) | 165 | |||

NOTEUse of approved Fuel System Icing Inhibitor (FSII) of 0.1% or greater. OAT - Outside Air Temperature. Prior to take-off, minimum oil temperatures for fuel inlet temperature of -45°C. | ||||

Rotor operation speed limits

The maximum N1 is 5,465 RPM/100%.

The maximum N2 is 14,915 RPM/100%.

Vibration limits

Fan case (VFAVM-1) (SEE NOTE)

Overall - 1.0 IPS (21 to 400 Hz at 3dB)

N1 (Peak) - 0.6 IPS

N2 (Peak) - 0.6 IPS

Fan case (VFAVM-2) (SEE NOTE)

Overall - 1.0 IPS (21 to 400 Hz at 3dB)

N1 (Peak) - 0.6 IPS

N2 (Peak) - 0.6 IPS

Overtemperature limit

Refer to Procedure After Engine Overtemperature (No Surge or Stall) (Refer to TASK 71-00-00-700-056-A00) (TESTING-000, CONFIG-001) or Procedure After Engine Overtemperature (with Surge or Stall) (Refer to TASK 71-00-00-700-057-A00) (TESTING-000, CONFIG-001).

Nacelle temperature limit

The maximum temperature is 500 deg F (260 deg C).

Fuel pressure limit

The fuel inlet pressure supplied to the engine must be 5 psig to 70 psig (34.5 kPa to 482.6 kPa).

Engine Operation Guidelines

Oil consumption guidelines

Oil consumption is acceptable if the consumption is not more than 0.6 pints (0.5 Imperial pint, 0.285 liters, 0.3 quarts) each hour.

If it is found that the oil level has increased by 0.42 US pints (200 cc, 0.21 quarts) or more compared to before, obtain an oil sample and send it to the laboratory for fuel contamination check.

The minimum time of operation for a check of oil consumption is 30 minutes. The engine must have operated at high and low thrust lever positions.

Starter operation guideline

Usual starter operation time must not be more than two minutes.

Do the starter procedure that follows:

Do three consecutive cycles (two cycles of two minutes and one cycle of one minute).

Stop for 15 seconds between cycles to let the starter rotor lubricate again.

After three cycles, stop for 30 minutes to let the starter become cool.

Do not engage the starter again with the engine motoring above 1490 RPM (10 percent N2)

Starter operating pressure is 30 psig to 40 psig (206.8 kPa to 275.8 kPa).

Idle thrust setting guidelines:

Calculate the EPR modifier number and select the thrust/EPR value that is given below:

CORRECTED NET THRUST (lbs) | BASELINE EPR |

24290 | 1.388 |

21840 | 1.334 |

Engine limits of new overhauled engines.

The engine dry weight is 5300 pounds. The maximum engine weight which includes the engine build-up unit (EBU) is 5450 pounds.

Engine Operation Special Procedures

Procedure for the inspection of magnetic chip detectors (MCD) after test

Refer to INSPECTION/CHECK-08 TASK 72-00-00-200-008 (INSPECTION/CHECK-008)

NOTE

NOTE

NOTE

NOTE

The maximum spread that is allowed between VFAVM-1 and VFAVM-2 is 0.25 IPS.

If the spread is out of limits, refer to fault isoloation TASK 71-00-00-810-024 (FAULT ISOLATION-024).

1.5 IPS = 5.0 Aircraft units

NOTE

Run the engine at Approach Idle for 20 minutes

Inspect the No.4 bearing compartment weep tube exit at the bottom of the turbine exhaust case for signs of oil. If you see wetness, contact IAE for instructions

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-277 KEROSINE | LOCAL | CoMat 01-277 |

Spares

NONESafety Requirements

NONEProcedure

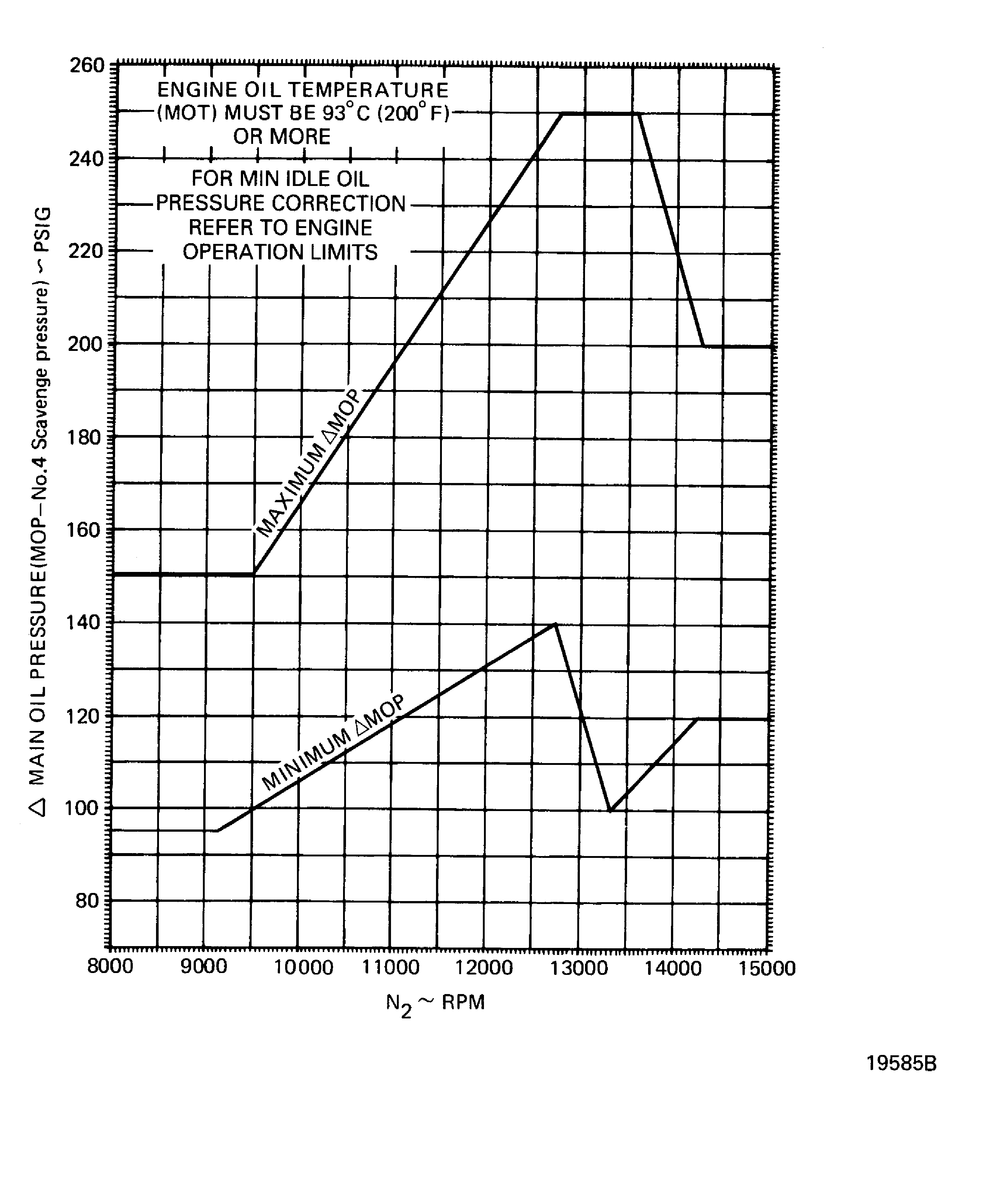

Figure: Main oil pressure (MOP) limits

Main oil pressure (MOP) limits

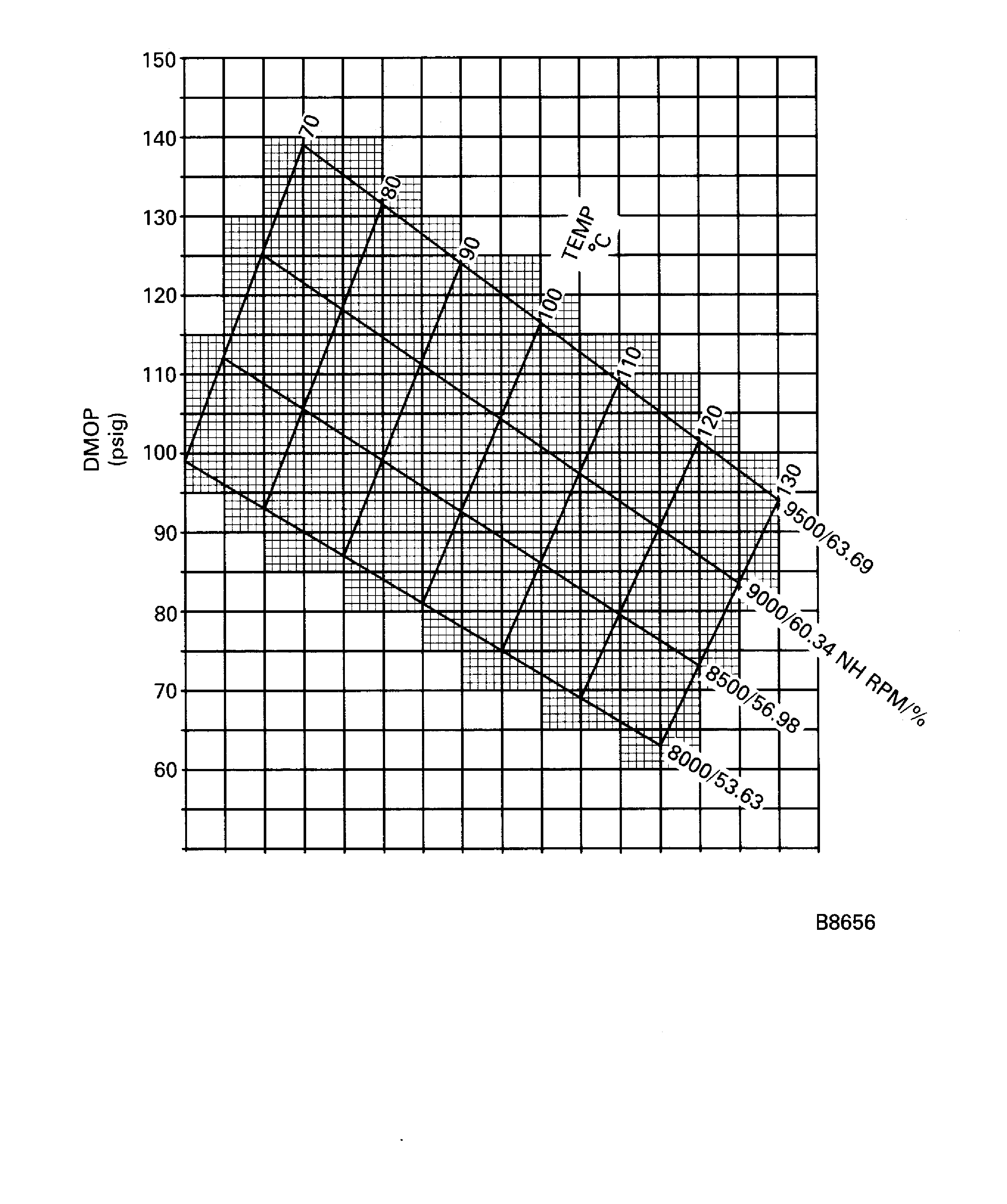

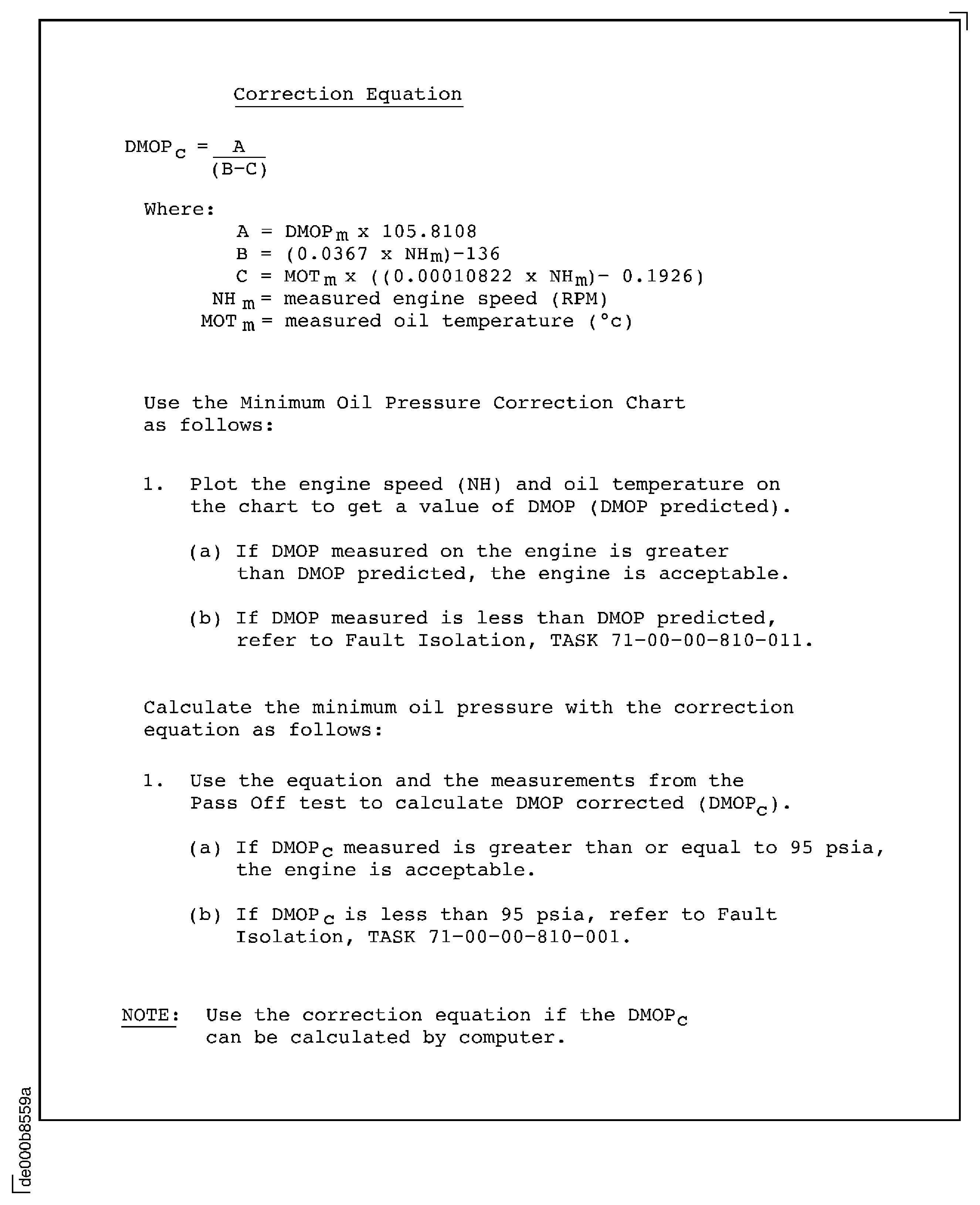

Figure: Main oil pressure (MOP) limits during operation at idle

Main oil pressure (MOP) limits during operation at idle

Figure: Main oil pressure (MOP) limits during operation at idle

Main oil pressure (MOP) limits during operation at idle

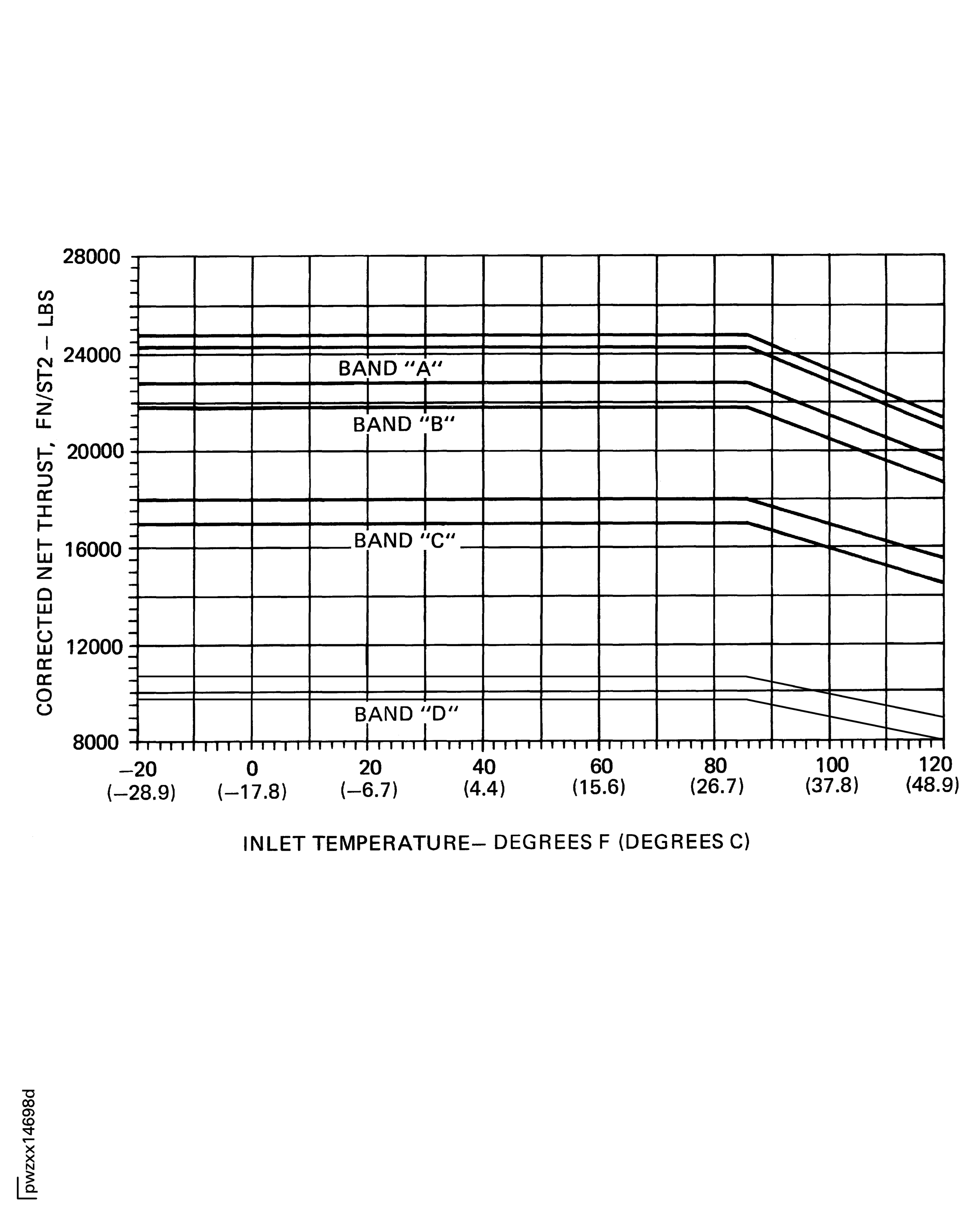

Figure: Thrust setting curve

Thrust setting curve