Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-00-200-008 Engine General - Examine The Magnetic Chip Detectors (MCD) And The Oil Filters, Inspection-008

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Discard all rubber seal rings removed in this procedure.

Discard the scavenge oil filter element when the inspection is complete.

The policy that is necessary for the inspection is given in the SPM TASK 70-20-01-200-501.

To identify, lubricate and install seal rings refer to the SPM TASK 70-44-01-400-501.

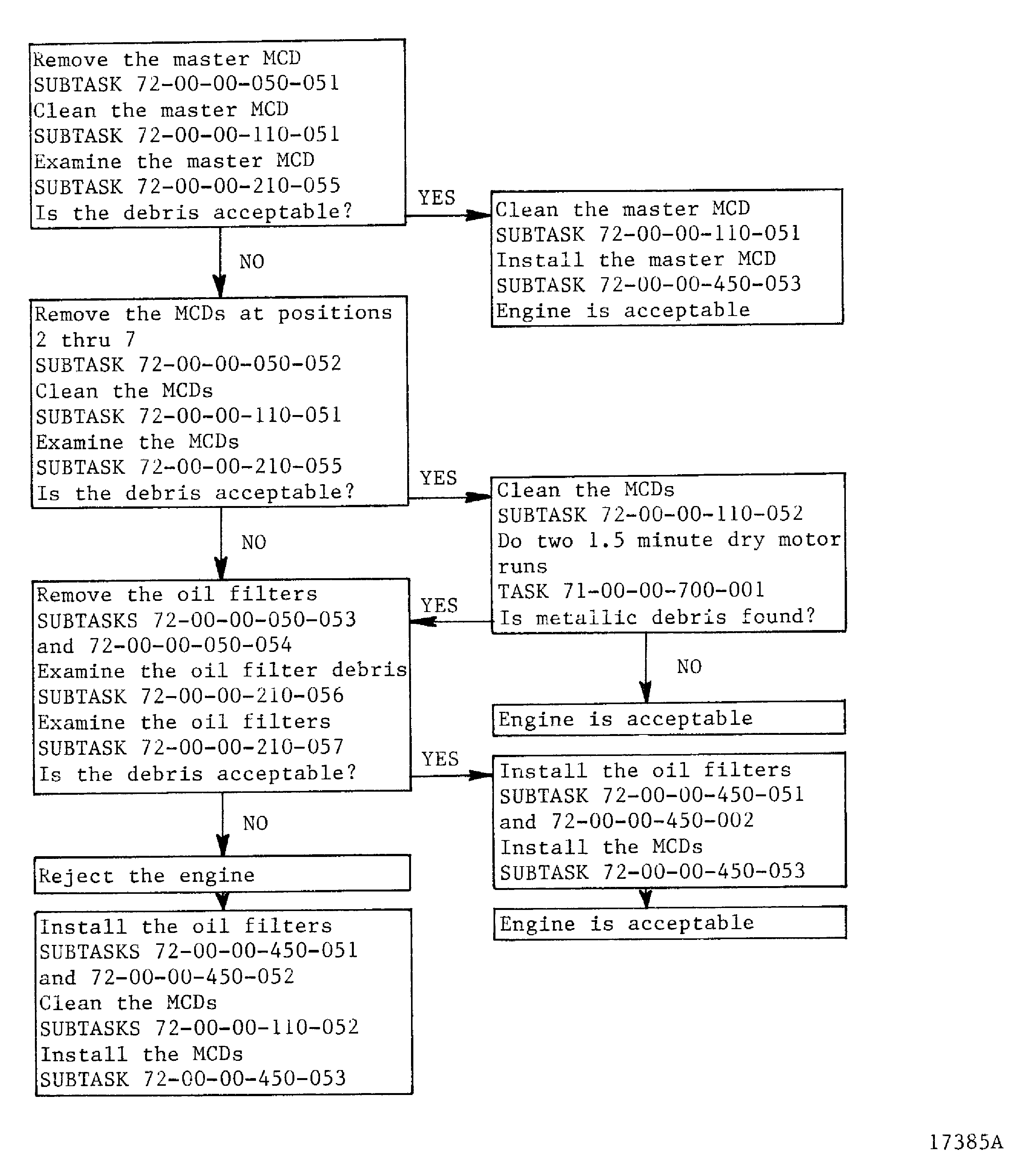

This TASK gives the procedure to examine the magnetic chip detectors and oil filters. For the correct sequence of SUBTASKS, refer to Figure. Other related TASKS are TASK 72-00-00-050-001 Removal of MCDs and TASK 72-00-00-450-001 Installation of MCDs.

All debris must be examined. Any debris that can not be identified must be referred to IAE.

Definitions of Debris

There are five main types of debris found on Magnetic Chip Detectors (MCDs) and in filters. They are; build debris, magnetic fines, metallic flakes, chips and gear tooth fragments.

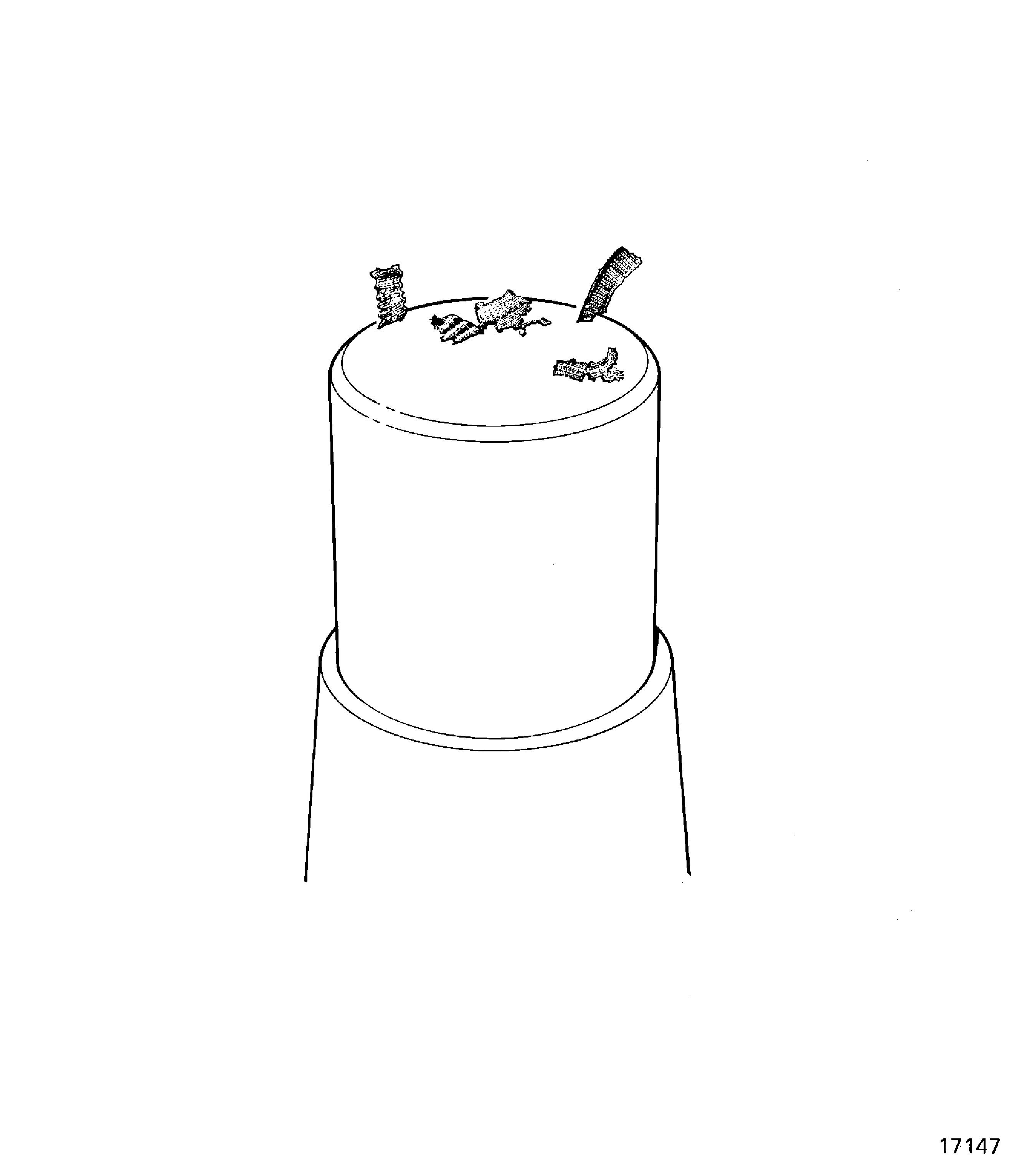

Build debris, refer to Figure.

This is unwanted material that remains in the engine after it has been assembled. The build debris comes from machine operations when the components are made. It is not easy to see the difference between build material and gear or steel seal material.

Magnetic fines, refer to Figure.

These are very small steel particles which show as a black sludge on the MCD. When the oil is removed from the MCD they show as a dark fur around the magnet.

Metallic flakes, refer to Figure.

Metallic flakes can be from; ball bearings, roller bearings and gear teeth. Metallic flakes that have an irregular shape must be examined to find their origin.

Gear teeth flakes are shiny with an irregular shape. They are usually thicker and not as bright as any of the ball or roller bearing flakes.

Chips, refer to Figure.

These are very thick flakes or pieces of metal which usually have one smooth machined surface.

Gear tooth fragments

These are the corner pieces of gear teeth and may show that the gears are not correctly aligned.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| 20X Binocular Microscope | LOCAL | Binocular Microscope, 20x | ||

| 20X Magnifying Glass | LOCAL | Magnifying glass, 20x | ||

| Small Bar Magnet | LOCAL | Small Bar Magnet | ||

| IAE 1F10082 Guide Pin | 0AM53 | IAE 1F10082 | 2 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-277 KEROSINE | LOCAL | CoMat 01-277 | ||

| CoMat 02-011 FILTER PAPER | LOCAL | CoMat 02-011 | ||

| CoMat 10-061 STODDARD SOLVENT | LOCAL | CoMat 10-061 |

Spares

NONESafety Requirements

NONEProcedure

Refer to TASK 72-00-00-050-001.

SUBTASK 72-00-00-050-051 Remove the Master MCD

Refer to TASK 72-00-00-050-001.

SUBTASK 72-00-00-050-052 Remove the MCDs

NOTE

Make sure that the non-metallic container is clean before you use it.Partially fill the non-metallic container with CoMat 01-277 KEROSINE or CoMat 10-061 STODDARD SOLVENT.

Gently lower the MCD in to the CoMat 01-277 KEROSINE or CoMat 10-061 STODDARD SOLVENT. Make sure that the metallic debris remains on the MCD. Gently remove the MCD when the debris is clean.

SUBTASK 72-00-00-110-051 Clean the Debris on the MCD

Examine the debris on the MCD with the 20X Binocular Microscope 1 off, or the 20X Magnifying Glass 1 off.

SUBTASK 72-00-00-210-055 Examine the Debris on the MCD

Remove the pressure oil filter element, refer to TASK 72-00-60-050-011.

Put the oil, previously drained from the filter housing, through CoMat 02-011 FILTER PAPER to remove the debris.

Wash the filter element in clean CoMat 01-277 KEROSINE or CoMat 10-061 STODDARD SOLVENT in a clean container.

Put the CoMat 01-277 KEROSINE or CoMat 10-061 STODDARD SOLVENT through the filter paper to remove the debris.

Move a Small Bar Magnet 1 off, covered in tissue, above the debris to remove the ferrous material. The debris is to be examined as given in Step.

SUBTASK 72-00-00-050-053 Remove the Pressure Oil Filter

Remove the scavenge oil filter element, refer to TASK 72-00-60-050-010.

Put the oil, previously drained from the filter housing, through CoMat 02-011 FILTER PAPER to remove the debris.

Wash the filter element in clean CoMat 01-277 KEROSINE or CoMat 10-061 STODDARD SOLVENT in a clean container.

Put the CoMat 01-277 KEROSINE or CoMat 10-061 STODDARD SOLVENT through the filter paper to remove the debris.

Move a Small Bar Magnet, covered in tissue, above the debris to remove the ferrous material. The debris is to be examined as given in Step.

SUBTASK 72-00-00-050-054 Remove the Scavenge Oil Filter

More than in Step.

NOTE

You will get greater amounts of debris on engines that have been overhauled. This debris is caused by the breaking-in of the seals and bearings. If you require any further information about any of this type of unwanted material contact IAE.Light alloy or silver.

More than in Step.

Magnetic fines.

SUBTASK 72-00-00-210-056 Examine the Debris

Use a 20X Magnifying Glass 1 off, to examine the oil filter elements.

SUBTASK 72-00-00-210-057 Examine the Oil Filter Elements

Refer to TASK 72-00-60-450-010.

SUBTASK 72-00-00-450-051 Install the Scavenge Oil Filter

Refer to TASK 72-00-60-450-011.

SUBTASK 72-00-00-450-052 Install the Pressure Oil Filter

Thoroughly clean the MCDs in clean CoMat 01-277 KEROSINE or CoMat 10-061 STODDARD SOLVENT.

SUBTASK 72-00-00-110-052 Clean the Magnetic Chip Detectors (MCD)

Refer to TASK 72-00-00-450-001.

SUBTASK 72-00-00-450-053 Install the Magnetic Chip Detectors (MCD)

Figure: Magnetic chip detector and oil filter examination procedure

Magnetic chip detector and oil filter examination procedure

Figure: Build debris

Build debris

Figure: Fines

Fines

Figure: Flakes

Flakes

Figure: Chips

Chips