Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-00-00-700-020 Test No. 20 - Pre-Rig The Engine For Test, Testing-020

Pre-Rig the Engine for Test

Refer to the Powerplant Build-up Manual to install the items that follow:

Aft engine mount.

Forward engine mount.

Engine exhaust cone.

Common nozzle assembly.

Starter - make sure the starter is serviced with oil.

Lower starter air duct and the starter control valve on the starter.

Install IAE 4F10296 Breather pipe 1 off. Torque the bolts to 75 - 85 lbfin (8.474 - 9.604 Nm).

Install the seal drain hoses and bottles on the seal drains that follow:

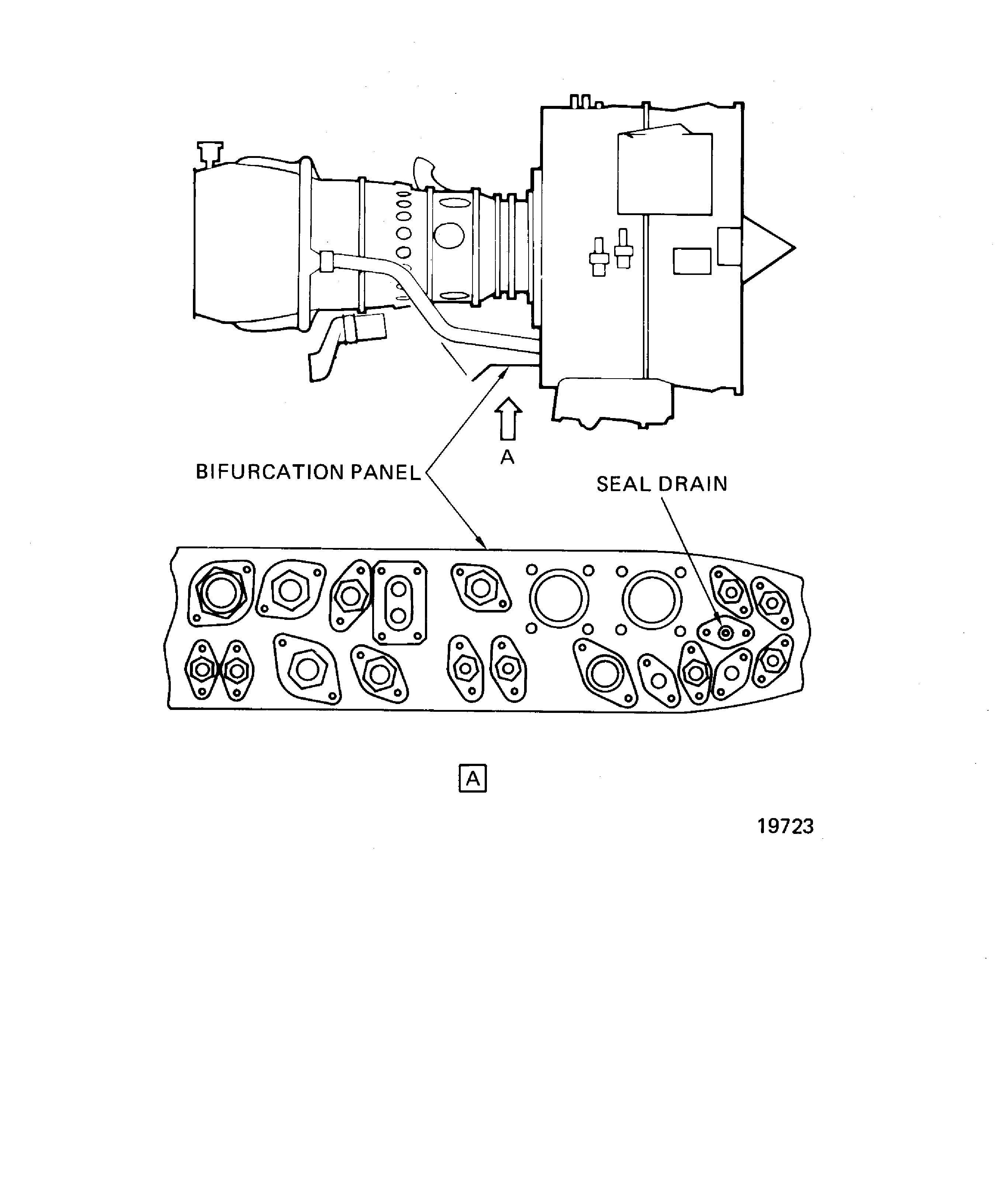

Bifurcation panel common core seal drain. This drain is located on the forward end of the bifurcation panel and is connected to the 2.5 Master and Slave actuators and the ACC actuator. The drain faces downward (as viewed from rear of the engine). Refer to Figure.

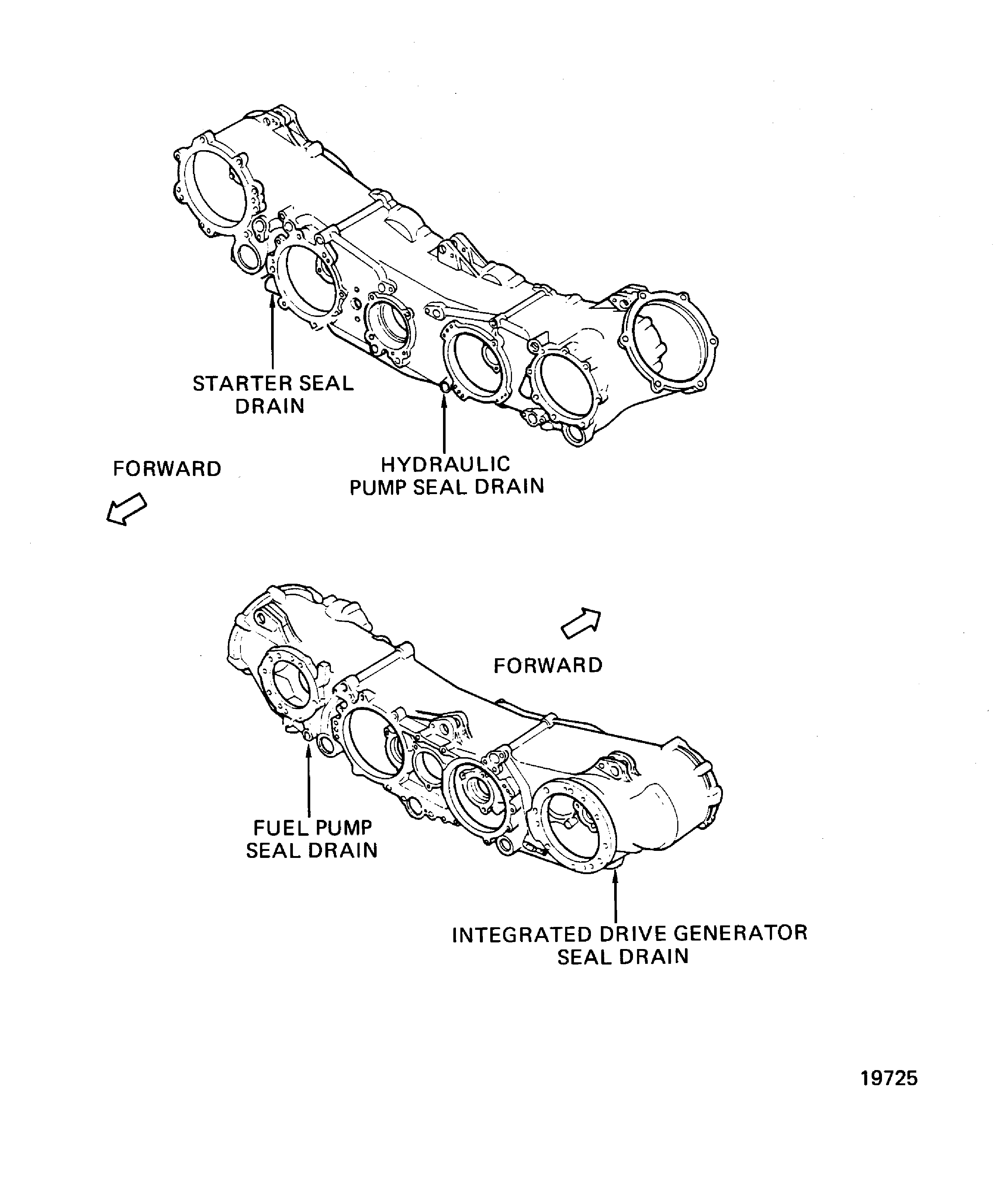

Fuel pump seal drain. This drain is located on the rear of the gearbox at approximately the 7 o-clock position (as viewed from rear of the engine) and faces rearward. Refer to Figure.

Hydraulic pump seal drain. This drain is located on the forward side of the gearbox at approximately the 5:30 o-clock position (as viewed from the front of the engine) and faces rearward. Refer to Figure.

Starter seal drain. This drain is located on the forward side of the gearbox at approximately the 6:30 o-clock position (as viewed from the front of the engine) and faces outboard. Refer to Figure.

Integrated Drive Generator (IDG) seal drain. This drain is located on the rear of the gearbox at approximately the 5 o-clock position and faces downward. Refer to Figure.

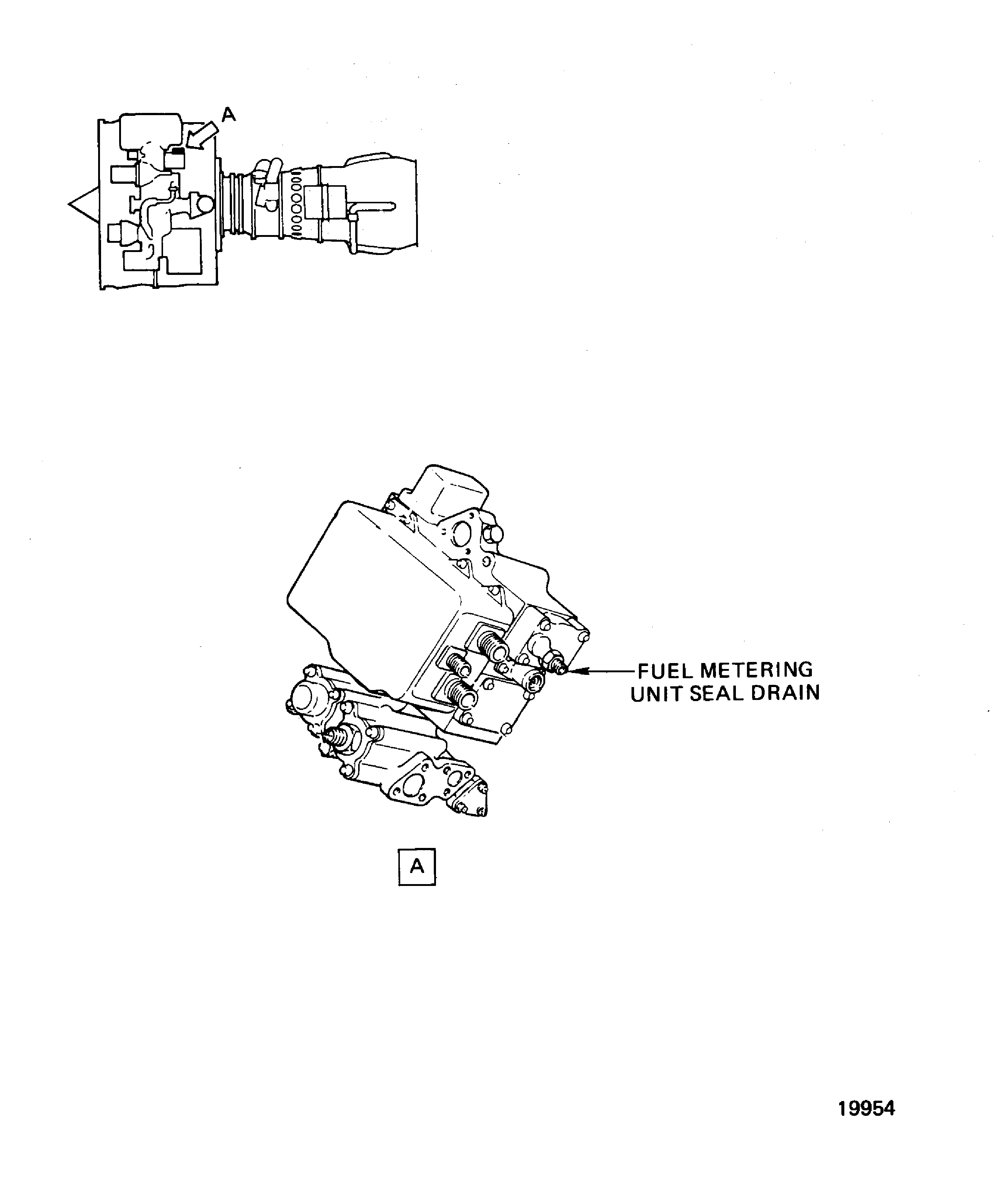

Fuel Metering Unit (FMU) seal drain. This drain is located on the FMU at approximately the 7 o-clock position at the rear of the gearbox and faces rearward. Refer to Figure.

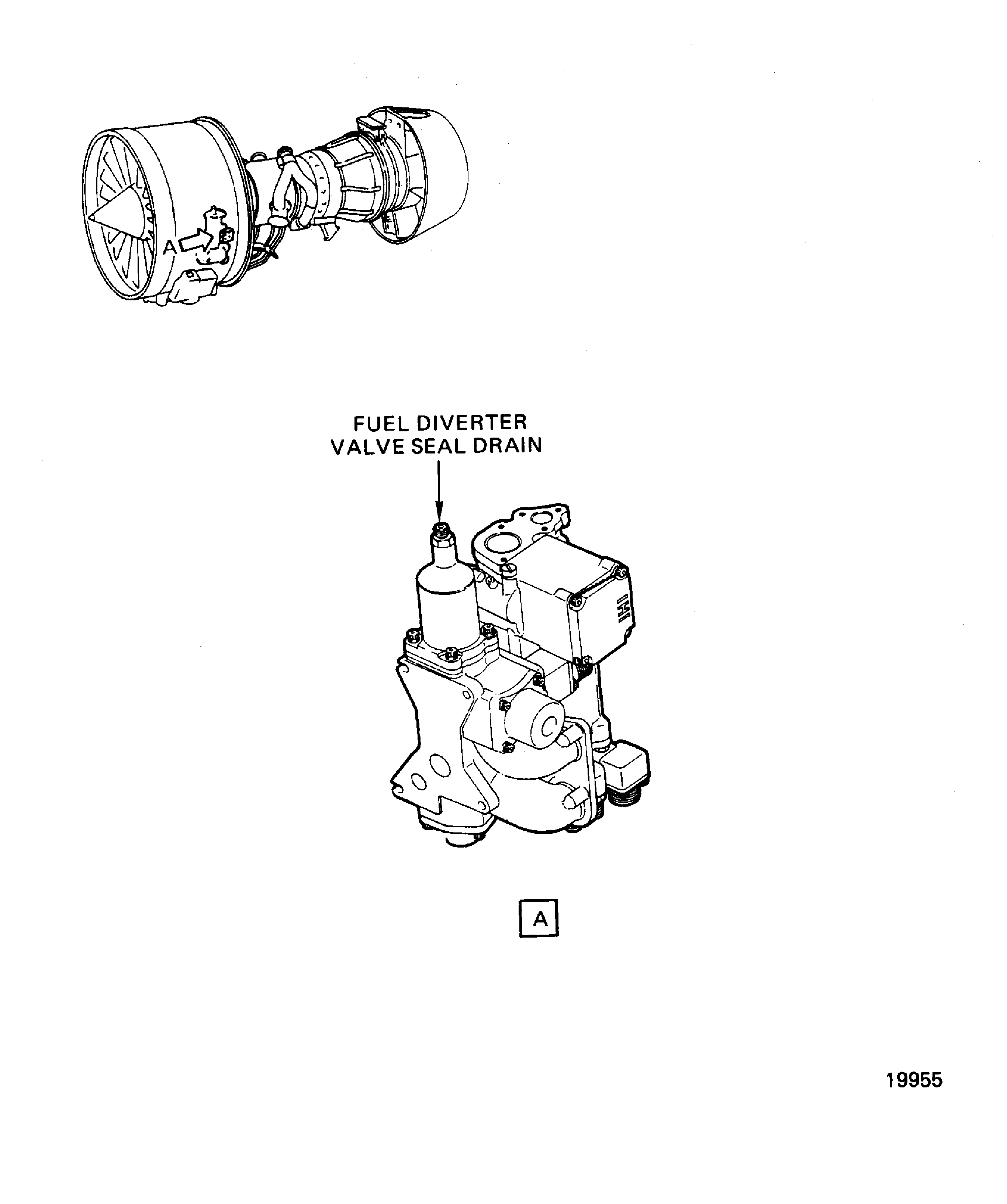

Fuel Diverter Valve seal drain. This drain is located on the Fuel Diverter Valve on the fan case near the fan case wall at approximately the 9 o-clock position and is marked with the letters DR. The drain faces upward. Refer to Figure.

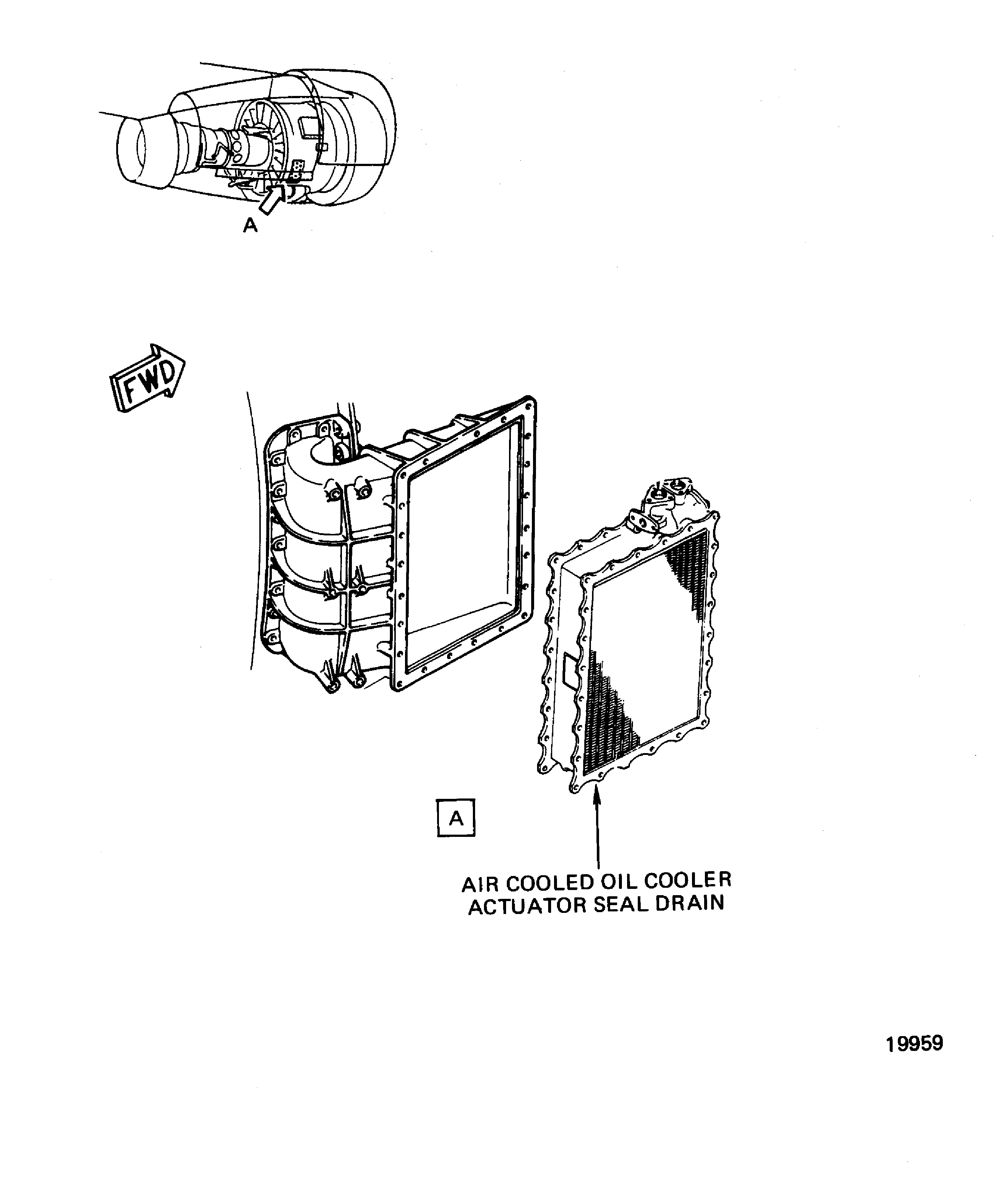

Air Cooled Oil Cooler (ACOC) actuator seal drain. This drain is located on the ACOC on the fan case at approximately the 4 o-clock position and faces downward. Refer to Figure.

Make sure the oil tank is empty, then remove the smaller of two plugs that are on the front face of the oil tank.

Put an AN3208-06 seal on the IAE 4F10373 Oil tank temperature probe 1 off. Install the probe and torque it to 55 - 70 lbfin (6.214 - 7.909 Nm).

Install IAE 4R18302 7th stage anti-ice blank 1 off on the compressor at approximately the 1 o-clock position. Torque the bolts to 75 - 85 lbfin (8.474 - 9.604 Nm).

Install the fan case vibration transducer. Refer to the Powerplant Build-up Manual.

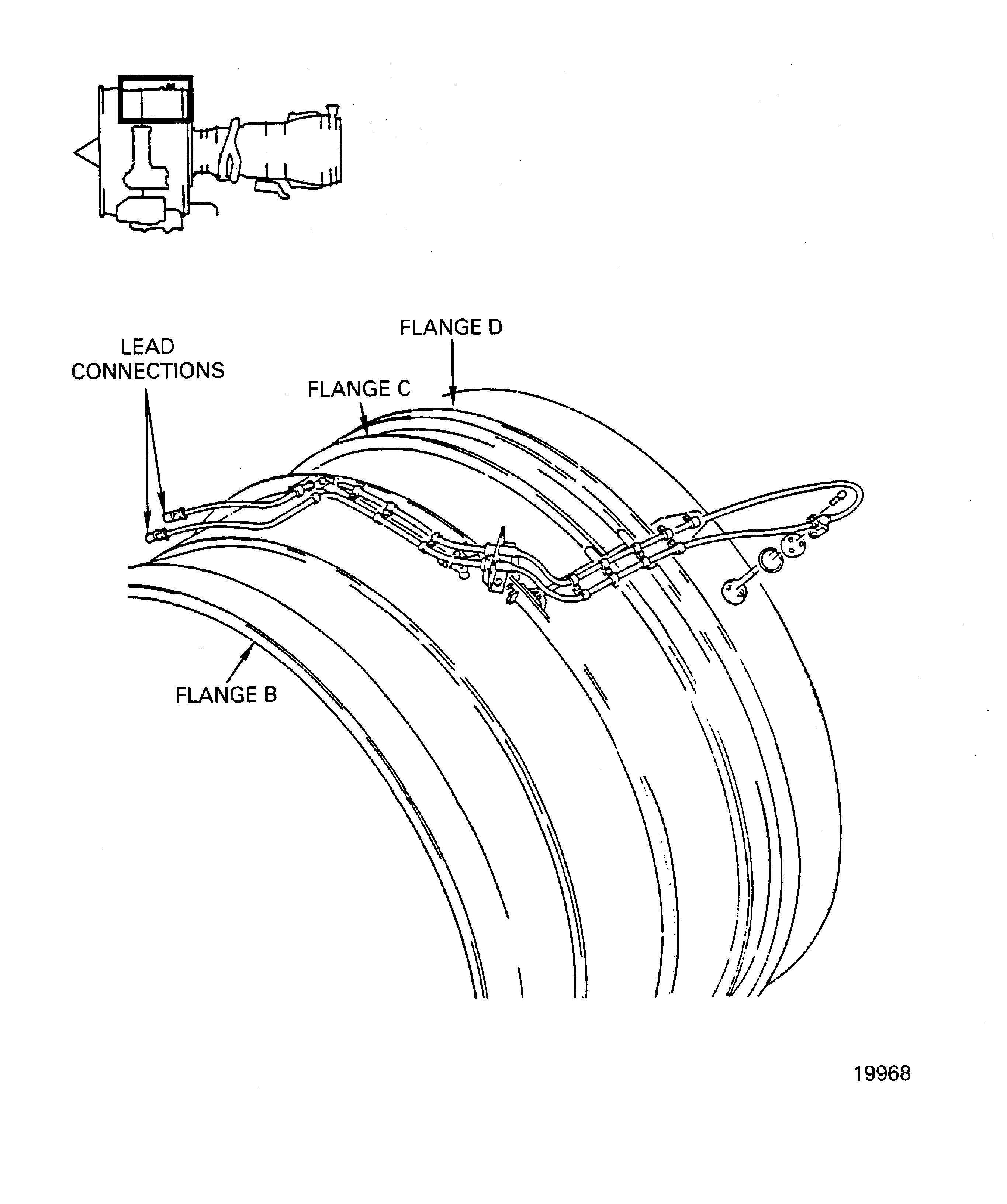

(Optional) Install the turbine exhaust case vibration transducer (Vibrometer - PN 144-951-000-03 or equivalent) on IAE 4F10284 Clamping bracket 1 off with the lead facing forward. Torque the nuts to 10 - 12 lbfin (1.130 - 1.356 Nm). Refer to Figure.

Remove two bolts on P flange at the 12 o-clock position. Install the bracket to the front of the flange and attach the bracket with the flange bolts you removed. Torque the bolts to 85 - 95 lbfin (9.604 - 10.734 Nm). Refer to Figure.

Install IAE 4R18301 7th and 10th stage offtake blank assembly 2 off on the 7th and 10th stage offtake elbows. Torque the clamps to 75 - 85 lbfin (8.474 - 9.604 Nm).

Install the IAE 4R18303 Pressure cap 1 off at the HP valve.

Install the IAE 4R18313 Pressure cap 1 off at the 10 stage HP valve.

Install the IAE 4R18324 Coupling nut 1 off at the LP fuel return.

Install the IAE 4R18448 LP fuel return blanking cap 1 off into the coupling nut and secure it with thrust wire.

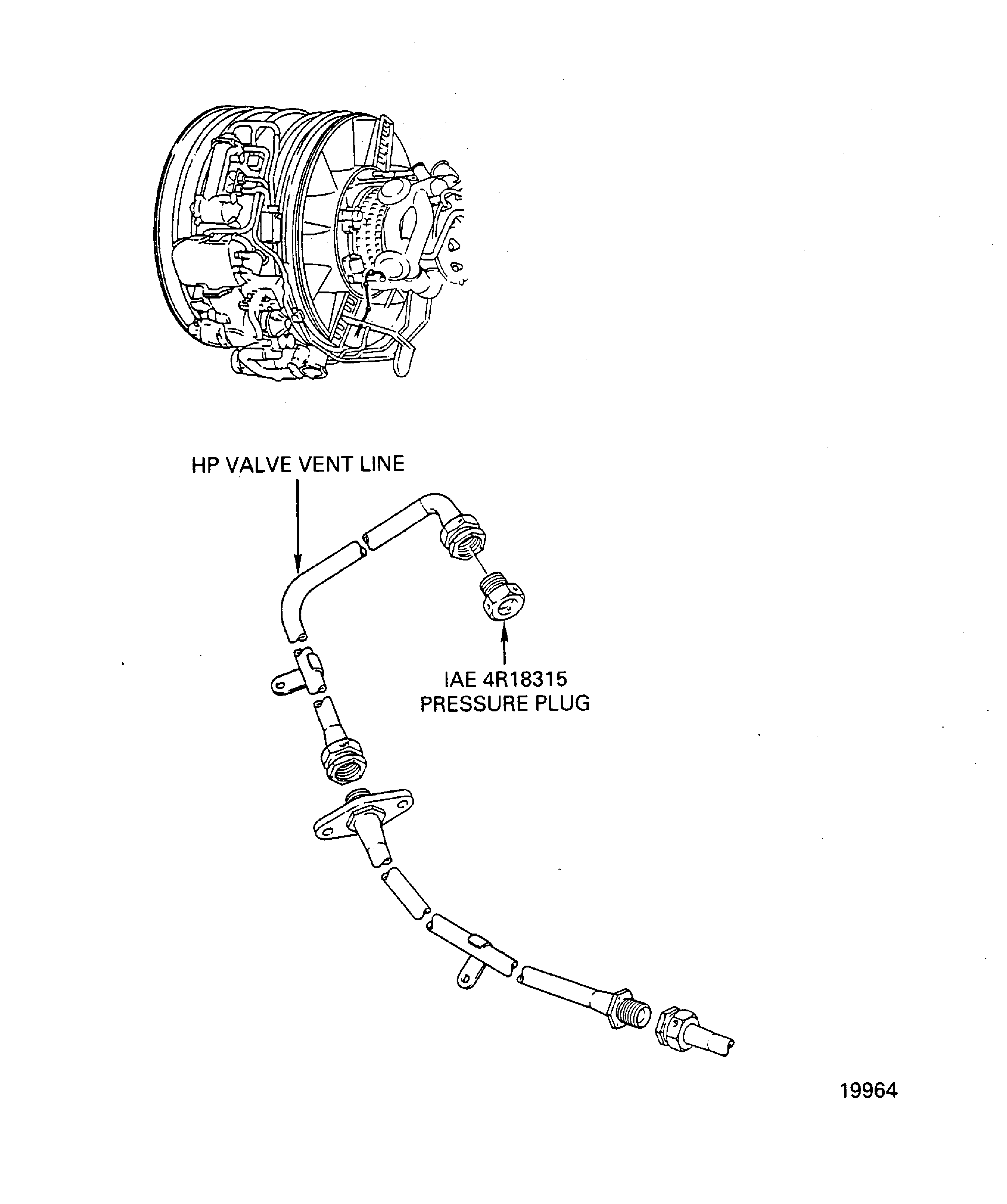

Install IAE 4R18315 Pressure plug 1 off on the HP valve vent line fitting. The HP valve vent line is located behind the 7th stage bleed elbow at approximately the 7 o-clock position. Refer to Figure.

Install IAE 4R18316 Flange 1 off and IAE 4R18314 Tube assembly 1 off to the Air Cooled Air Cooler (ACAC) assembly. The ACAC is located at approximately the 6 o-clock position adjacent to FN flange. Torque the clamp to 70 - 80 lbfin (7.909 - 9.039 Nm).

Install slave 10th stage bleed valve.

If a bleed valve (Part Number AC69922, AC69514 or AC69861) is to be fitted to the engine for despatch, remove the bleed valve in accordance with the Engine manual (TASK 72-00-40-020-004, SUBTASK 72-00-40-020-104-A00 and SUBTASK 72-00-40-020-104-B00).

Install a suitably identified Slave 10th stage bleed valve 1 off, and refit the bleed valve silencer in accordance with the Engine manual (TASK 72-00-40-420-004). A slave bleed valve is identified by a red band painted on the valve body.

Retain the removed valve for re-installation after test bed running.

Install the nacelle system bumper plates on the turbine exhaust case at approximately the 3 o-clock and 9 o-clock positions. Torque the bolts to 110 - 120 lbfin (12.428 - 13.558 Nm).

Assemble IAE 4F10280 Front section unit 1 off.

Install IAE 4F10263 Instrumentation ring 1 off on IAE 4F10264 Intake flare 1 off. Torque the bolts to 275 - 300 lbfin (31.071 - 33.895 Nm).

Install IAE 4F10282 Pressure/temperature probe 1 off into the instrumentation ring.

Connect IAE 4F10283 Connection hose 1 off to IAE 4F10282 Pressure/temperature probe probe 1 off.

Install IAE 4F10285 Handling bracket 2 off.

Install IAE 4F10280 Front section unit front section unit 1 off on engine flange A. Torque the bolts to 150 - 170 lbfin (16.948 - 19.207 Nm).

Connect IAE 4F10283 Connection hose connection hose 1 off to IAE 4F10282 Pressure/temperature probe probe 1 off in the instrumentation ring. Also connect IAE 4F10282 Pressure/temperature probe probe 1 off to the cables that follow: P805, P806 and P807 located on the fan case at approximately the 1 o-clock position.

Remove the EEC Data Entry Plug (DEP) and install an A1, BOM A5 or SelectOne(TM) DEP into the J6 connector on the EEC. (You can program the engine DEP to EPR modifier number 08 and EPR class bias 0 (SCN 20 and above) or install a slave DEP. The recommended procedure is to install a slave DEP). The EEC is located on the upper right side of the fan case.

Install the engine in the IAE 6F10291 Nacelle system 1 off.

Install the correct test cell adaptor for the engine.

Make sure all leads and hoses are attached correctly. Examine for any loose objects on the engine.

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

A null DEP (EPR modifier number 08 and EPR class bias 0 (SCN 20 and above)) is necessary for engine performance calibration (Test No.10) after a module change. Refer to TASK 71-00-00-700-052-A00 (TESTING-000, CONFIG-001) and

TASK 71-00-00-700-052-B00 (TESTING-000, CONFIG-002).

If Test No.10 will be done before any repair work or if Test No.10 will not be done, a null DEP is not necessary. Make sure that the DEP part number is the correct one for the EEC on the engine. Refer to Test No.11, TASK 71-00-00-700-011-A00 (TESTING-0011, CONFIG-001) and

TASK 71-00-00-700-011-B00 (TESTING-011, CONFIG-002).

We recommend you have a minimum of two uniquely identified null DEP plugs for the V2500-A5:

1. BOM A5

2. SelectOne(TM) (SCN 20 and above)

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluid Drain Collector/Container (Approximately 5 Gal (20 L)) | LOCAL | Fluid Drain Collector/Container (Approximately 5 Gal (20 L)) | ||

| Vibration Transducer | LOCAL | 144-951-000-03 | ||

| IAE 4F10263 Instrumentation ring | 0AM53 | IAE 4F10263 | 1 | |

| IAE 4F10264 Intake flare | 0AM53 | IAE 4F10264 | 1 | |

| IAE 4F10280 Front section unit | 0AM53 | IAE 4F10280 | 1 | |

| IAE 4F10282 Pressure/temperature probe | 0AM53 | IAE 4F10282 | 1 | |

| IAE 4F10283 Connection hose | 0AM53 | IAE 4F10283 | 1 | |

| IAE 4F10284 Clamping bracket | 0AM53 | IAE 4F10284 | 1 | |

| IAE 4F10285 Handling bracket | 0AM53 | IAE 4F10285 | 2 | |

| IAE 4F10288 Protective guard | 0AM53 | IAE 4F10288 | 1 | |

| IAE 4F10289 Shop transport dolly | 0AM53 | IAE 4F10289 | 1 | |

| IAE 4F10296 Breather pipe | 0AM53 | IAE 4F10296 | 1 | |

| IAE 4F10373 Oil tank temperature probe | 0AM53 | IAE 4F10373 | 1 | |

| IAE 6F10291 Nacelle system | 0AM53 | IAE 6F10291 | 1 | |

| IAE 4R18301 7th and 10th stage offtake blank assembly | 0AM53 | IAE 4R18301 | 2 | |

| IAE 4R18302 7th stage anti-ice blank | 0AM53 | IAE 4R18302 | 1 | |

| IAE 4R18303 Pressure cap | 0AM53 | IAE 4R18303 | 1 | |

| IAE 4R18313 Pressure cap | 0AM53 | IAE 4R18313 | 1 | |

| IAE 4R18314 Tube assembly | 0AM53 | IAE 4R18314 | 1 | |

| IAE 4R18315 Pressure plug | 0AM53 | IAE 4R18315 | 1 | |

| IAE 4R18316 Flange | 0AM53 | IAE 4R18316 | 1 | |

| IAE 4R18324 Coupling nut | 0AM53 | IAE 4R18324 | 1 | |

| IAE 4R18448 LP fuel return blanking cap | 0AM53 | IAE 4R18448 | 1 | |

| Slave 10th stage bleed valve | LOCAL | Bleed Valve |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 07-163 TWO PACK EPOXY FINISHRED (BSC381: No.538) | 0AM53 | CoMat 07-163 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-084 CORROSION PREVENTIVE | 0AM53 | CoMat 10-084 |

Spares

NONESafety Requirements

NONEProcedure

Align the engine under the test bed. Connect the hoisting cables and lift the engine up to the test bed and lock it into place.

(Optional) Install IAE 4F10288 Protective guard 1 off on the intake flare.

Connect the fuel line of the stand to the fuel inlet line. The fuel inlet line is the larger of two fuel lines located at approximately the 10 o-clock position on the fan case. Torque the connector to 1700 - 1800 lbfin (192.074 - 203.373 Nm).

Connect leads to the vibration transducer that is mounted on the fan case. Refer to Figure.

(Optional) Connect leads to the vibration transducer that is mounted on the turbine exhaust case. Refer to Figure.

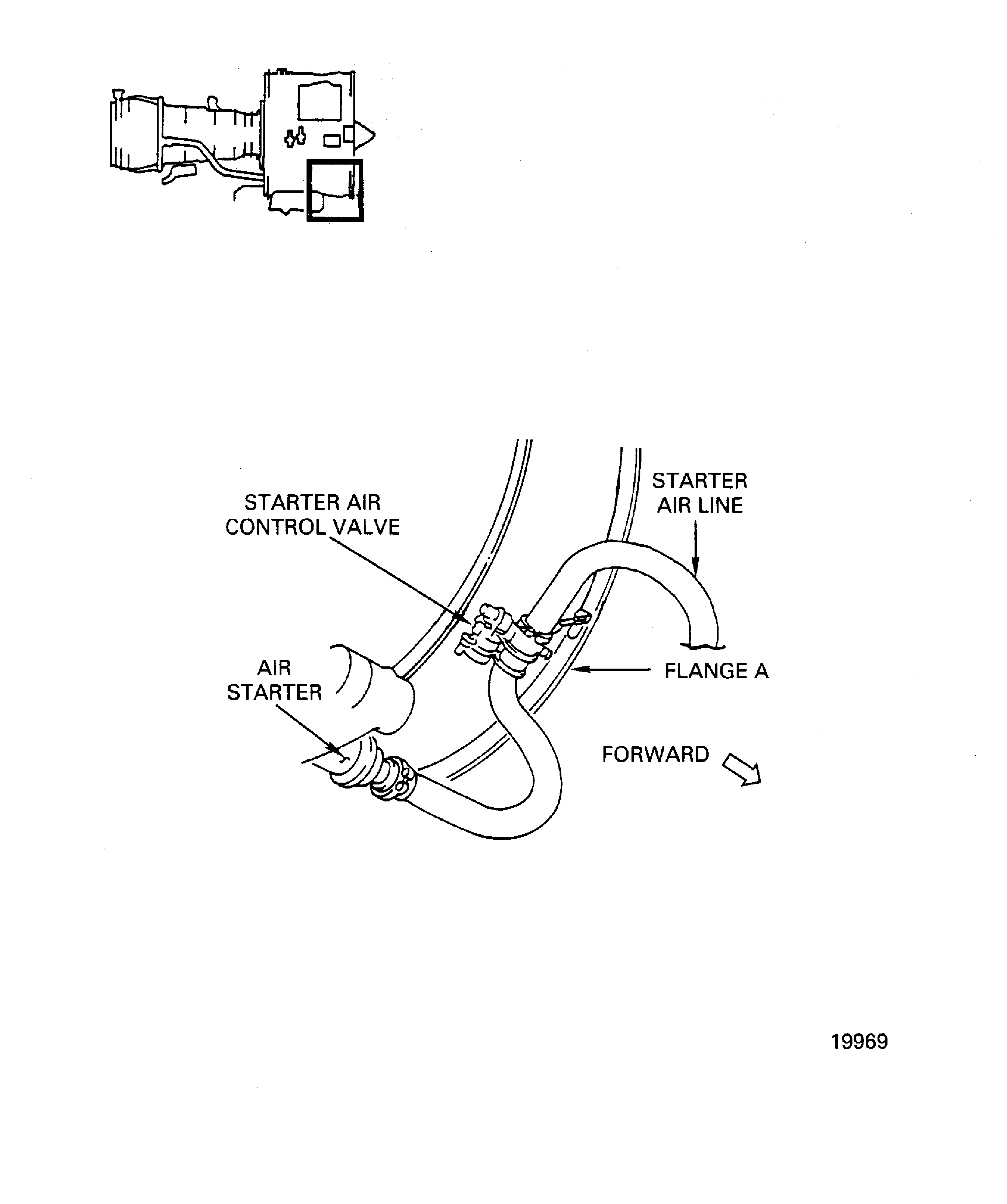

Connect the starter air line to the starter air control valve. Refer to Figure.

Connect the electrical lead to the starter air control valve.

Connect the lead to IAE 4F10373 Oil tank temperature probe 1 off.

Connect the test cell systems to the electrical cable assemblies (located at the 1 o-clock position on the fan case) that follow:

Cable Label - 402 VC - ARINC, Channel A

Cable Label - 403 VC - ARINC, Channel B

Cable Label - 404 VC - Instrumentation

Cable Label - 405 VC - Instrumentation

Cable Label - 406 VC - TLA, Channel A

Cable Label - 407 VC - TLA, Channel B

Cable Label - 447 VC - Fuel Metering Unit

Cable Label - 448 VC - Vibration

Cable Label - 457 VC - Vibration

The engine ignition requires a nominal or 115 volts AC, 400 cycles.

Check the fire extinguishing system.

Check the thrust lever actuation system.

If you use T1 instrumentation, make sure it is attached correctly.

Make sure that all leads and hoses are attached. Check for any loose objects on or around the engine.

Make sure that the engine nacelle doors are closed correctly.

Examine the engine inlet for loose or foreign objects.

make sure that the pedestrian doors are closed.

Do the general checks and procedures that follow before you motor or operate the engine after the hook-up is complete.

Install and Hook-up the Engine in the Test Cell

Open the C-ducts.

Remove and inspect the fuel filter. Install or replace the filter if necessary. Refer to TASK 72-00-32-050-020 (REMOVAL-027).

Install (or replace) the fuel filter. Refer to TASK 72-00-32-450-020 (INSTALLATION-027).

Drain all the fuel from the Fuel Cooled Oil Cooler (FCOC). The FCOC is located at the 9 o-clock position on the fan case. The drain extends from the bottom of the FCOC.

Remove and inspect the magnetic chip detectors. Refer to TASK 72-00-00-050-001 (REMOVAL-001).

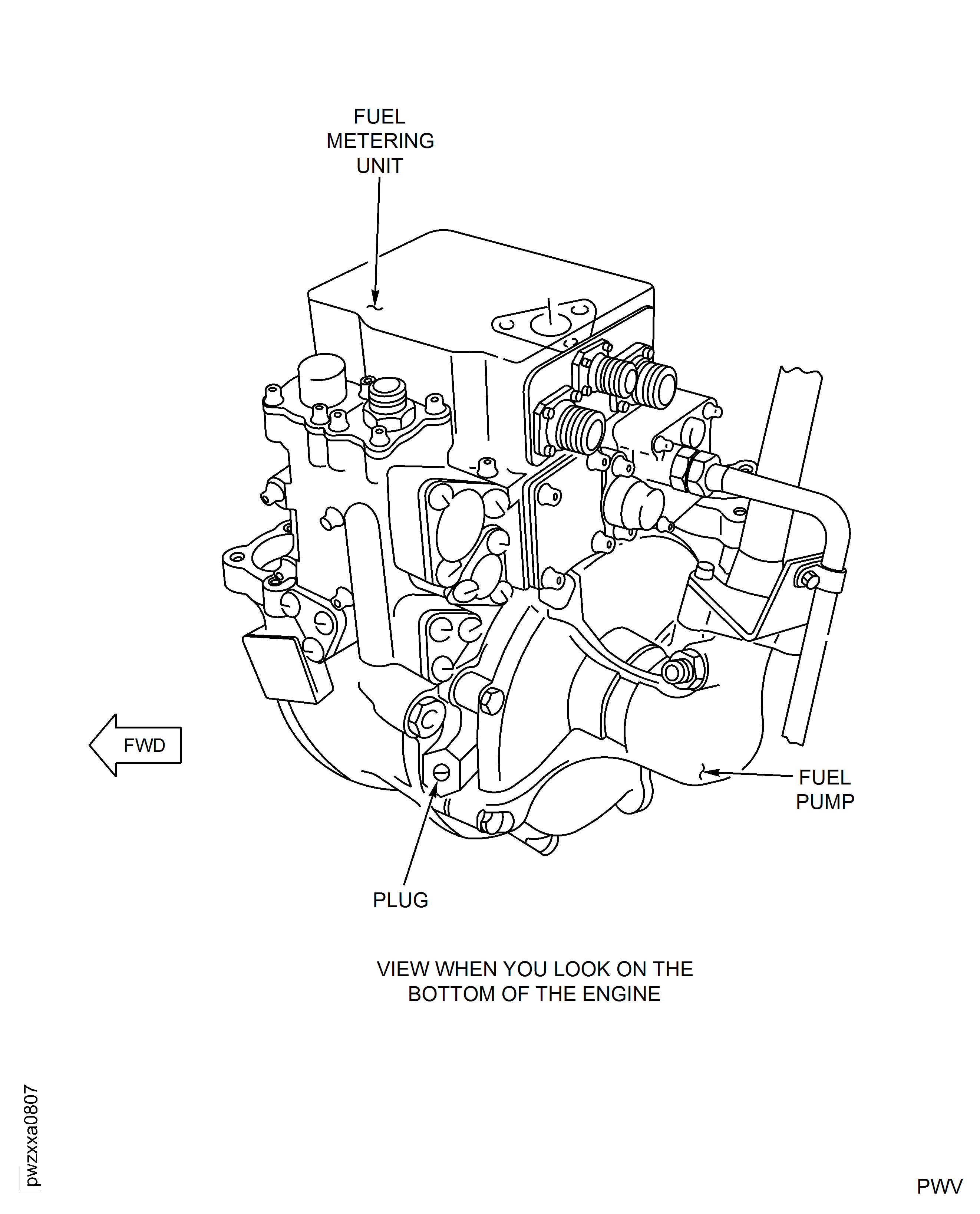

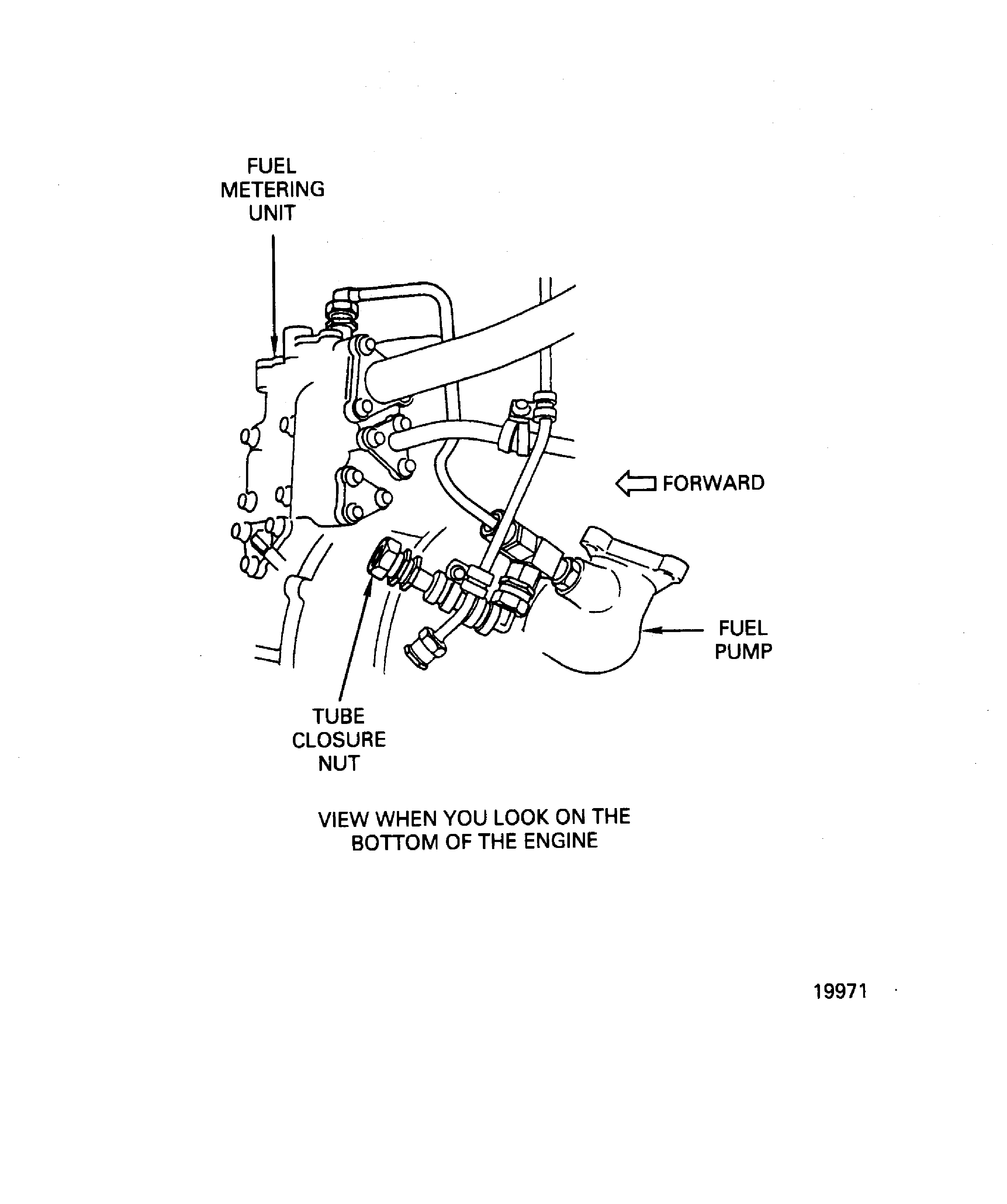

Remove the tube closure nut from the fuel drain fitting to drain the fuel system. Refer to Figure.

Install the nut again and torque it to 230 to 248 lbf-in (25.987 to 28.020 N.m). Hold the tube assembly while you torque the nut. Loosen the nut and torque it again.

(For V2500-A1 Series)

Remove lockwire and ferrule from plug and boost housing and then remove plug to drain fuel system. Remove the packing from the plug and discard it. Refer to Figure.

Install packing to plug and screw the plug into the boost pump housing assembly and torque it to 75 to 100 lbf-in (8.5 to 11.3 N.m). Attach CoMat 02-119 LOCKWIRE from plug to boost housing.

(For V2500-A5 Series)

Disconnect the fuel inlet line on the fan case at approximately the 10 o-clock position.

Install the hose from the preservation cart.

Connect the fuel inlet line to the supply of preservation oil. Be very careful that foreign material does not get into the engine fuel system.

Do a wet motoring of the engine until you see the preservation fluid vapor go out of the tail pipe. Refer to TASK 71-00-00-700-002 (TESTING-002).

Discontinue motoring and disconnect the supply of preservation oil. Install a protective closure on the fuel inlet line.

Preserve the fuel system.

Remove and inspect the oil pressure pump and filter assembly. Replace it if necessary. Torque the bolts to 65 - 75 lbfin (7.344 - 8.474 Nm). Refer to TASK 72-00-60-020-003-002 (REMOVAL-004).

Remove and inspect the scavenge oil filter. Replace it if necessary. Torque the bolts to 65 - 75 lbfin (7.344 - 8.474 Nm). Refer to TASK 72-00-60-020-003-002 (REMOVAL-004).

Remove the gearbox drain fitting and drain the oil from the gearbox.

Drain the oil tank.

Remove the vibration transducer leads from the transducer that is mounted on the fan case.

Disconnect the starter air line.

Disconnect the lead to the starter air valve.

Disconnect the lead to IAE 4F10373 Oil tank temperature probe 1 off.

Disconnect the electrical cable assemblies (located at the 1 o-clock position on the fan case) that follow:

Cable Label - 402 VC - ARINC, Channel A

Cable Label - 403 VC - ARINC, Channel B

Cable Label - 404 VC - Instrumentation

Cable Label - 405 VC - Instrumentation

Cable Label - 406 VC - TLA, Channel A

Cable Label - 407 VC - TLA, Channel B

Cable Label - 447 VC - Fuel Metering Unit

Cable Label - 448 VC - Vibration

Cable Label - 457 VC - Vibration

(Optional) Remove the protective guard from the intake flare.

Remove the engine and the nacelle system from the test cell.

Remove the Engine from the Test Cell

Figure: Bifurcation Panel Common Core Seal Drain

Bifurcation Panel Common Core Seal Drain

Figure: Starter, Hydraulic Pump, Fuel Pump and IDG Seal Drains

Starter, Hydraulic Pump, Fuel Pump and IDG Seal Drains

Figure: Fuel Metering Unit Seal Drain

Fuel Metering Unit Seal Drain

Figure: Fuel Diverter Valve Seal Drain

Fuel Diverter Valve Seal Drain

Figure: Air Cooled Oil Cooler Actuator Seal Drain

Air Cooled Oil Cooler Actuator Seal Drain

Figure: Turbine Exhaust Case Vibration Transducer

Turbine Exhaust Case Vibration Transducer

Figure: IAE 4R18315 Pressure Plug

IAE 4R18315 Pressure Plug

Figure: Fan Case Wire Vibration Transducer Connection

Fan Case Wire Vibration Transducer Connection

Figure: Starter Air Line Connection

Starter Air Line Connection

Figure: V2500-A1 Fuel System Drain

V2500-A1 Fuel System Drain

Figure: V2500-A5 Fuel System Drain

V2500-A5 Fuel System Drain