Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-40-020-004 HP System Module - Remove The Remaining HP System Module Components And Air Off-Take Ducts, Removal-004

General

This TASK gives the procedure to remove the components and the air off-take ducts from the HP compressor/diffuser case assembly. Refer to the TASKs which follow for other related procedures:

TASK 72-00-40-020-001-A00 (REMOVAL-001, CONFIG-001) or TASK 72-00-40-020-001-B00 (REMOVAL-001, CONFIG-002). Remove the components, the electrical harnesses and the tubes from the HP turbine.

TASK 72-00-40-020-002-A00 (REMOVAL-002, CONFIG-001) or TASK 72-00-40-020-002-B00 (REMOVAL-002, CONFIG-002). Remove and disconnect the components, the electrical harnesses and the tubes from the front of the HP compressor case.

TASK 72-00-40-020-003-A00 (REMOVAL-003, CONFIG-001) or TASK 72-00-40-020-003-B00 (REMOVAL-003, CONFIG-002). Remove the components, the ducts, the electrical harnesses and the tubes from the HP compressor case vertical splitline.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For service bulletin alpha variants refer to the IPC.

For all the parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

All ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

Discard all rubber seal rings removed in this procedure.

Seal all openings to prevent contamination from unwanted materials.

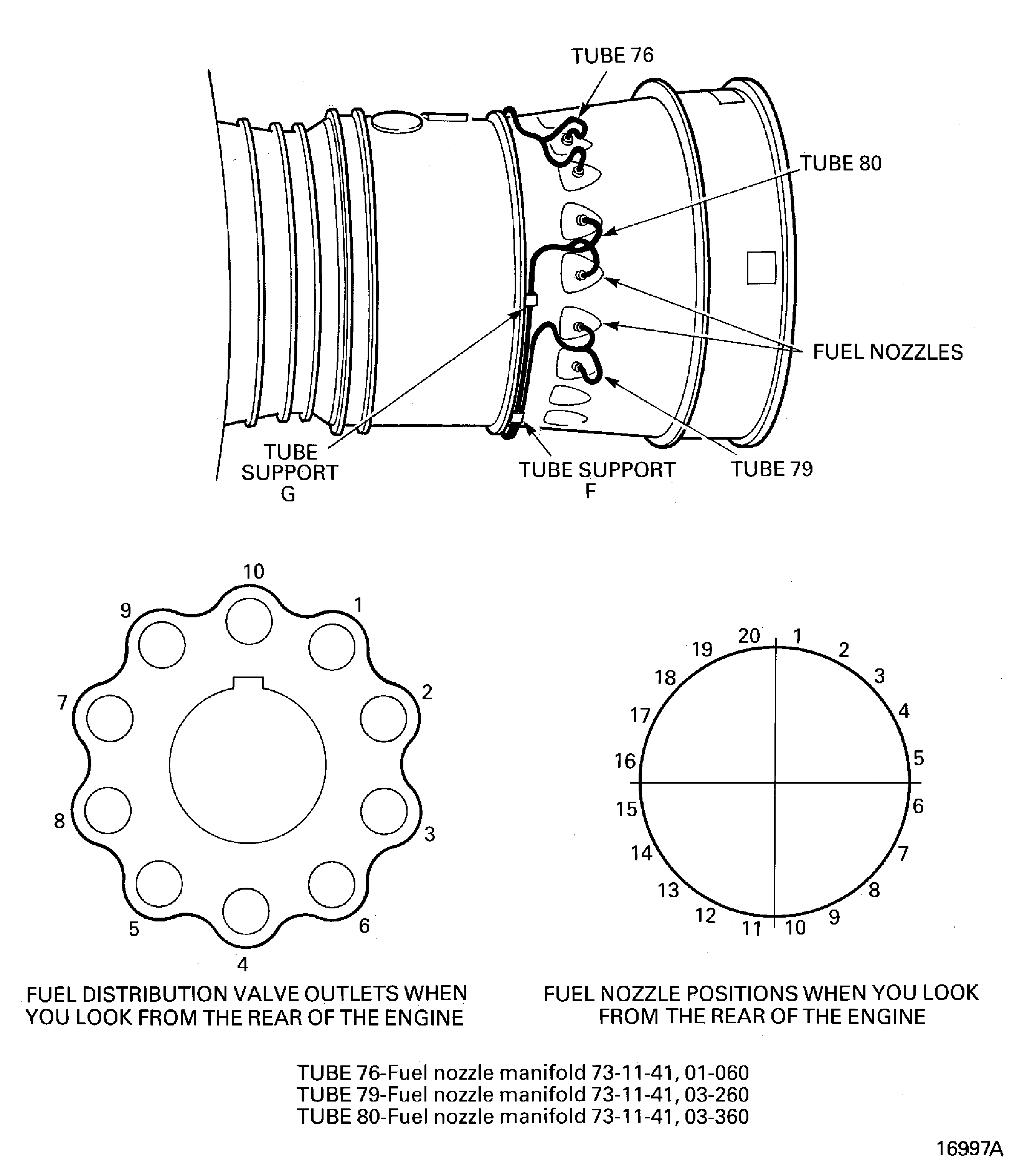

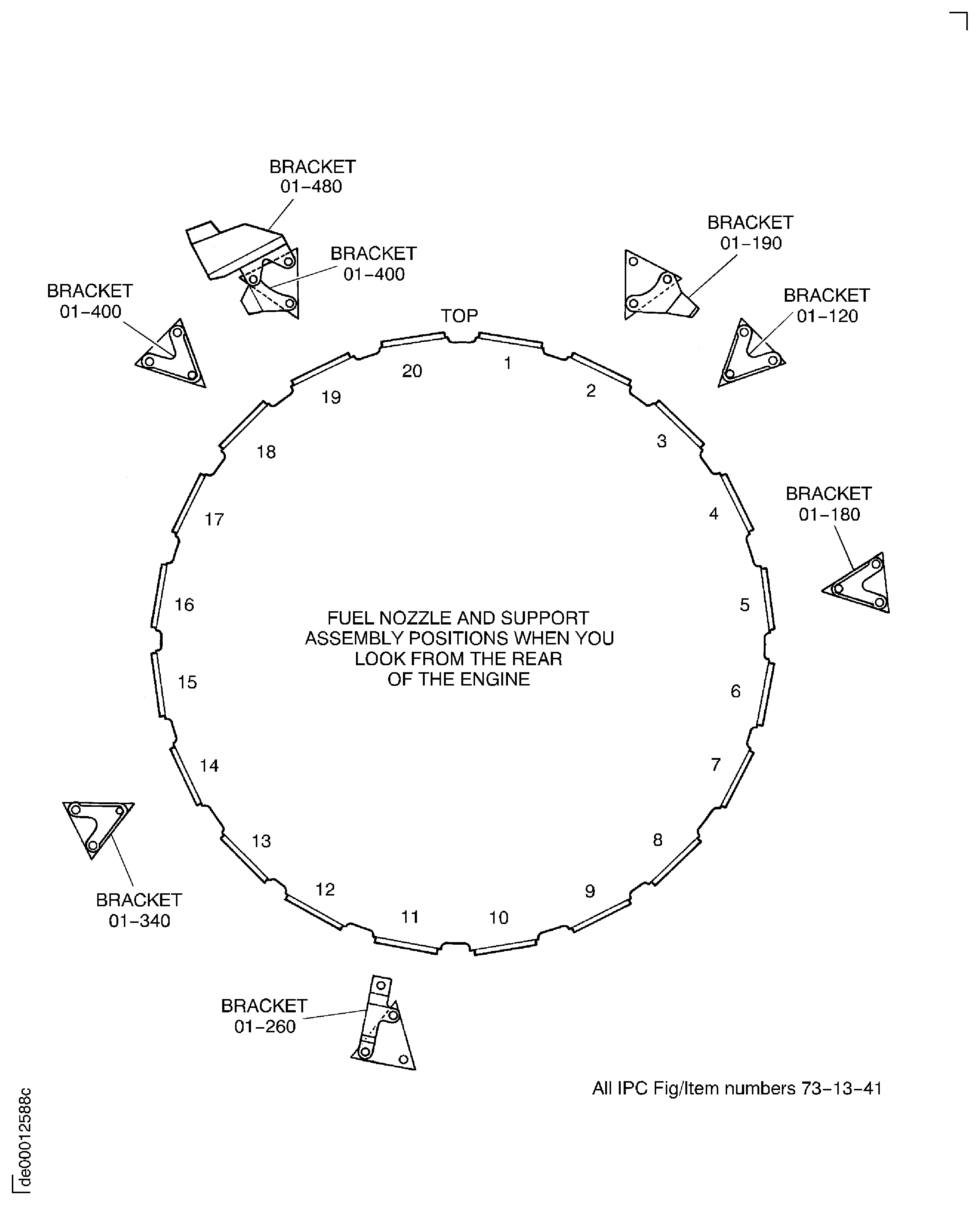

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1P16139 Wrench | 0AM53 | IAE 1P16139 | 1 | |

| IAE 1R18001 Wrench | 0AM53 | IAE 1R18001 | 1 | |

| IAE 1R18003 Wrench | 0AM53 | IAE 1R18003 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | X222X | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

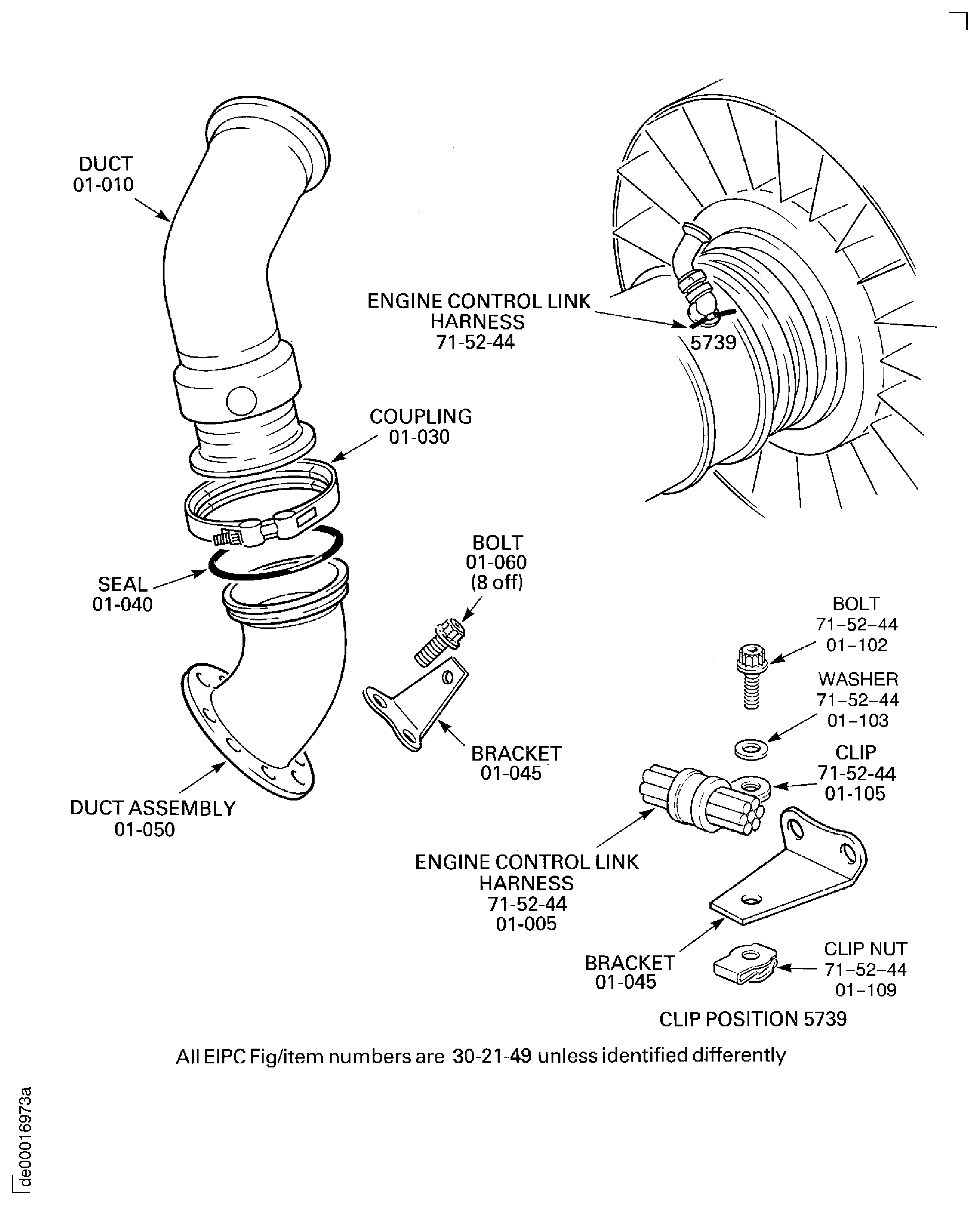

Remove the eight bolts and the bracket Anti-Ice Ducts (30-21-49, 01-045) that attach the duct assemblies to the HP compressor case.

SUBTASK 72-00-40-020-087 Remove the Thermal Anti-Icing Ducts

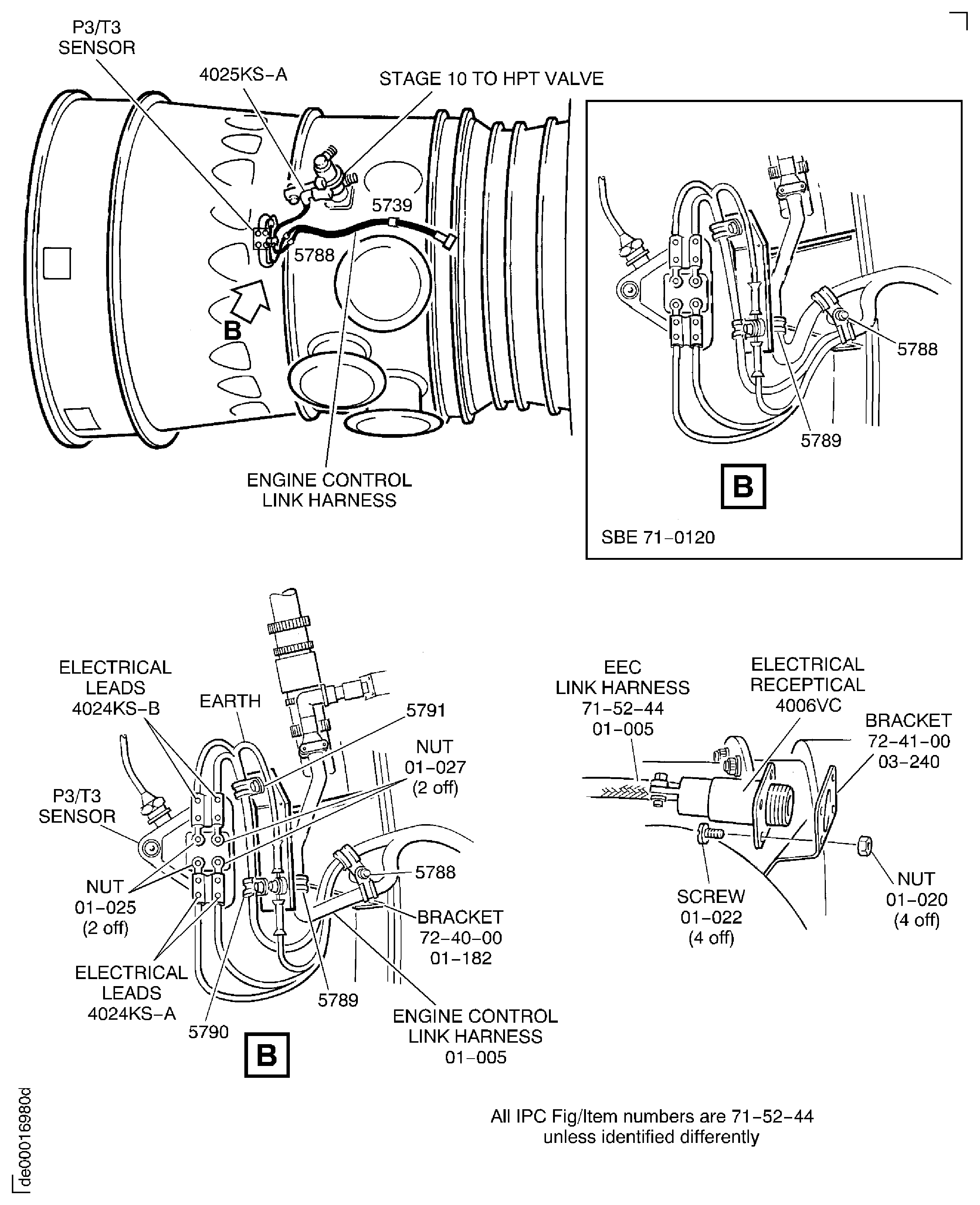

Pre SBE 75-0081: Disconnect the electrical connector 4025KS-A from the stage 10 to HPT air valve.

Disconnect the electrical receptacle 4006VC from the bracket HPC Assembly (72-41-00, 03-240).

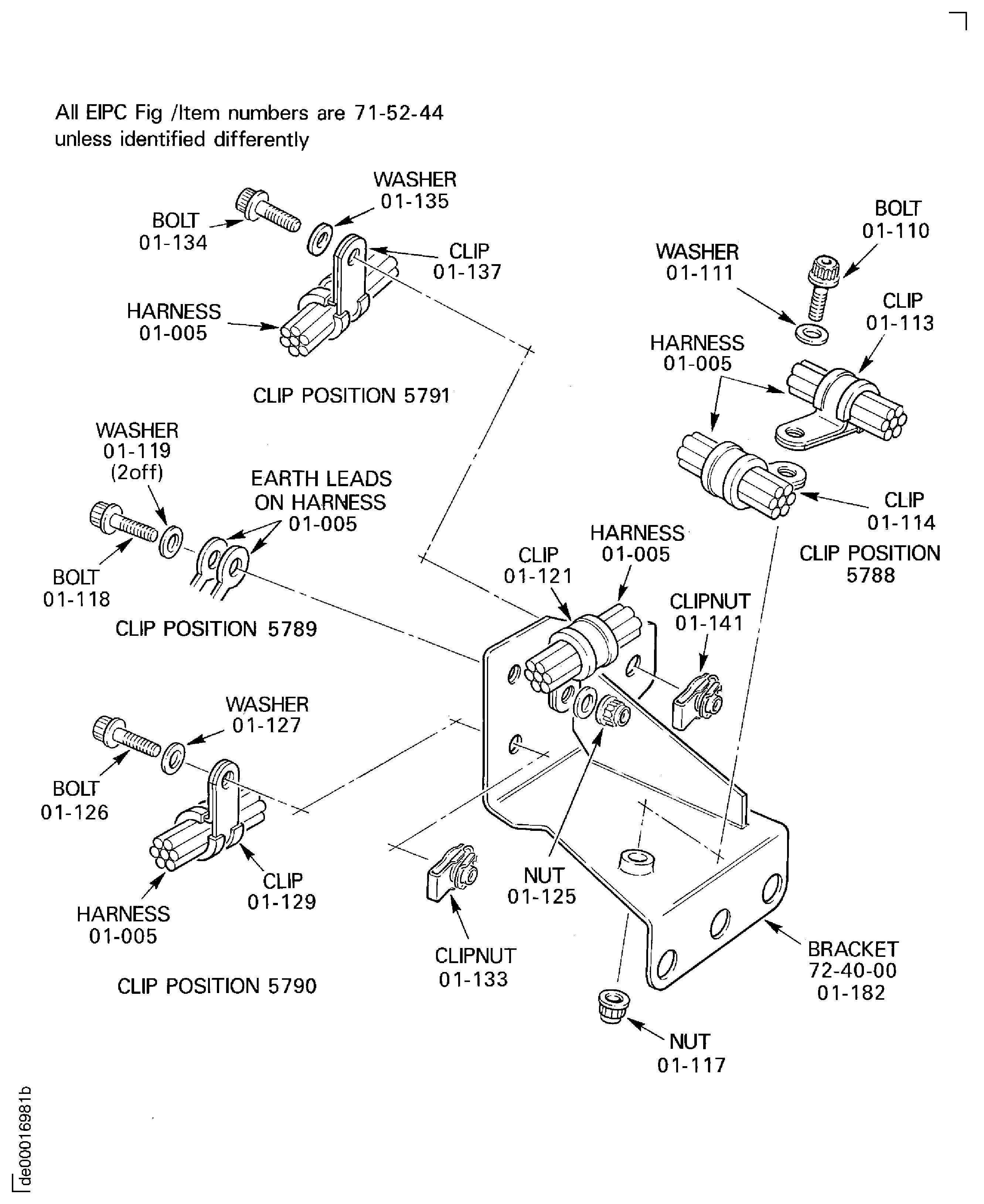

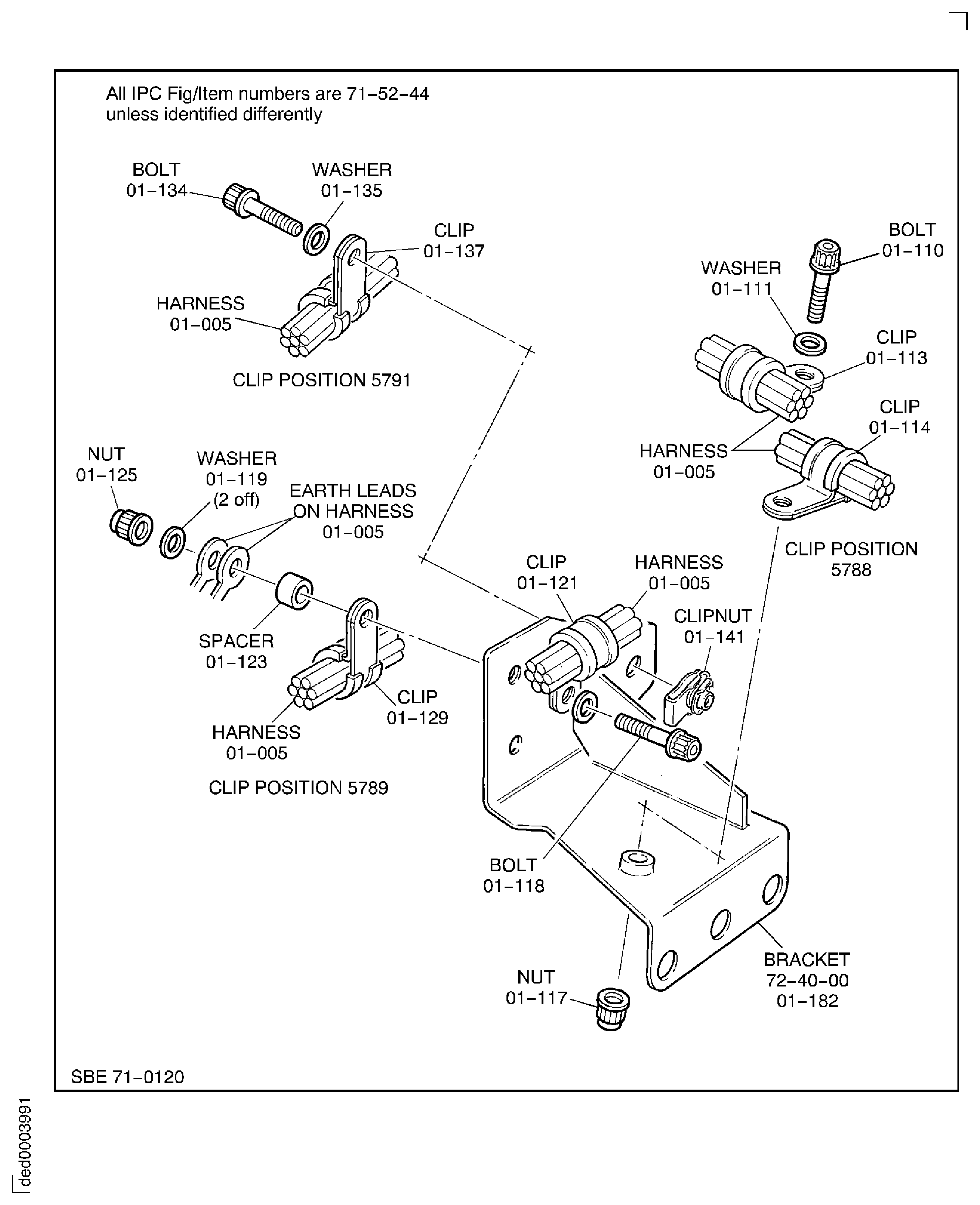

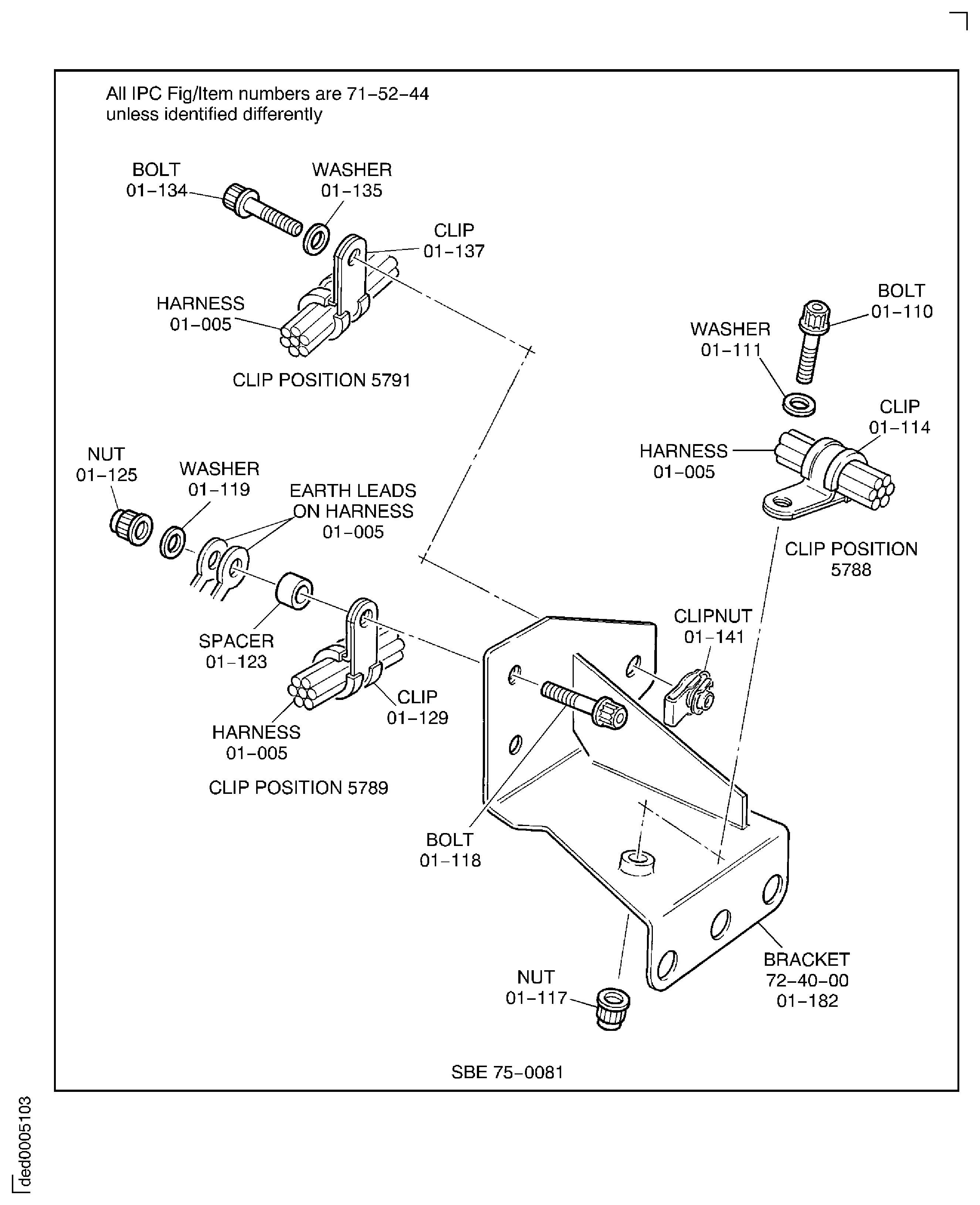

Pre SBE 71-0120: Remove the bolt, the washer, the clipnut and the clip from the clip position 5790. Refer to Figure.

Pre SBE 71-0120: Remove the bolt, the washers, the nut and the clip, (together with the two leads) from the clip position 5789. Refer to Figure.

SBE 71-0120: Remove the bolt, the washers, the spacer, the nut and the clips, (together with the two leads) from the clip position 5789. Refer to Figure.

SBE 75-0081: Remove the bolt, the washer, the spacer, the nut and the clip, (together with the lead) from the clip position 5789. Refer to Figure.

Remove the bolt, the washer, the nut and the clips from the clip position 5788. Refer to Figure.

SBE 75-0081: Remove the bolt, the washer, the nut and the clip, (together with the lead) from the clip position 5788. Refer to Figure.

Remove the bolt, the washer, the clipnut and the clip from clip position 5791. Refer to Figure.

SUBTASK 72-00-40-020-090 Remove the Engine Control Link Harness (Pre SBE 71-0120, SBE 71-0120, Pre SBE 75-0081 and SBE 75-0081)

Refer to Figure.

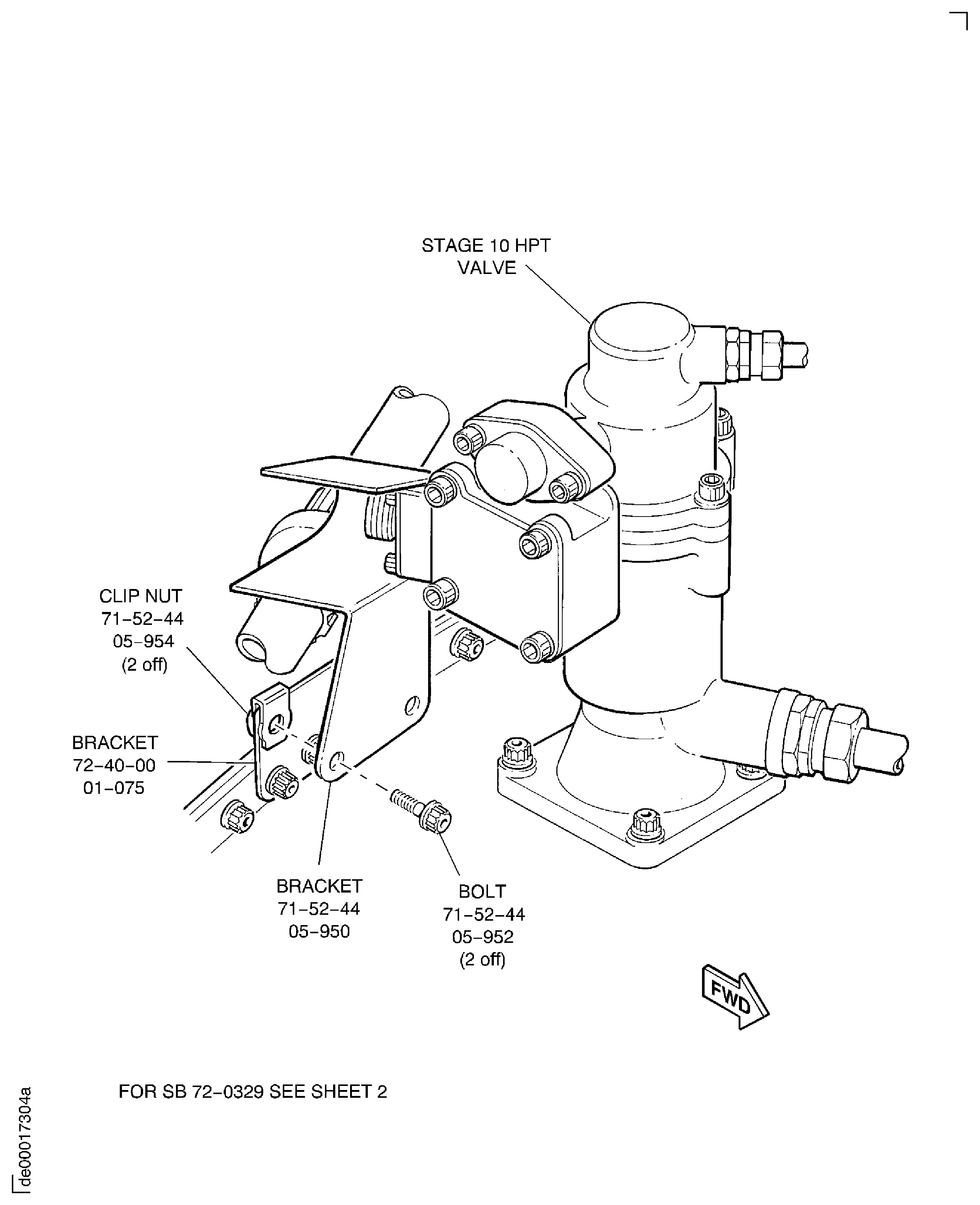

Remove the two clip nuts and the two bolts that attach the air deflector bracket EEC Link Core Harness (71-52-44, 05-950) to the bracket HPC Module - Attaching Parts (72-40-00, 01-075).

SUBTASK 72-00-40-020-098-A00 Remove the Air Deflector Bracket (Pre SBE 72-0329 and SBE 75-0005)

Refer to Figure.

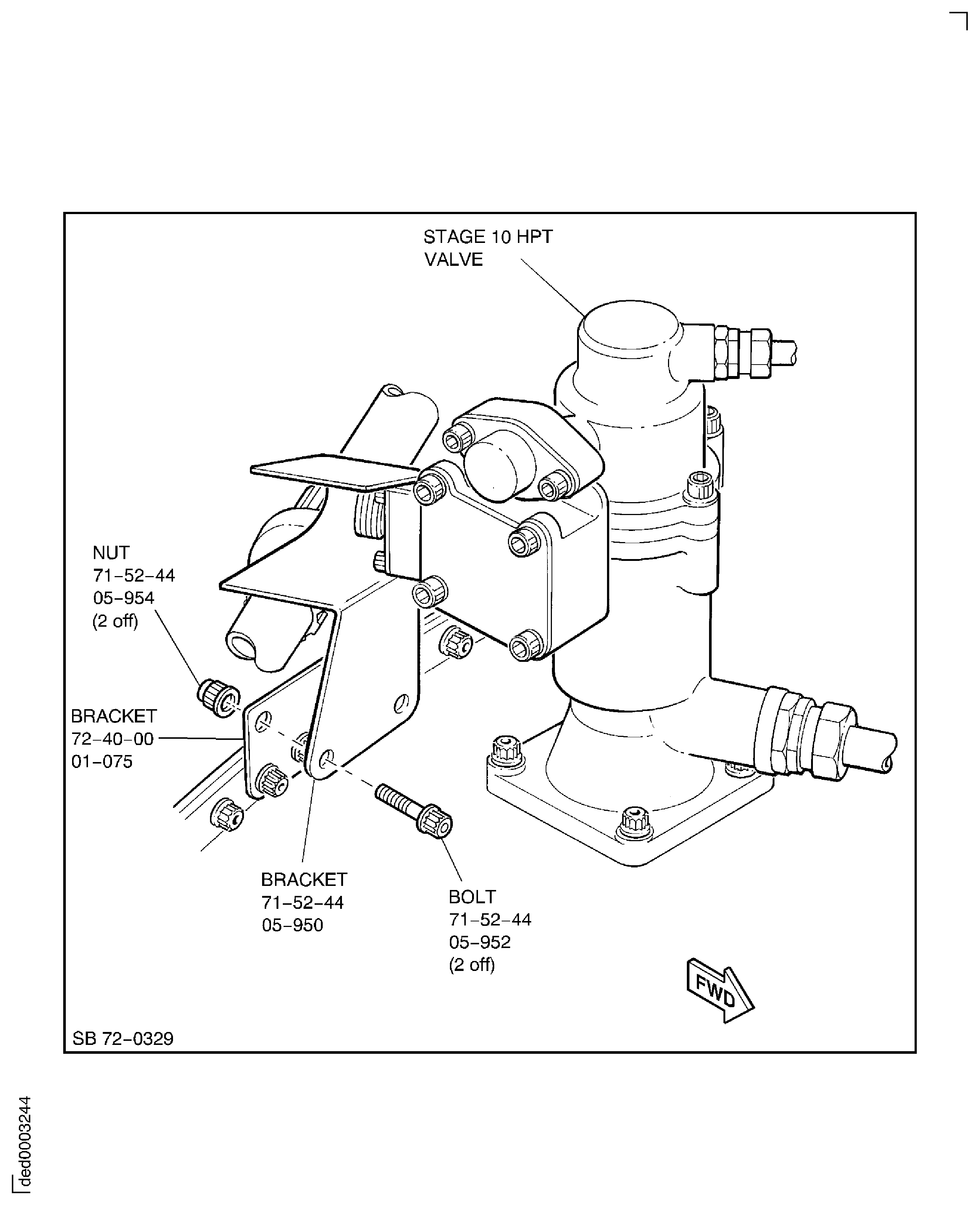

Remove the two nuts and the two bolts that attach the air deflector bracket EEC Link Core Harness (71-52-44, 05-950) to the bracket HPC Module - Attaching Parts (72-40-00, 01-075).

SUBTASK 72-00-40-020-098-B00 Remove the Air Deflector Bracket (SBE 72-0329 and SBE 75-0005)

Refer to Figure.

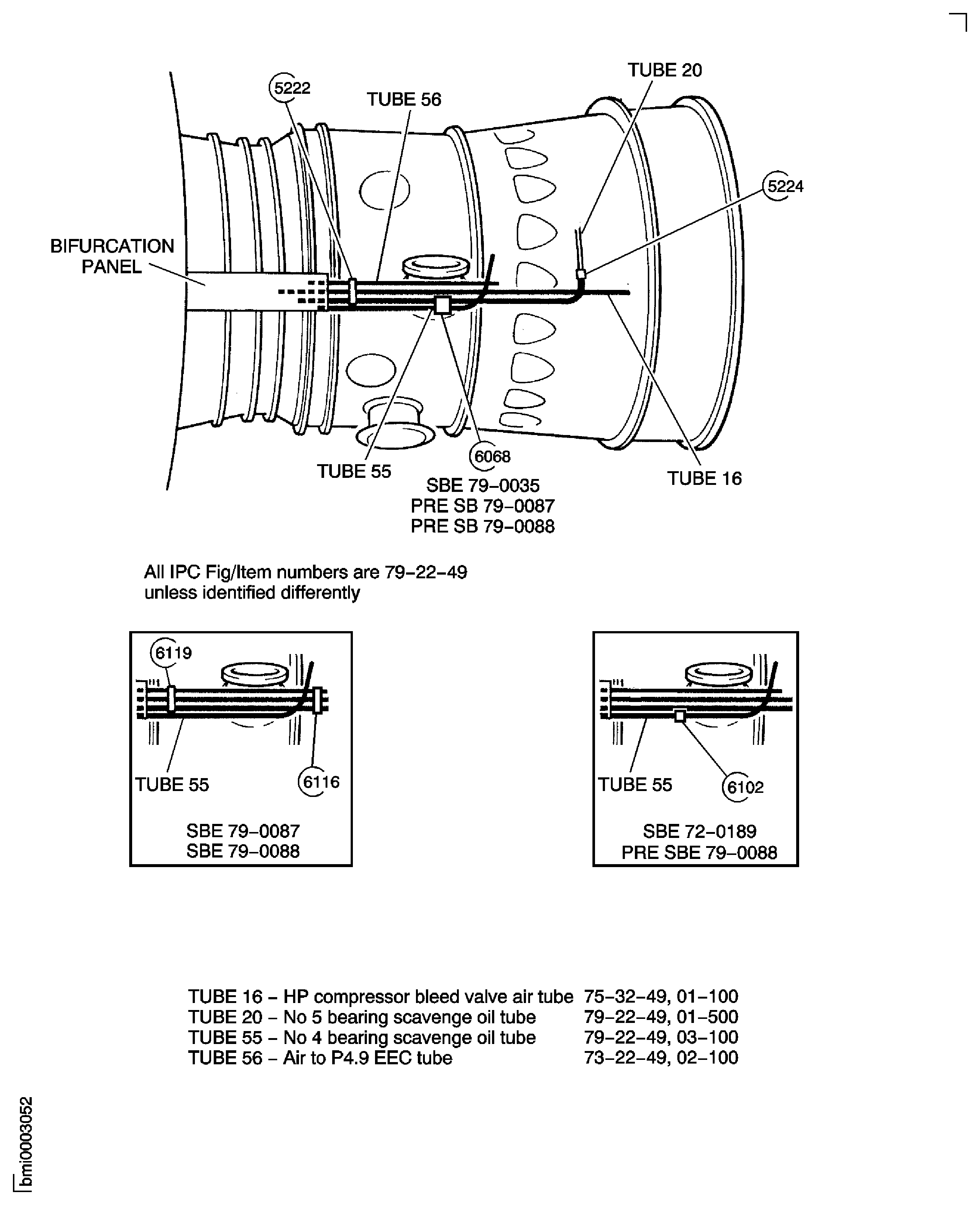

Pre SBE 75-0049, Pre SBE 79-0087 or Pre SBE 79-0088: Remove the bolt, the washer, the clipnut and the clip from the clip position 5224.

SBE 79-0087 or SBE 79-0088: Remove the nut, the bolt, the two washers, the spacer and the clip from the clip position 5224.

Pre SBE 79-0087 or Pre SBE 79-0088: Remove the nut, the bolt, the spacers, the washers and the clips from the clip position 5222.

Remove the tubes 16, 20 and 56.

SUBTASK 72-00-40-020-092-A00 Remove the HP Compressor Bleed Valve Air Tube (16), the Oil Scavenge Tubes (20 and 55) and the P4.9/EEC Tube (56) (Pre SBE 79-0035, Pre SBE 79-0087, Pre SBE 79-0088, SBE 79-0087 and SBE 79-0088)

Pre SBE 75-0049, Pre SBE 79-0087 or Pre SBE 79-0088: Remove the bolt, the washer, the clipnut and the clip from the clip position 5224.

SBE 79-0087 or SBE 79-0088: Remove the nut, the bolt, the two washers, the spacer and the clip from the clip position 5224.

Pre SBE 79-0087 or Pre SBE 79-0088: Remove the clipnut, the bolt and the spacer from the clip position 6068.

SBE 79-0087 or SBE 79-0088: Remove the nut, the bolt, the washer, the clip and the spacer from the clip positions 6116 and 6119.

Pre SBE 79-0087 or Pre SBE 79-0088: Remove the nut, the bolt, the spacers from the clip position 5222.

SBE 72-0189 and Pre SBE 79-0088 - A5 series: Remove the clip, the spacer, the bolt and the clipnut at the clip position 6102.

Remove the tubes 16, 20 and 56.

SUBTASK 72-00-40-020-092-B00 Remove the HP Compressor Bleed Valve Air Tube (16), the Oil Scavenge Tubes (20 and 55) and the P4.9/EEC Tube (56) (Pre SBE 79-0087, Pre SBE 79-0088, SBE 79-0087, SBE 79-0088, SBE 79-0035 and SBE 72-0189)

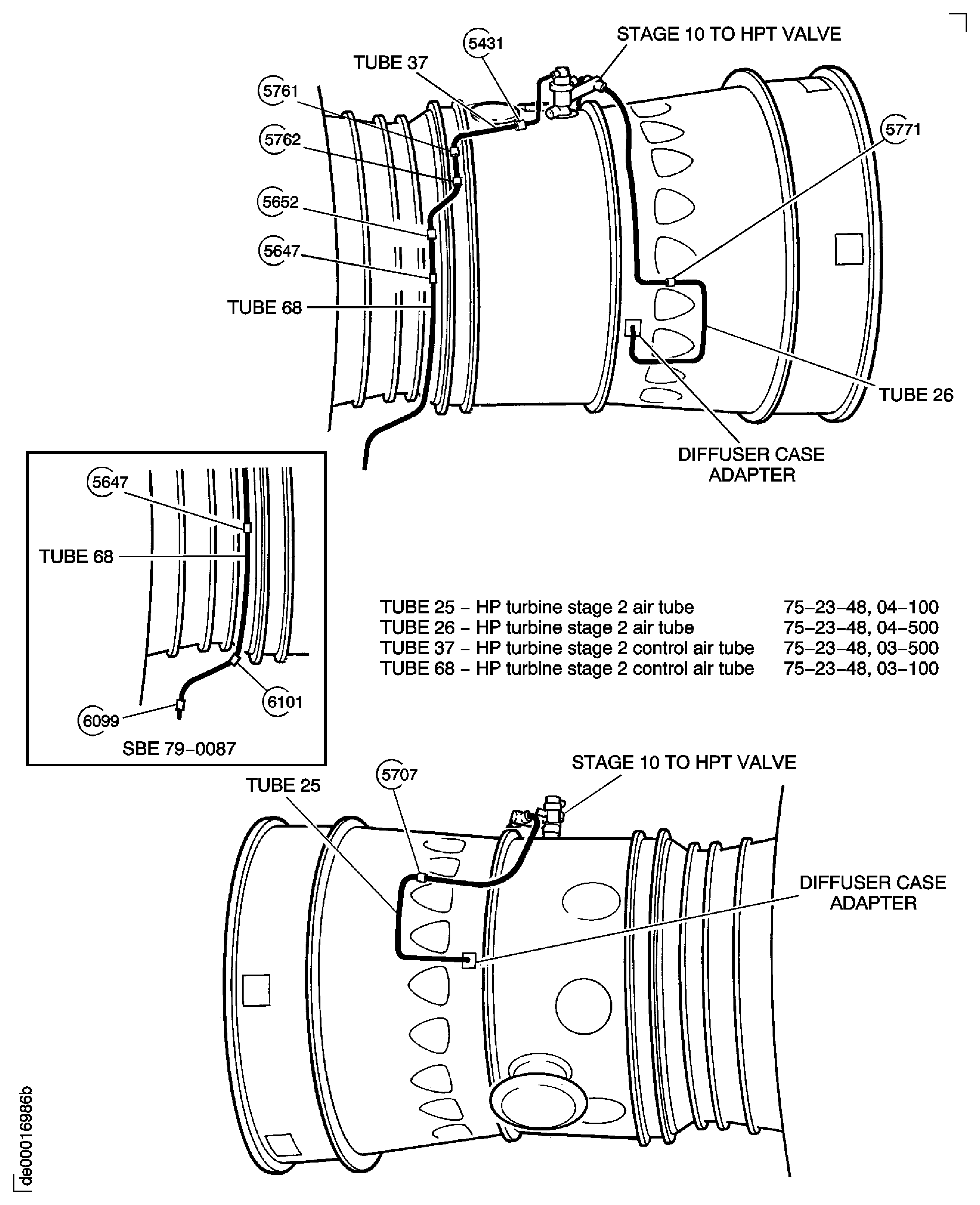

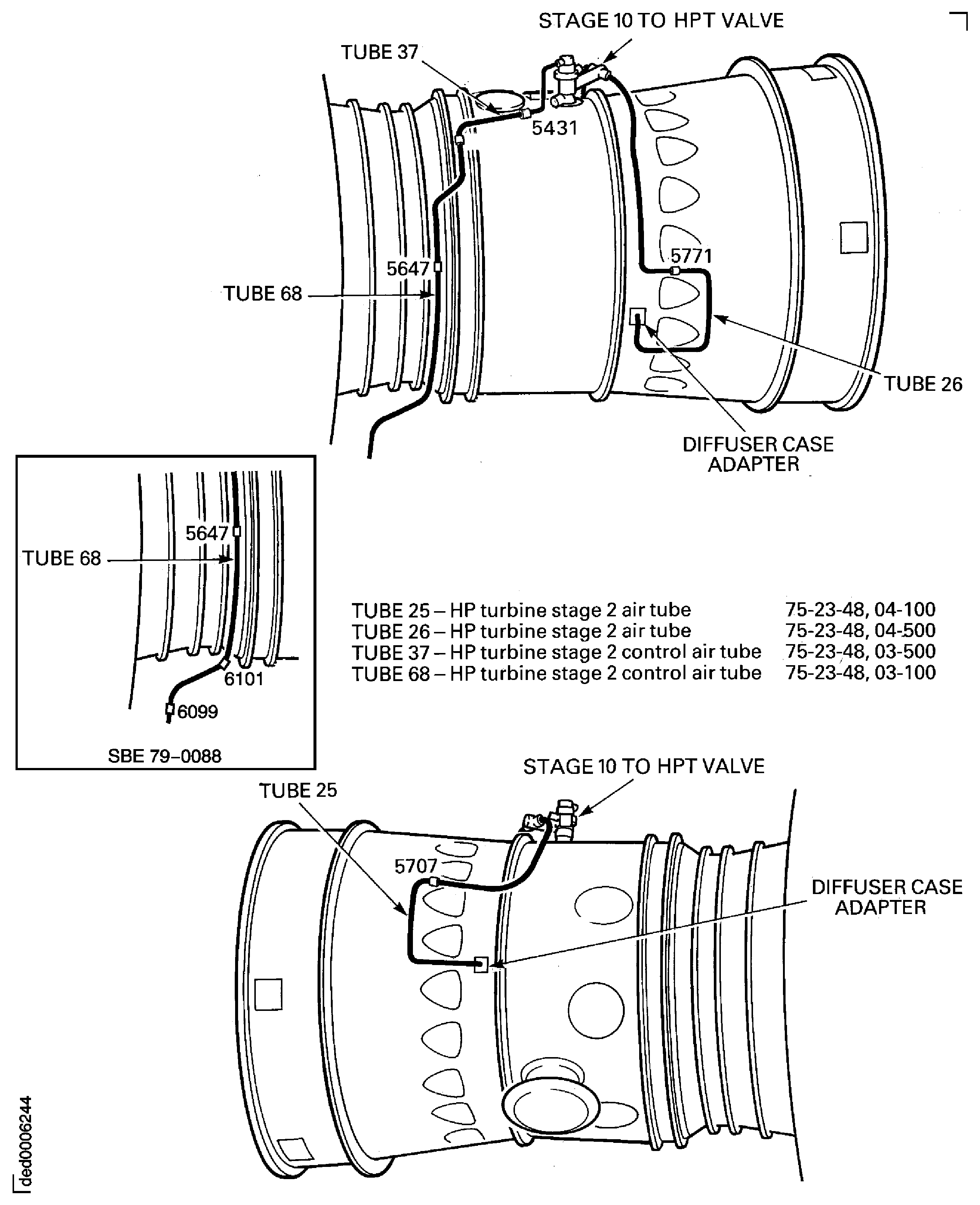

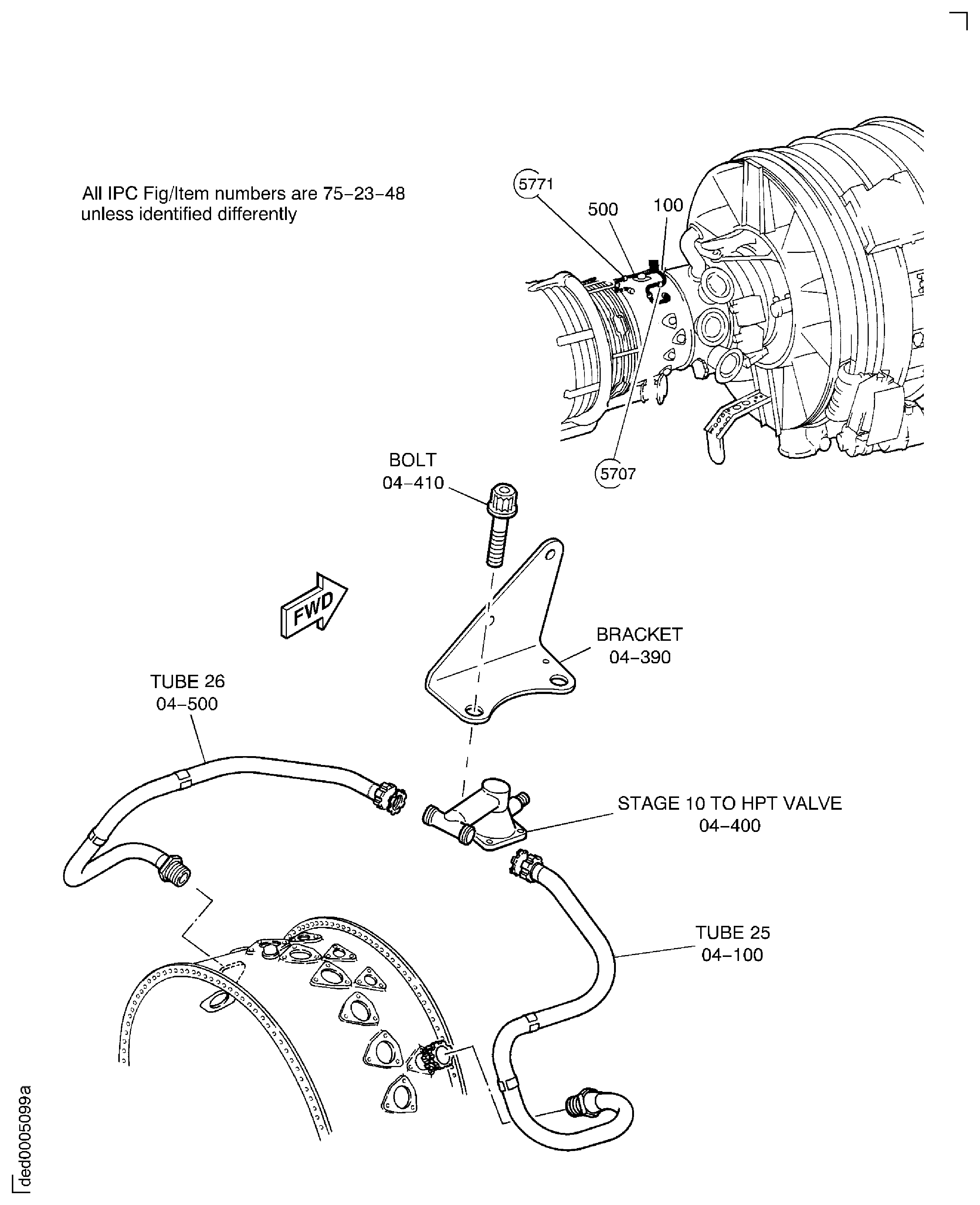

Use IAE 1R18003 Wrench 1 off to disconnect the tube 25 from the diffuser case adapter. Disconnect the tube 25 from the stage 10 to HPT air valve.

Remove the tube 25.

Use IAE 1R18001 Wrench 1 off to disconnect the tube 26 from the diffuser case adapter. Disconnect the tube 26 from the stage 10 to HPT air valve.

Remove the tube 26.

A1 series and A5 series Pre SBE 75-0081: Remove the tube 37.

A1 series and A5 series Pre SBE 75-0081: Remove the tube 37.

Pre SBE 79-0087 and SBE 79-0087: Remove the nut, the bolt, the washer and the clip from the clip position 5652.

SBE 79-0087 and SBE 79-0088: Remove the clips, the washers, the bolts and the nuts at the clip position 6099 and 6101.

A5 series: SBE 72-0189 Pre SBE 75-0081: Remove the clip, the washer, the bolt and the nut at the clip position 6101.

SBE 72-0189: Remove the clip, the bolt and the nut at the clip position 5647.

Pre SBE 72-0189, SBE 79-0087 and SBE 79-0088: Remove the bolt, the washer, the spacer, the clipnut and the clips from the clip position 5647.

Pre SBE 75-0081: Remove the tube 68.

A1 series and A5 series Pre SBE 75-0081: Remove the tube 68.

SUBTASK 72-00-40-020-093 Remove the HP Turbine Stage 2 Control Air Tubes (25, 26, 37 and 68) (Pre SBE 75-0081, Pre SBE 72-0189, Pre SBE 79-0087, Pre SBE 79-0088, SBE 72-0189, SBE 79-0087 and SBE 79-0088)

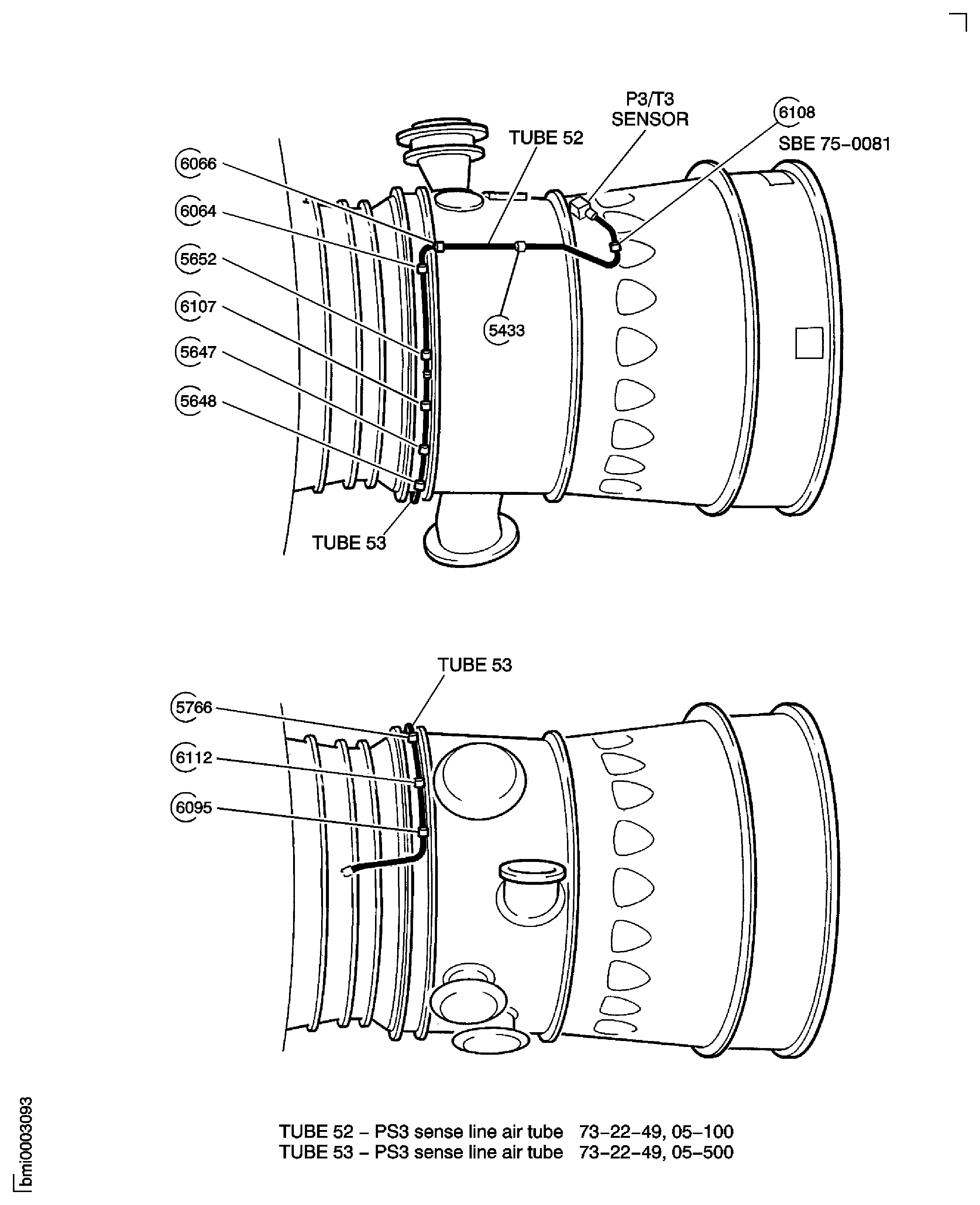

Refer to Figure.

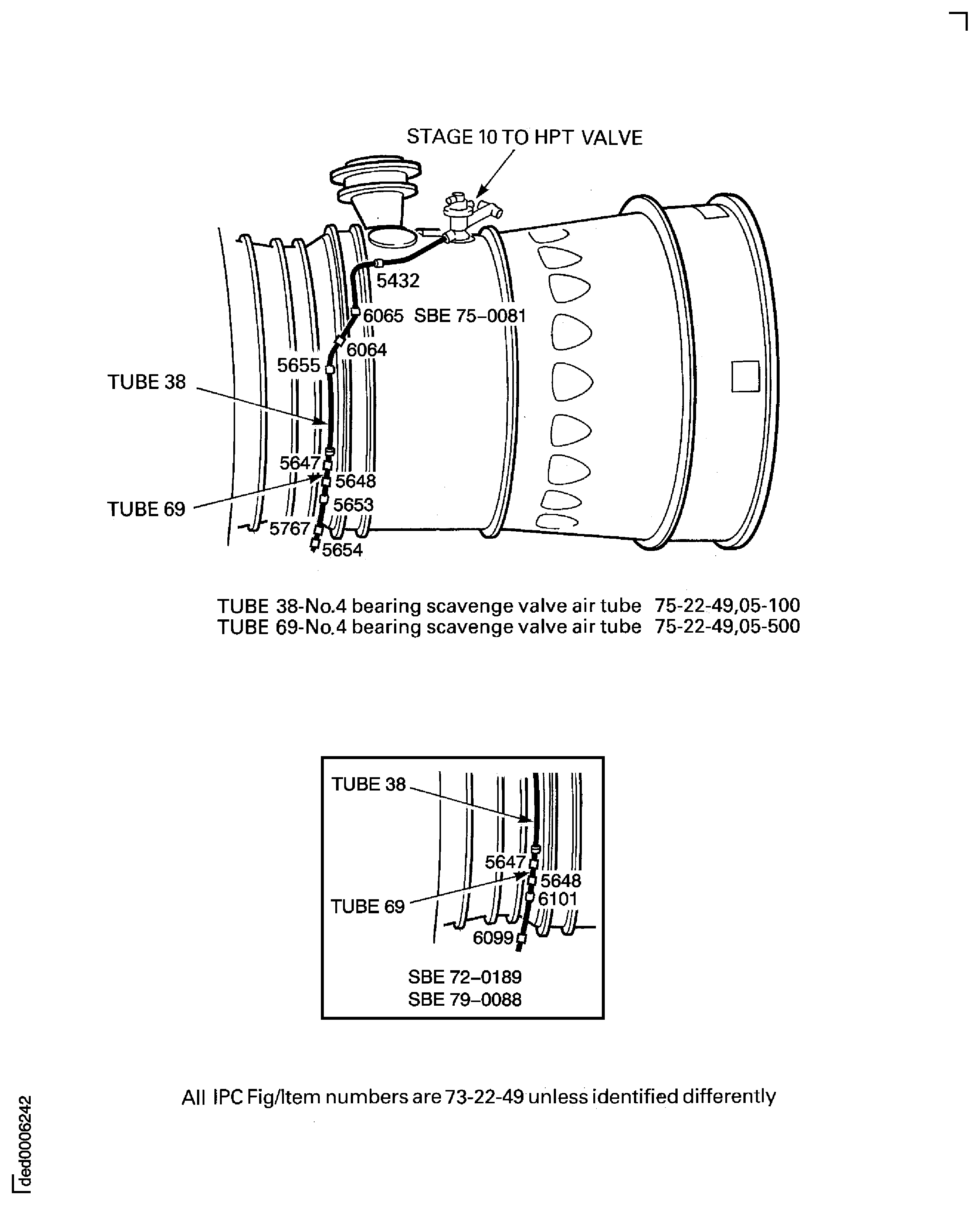

Pre SBE 72-0189, Pre SBE 79-0087 or Pre SBE 79-0088: Remove the bolt, the washers, the spacer, the nut and the clips from the clip position 5653. Remove the tube 69.

Pre SBE 79-0087 or Pre SBE 79-0088: Remove the bolts, the washers, the spacers, the nuts and the clips from the clip positions 5647, 5648, 5654 and 5767. Remove the tube 69.

SBE 79-0087 or SBE 79-0088: Remove the bolts, the washers, the spacers, the nuts and the clips from the clip positions 5647, 5648, 5668, 6076, 6099, 6100 and 6101. Remove the tube 69.

Remove the tube 38 and 69.

SUBTASK 72-00-40-020-094 Remove the No. 4 Bearing Scavenge Air Tubes (38 and 69) (Pre SBE 72-0189, Pre SBE 79-0087, Pre SBE 79-0088, SBE 79-0087 and SBE 79-0088)

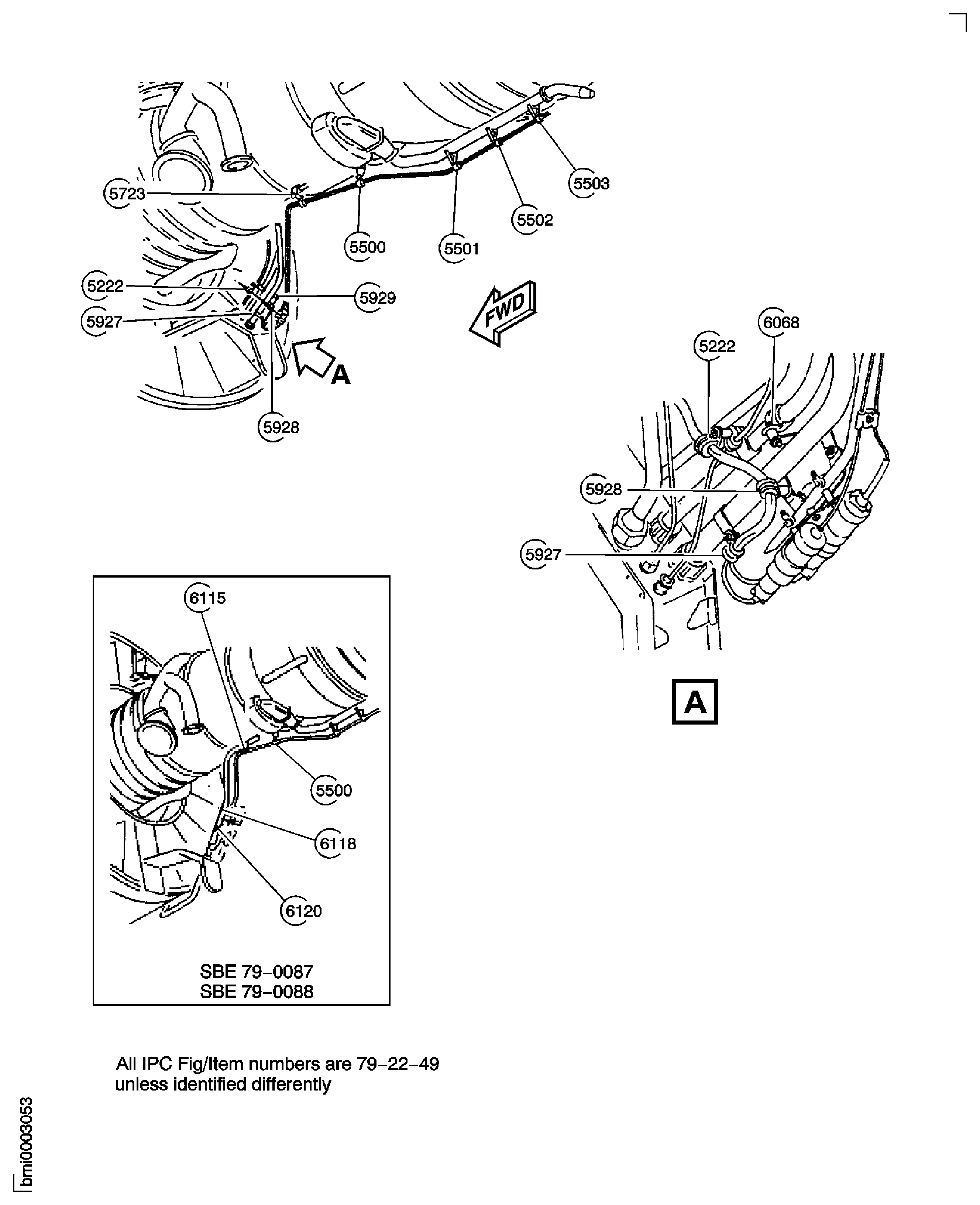

Refer to Figure.

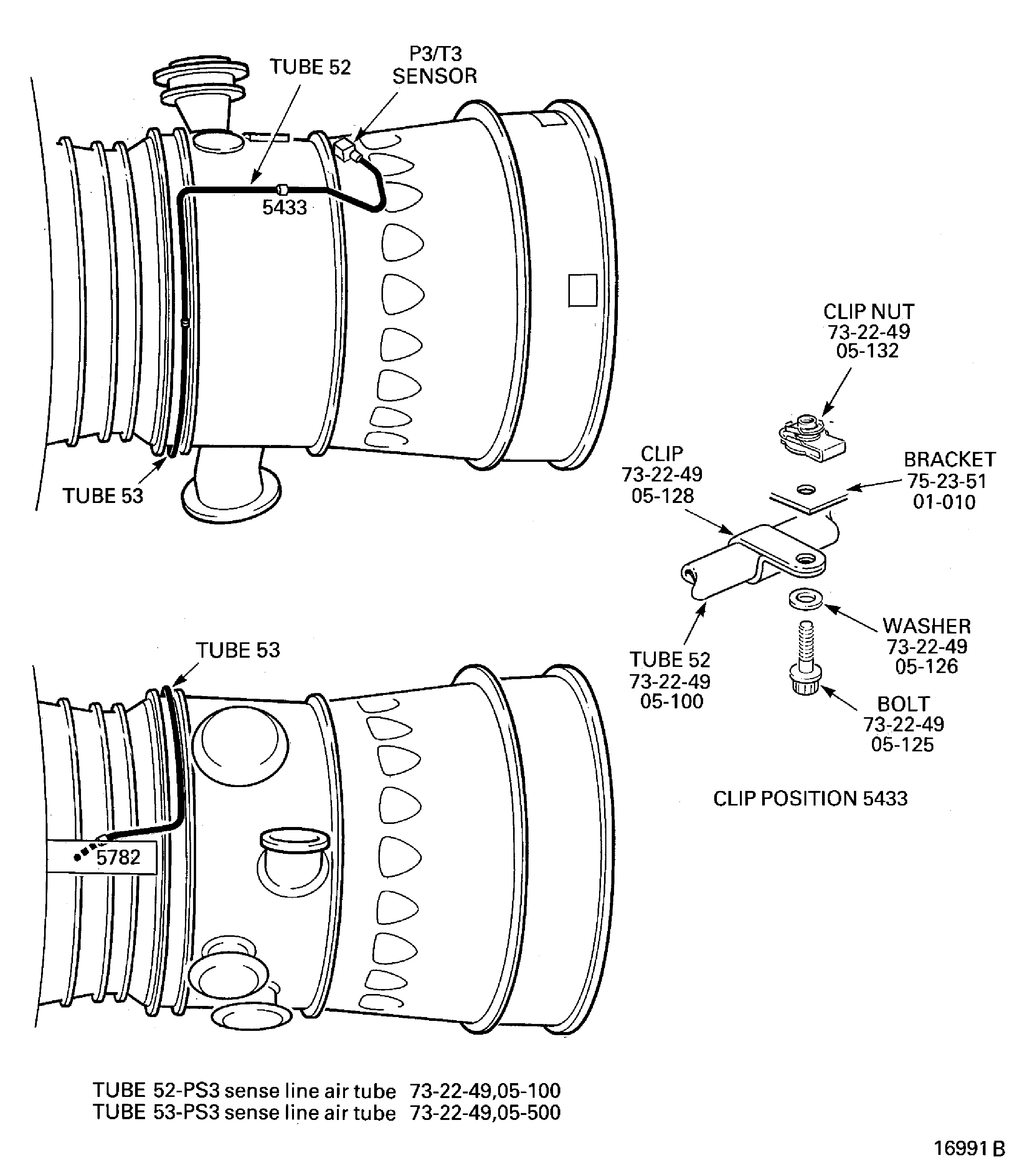

Pre SBE 79-0087: Remove the nuts, the bolts, the washers, the clips and the spacer from the clip positions 5650, 5782, 5766, 5648 and 5647.

SBE 79-0087: Remove the nuts, the bolts, the washers, the clips and the spacers from the clip positions 6095, 6112, 5766, 5648 and 5647.

Remove the tube 53.

SUBTASK 72-00-40-020-095-A00 A1 Series: Remove the PS3 Sensor Line Air Tubes (52 and 53) (Pre SBE 79-0087 and SBE 79-0087)

Refer to Figure.

NOTE

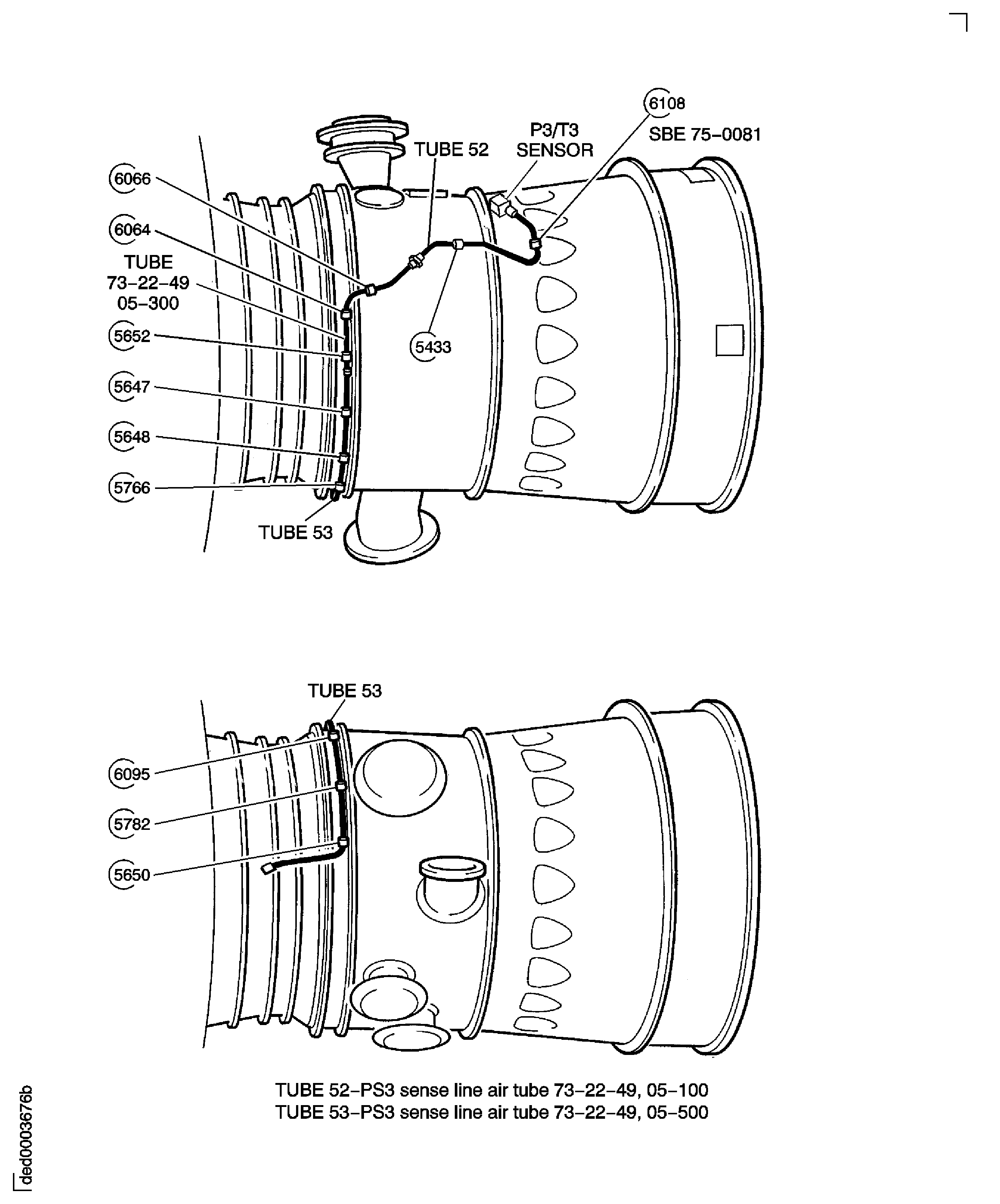

Tube 53 is temporarily attached to the tube 138 at the bifurcation panel.Disconnect the tube 53 from the PS3 tube Fuel System Air Tubes (73-22-49, 05-300) and from the tube 138.

Remove the tube 53.

Disconnect the tube Fuel System Air Tubes (73-22-49, 05-300) from the tube 52.

Remove the PS3 tube Fuel System Air Tubes (73-22-49, 05-300).

Pre SBE 75-0081: Remove the bolt, the washer, the clipnut and the clips from the clip position 5433.

SBE 75-0081: Remove the bolts, the washers, the clipnuts, the clips and the spacer from the clip positions 5433 and 6108.

Remove the PS3 tube Fuel System Air Tubes (73-22-49, 05-300).

SUBTASK 72-00-40-020-095-B00 A5 Series: Remove the PS3 Sensor Line Air Tubes (52 and 53) and Tube (05-300) (Pre SBE 79-0088, Pre SBE 75-0081 and SBE 75-0081)

Refer to Figure.

Pre SBE 75-0081: Remove the bolts, the washers, the nuts, the clips and the spacers from the clip positions 5652, 6064, 6066 and 5433.

SBE 75-0081: Remove the bolts, the washers, the nuts, the clips and the spacers from the clip positions 5652, 6064, 6066, 5433 and 6108..

Remove the tube 52.

SUBTASK 72-00-40-020-095-C00 A5 Series: Remove the PS3 Sensor Line Air Tubes (52 and 53) (Pre SBE 75-0081, SBE 75-0081 and SBE 79-0088)

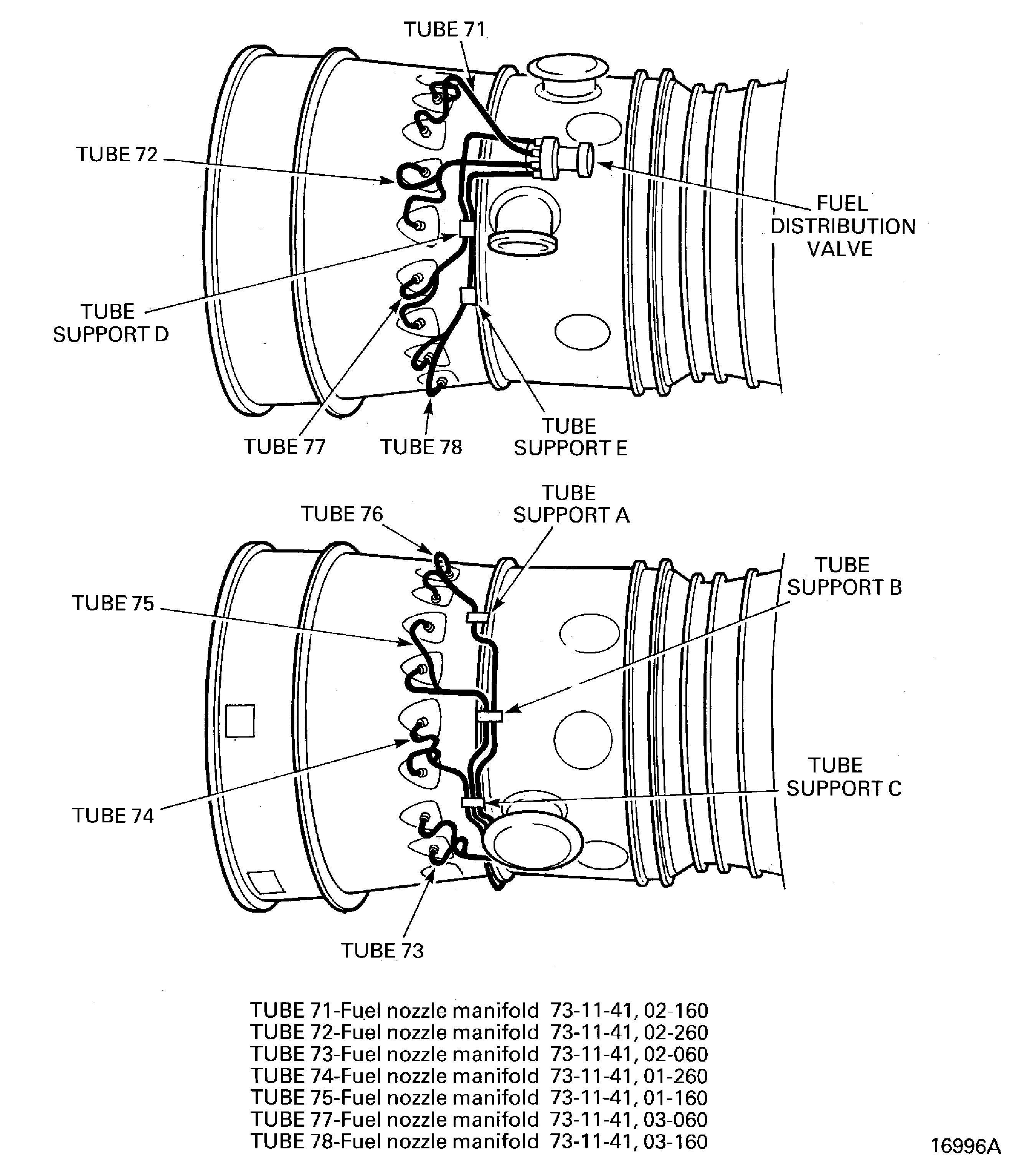

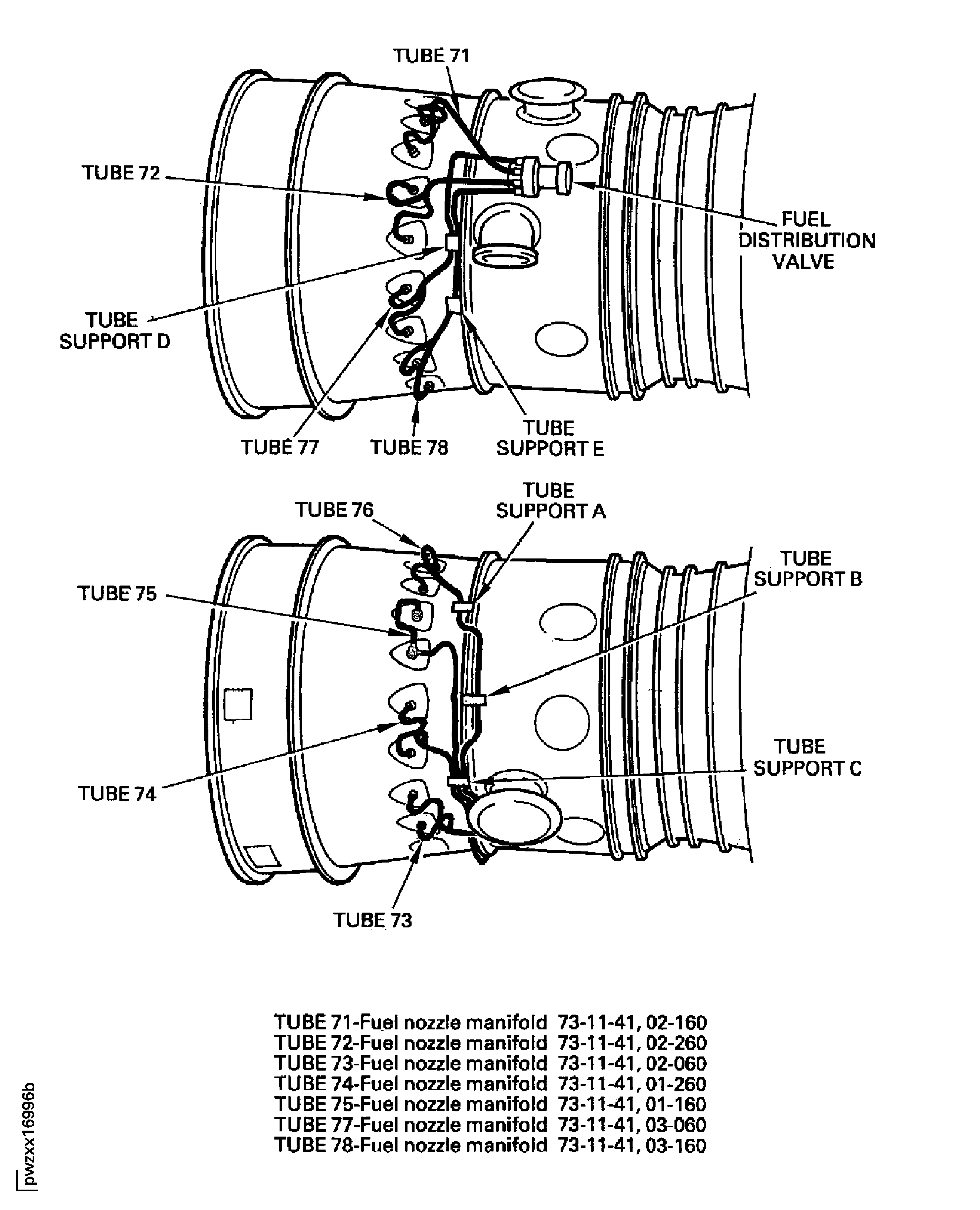

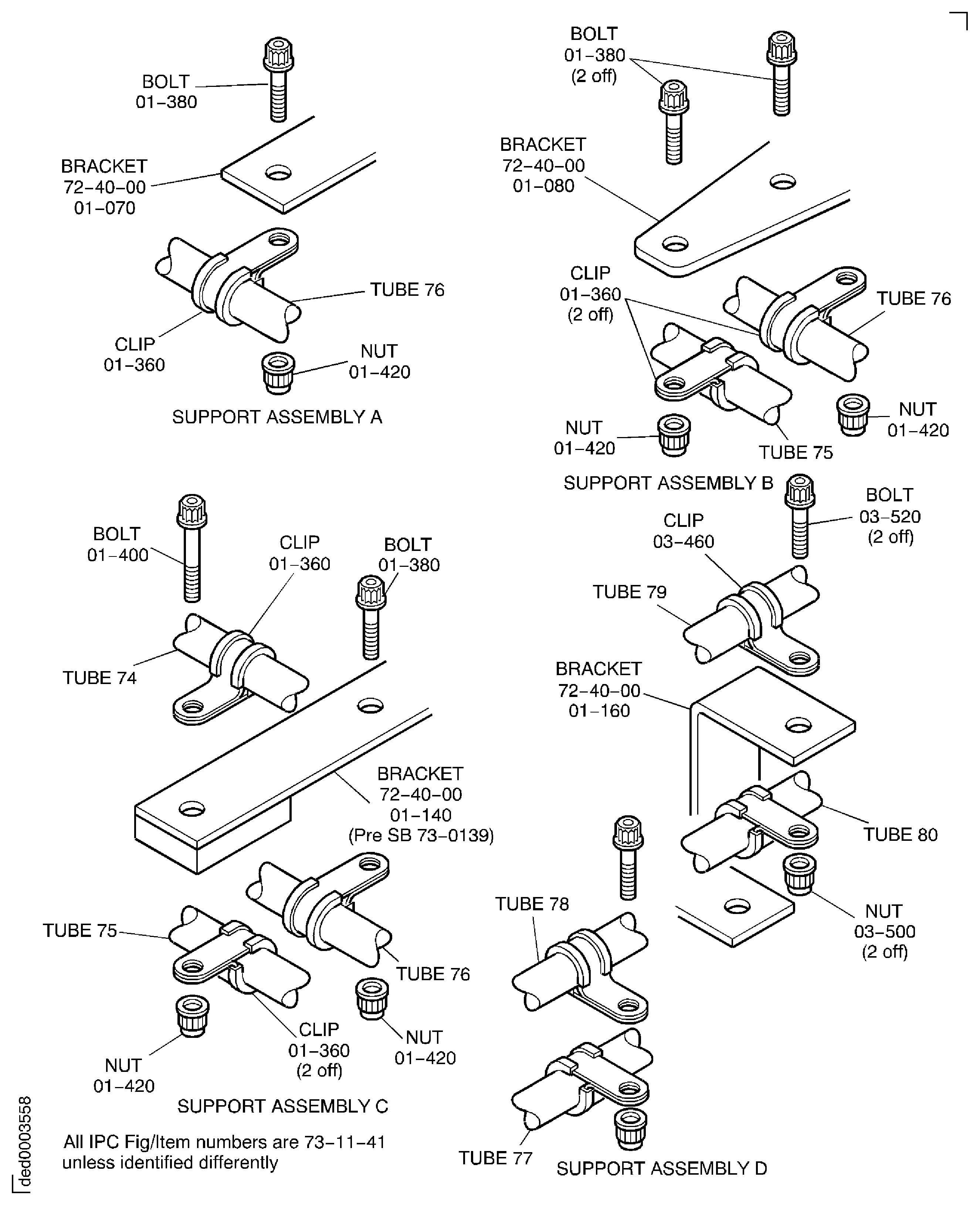

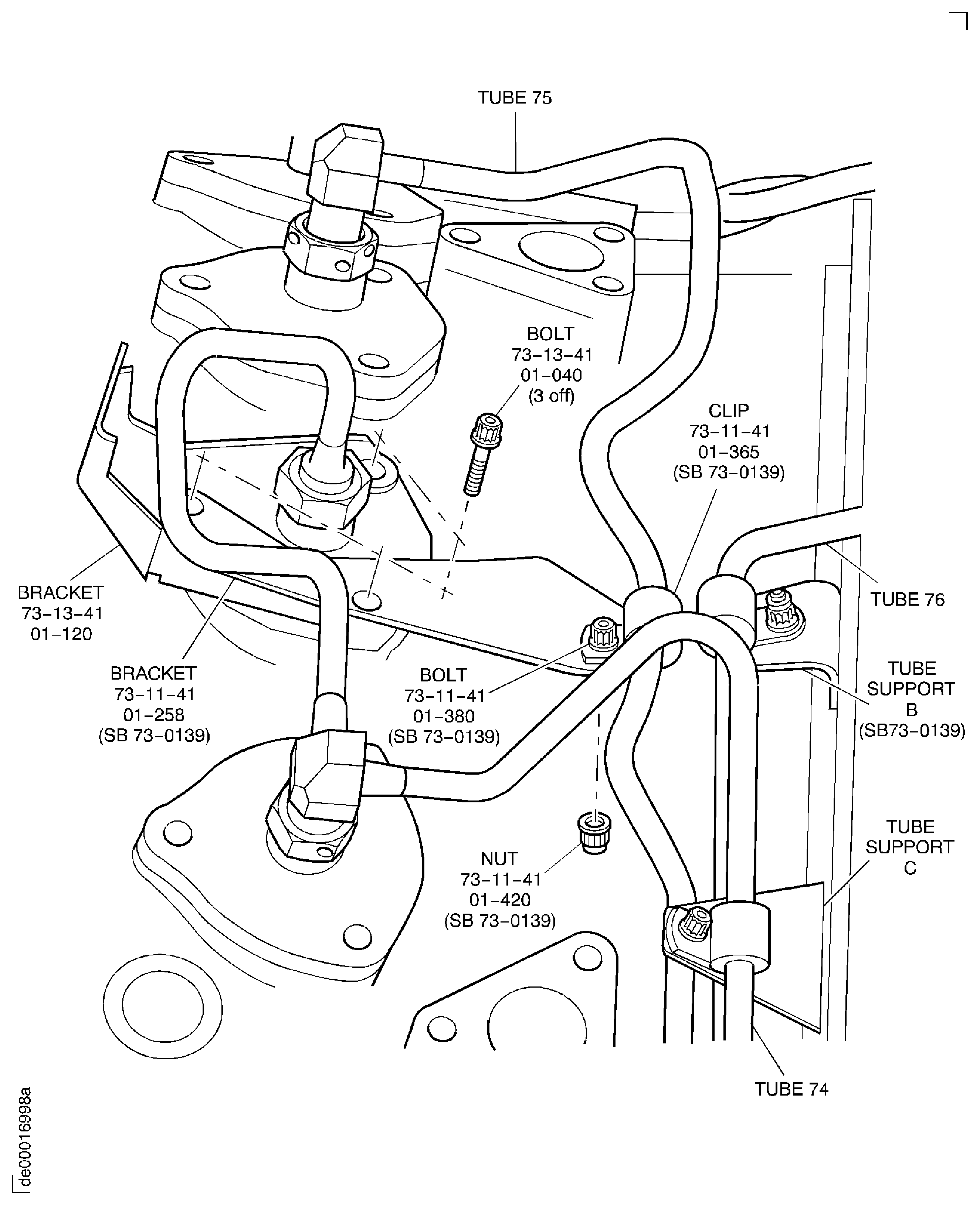

Use IAE 1P16139 Wrench 1 off to disconnect the tubes 74, 75 and 76 from the fuel distribution valve.

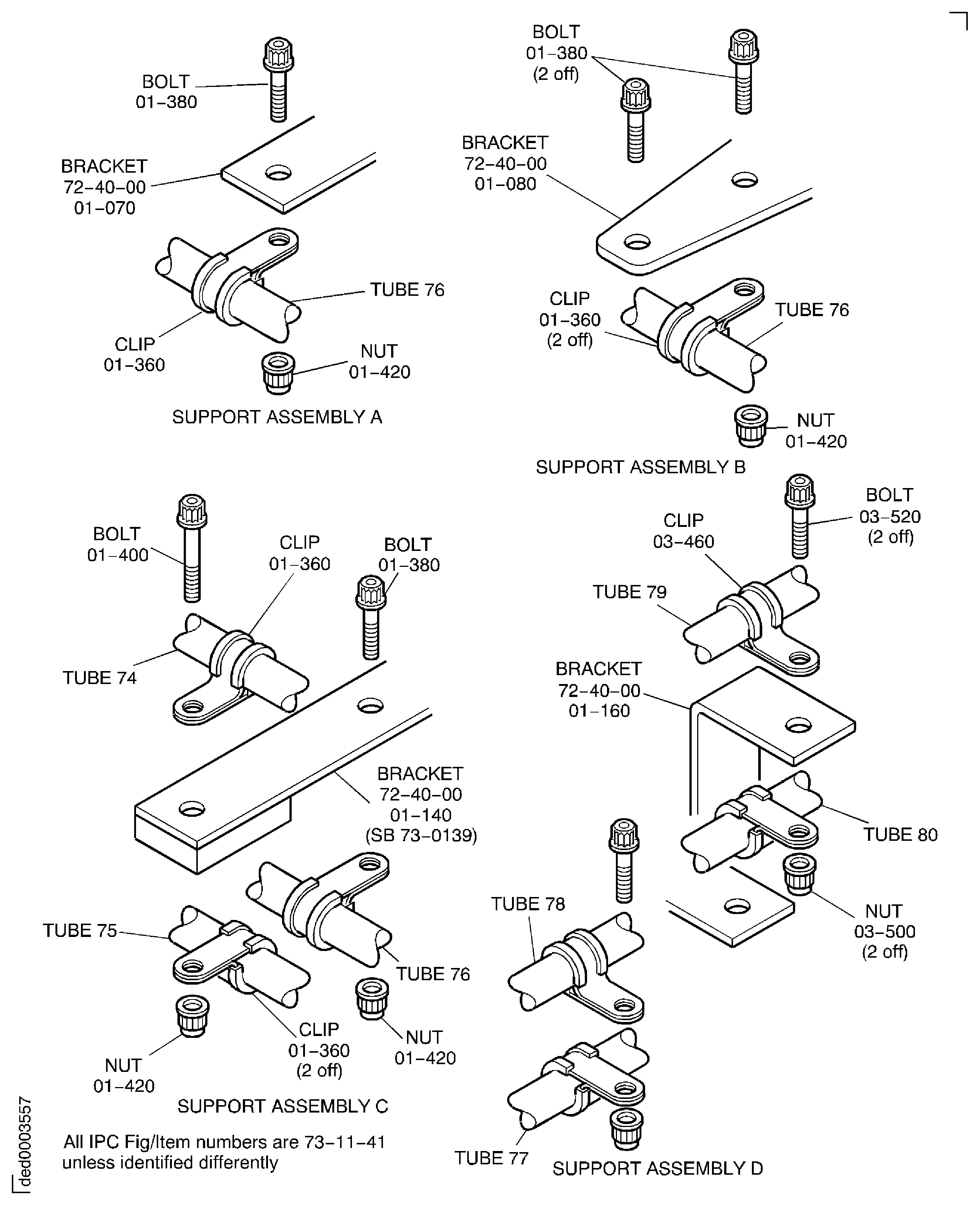

Remove the nuts, the bolts and the clips at the brackets HPC Module - Attaching Parts (72-40-00, 01-140), HPC Module - Attaching Parts (72-40-00, 01-080) and HPC Module - Attaching Parts (72-40-00, 01-070).

Remove the tube 74, 75 and 76.

Use IAE 1P16139 Wrench 1 off to disconnect the 71, 72 and 73 from the fuel distribution valve.

Remove the tubes 71, 72 and 73.

Use IAE 1P16139 Wrench 1 off to disconnect the tubes 77 thru 80 from the fuel distribution valve.

Remove the nuts, the bolts and the clips at the brackets HPC Module - Attaching Parts (72-40-00, 01-160), HPC Module - Attaching Parts (72-40-00, 01-170), HPC Module - Attaching Parts (72-40-00, 01-100) and HPC Module - Attaching Parts (72-40-00, 01-060).

Remove the tubes 77 thru 80.

SUBTASK 72-00-40-020-097-A00 Remove the Fuel Nozzle Manifolds (Pre SBE 73-0139)

NOTE

Before a fuel nozzle manifold assembly is removed it must be identified with its engine position on a label.Use IAE 1P16139 Wrench 1 off to disconnect the tubes 74, 75 and 76 from the fuel distribution valve.

Remove the nut, the bolt and the clip at the bracket Fuel Nozzle Supply Fuel Manifolds (73-11-41, 01-258).

Remove the nuts, the bolts and the clips at the brackets HPC Module - Attaching Parts (72-40-00, 01-070), HPC Module - Attaching Parts (72-40-00, 01-080) and HPC Module - Attaching Parts (72-40-00, 01-140).

Remove the tube 74, 75 and 76.

Use IAE 1P16139 Wrench 1 off to disconnect the 71, 72 and 73 from the fuel distribution valve.

Remove the tubes 71, 72 and 73.

Remove the nuts, the bolts and the clips at the brackets =HPC Module - Attaching Parts (72-40-00, 01-160), HPC Module - Attaching Parts (72-40-00, 01-170), HPC Assembly (72-41-00, 01-100) and HPC Assembly (72-41-00, 01-060).

Use IAE 1P16139 Wrench 1 off to disconnect the tubes 77 thru 80 from the fuel distribution valve.

Remove the nuts, the bolts and the clips at the brackets HPC Module - Attaching Parts (72-40-00, 01-160), HPC Assembly (72-41-00, 01-170), HPC Assembly (72-41-00, 01-100) and HPC Assembly (72-41-00, 01-060).

Remove the tubes 77 thru 80.

SUBTASK 72-00-40-020-097-B00 Remove the Fuel Nozzle Manifolds. (SBE 73-0139)

NOTE

Before a fuel nozzle manifold assembly is removed it must be identified with its engine position on a label.Refer to Figure.

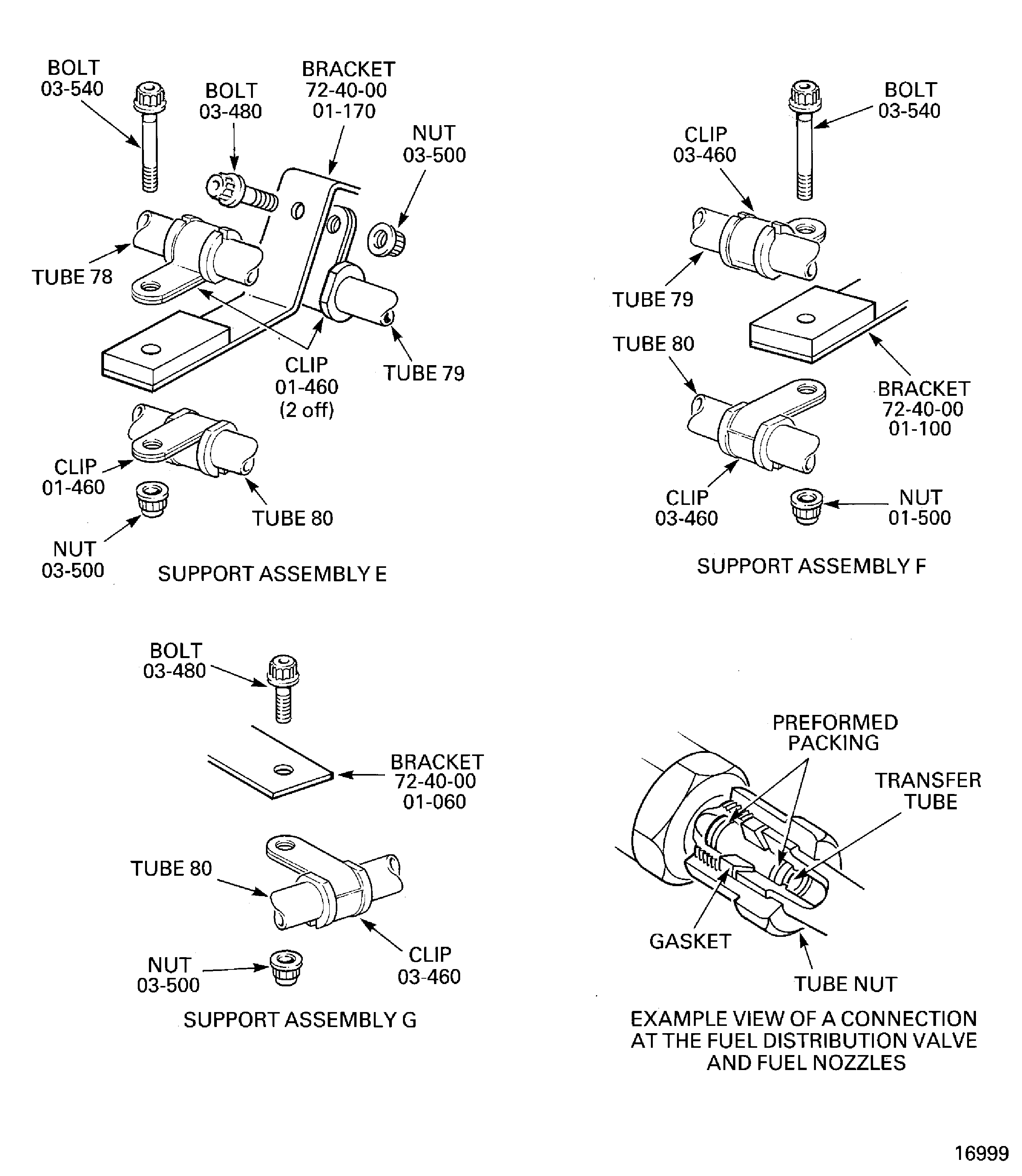

Remove the raceway Fuel System Air Tubes (73-22-49, 05-900).

SUBTASK 72-00-40-020-100 Remove the Tube Raceway

Refer to Figure.

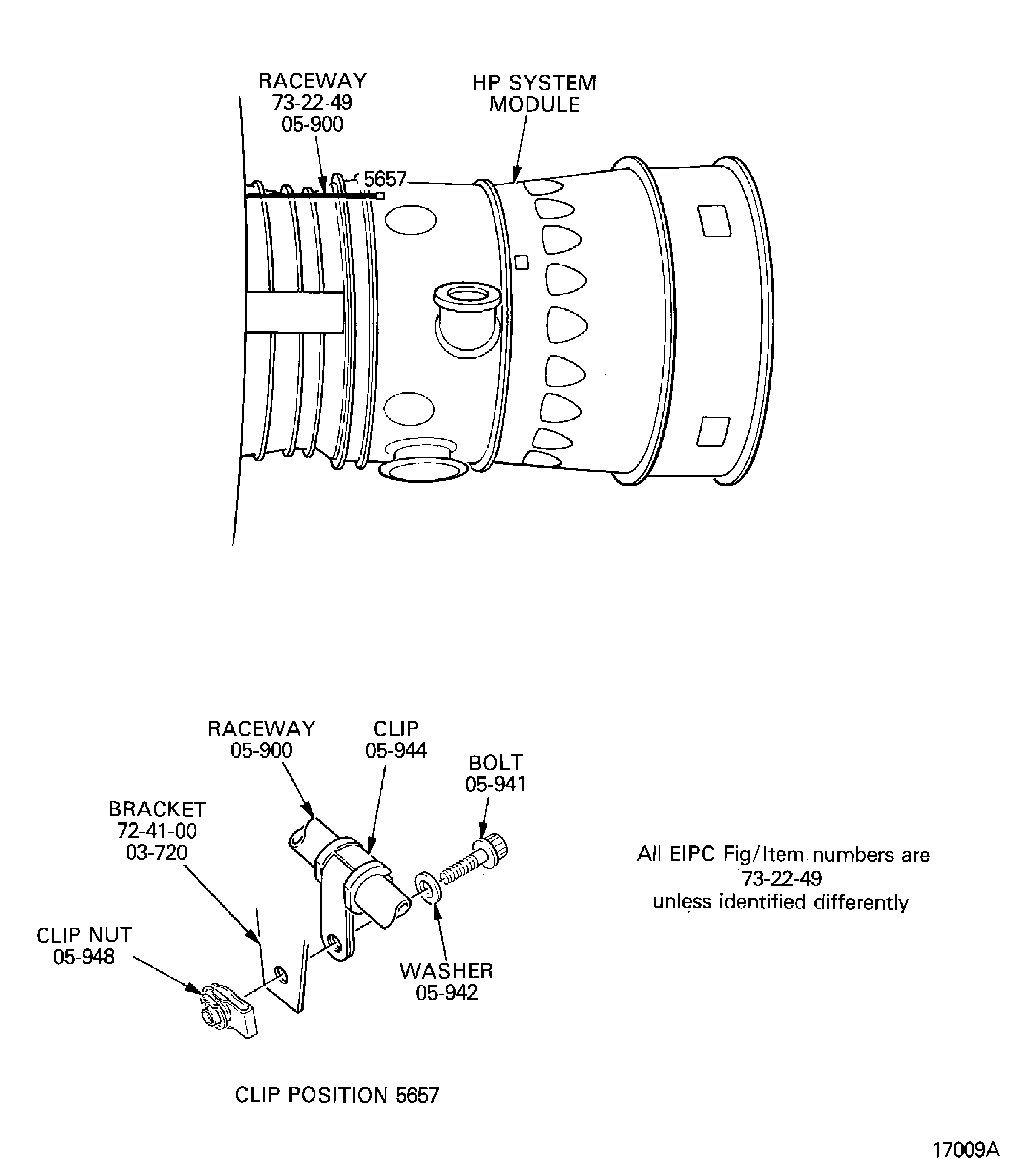

NOTE

The bleed valve must have its maintenance completed, as given in the Dunlop Component Maintenance Manual (75-32-54).

The silencer and the seal assembly must have its maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

Remove the 12 bolts and the 12 nuts (together with the two brackets) that attach the bleed valve to the air off-take duct and remove the bleed valve.

Remove the stage 10 silencer, the seal assembly and the bleed valve.

SUBTASK 72-00-40-020-104-A00 Remove the Stage 10 Silencer, the Seal Assembly and the Bleed Valve (Pre SBE 75-0072)

Refer to Figure.

NOTE

The bleed valve must have its maintenance completed, as given in the Dunlop Component Maintenance Manual (75-32-54).

The silencer assembly must have its maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

Remove the 12 bolts and the 12 nuts (together with the two brackets) that attach the bleed valve to the air off-take duct and remove the bleed valve.

Remove the stage 10 silencer assembly and the bleed valve from the 3 o'clock position.

SUBTASK 72-00-40-020-104-B00 Remove the Stage 10 Silencer Assembly and the Bleed Valve (SBE 75-0072)

Refer to Figure.

SUBTASK 72-00-40-020-129 Remove the Air Off-Take Ducts

Refer to Figure.

NOTE

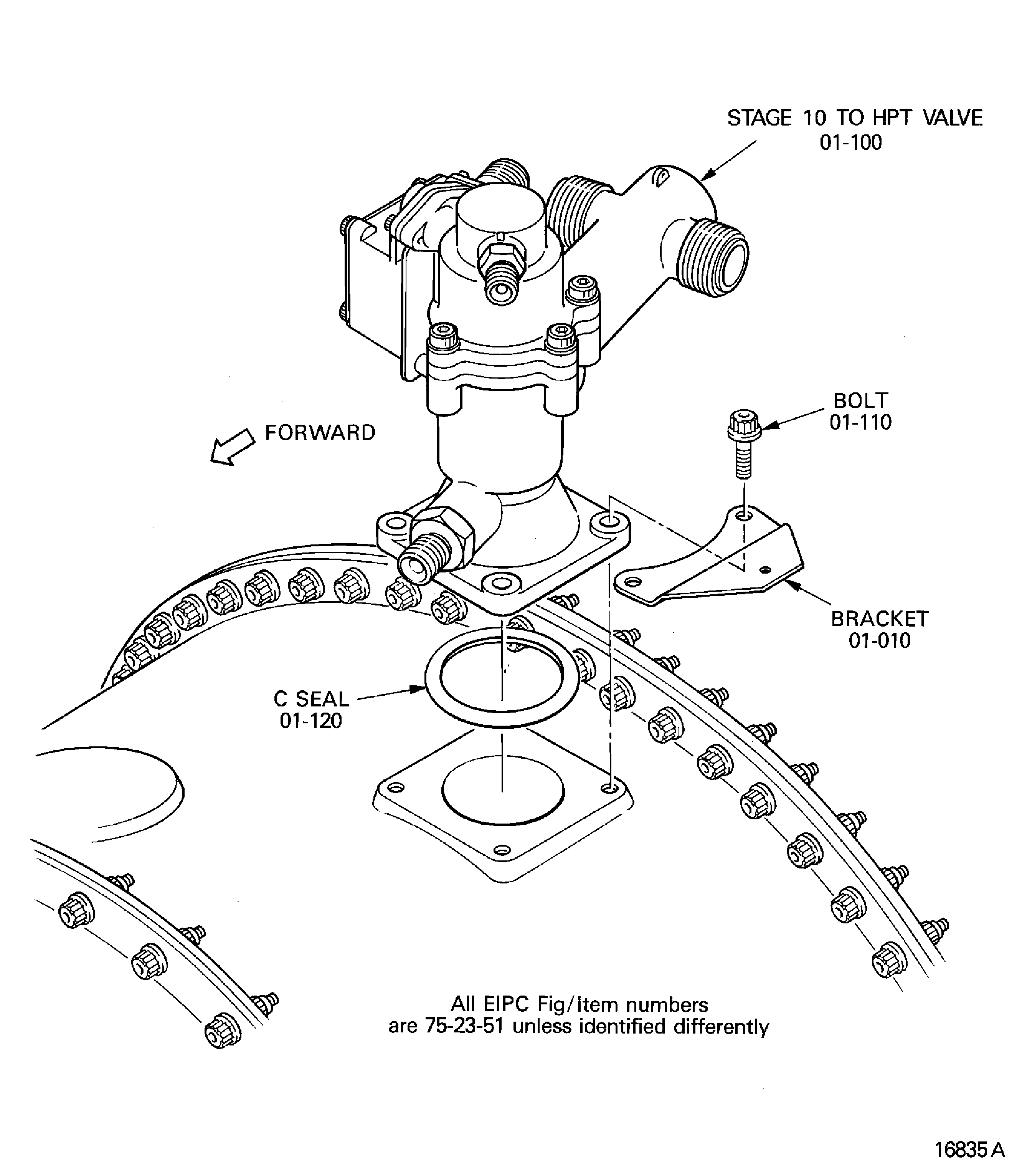

The stage 10 to HPT air valve must have its maintenance completed, as given in the Parker Hannifin Component Maintenance Manual (75-23-51).Remove the four bolts (together with the bracket AIR-STAGE 10 TO HPT AIR VALVE (75-23-51, 01-010) that attach the stage 10 to HPT air valve to the HP compressor case and remove the valve and the C seal.

SUBTASK 72-00-40-020-108-A00 Remove the Stage 10 to HPT Air Valve (Pre SBE 75-0081)

Refer to Figure.

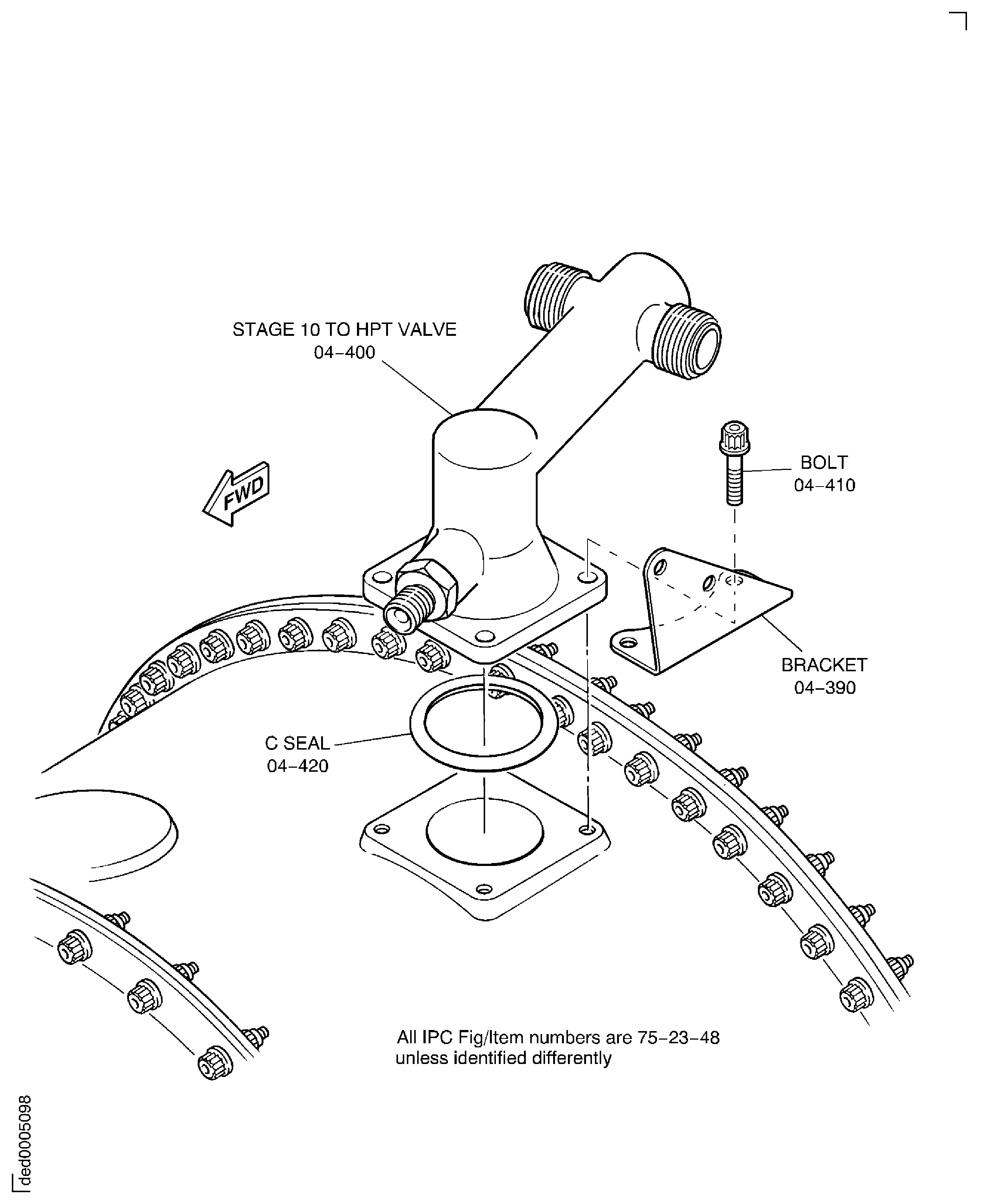

SBE 75-0081: Deletion of HPC stage 10 make-up air valve and associated hardware

NOTE

The stage 10 to HPT air valve must have its maintenance completed, as given in the Parker Hannifin Component Maintenance Manual (75-23-48).Remove the four bolts (together with the bracket Turbine Cooling Air (TCA) Controlled Air Tubes (75-23-48, 04-390) that attach the stage 10 to HPT air valve to the HP compressor case and remove the valve and the C seal.

SUBTASK 72-00-40-020-108-B00 A5 Series: Remove the Stage 10 to HPT Air Valve (SBE 75-0081)

Refer to Figure.

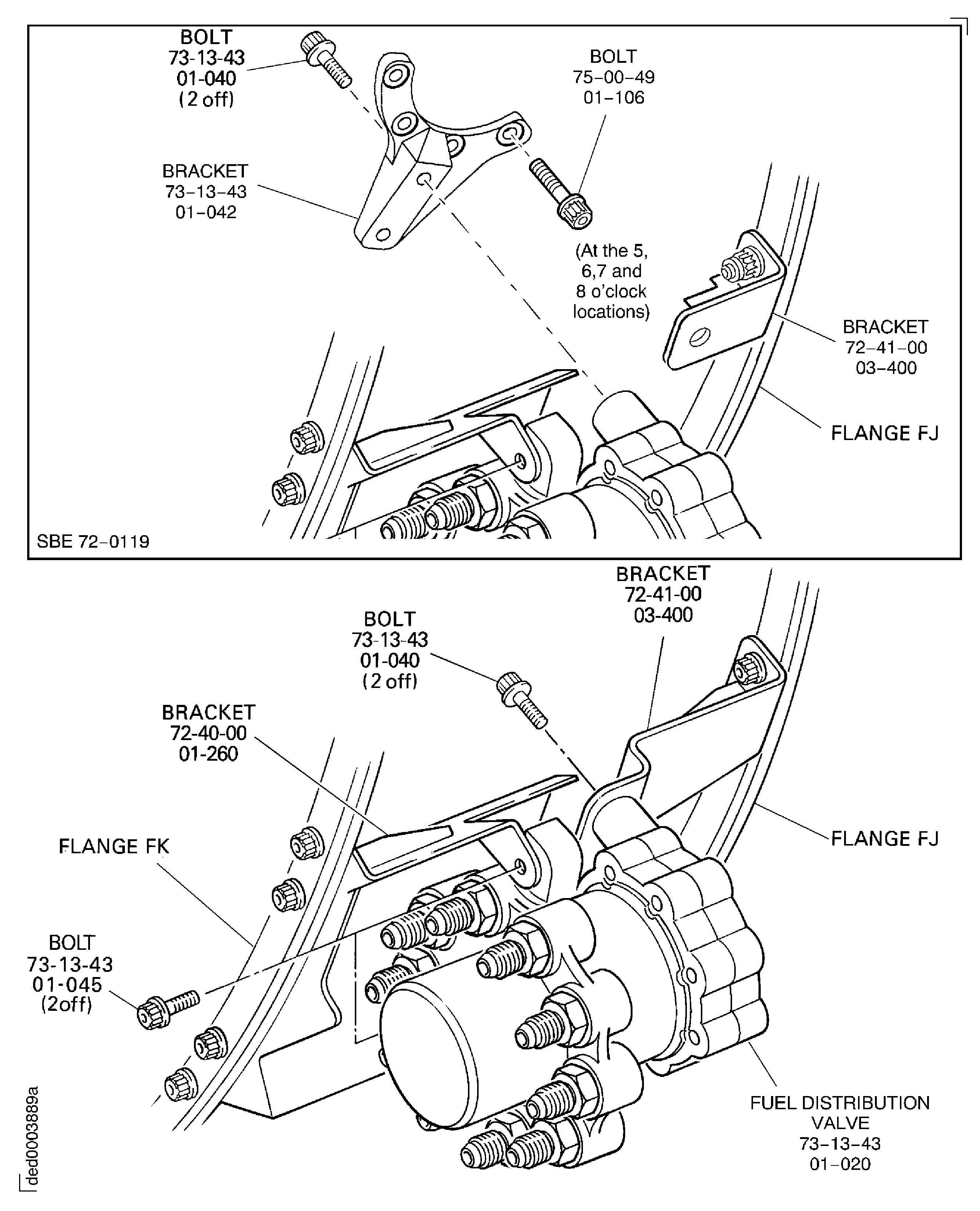

Remove the two bolts that attach the distribution valve to the bracket HPC Assembly(72-41-00, 03-400) on the HP compressor case flange FJ.

NOTE

The fuel distribution valve must have its maintenance completed, as given in the Hamilton Standard Component Maintenance Manual (73-13-43).Remove the two bolts that attach the distribution valve to the bracket HPC Module - Attaching Parts(72-40-00, 01-260) on the HP compressor case flange FK. Remove the distribution valve.

SUBTASK 72-00-40-020-109-A00 Remove the Fuel Distribution Valve (Pre SBE 72-0119)

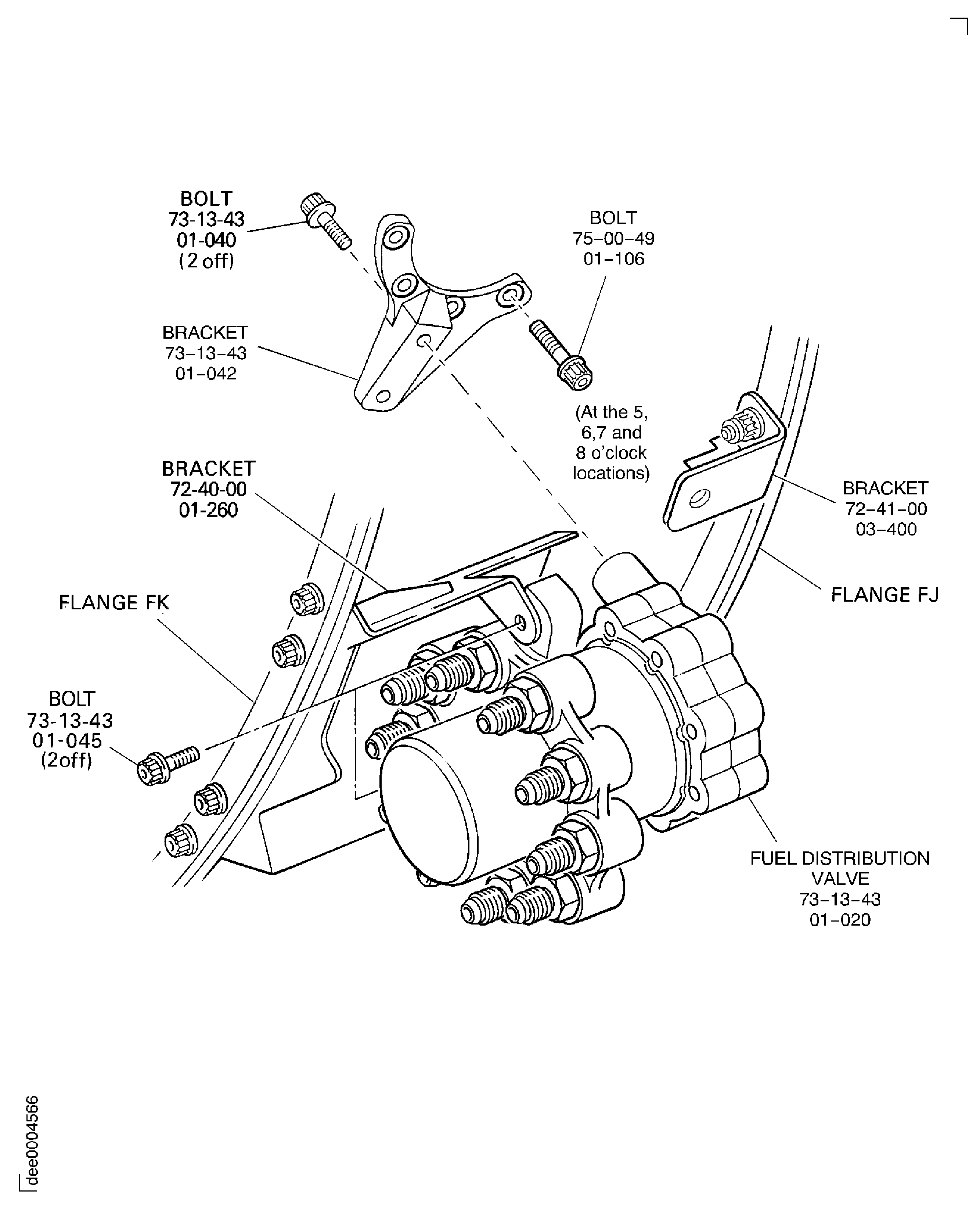

A1 series: Refer to TASK 72-00-40-020-003-A00 (REMOVAL-003, CONFIG-001) SUBTASK 72-00-40-020-105 for the removal of the upper part of bracket ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-042).

A5 series: Refer to TASK 72-00-40-020-003-B00 (REMOVAL-003, CONFIG-002) SUBTASK 72-00-40-020-204 for the removal of the upper part of bracket ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-042).

Remove the two bolts ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-040) that attach the distribution valve to the bracket ENGINE FUEL AND CONTROL-FUEL DISTRIBUTION VALVE (73-13-43, 01-042).

NOTE

The fuel distribution valve must have its maintenance completed, as given in the Hamilton Standard Component Maintenance Manual (73-13-43).Remove the two bolts that attach the distribution valve to the bracket HPC Module - Attaching Parts (72-40-00, 01-260) on the HP compressor case flange FK. Remove the distribution valve.

SUBTASK 72-00-40-020-109-B00 A1 and A5 Series: Remove the Fuel Distribution Valve (SBE 72-0119, Pre SBE 79-0087, Pre SBE 79-0088, SBE 79-0087 and SBE 79-0088)

Refer to Figure.

NOTE

The igniter plugs must have their maintenance completed, as given in the NGK Component Maintenance Manual (74-21-41).Remove each of the two igniter plugs Igniter Plug (74-21-41, 01-100).

SUBTASK 72-00-40-020-111 Remove the Igniter Plugs

Refer to Figure.

SUBTASK 72-00-40-020-112 Remove the P3/T3 Sensor

Refer to Figure.

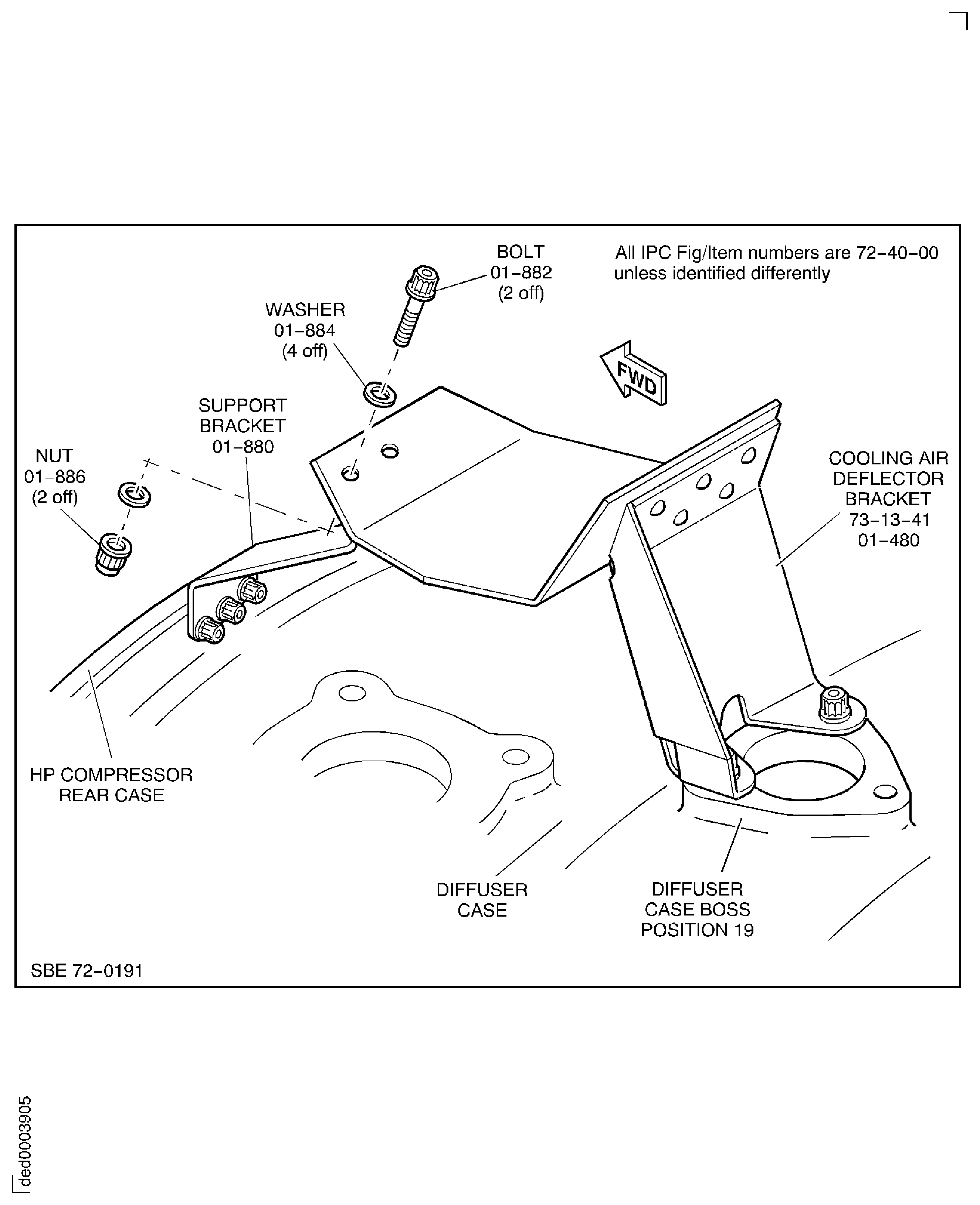

Remove the two bolts HPC Module - Attaching Parts (72-40-00, 01-882), four washers HPC Module - Attaching Parts (72-40-00, 01-884) and the two nuts HPC Module - Attaching Parts (72-40-00, 01-886) which attach the support bracket HPC Module - Attaching Parts (72-40-00, 01-880) to the bracket Fuel Nozzle And Support Assembly (73-13-41, 01-480).

SUBTASK 72-00-40-020-210 A5 Series: Disconnect Support Bracket (72-40-00,01-880) from the Air Deflector Bracket Assembly (73-13-41 01-480) (SBE 72-0191)

SUBTASK 72-00-40-020-113-A00 Remove the Fuel Nozzles (Pre SBE 73-0139)

SUBTASK 72-00-40-020-113-B00 Remove the Fuel Nozzles (SBE 73-0139)

Figure: Remove the thermal anti-icing ducts

Remove the thermal anti-icing ducts

Figure: Remove the engine control link harness

Sheet 1

Figure: Remove the engine control link harness

Sheet 2

Figure: SBE 71-0120: Remove the engine control link harness

Sheet 3

Figure: SBE 75-0081: Install the engine control link harness

Sheet 4

Figure: Remove the air deflector bracket

Sheet 1

Figure: SBE 72-0329: Remove the air deflector bracket

Sheet 2

Figure: Remove the Tubes (16, 20, 55 and 56)

Sheet 1

Figure: Pre SBE 79-0087 and Pre SBN 71-0272: Remove the Tubes (16, 20, 55 and 56)

Sheet 2

Figure: Remove the Tubes (16, 20, 55 and 56)

Sheet 3

Figure: A1 Series: Remove the HP Turbine Stage 2 Control Air Tubes (25, 26, 37 and 68)

Sheet 1

Figure: A5 Series: Pre SBE 75-0081 Remove the HP Turbine Stage 2 Control Air Tubes (25, 26, 37 and 68)

Sheet 2

Figure: A5 Series: SBE 75-0081 Remove the HP turbine stage 2 control air tubes (25 and 26)

Sheet 3

Figure: Remove the No.4 Bearing Scavenge Air Tubes (38 and 69)

Sheet 1

Figure: A1 Series: Remove the No.4 Bearing Scavenge Air Tubes (38 and 69)

Sheet 2

Figure: A5 Series: Remove the No.4 Bearing Scavenge Air Tubes (38 and 69)

Sheet 3

Figure: A1 Series: Remove the PS3 Sensor Line Air Tubes

Sheet 1

Figure: A5 Series Pre SBE 75-0081: Remove the PS3 Sensor Line Air Tubes

Sheet 2

Figure: A5 Series SBE 75-0081: Remove the PS3 Sensor Line Air Tubes

Sheet 3

Figure: Pre SBE 73-0139: Remove the fuel nozzle manifolds

Sheet 1

Figure: SBE 73-0139: Remove the fuel nozzle manifolds

Sheet 2

Figure: Remove the fuel nozzle manifolds

Sheet 3

Figure: Pre SBE 73-0139: Remove the fuel nozzle manifolds

Sheet 4

Figure: Remove the fuel nozzle manifolds

Sheet 5

Figure: Remove the tube raceway

Remove the tube raceway

Figure: Remove the HP Compressor Stage 10 Bleed Valve Assemblies and the Air Off-Take Ducts

Remove the HP Compressor Stage 10 Bleed Valve Assemblies and the Air Off-Take Ducts

Figure: A1 Series and A5 Series Pre SBE 75-0081: Remove the stage 10 to HPT air valve

Sheet 1

Figure: A5 Series SBE 75-0081: Remove the stage 10 to HPT air valve

Sheet 2

Figure: A1 Series: Remove the fuel distribution valve

Sheet 1

Figure: A5 Series: Remove the fuel distribution valve

Sheet 2

Figure: Remove the igniter plugs

Remove the igniter plugs

Figure: Remove the P3/T3 sensor

Remove the P3/T3 sensor

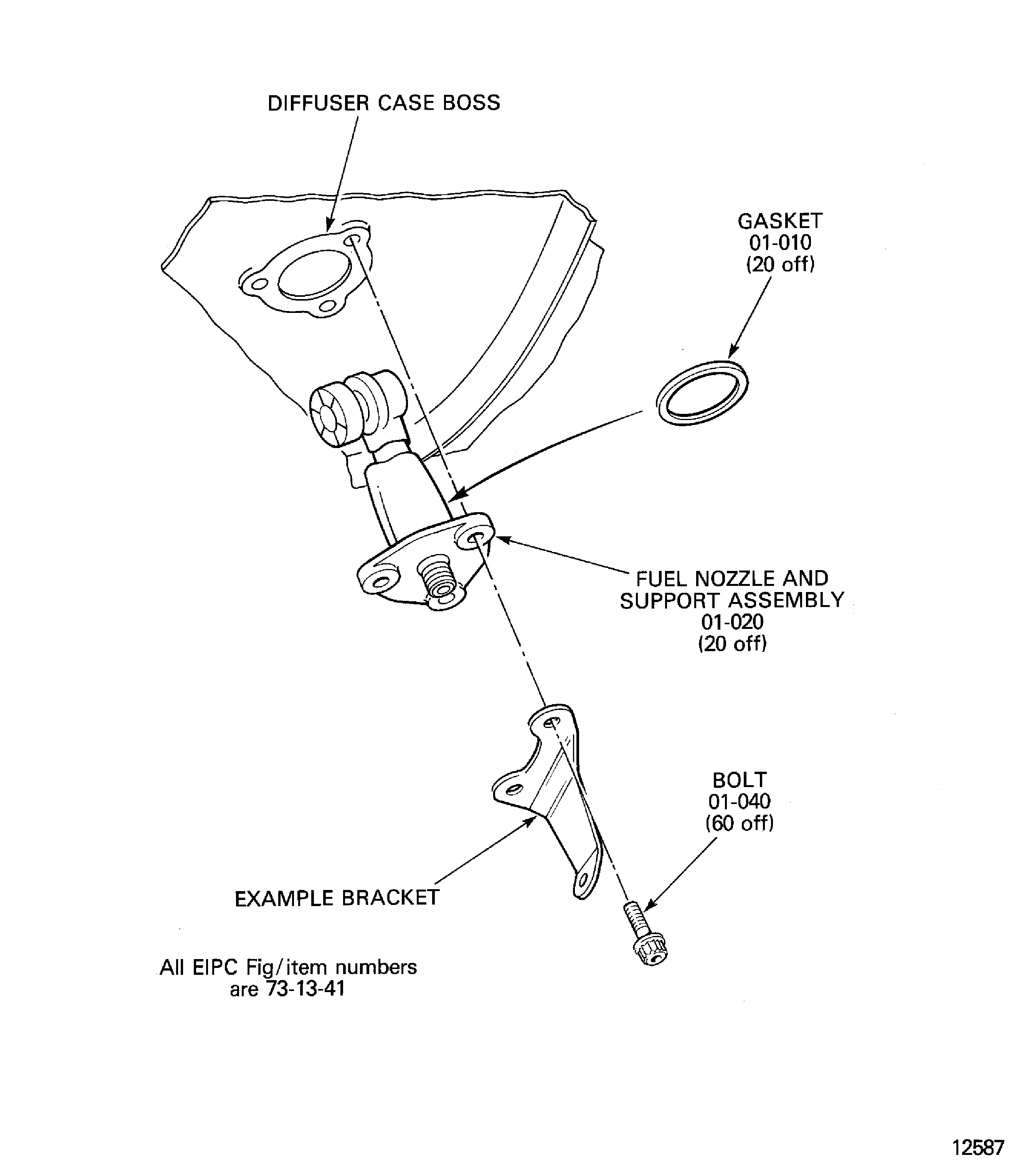

Figure: Remove the fuel nozzles

Sheet 1

Figure: Remove the fuel nozzles

Sheet 2

Figure: SBE 72-0191: (A5 Series) Remove the fuel nozzles

Sheet 3

Figure: SBE 73-0139: Remove the fuel nozzles

Sheet 1

Figure: SBE 73-0139: Remove the fuel nozzles

Sheet 2