Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-40-020-002-A00 HP System Module - Remove And Disconnect The Components, Electrical Harnesses, And Tubes From The Front Of The HPC Case, Removal-002

General

This TASK gives the procedure to remove and disconnect the necessary components, the electrical harnesses and the tubes, so the HP system module can be removed from the LP compressor intermediate case module. Refer to the TASKS which follow for other related procedures:

TASK 72-00-40-020-001-A00 (REMOVAL-001) Remove the components, the electrical harnesses, the tubes and the brackets from the HP turbine.

TASK 72-00-40-020-003-A00 (REMOVAL-003) Remove the components, the electrical harnesses and the tubes from the HP compressor vertical splitline.

TASK 72-00-40-020-004 (REMOVAL-004) Remove the remaining HP system module components and air off-take ducts.

Fig./item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig./item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig./item number.

Apply the approved penetrating oil before the removal of threaded parts and parts with an interference fit. Let the parts soak before removal.

For the approved oils and procedures, refer to the SPM TASK 70-64-00-640-501.

Remove and discard the lockwire before the tube or connector is disconnected.

When electrical connections are disconnected, special plastic caps must be installed.

During the electrical harness removal remove the lacing tape that attaches the different harnesses together.

All tubes, hoses and ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

Seal all openings to prevent contamination from unwanted materials.

Discard all rubber seal rings removed in this procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| 0.937 in. (24.00 mm) crowsfoot spanner | LOCAL | 0.937 in. (24.00 mm) crowsfoot spanner | ||

| IAE 1N20014 Forward engine mount sling | 0AM53 | IAE 1N20014 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Remove the forward mount as detailed in TASK 71-00-32-350-001 (REMOVAL-001).

SUBTASK 72-00-40-020-076 Remove the Forward Mount Assembly

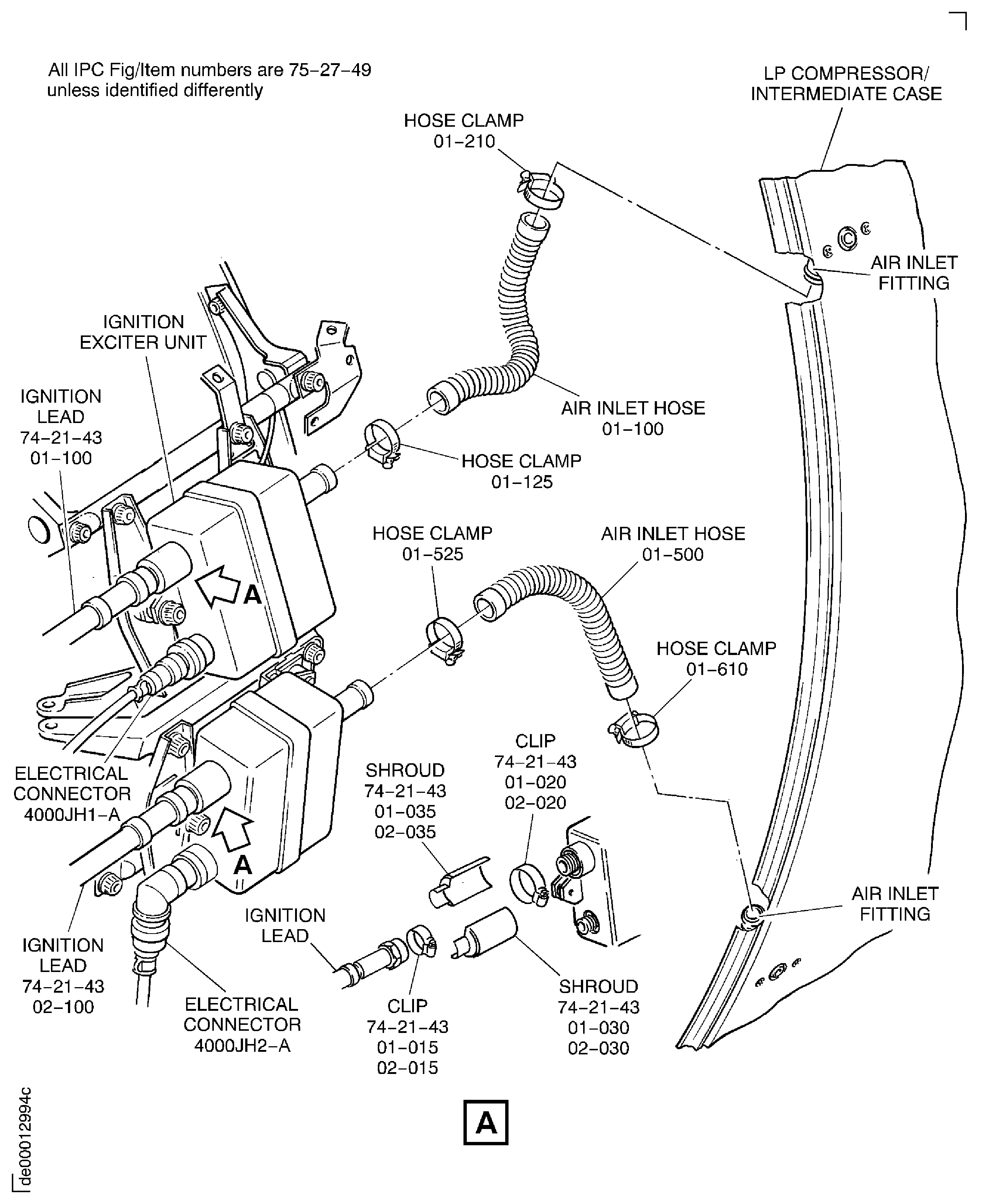

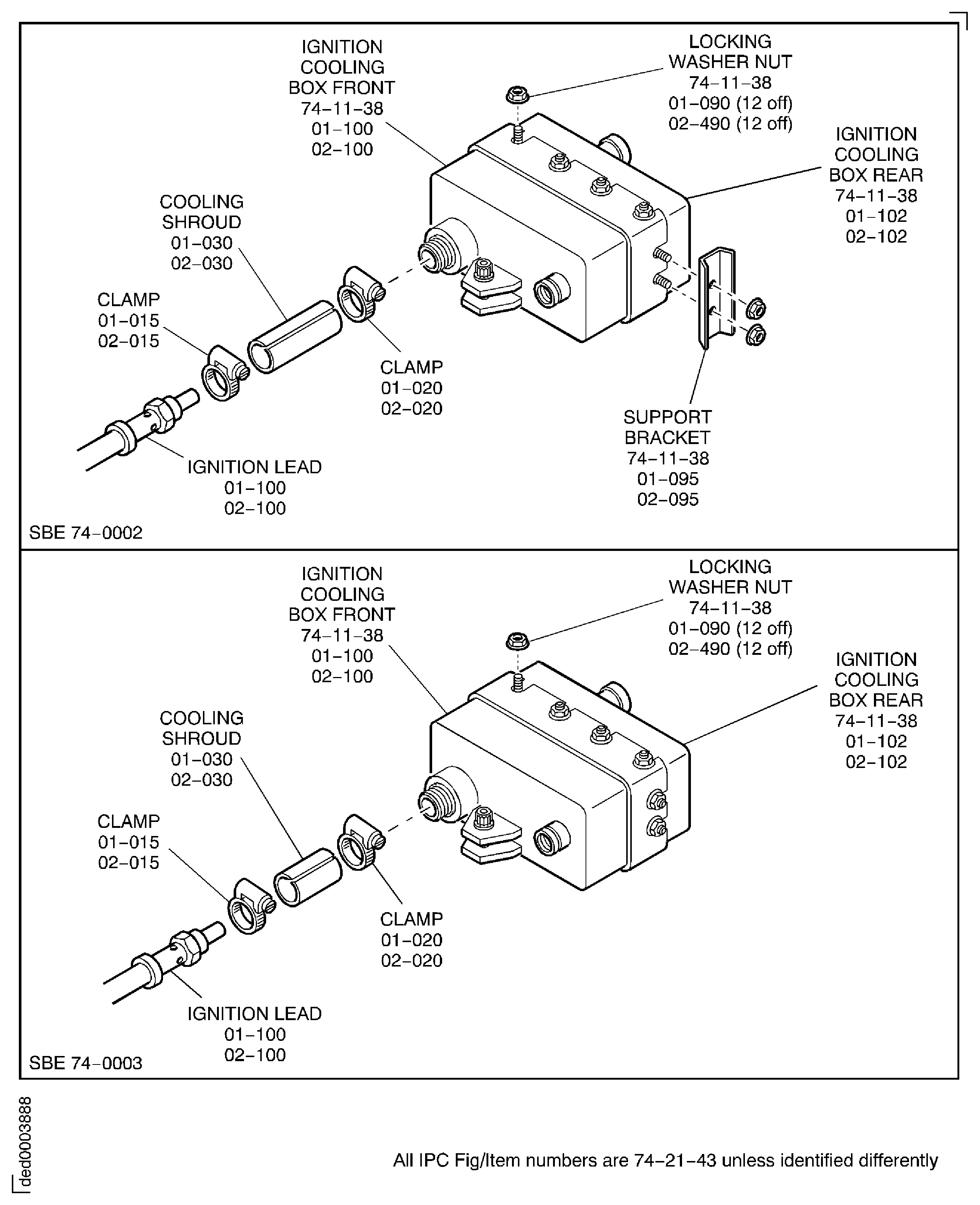

Pre SBE 74-0002 and Pre SBE 74-0003: Remove the four clamps and the four shrouds from the exciter ends of the harnesses.

SBE 74-0002 and SBE 74-0003 : Remove the four clamps and the two shrouds from the exciter ends of the harnesses.

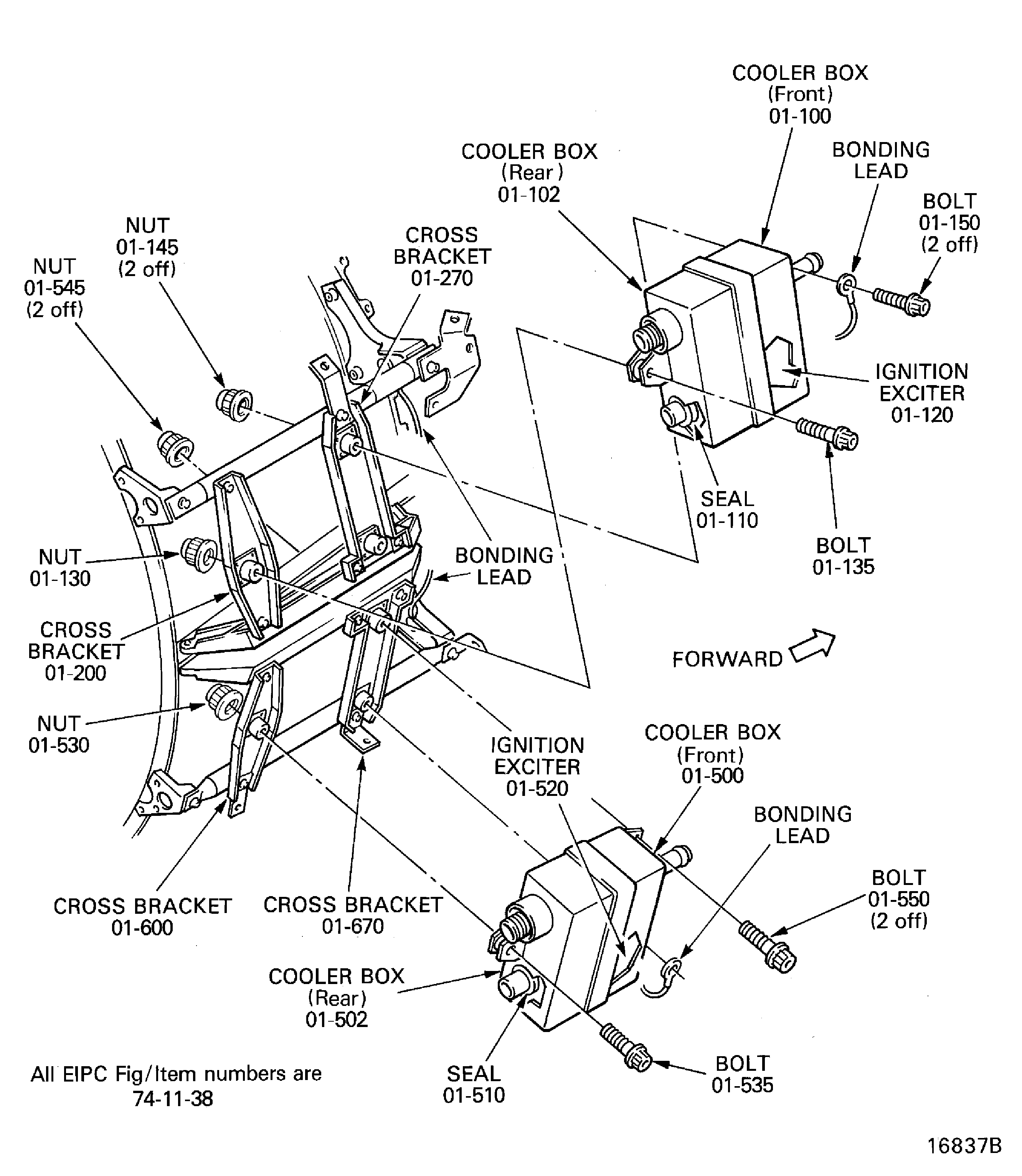

Pre SBE 74-0002 and Pre SBE 74-0003: Remove the two front and rear cooling boxes of the two ignition cooling exciters.

SBE 74-0002 and SBE 74-0003: Remove the 24 locking washer nuts that attach the two front and rear cooling boxes.

SBE 74-0002 and Pre SBE 74-0003: Remove the four support brackets from the cooling boxes.

SBE 74-0002 and SBE 74-0003: Remove the two front and rear cooling boxes.

CAUTION

DO NOT BEND THE HIGH ENERGY IGNITION HARNESS MORE THAN IS NECESSARY BECAUSE THIS CAN DAMAGE THE CONDUIT.Remove the two high energy ignition exciters.

SUBTASK 72-00-40-020-110 Remove the Ignition Exciters (Pre SBE 74-0002, SBE 74-0002, Pre SBE 74-0003 and SBE 74-0003)

SBE 74-0002: Engine - Ignition - Introduction of improved ignition lead, cooling shroud and the ignition cooling box.

SBE 72-0003: Engine - Ignition - Introduction of a redimensioned ignition lead cooling shroud and the deletion of ignition cooling box support bracket.

NOTE

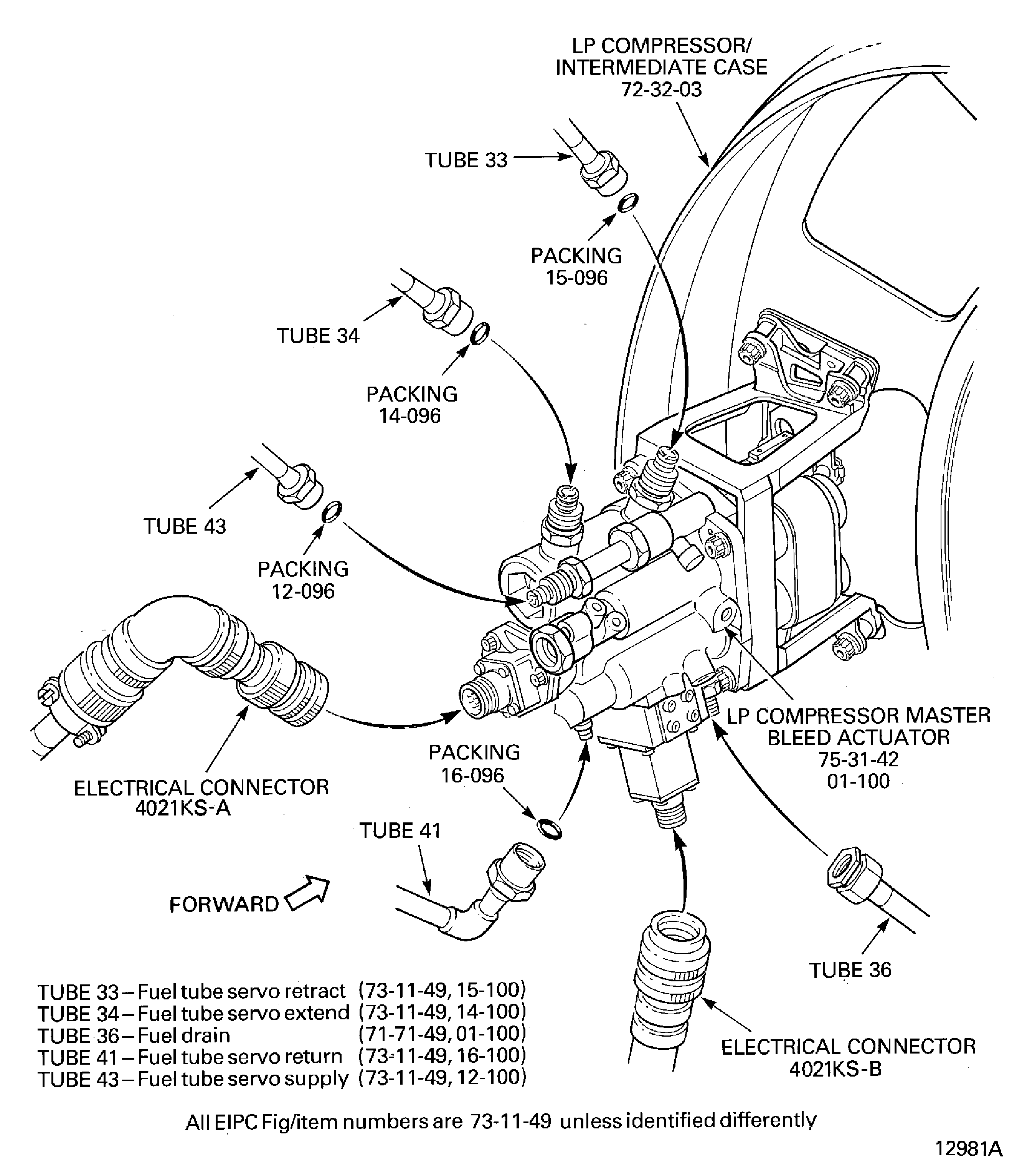

The LP compressor master bleed actuator must have its maintenance completed, as given in the D.S.I.C. Component Maintenance Manual (75-31-42).Remove the four bolts that attach the bleed actuator to the mount bracket and remove the bleed actuator and the bracket "AIR-LP COMPRESSOR BLEED,MASTER ACTUATOR (75-31-42, 01-080).

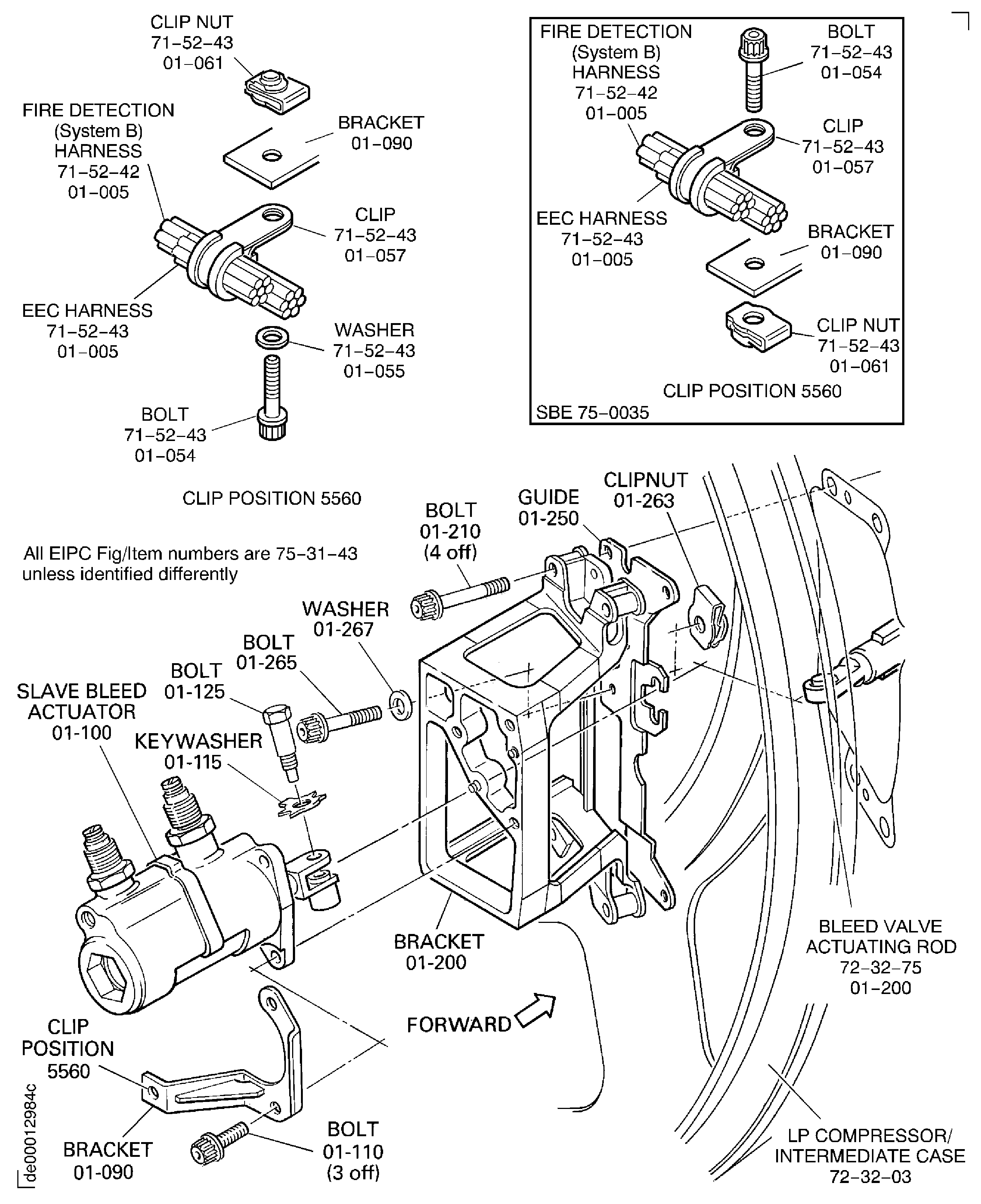

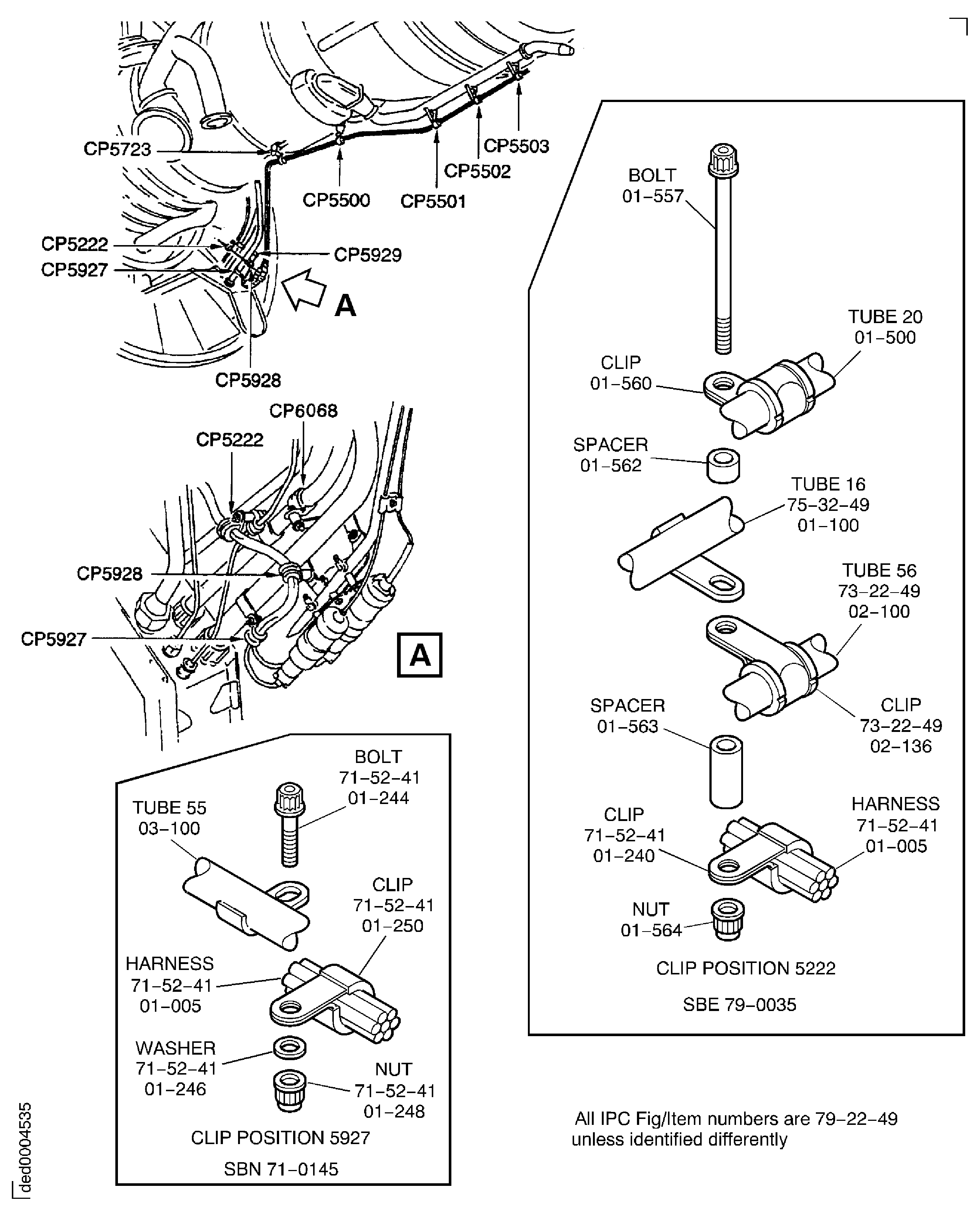

Pre SBE 75-0035 : Remove the bolt, the washer, the clip and the clipnut from the clip position 5560.

SBE 75-0035 : Remove the bolt, the clip and the clipnut from the clip position 5560.

NOTE

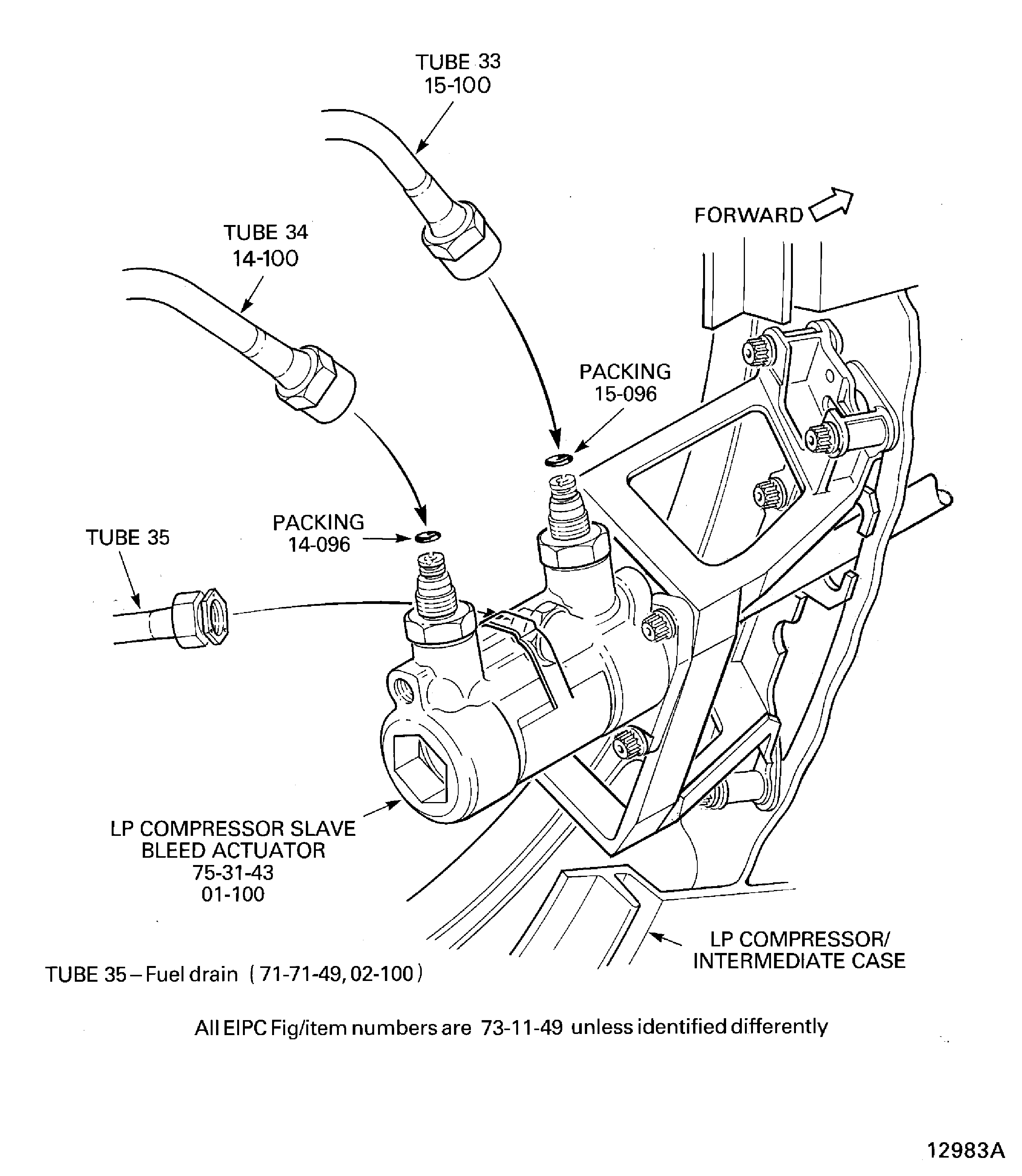

The LP compressor slave bleed actuator must have its maintenance completed, as given in the D.S.I.C. Component Maintenance Manual (75-31-43).Remove the three bolts that attach the bleed actuator to the mount bracket and remove the bleed actuator and the bracket "AIR-LP COMPRESSOR BLEED,SLAVE ACTUATOR(75-31-43, 01-090).

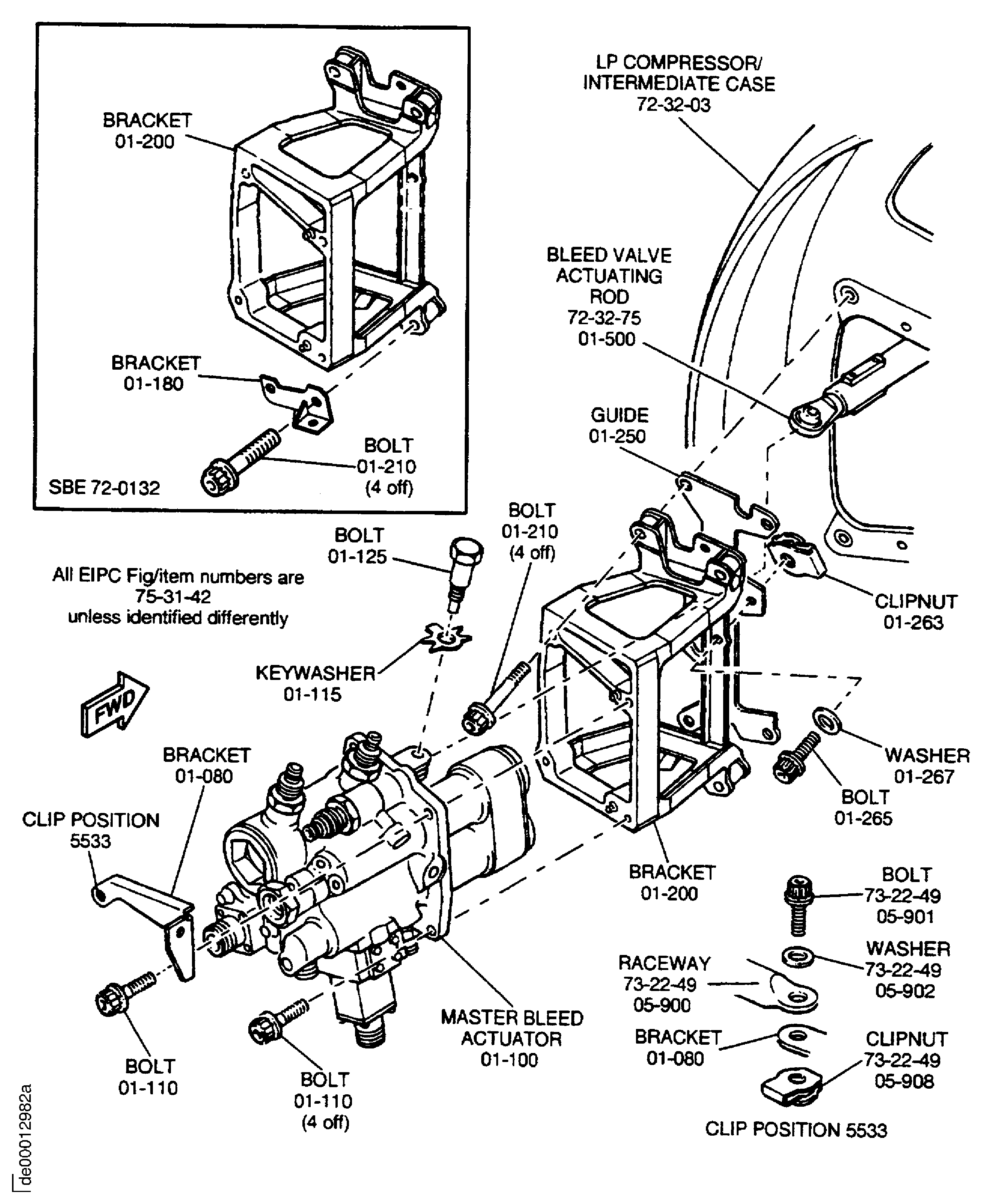

SUBTASK 72-00-40-020-079 Remove the LP Compressor Bleed Actuators (SBE 75-0035)

SBE 75-0035: Air - Revise the orientation of clipping point 5560

Remove the bolt, the washer and the clipnut that attaches the guide "AIR-LP COMPRESSOR BLEED,MASTER ACTUATOR (75-31-42, 01-250) to the mount bracket.

Remove the bolt, the washer and the clipnut that attaches the guide "AIR-LP COMPRESSOR BLEED,SLAVE ACTUATOR (75-31-43, 01-250) to the mount bracket.

NOTE

The two bleed actuator mount brackets and guides must have their maintenance completed, as given in the Component Maintenance Manual (CMM-MECH-V2500-1IA).Remove the four bolts that attach the mount bracket and the guide to the LP compressor/intermediate case rear frame. Remove the mount bracket and the guide.

SUBTASK 72-00-40-020-080-A00 Remove the LP Compressor Bleed Actuator Mount Brackets (Pre SBE 72-0051 and Pre SBE 72-0132)

Remove the bolt, the washer and the clipnut that attaches the guide "AIR-LP COMPRESSOR BLEED,MASTER ACTUATOR (75-31-42, 01-250) to the mount bracket.

Remove and discard the lockwire then remove the two bolts that attach the raceway bracket "AIR-LP COMPRESSOR BLEED,MASTER ACTUATOR (75-31-42, 01-180) to the mount bracket and the LP compressor/intermediate case rear frame. Remove the raceway bracket.

Remove the bolt, the washer and the clipnut that attaches the guide "AIR-LP COMPRESSOR BLEED,SLAVE ACTUATOR (75-31-43, 01-250) to the mount bracket.

NOTE

The two bleed actuator mount brackets and guides must have their maintenance completed, as given in the Component Maintenance Manual (CMM-MECH-V2500-1IA).Remove the lockwire and the four bolts that attach the mount bracket and the guide to the LP compressor/intermediate case rear frame and discard the lockwire. Remove the mount bracket and the guide.

SUBTASK 72-00-40-020-080-B00 Remove the LP Compressor Bleed Actuator Mount Brackets (SBE 72-0051 and SBE 72-0132)

SBE 72-0051: LP compressor - Incorporate a fuel drain tube in the fan frame assembly.

SBE 72-0132: LP compressor - Removal of stage 6 buffer air system

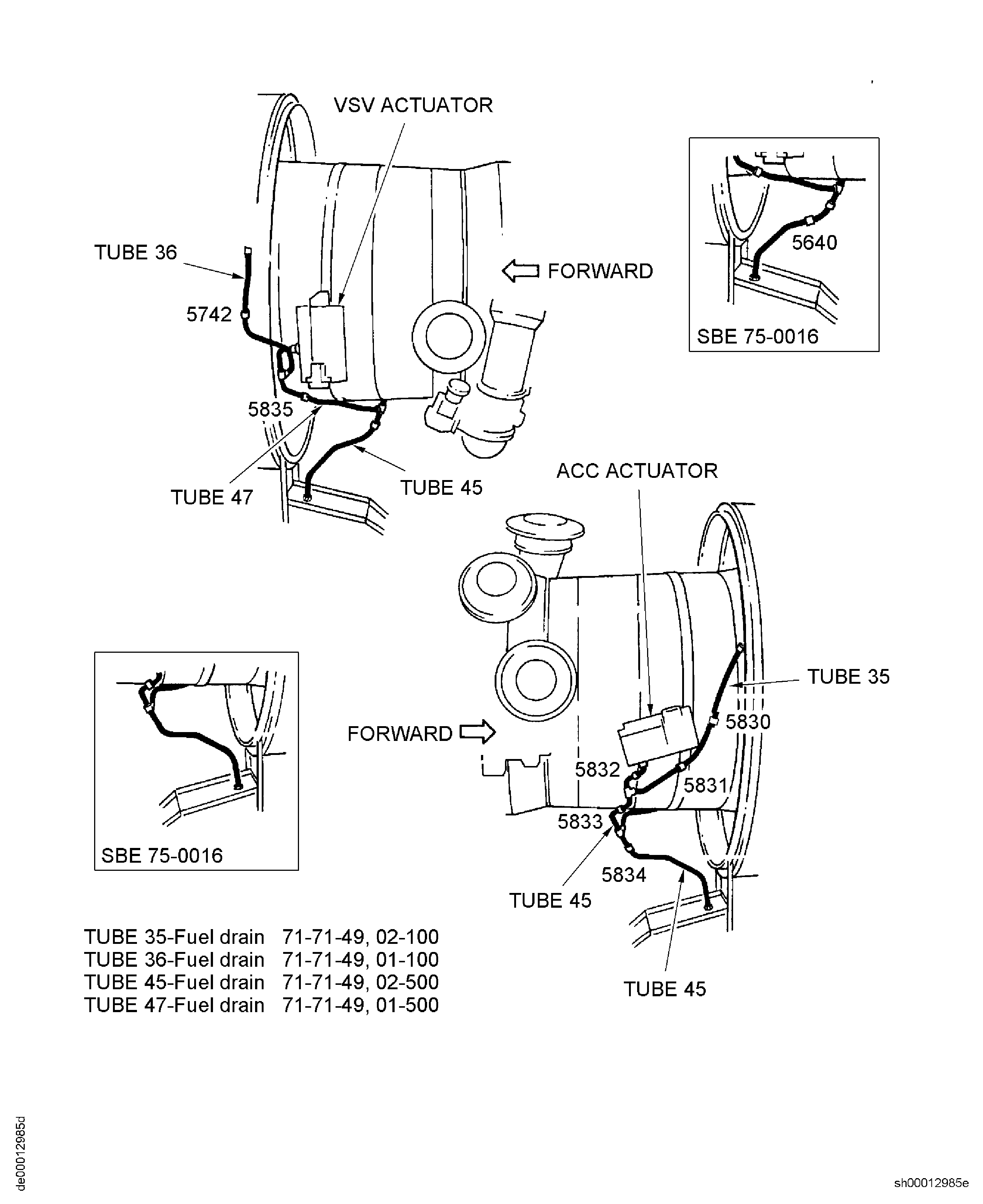

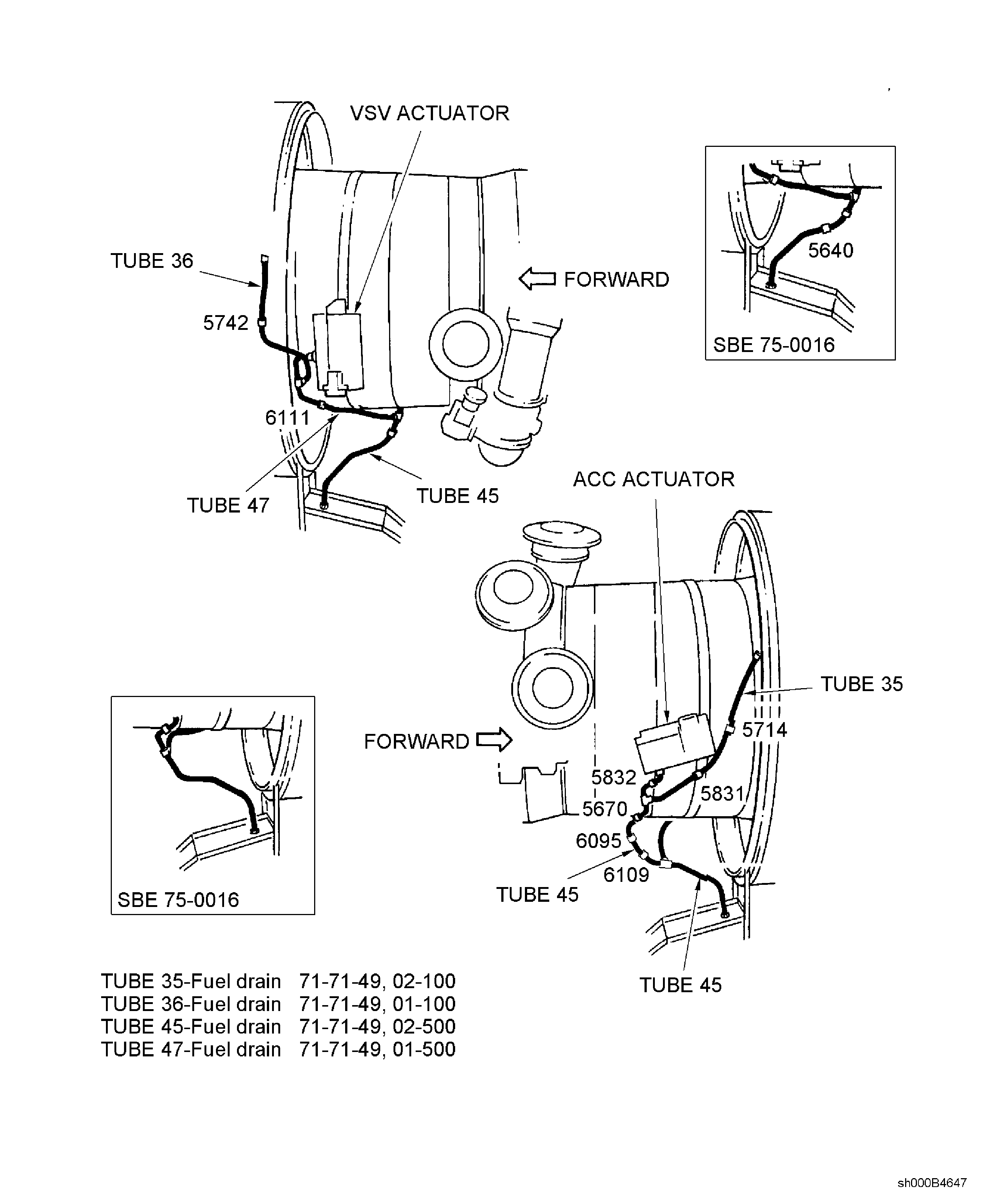

SUBTASK 72-00-40-020-081-A00 Remove the Fuel Drain Tubes (Pre SBE 75-0016)

SUBTASK 72-00-40-020-081-B00 Remove the Fuel Drain Tubes (SBE 75-0016 and Pre SBE 79-0087)

SBE 75-0016: Air - HPC bleed air tubes - Revised core engine tubes to improve clearance with harness bifurcation area - RH side

Refer to Figure.

SUBTASK 72-00-40-020-081-C00 Remove the Fuel Drain Tubes (SBE 79-0087)

SBE 79-0087: Oil - Revised routing of EBU systems to allow re-routing of the oil scavenge tubes

Remove the Ignition Supply Harness, Step.

Remove the EEC and Fire Detection Harness, Step.

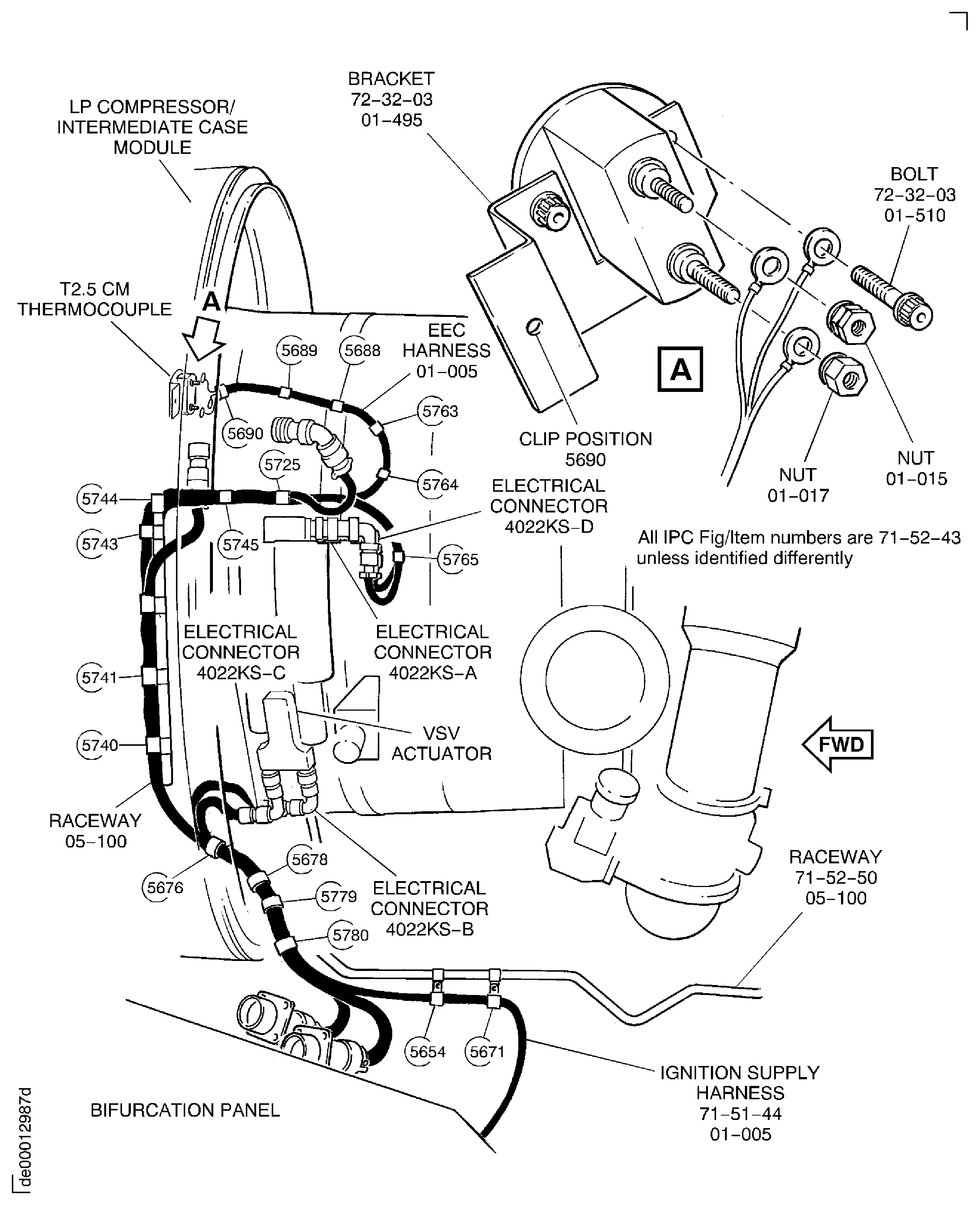

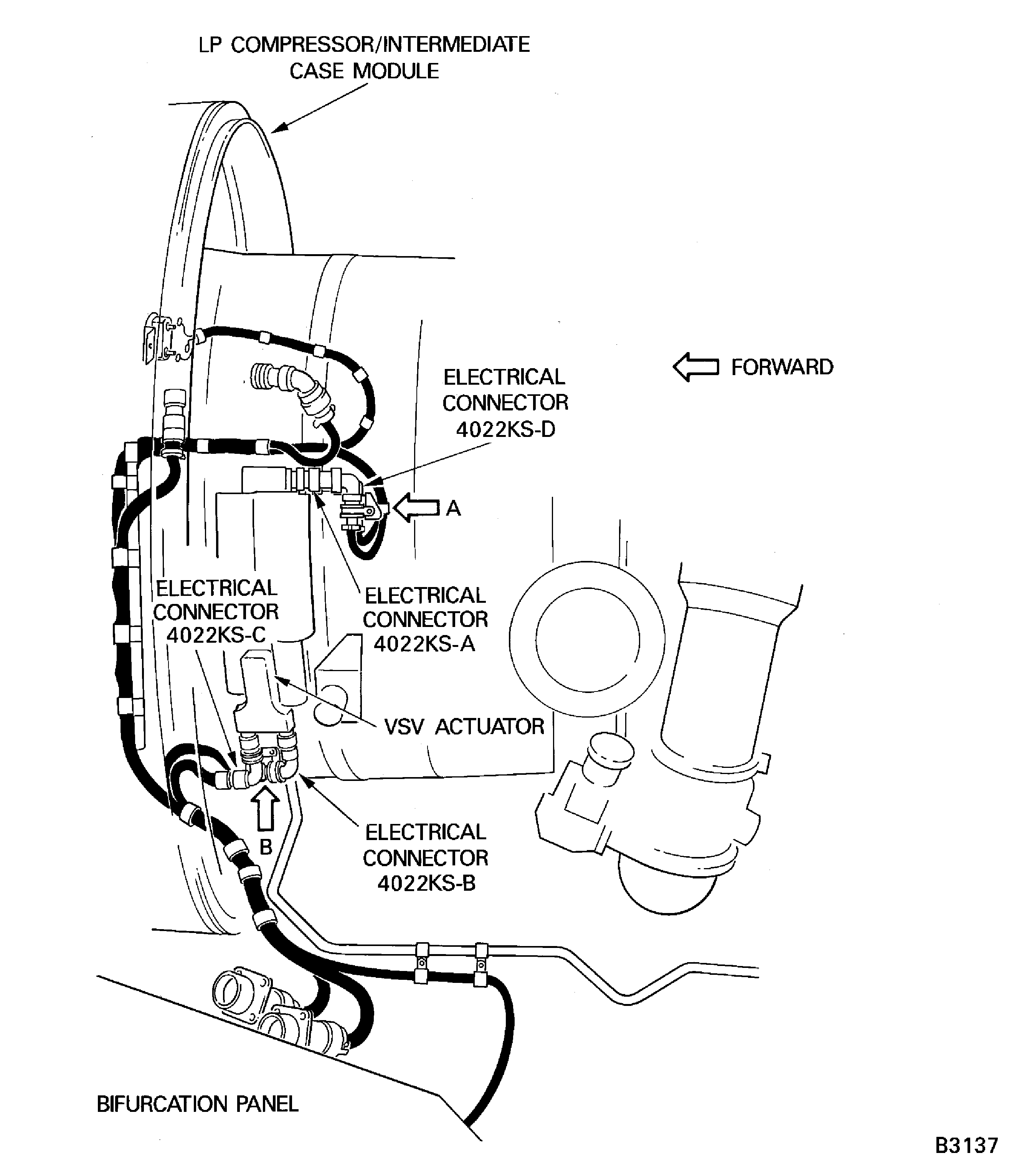

Disconnect the Electrical Connectors 4022KS-A, 4022KS-B, 4022KS-C and 4022KS-D, Step.

Disconnect the Fan Speed Terminal Block, Step.

Disconnect the Core Overheat Detector, Step.

The procedures that were in this SUBTASK have been transferred to the SUBTASKS that follow:

SUBTASK 72-00-40-020-082-A00 Remove the EEC Harness, the Ignition Supply Harness, the Fire Detection (System B) Harness and the Core Overheat Detector (Pre SBE 71-0063 and Pre SBE 72-0132)

Remove the Ignition Supply Harness, Step.

Remove the EEC and Fire Detection Harness, Step.

Disconnect the Electrical Connectors 4022KS-A, 4022KS-B, 4022KS-C and 4022KS-D, Step.

Disconnect the Fan Speed Terminal Block, Step.

Disconnect the Core Overheat Detector, Step.

The procedures that were in this SUBTASK have been transferred to the SUBTASKS that follow:

SUBTASK 72-00-40-020-082-B00 Remove the EEC Harness the Ignition Supply Harness, the Fire Detection (System B) Harness and the Core Overheat Detector (SBE 71-0063 and SBE 72-0132)

SBE 71-0063: EEC harness - Fan and EEC harness - Core - Introduction of additional support for electrical connectors

SBE 72-0132: Engine LP compressor - Removal of stage 6 buffer air system

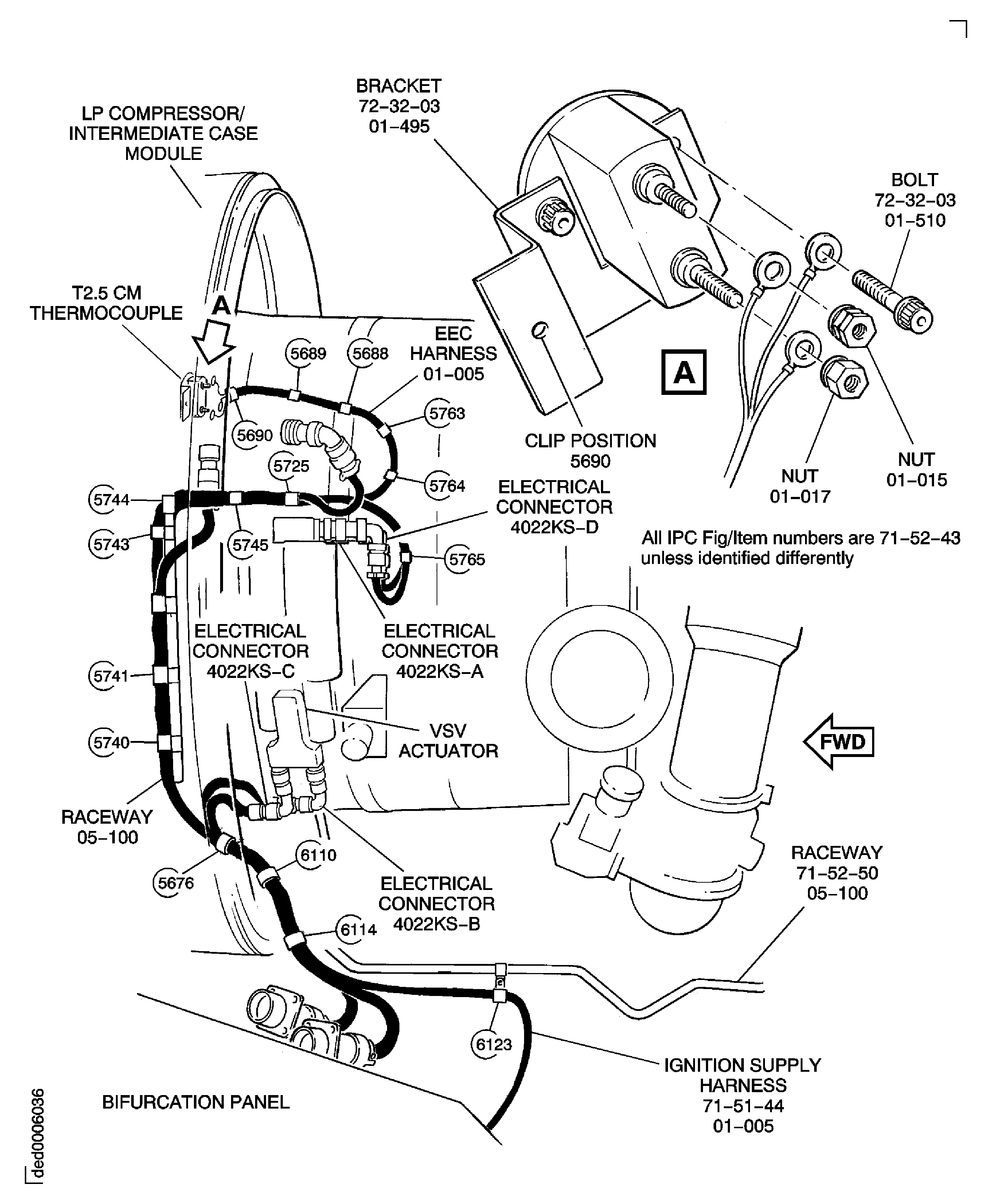

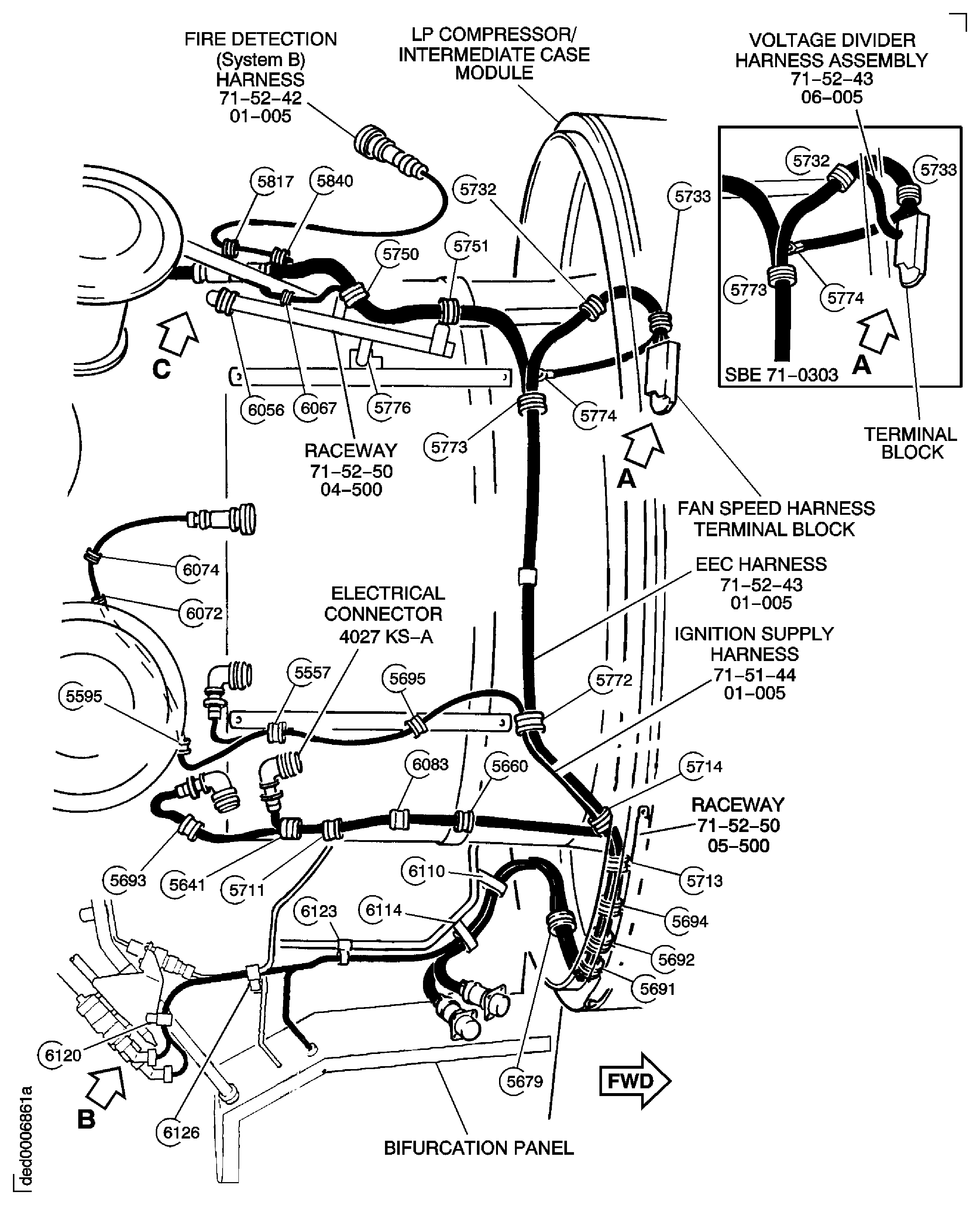

Pre SBE 79-0087: Remove the bolts, the washers, the spacers, the clipnuts, the nuts and the clips from the clip positions that follow:

5675, 5696, 5595, 5557, 5695, 5772, 5714, 5713, 5694, 5692, 5691, 5679, 5678, 5779, 5780, 5654 and 5671.

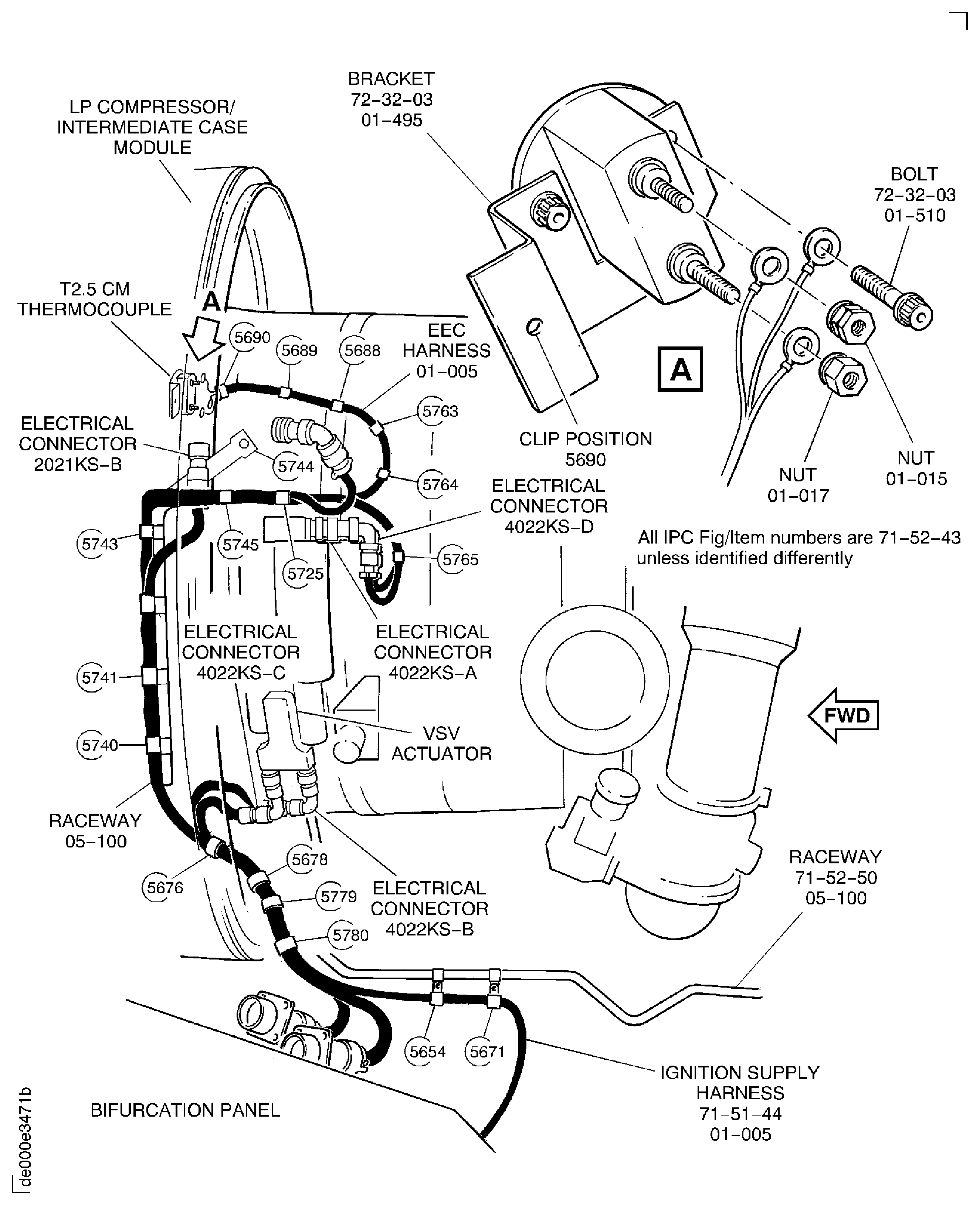

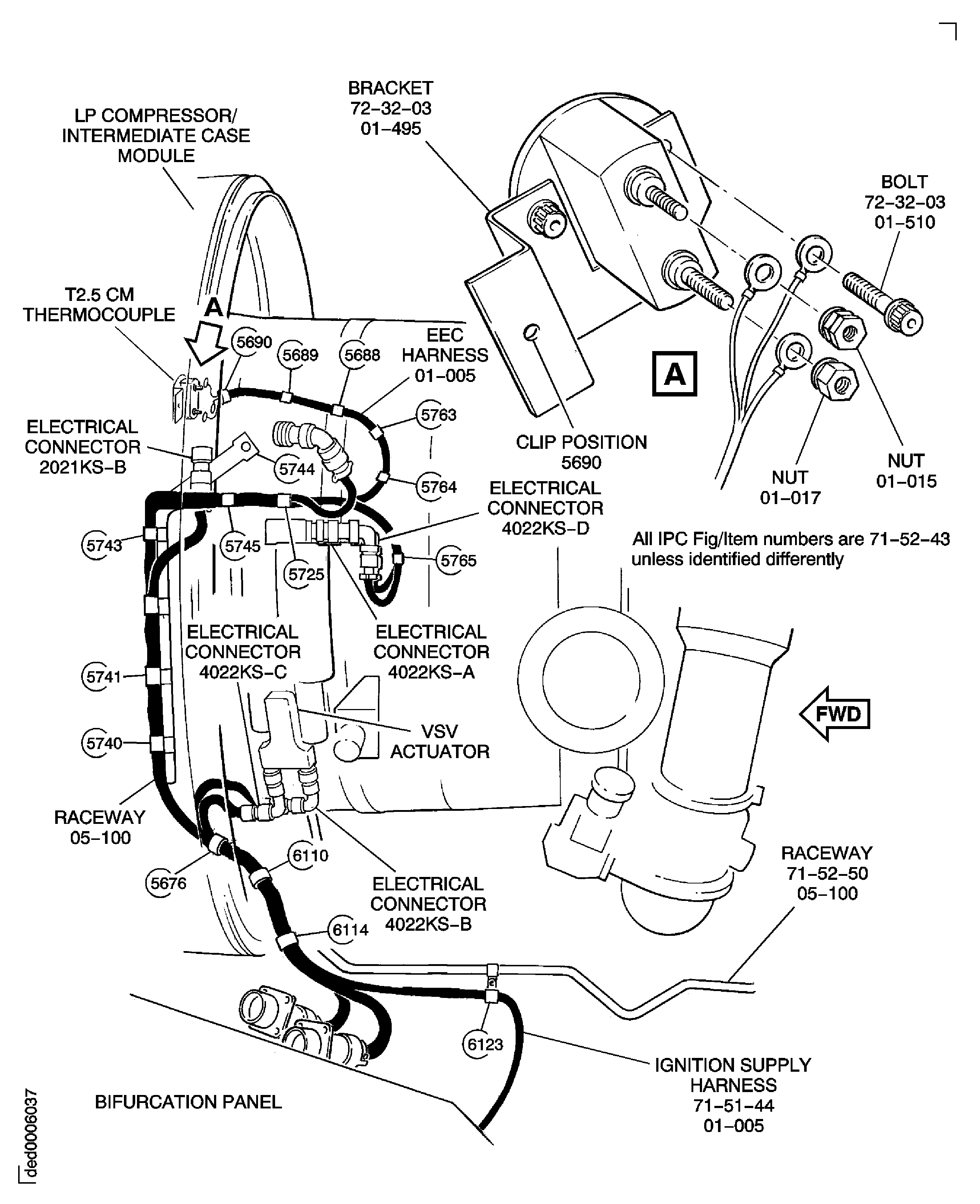

SBE 79-0087: Remove the bolts, the washers, the spacers, the clipnuts, the nuts and the clips from the clip positions that follow:

5675, 5696, 5595, 5557, 5695, 5772, 5714, 5713, 5694, 5692, 5691, 5679, 5678, 5779, 6110, 6114 and 6123.

Remove the ignition supply harness ELECT HARNESS-LIGHT DUTY-IGNITION SUPPLY HARNESS (71-51-44, 01-005).

SUBTASK 72-00-40-020-192 Remove the Ignition Supply Harness (Pre SBE 73-0006, SBE 73-0006, Pre SBE 79-0087 and SBE 79-0087)

SBE 73-0006: Fuel and control - Incorporate revised EBU harness clipping requirements at CP 5671 and CP 1097

SBE 79-0087: Oil - Revised routing of EBU systems to allow re-routing of the oil scavenge tubes

Refer to Figure.

SUBTASK 72-00-40-020-193-A00 Disconnect the EEC Harness Electrical Connectors from the VSV Actuator (Pre SBE 71-0063 and Pre SBE 71-0111)

SUBTASK 72-00-40-029-193-B00 Disconnect the EEC Harness Electrical Connectors from the VSV Actuator (SBE 71-0063 and Pre SBE 71-0111)

SBE 71-0063: EEC harness - Fan and harness-core - Introduction of additional support for electrical connectors

Refer to Figure.

SUBTASK 72-00-40-020-193-C00 Disconnect the EEC Harness Electrical Connectors from the VSV Actuator (SBE 71-0111)

SBE 71-0111: EEC harness fan/core - Deletion of clipping at VSVA and PMA harness connectors and introduction of wire locking to secure connectors

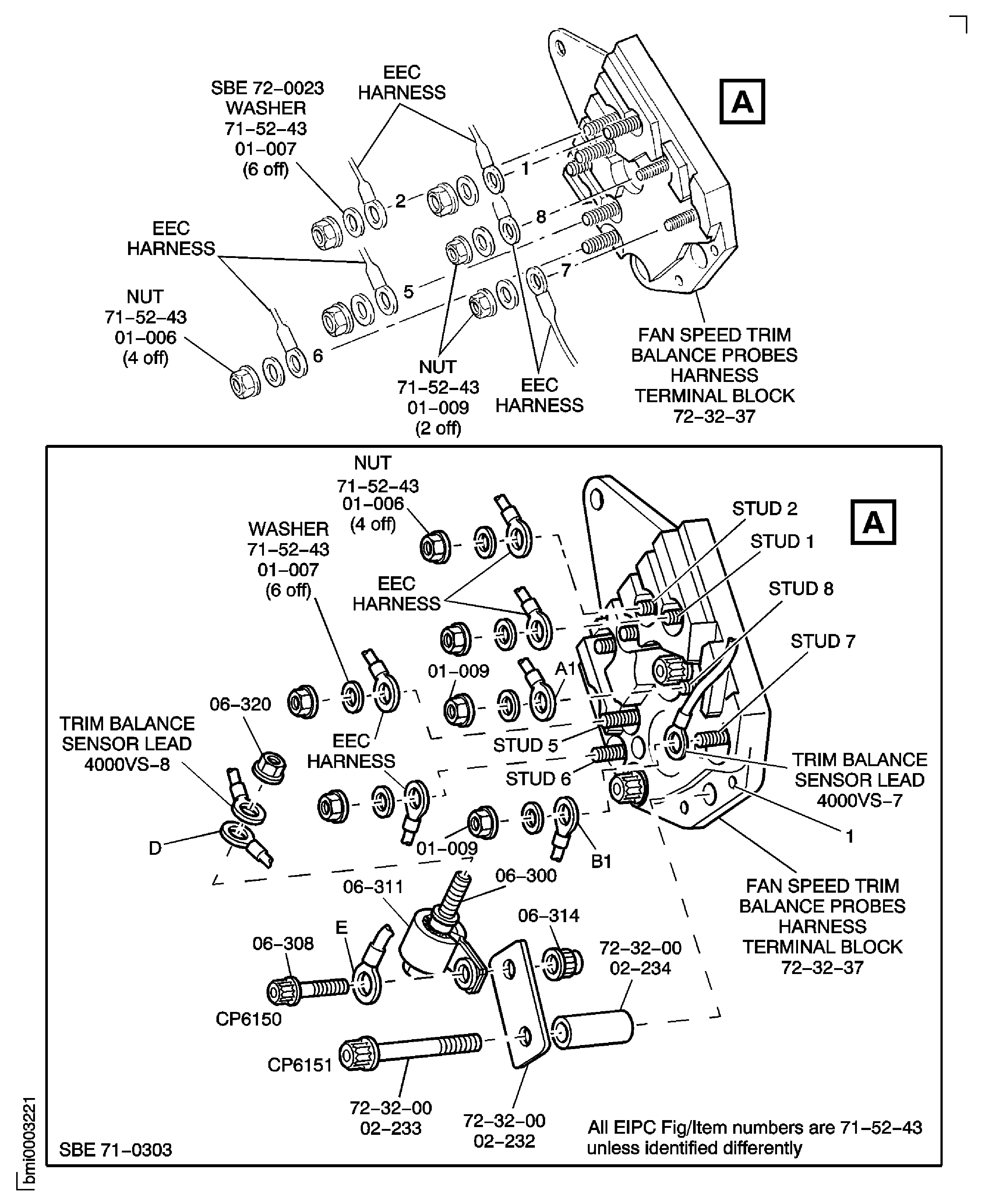

SUBTASK 72-00-40-020-194-A00 Disconnect the EEC Harness from the Fan Speed Terminal Block (Pre SBE 71-0303, Pre SBE 72-0023 and SBE 72-0553)

SBE 72-0553: Introduction of a new trim balance probe and deletion of related powerplant voltage divider harness assembly

SUBTASK 72-00-40-020-194-B00 Disconnect the EEC Harness from the Fan Speed Terminal Block (Pre SBE 71-0303, SBE 72-0023 and SBE 72-0553)

SBE 72-0023: Addition of washers for connection of the terminal block and the EEC harness-core.

SBE 72-0553: Introduction of a new trim balance probe and deletion of related powerplant voltage divider harness assembly.

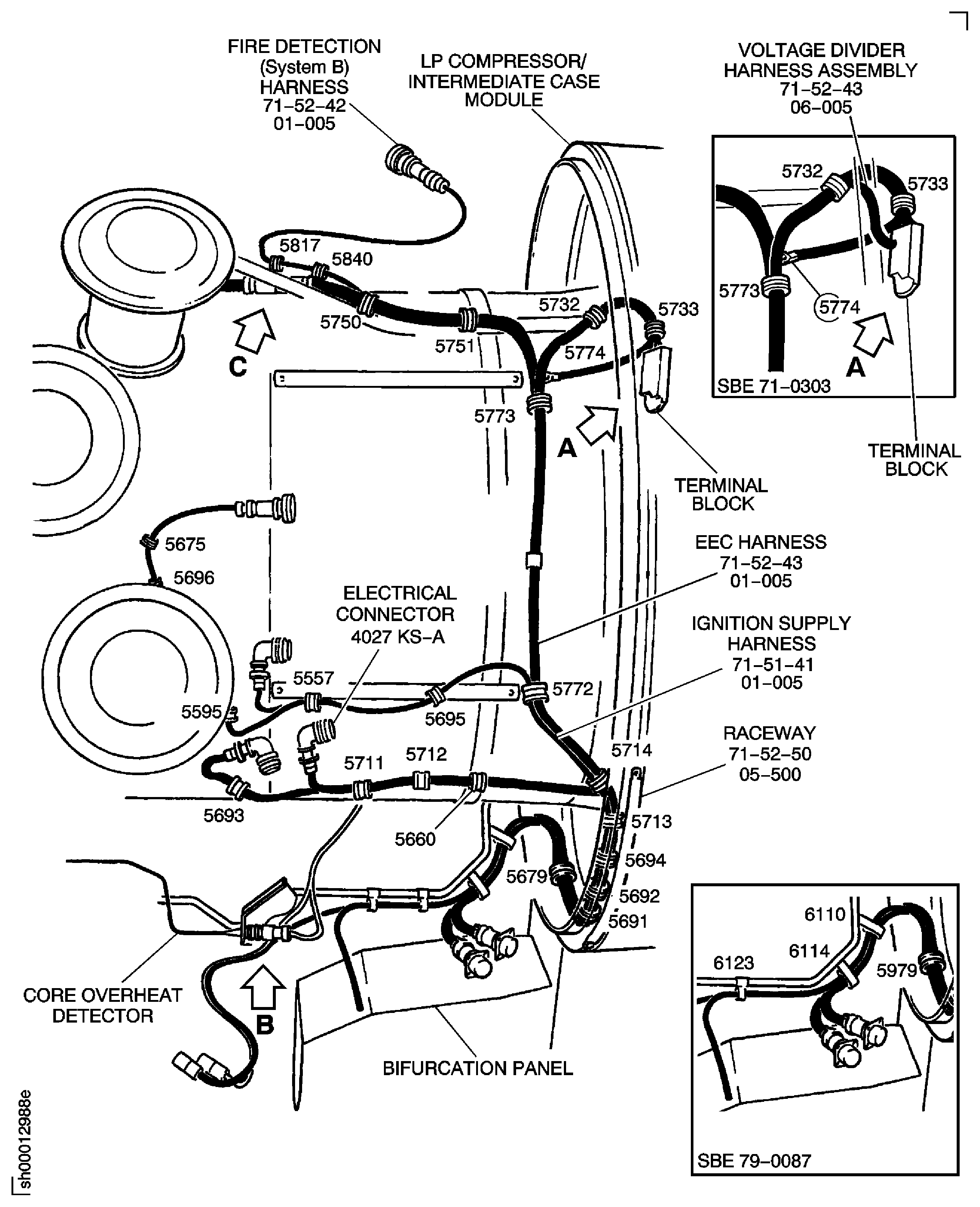

SUBTASK 72-00-40-020-194-C00 Disconnect the EEC Harness and the Voltage Divider Harness from the Fan Speed Terminal Block (SBE 71-0303 and Pre SBE 72-0553)

SBE 71-0303: EEC harness - Fan and EEC harness - Core - Introduction of voltage divider harness.

Remove the bolt, the washer, the nut and the clip from the clip position 5744 and remove the raceway ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 05-100).

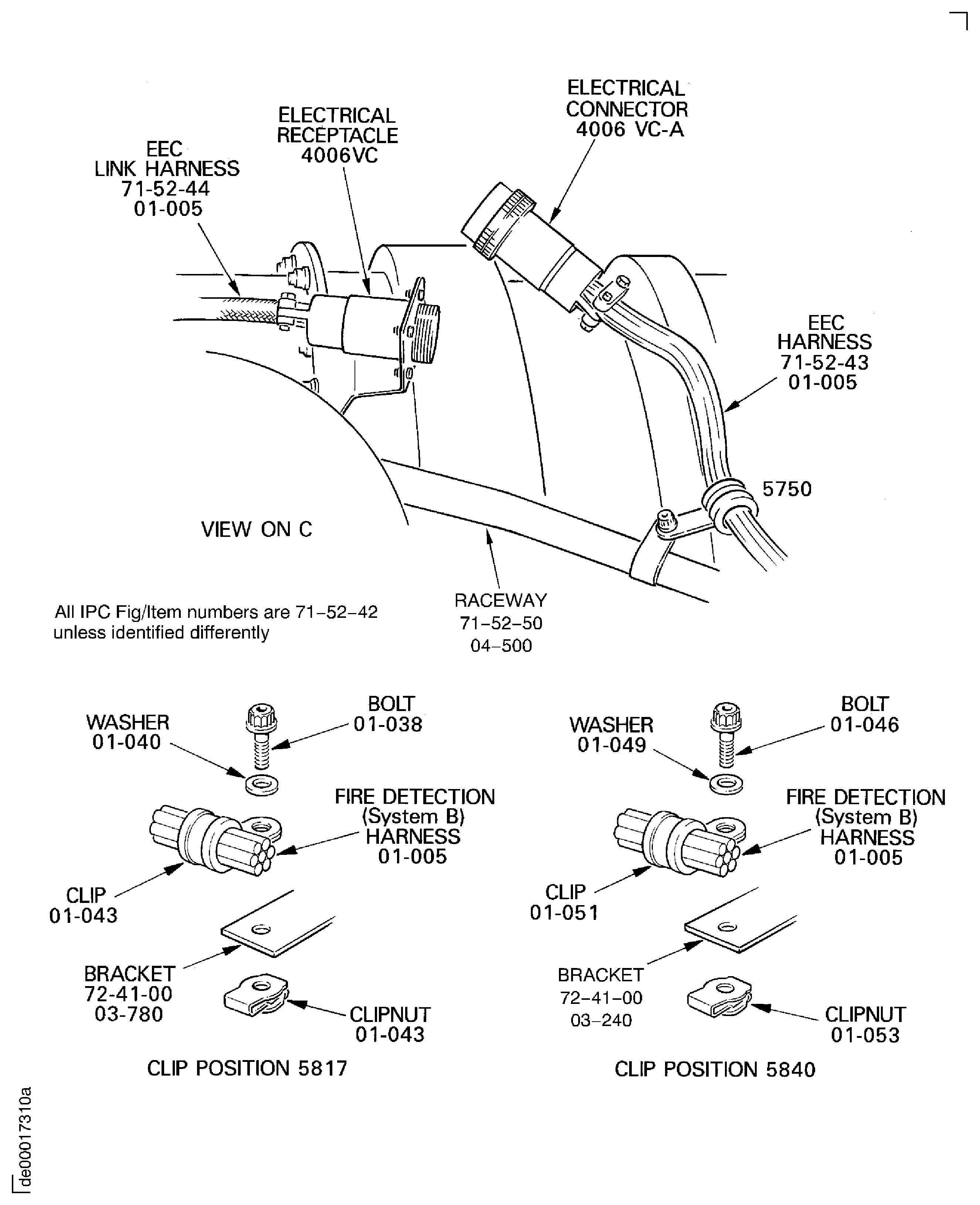

Remove the bolts, the washers, the spacers, the clips, the clipnuts and the nuts from the clip positions that follow:

Pre SBE 71-0145 and Pre SBE 79-0087: 5817, 5840, 5750, 5751, 5733, 5732, 5774, 5773, 5693, 5711, 5712, 5660, 5689, 5688, 5763, 5764, 5765, 5725, 5745, 5821, 5820, 5801 and 5800.

SBE 71-0145 and Pre SBE 79-0087: 5817, 5840, 5750, 5751, 5733, 5732, 5774, 5773, 5693, 5711, 5712, 5660, 5689, 5688, 5763, 5764, 5765, 5725, 5745, 5821 and 5820.

SBE 79-0087: 5817, 5840, 5750, 5751, 5733, 5732, 5774, 5773, 5693, 5711, 5712, 5660, 5689, 5688, 5763, 5764, 5765, 5725, 5745, 6126 and 6120.

Remove the EEC harness ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-005) and the fire detection (System B) harness ELECT HARNESS-LIGHT DUTY-FIRE DETECTION SYSTEM B (71-52-42, 01-005).

SUBTASK 72-00-40-020-195-A00 Remove the EEC Harness and the Fire Detection (System B) Harness (Pre SBE 71-0303, Pre SBE 72-0132 and SBE 72-0553)

SBE 72-0553: Introduction of a new trim balance probe and deletion of related powerplant voltage divider harness assembly.

Remove the bolt, the washer, the nut and the clip from the clip position 5744 and remove the raceway ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 05-100).

Remove the bolts, the washers, the spacers, the clips, the clipnuts and the nuts from the clip positions that follow:

Pre SBE 79-0087: 5817, 5840, 5750, 5751, 5733, 5732, 5774, 5773, 5693, 5711, 5712, 5660, 5689, 5688, 5763, 5764, 5765, 5725, 5745, 5821, 5820, 5801, 5800, 6067 and 5927.

SBE 79-0087: 5817, 5840, 5750, 5751, 5733, 5732, 5774, 5773, 5693, 5711, 5712, 5660, 5689, 5688, 5763, 5764, 5765, 5725, 5745, 6126, 6120 and 6067.

NOTE

The clip position 5222 is removed in TASK 72-00-40-020-004.Pre SBE 79-0087: Remove the bolt and the nut from the clip position 5222 and remove the harness from the clip position, temporarily refit the bolt and nut and lightly tighten the bolt.

SBE 72-0132 and SBE 79-0087: Remove the bolts, the washers, the clipnut, the nut and the clips from the clip positions 5776 and 6056 then remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE(71-52-50,04-500).

Remove the EEC harness ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-005) and the fire detection (System B) harness.

SUBTASK 72-00-40-020-195-B00 Remove the EEC Harness and the Fire Detection (System B) Harness (Pre SBE 71-0303, SBE 72-0132 and SBE 72-0553)

SBE 72-0132: LP compressor - Removal of stage 6 buffer air system.

SBE 72-0553: Introduction of a new trim balance probe and deletion of related powerplant voltage divider harness assembly.

Remove the bolt, the washer, the nut and the clip from the clip position 5744 and remove the raceway ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 05-100).

Remove the bolts, the washers, the spacers, the clips, the clipnuts and the nuts from the clip positions that follow:

Pre SBE 79-0087: 5817, 5840, 5750, 5751, 5733, 5732, 5774, 5773, 5693, 5711, 5712, 5660, 5689, 5688, 5763, 5764, 5765, 5725, 5745, 5821, 5820, 5801, 5800, 6067 and 5927.

SBE 79-0087: 5817, 5840, 5750, 5751, 5733, 5732, 5774, 5773, 5693, 5711, 5712, 5660, 5689, 5688, 5763, 5764, 5765, 5725, 5745, 6126, 6120 and 6067.

NOTE

The clip position 5222 is removed in TASK 72-00-40-020-004.Pre SBE 79-0087: Remove the bolt and the nut from the clip position 5222 and remove the harness from the clip position, temporarily refit the bolt and nut and lightly tighten the bolt.

SBE 72-0132 and SBE 79-0087: Remove the bolts, the washers, the clipnut, the nut and the clips from the clip positions 5776 and 6056 then remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 04-500).

Remove the EEC harness ELECTRICAL HARNESS-LIGHT DUTY-EEC HARNESS-CORE (71-52-43, 01-005) and the fire detection (System B) harness.

SUBTASK 72-00-40-020-195-C00 Remove the EEC Harness, the Voltage Divider Harness and the Fire Detection (System B) Harness (SBE 71-0303 and Pre SBE 72-0553)

SBE 71-0303: EEC harness - Fan and EEC harness - Core - Introduction of voltage divider harness.

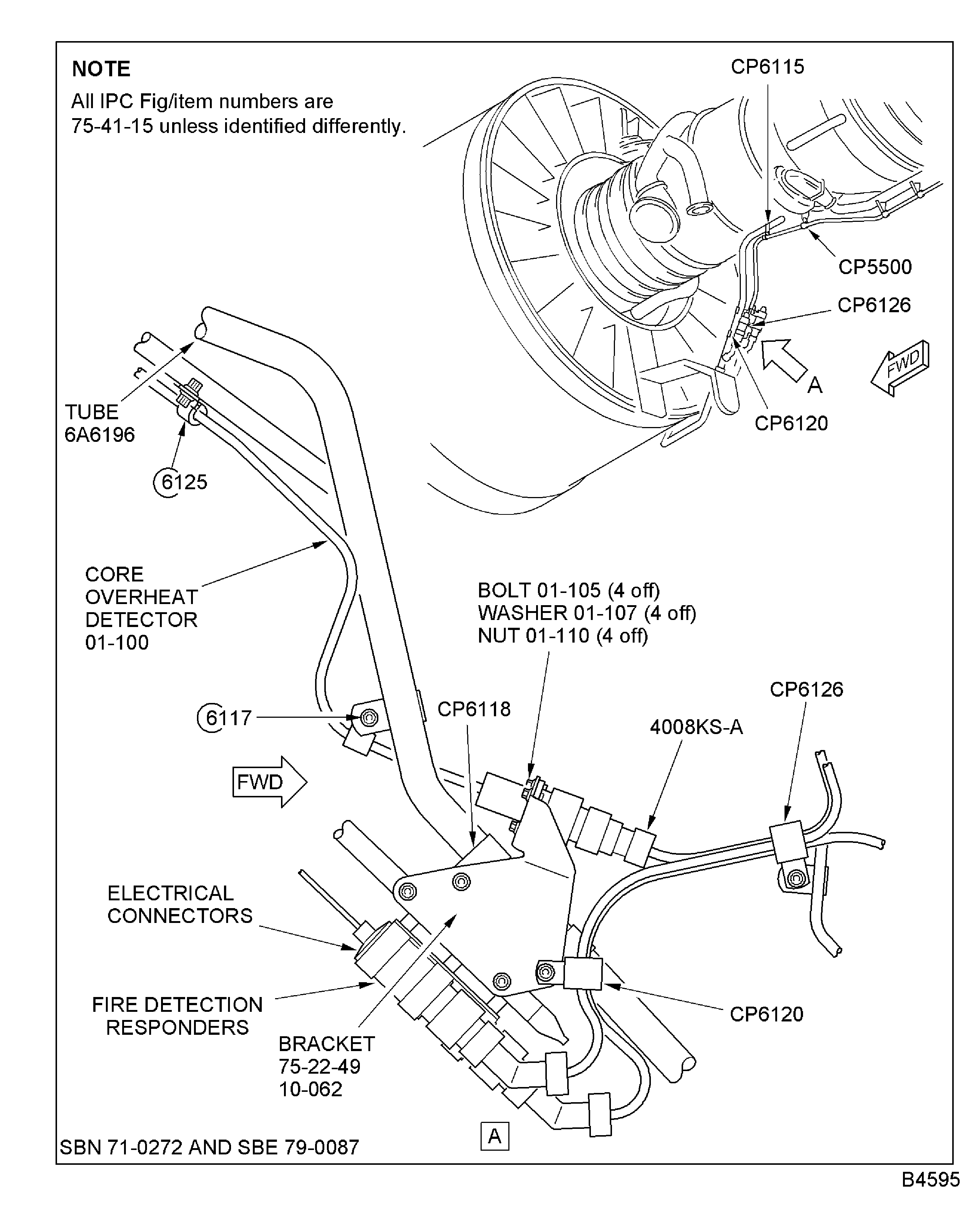

Pre SBE 79-0087: Remove the nuts, the bolts, the washers, the spacers and the clips from the clip positions 5221 and 5223.

SBE 79-0087: Remove the nuts, the bolts, the washers, the spacers and the clips from the clip positions 6117 and 6125.

NOTE

The core fire detector must have its maintenance completed, as given in the B.F. Goodrich Component Maintenance Manual (26-12-19).Remove the four nuts and bolts that attach the core overheat detector to the bracket NACELLE TEMPERATURE SENSOR (75-41-15, 05-010).

Remove the core overheat detector NACELLE TEMPERATURE SENSOR (75-41-15, 01-100).

SUBTASK 72-00-40-020-196-A00 Remove the Core Overheat Detector (Pre SBN 70-0151)

Pre SBE 79-0087: Remove the nuts, the bolts, the washers, the spacers and the clips from the clip positions 5221 and 5223.

SBE 79-0087: Remove the nuts, the bolts, the washers, the spacers and the clips from the clip positions 6117 and 6125.

NOTE

The core fire detector must have its maintenance completed, as given in the B.F. Goodrich Component Maintenance Manual (26-12-19).Remove the four nuts and bolts that attach the core overheat detector to the bracket NACELLE TEMPERATURE SENSOR (75-41-15, 05-010).

Remove the core overheat detector NACELLE TEMPERATURE SENSOR (75-41-15, 01-100),

SUBTASK 72-00-40-020-196-B00 Remove the Core Overheat Detector (SBN 70-0151)

SBN 70-0151: ATA Chapter relocation of the nacelle temperature sensor

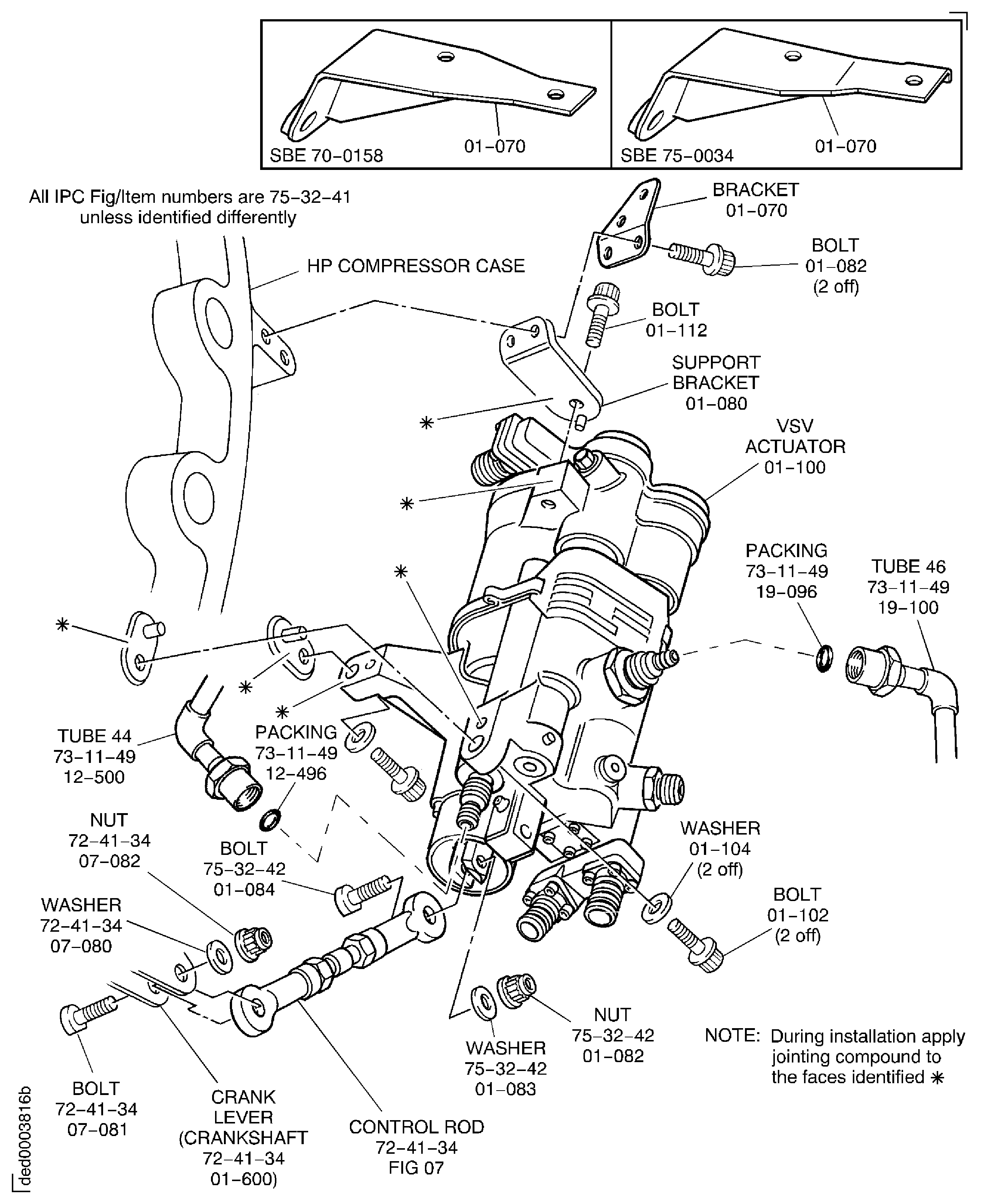

Hold the VSV actuator, remove the four bolts and the two washers that attach the actuator to the HP compressor case and remove the actuator. Remove the bracket AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41, 01-070).

NOTE

The VSV actuator must have its maintenance completed, as given in the D.S.I.C. Component Maintenance Manual (75-32-41).Remove the bolt and the washer that attaches the bracket AIR-HP COMPRESSOR VARIABLE STATOR VANE ACTUATOR (75-32-41, 01-080) to the actuator and remove the bracket.

SUBTASK 72-00-40-020-106 Remove the Variable Stator Vane (VSV) Actuator

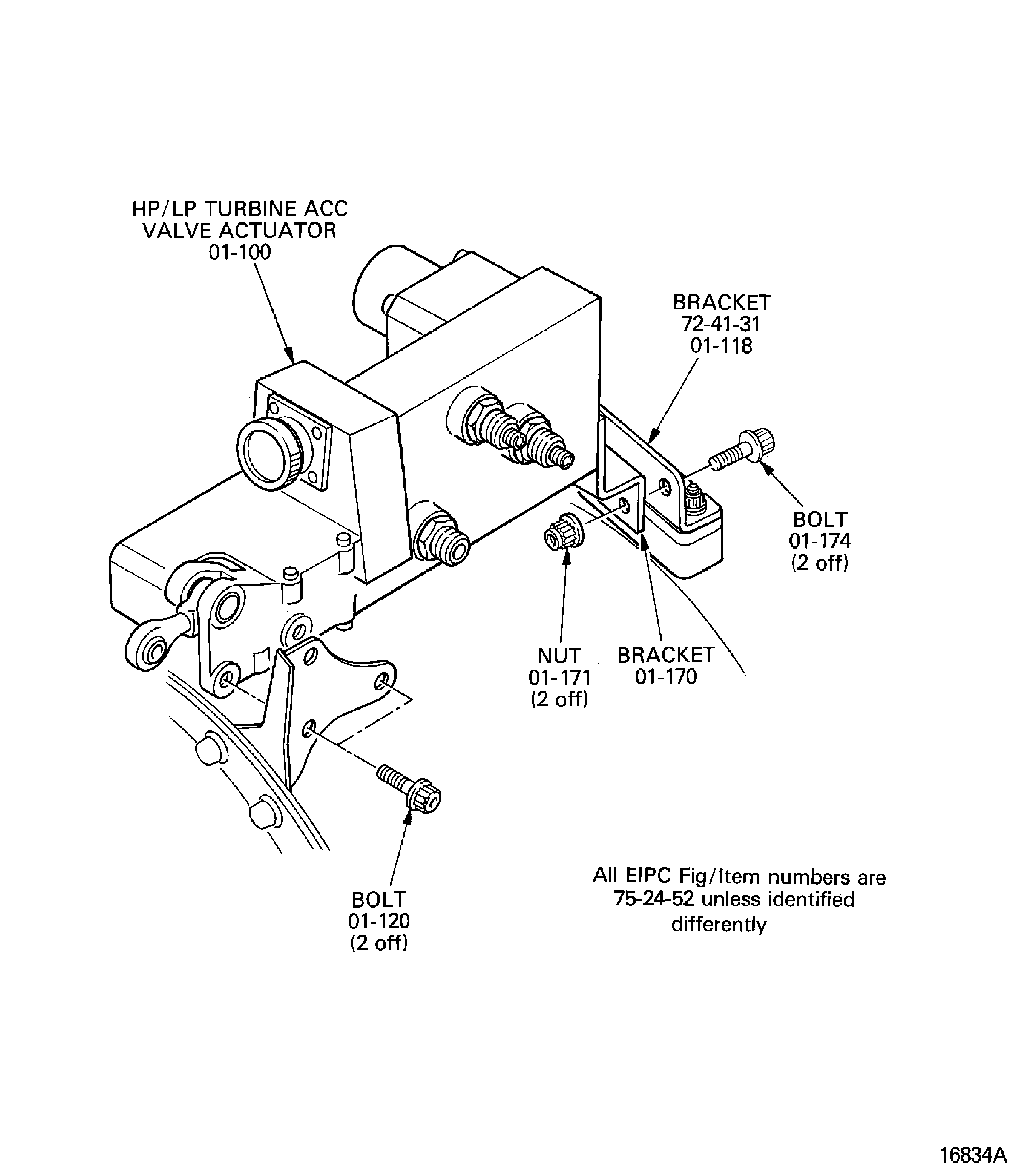

Remove the two bolts that attach the ACC actuator to the bracket ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 03-380) on flange FJ.

NOTE

The ACC actuator must have its maintenance completed, as given in the Parker Hannifin Component Maintenance Manual (75-24-52).Remove the two nuts and bolts that attach the ACC actuator to the bracket ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-118) on the HP compressor case. Remove the ACC actuator.

SUBTASK 72-00-40-020-107 Remove the Active Clearance Control (ACC) Actuator

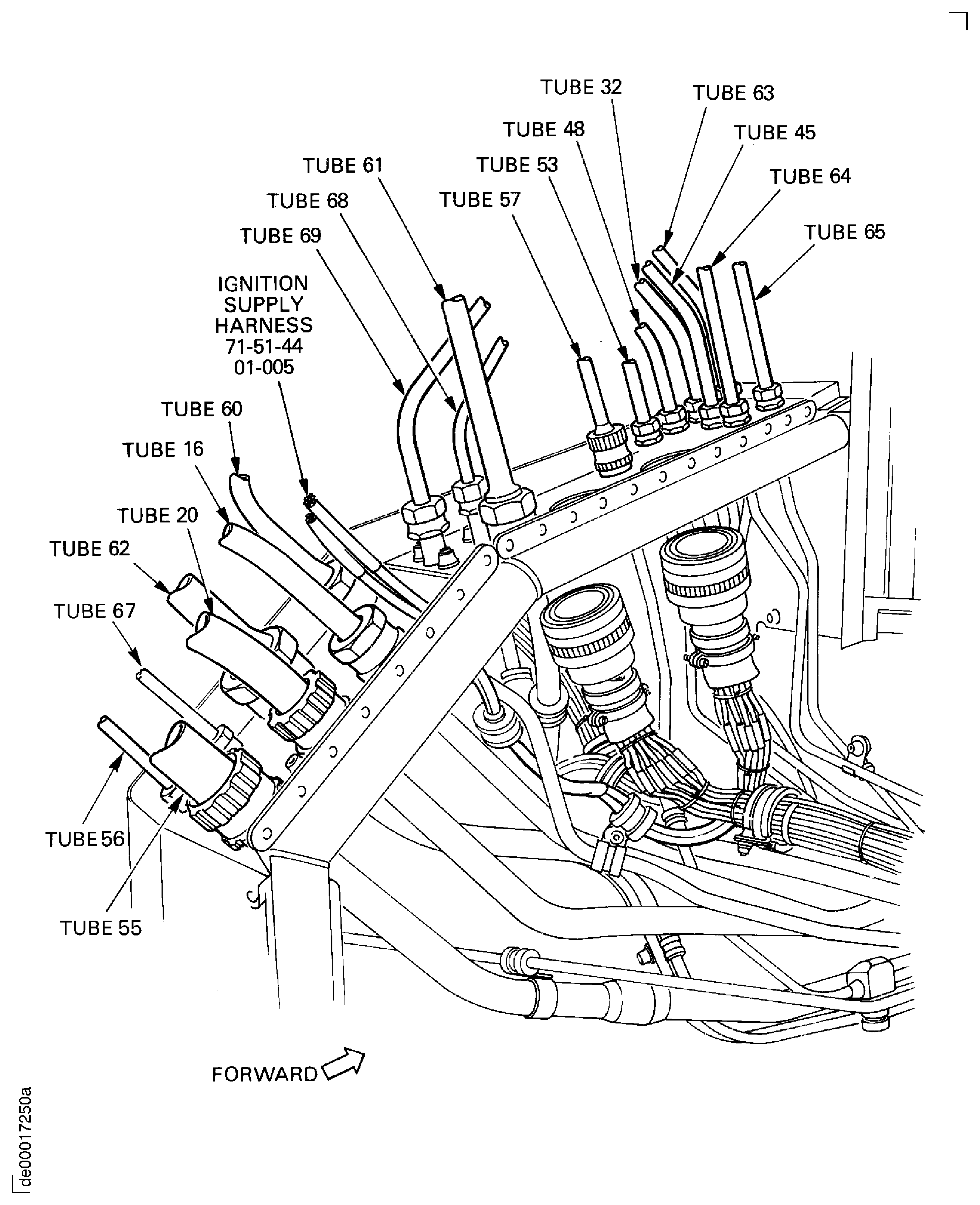

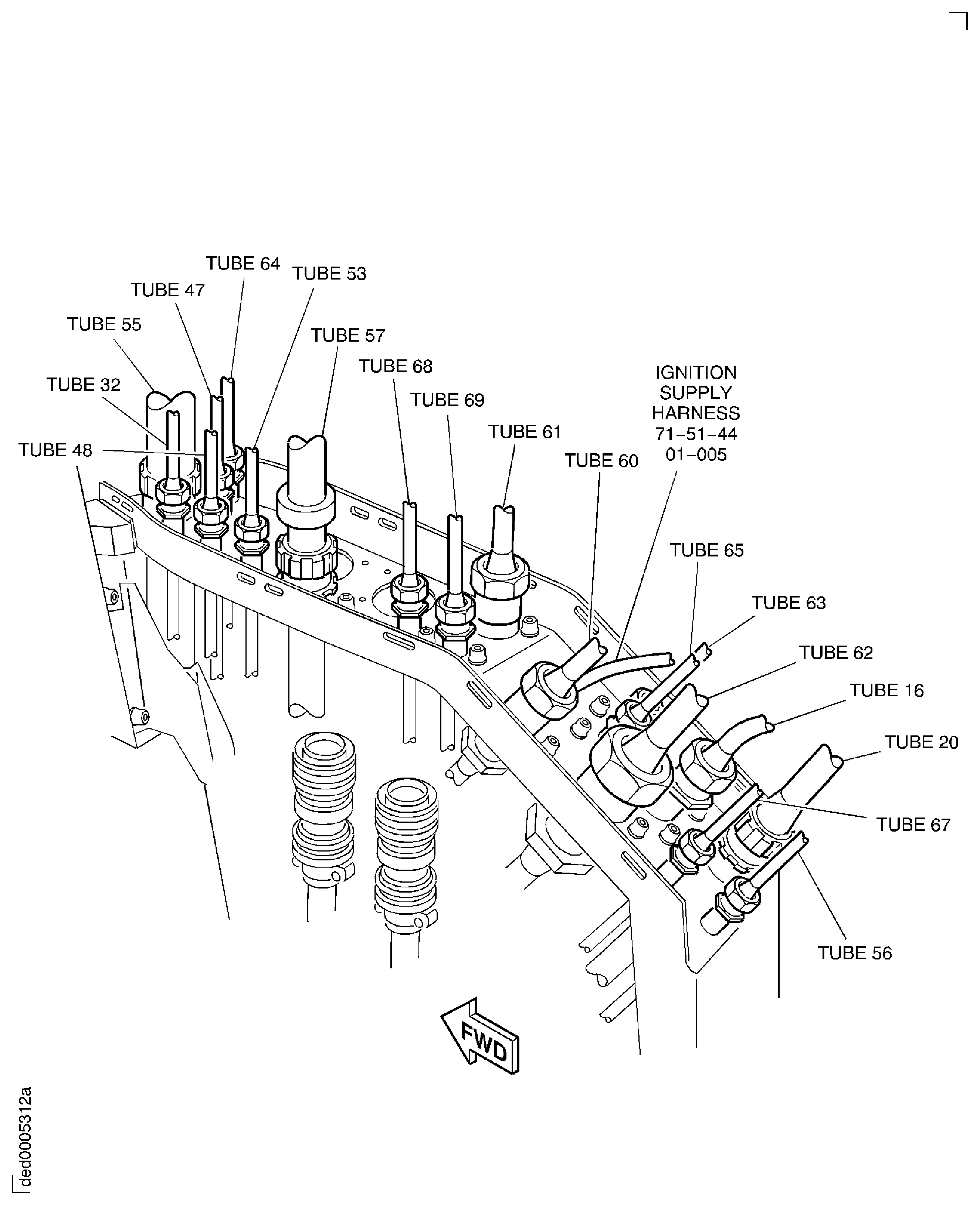

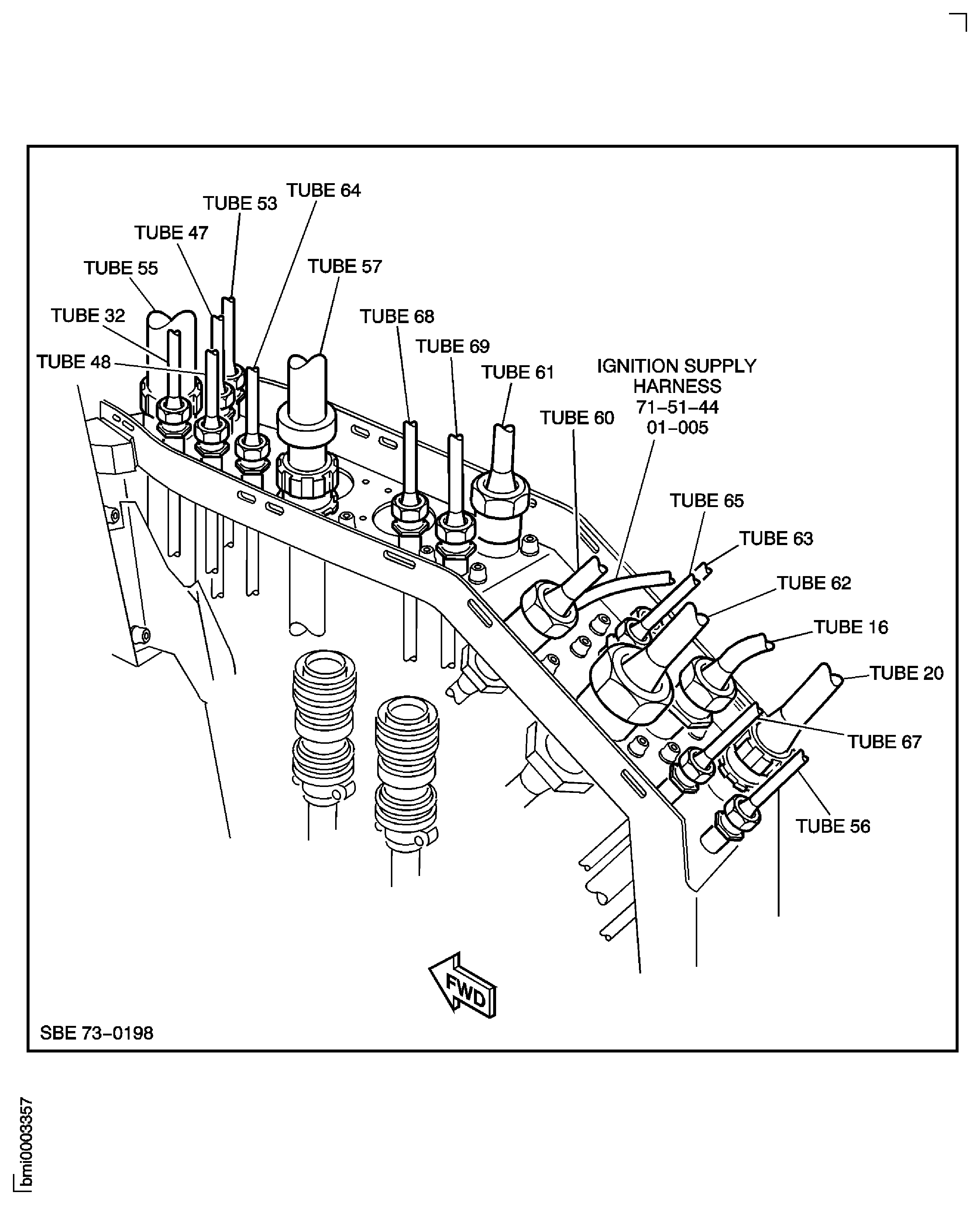

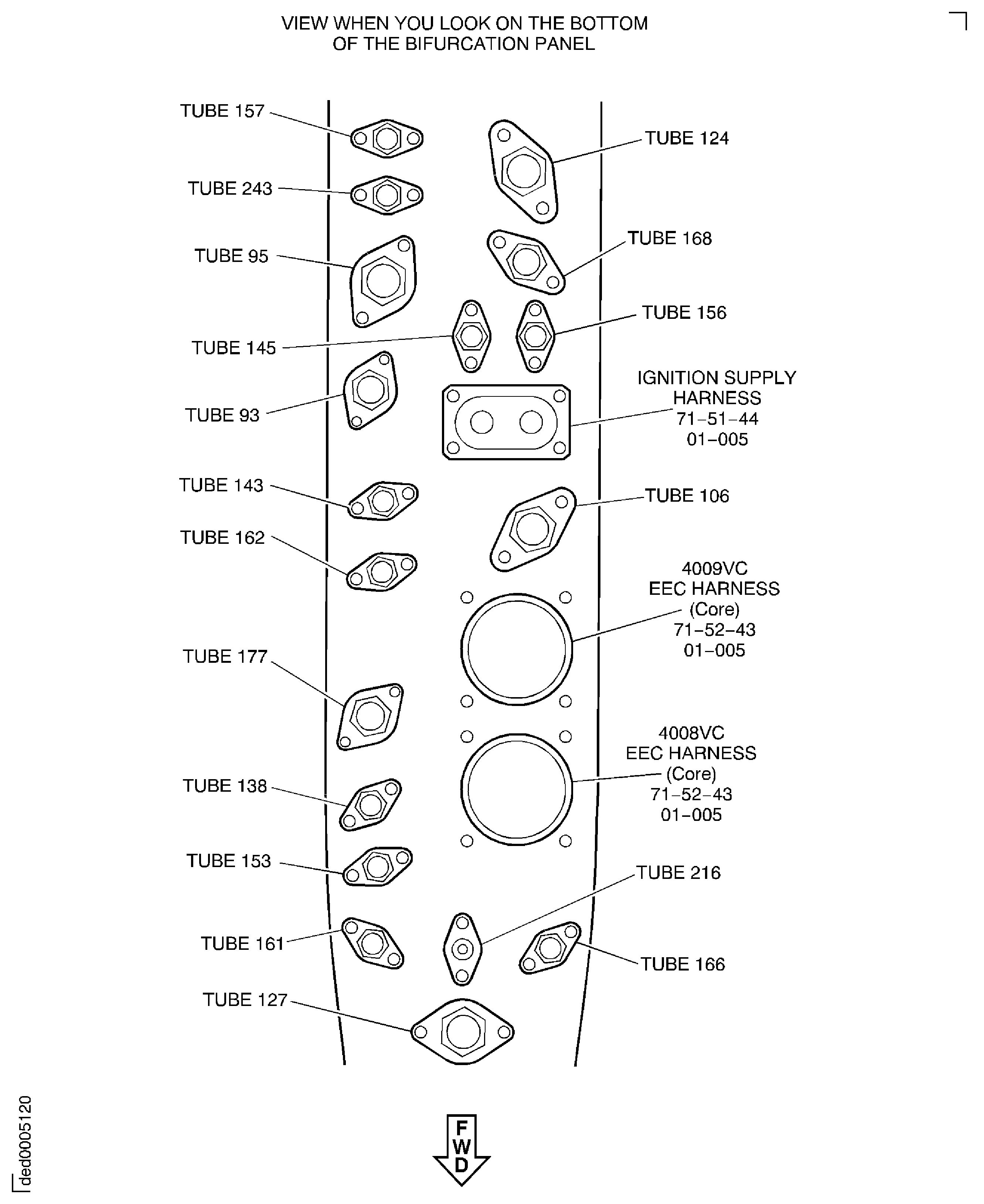

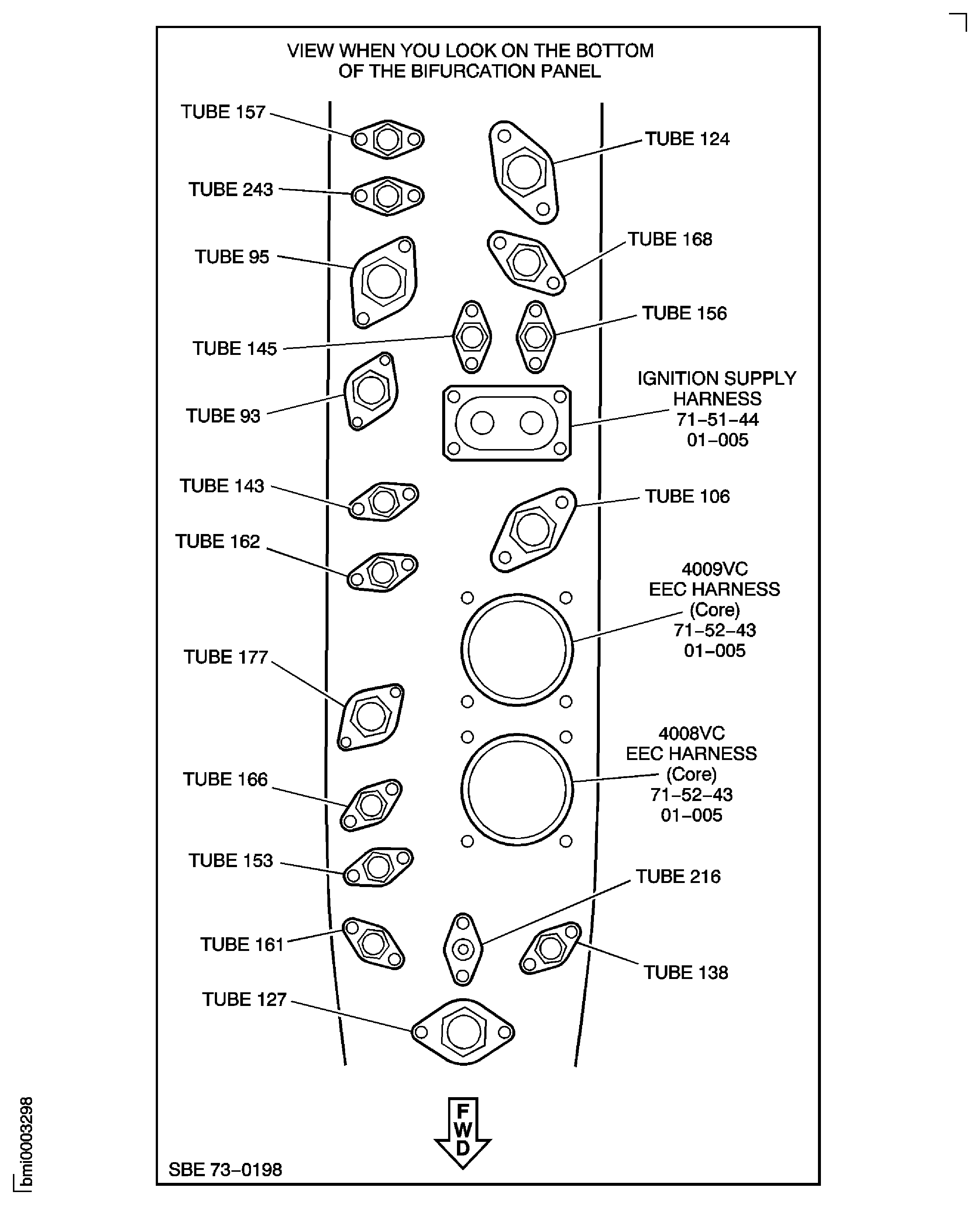

Disconnect the tubes at the bifurcation panel:

The stage 10 bleed air tube 16 from the tube 168.

The No. 5 bearing oil tube 20 from the tube 124.

The stage 7 bleed air tube 32 from the tube 161.

The cabin bleed air tube 48 from the tube 153.

The PS3 sense tube 53 from the tube 138.

The No. 4 bearing scavenge oil tube 55 from the tube 127.

The P4.9 pressure rake air tube 56 from the tube 157.

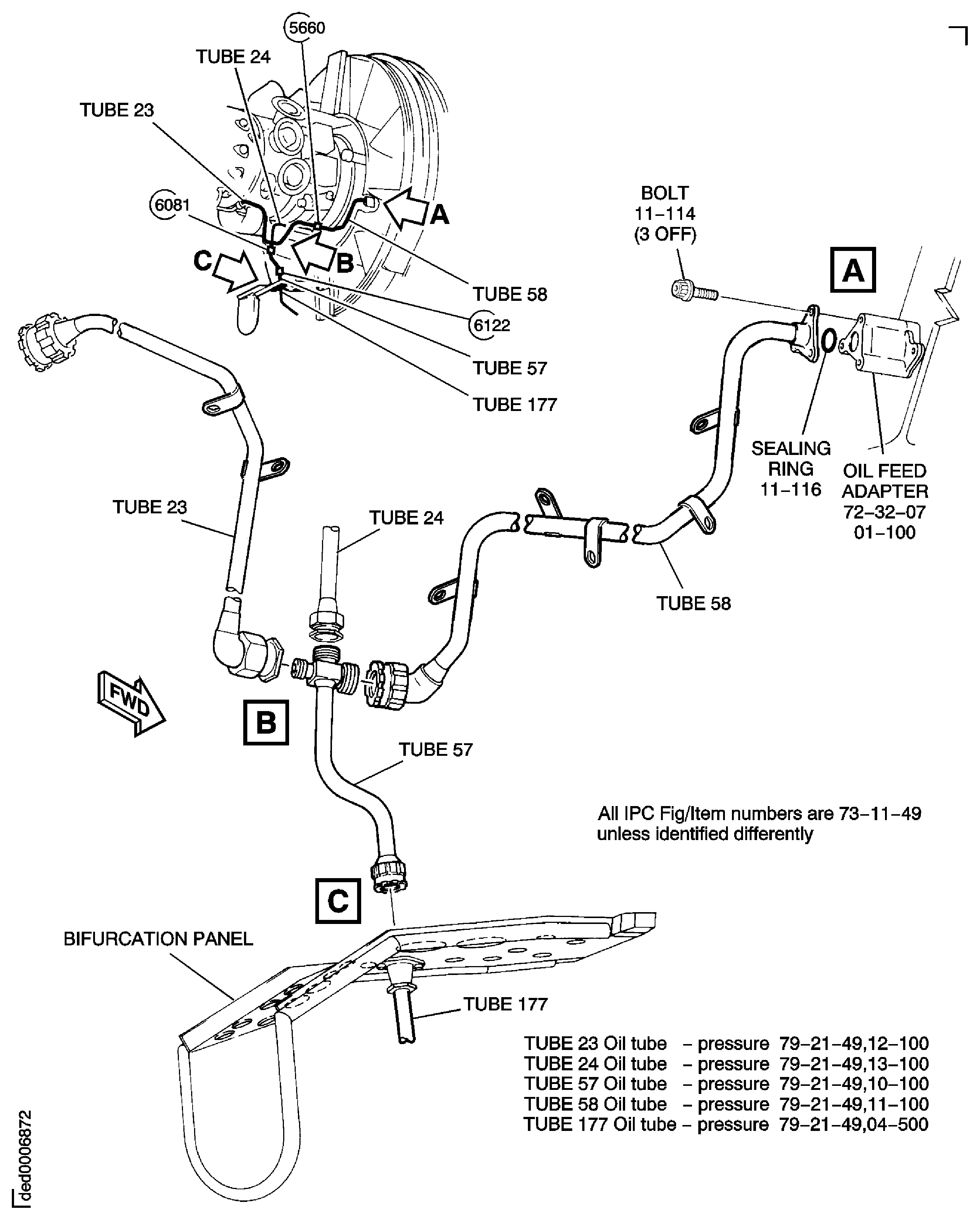

The bearing oil feed tube 57 from the tube 177.

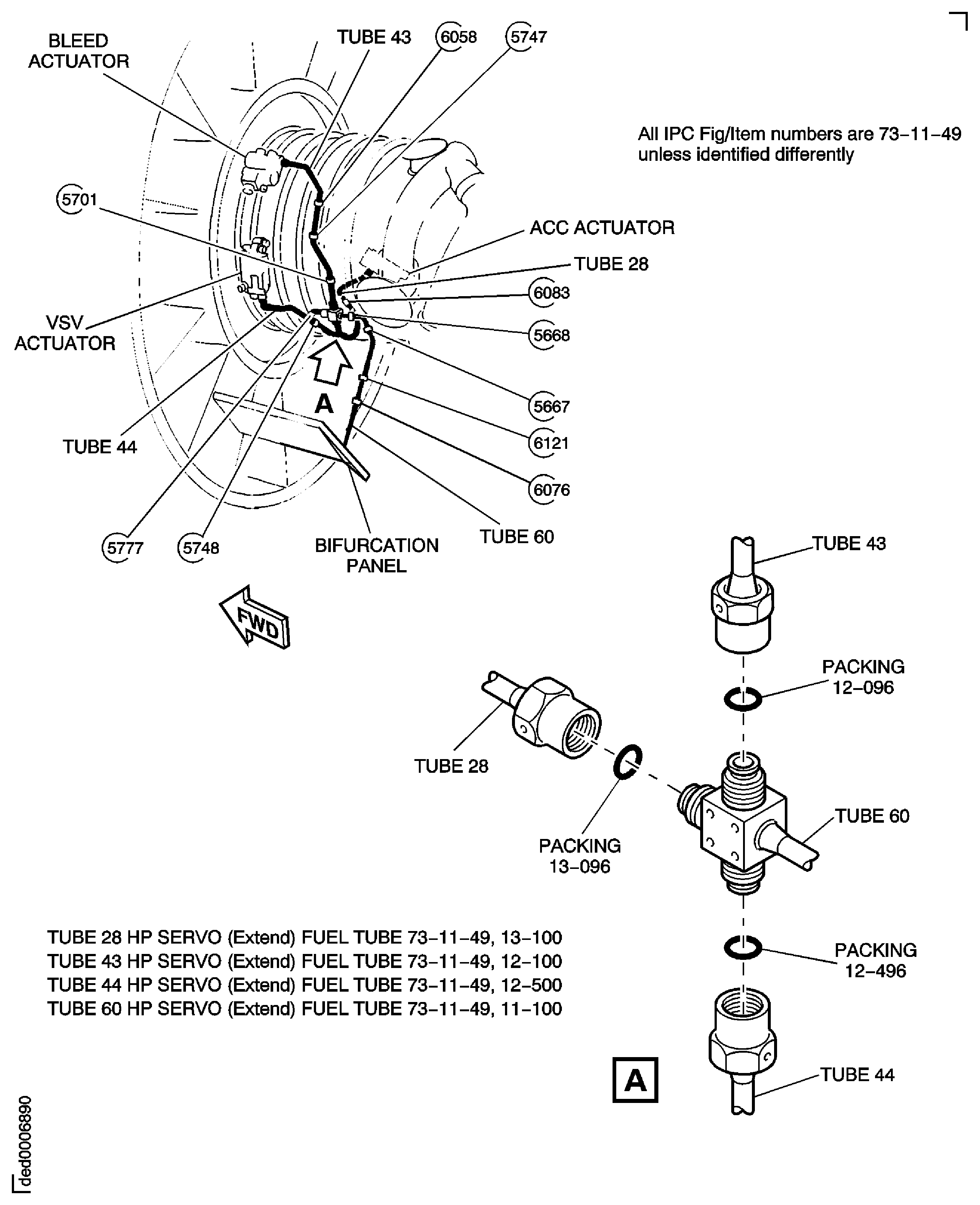

The servo extend fuel tube 60 from the tube 93.

The servo extend fuel tube 61 from the tube 106.

The fuel supply tube 62 from the tube 95.

The stage 7 bleed air tube 63 from the tube 156.

The stage 10 bleed air tube 64 from the tube 166.

The stage 7 bleed air tube 65 from the tube 145.

The P2.5 pressure air tube 67 from the tube 243.

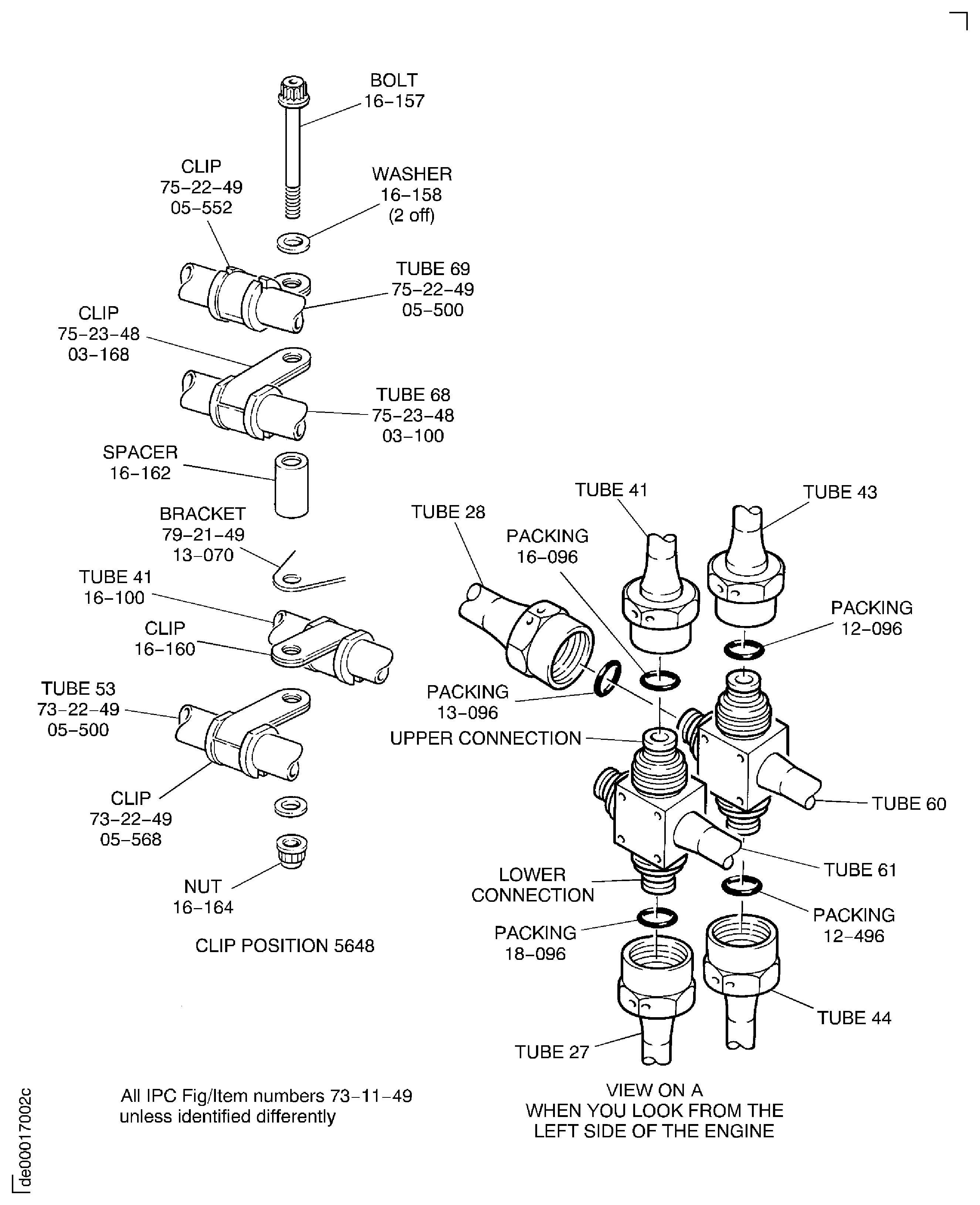

The stage 10 on/off solenoid air tube 68 from the tube 162.

The No.4 bearing scavenge valve air tube 69 from the tube 143.

SUBTASK 72-00-40-020-115 Disconnect the Tubes at the Bifurcation Panel

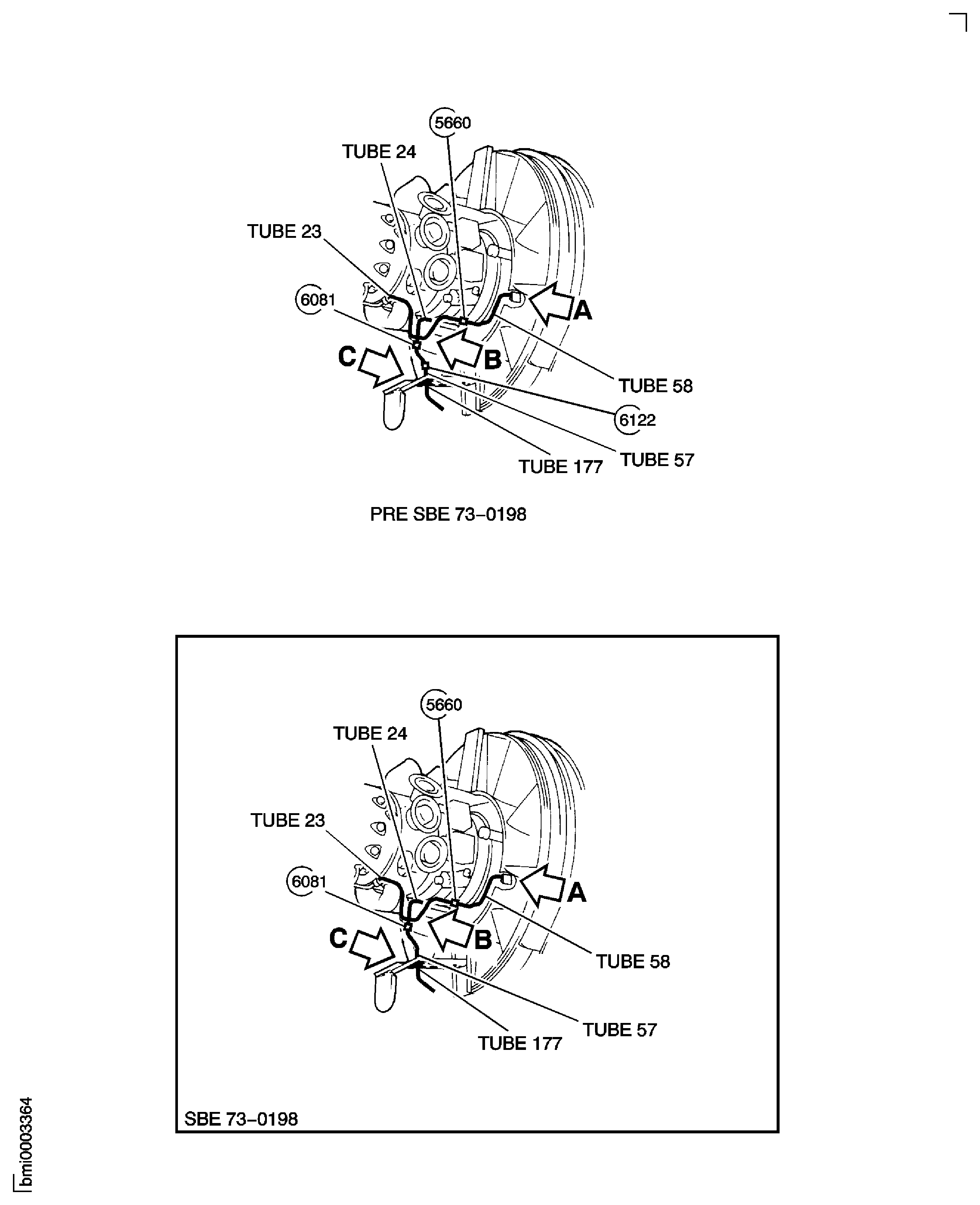

Pre SBE 79-0087: Remove the bolt, the washer, the clip and the nut from clip position 5658.

SBE 79-0087 and Pre SBE 73-0198: Remove the bolt, the washer, the clip and the nut from clip positions 6081 and 6122.

SBE 73-0198: Remove the bolt, the washer, the clip and the nut from clip position 6081.

SUBTASK 72-00-40-020-084 Remove the No. 1, 2 and 3 Bearing Oil Feed Tubes 58 and 57 (Pre SBE 73-0198, SBE 73-0198, Pre SBE 79-0087 and SBE 79-0087)

SBE 73-0198: Engine fuel and control - Fuel system air tube - Introduction of re-routed burner to Engine Electronic Controller (EEC) pressure (PB) sense line tube assemblies

SBE 79-0087: Oil - Scavenge oil tubes - Re-route of number 4 bearing scavenge tube

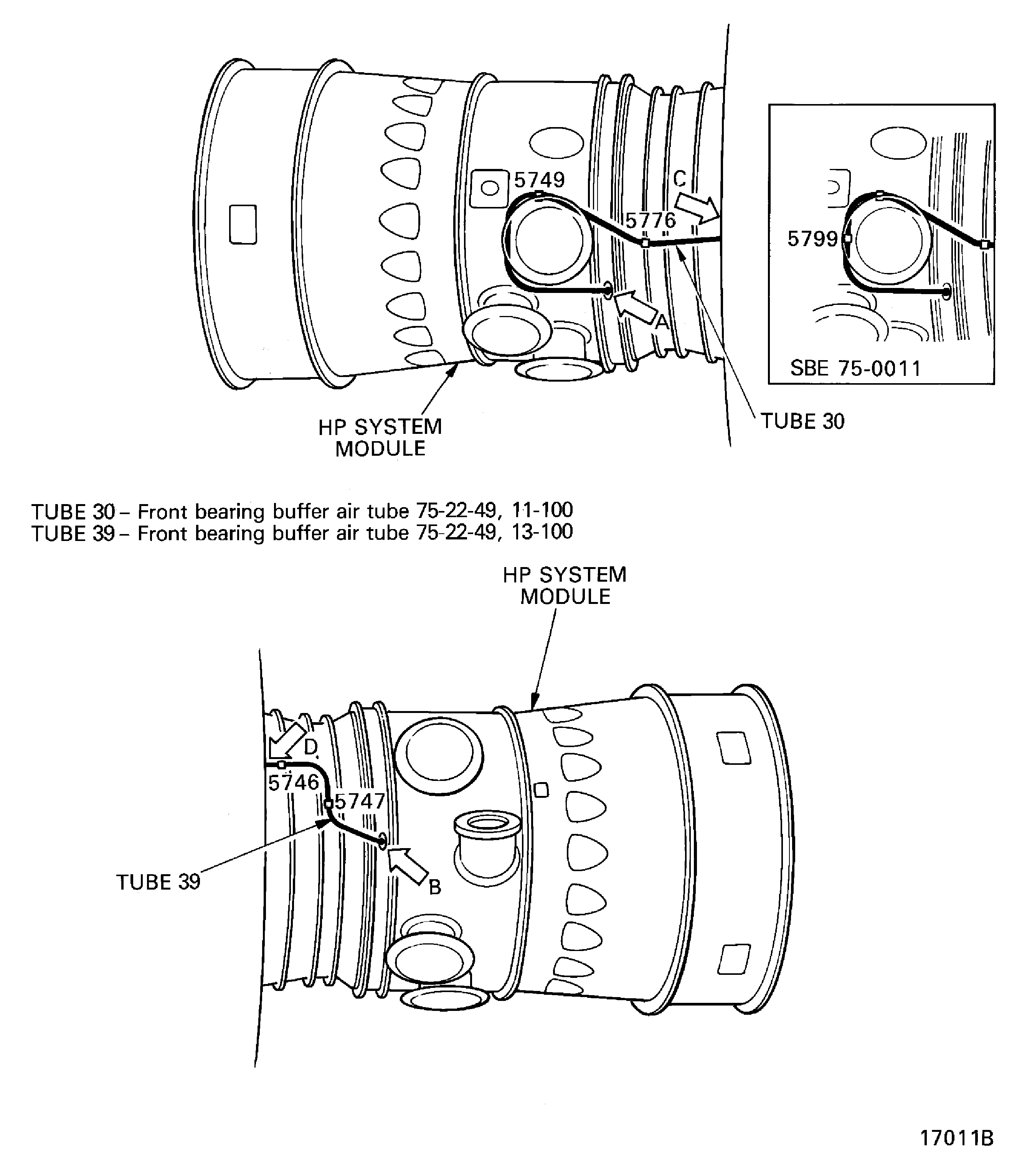

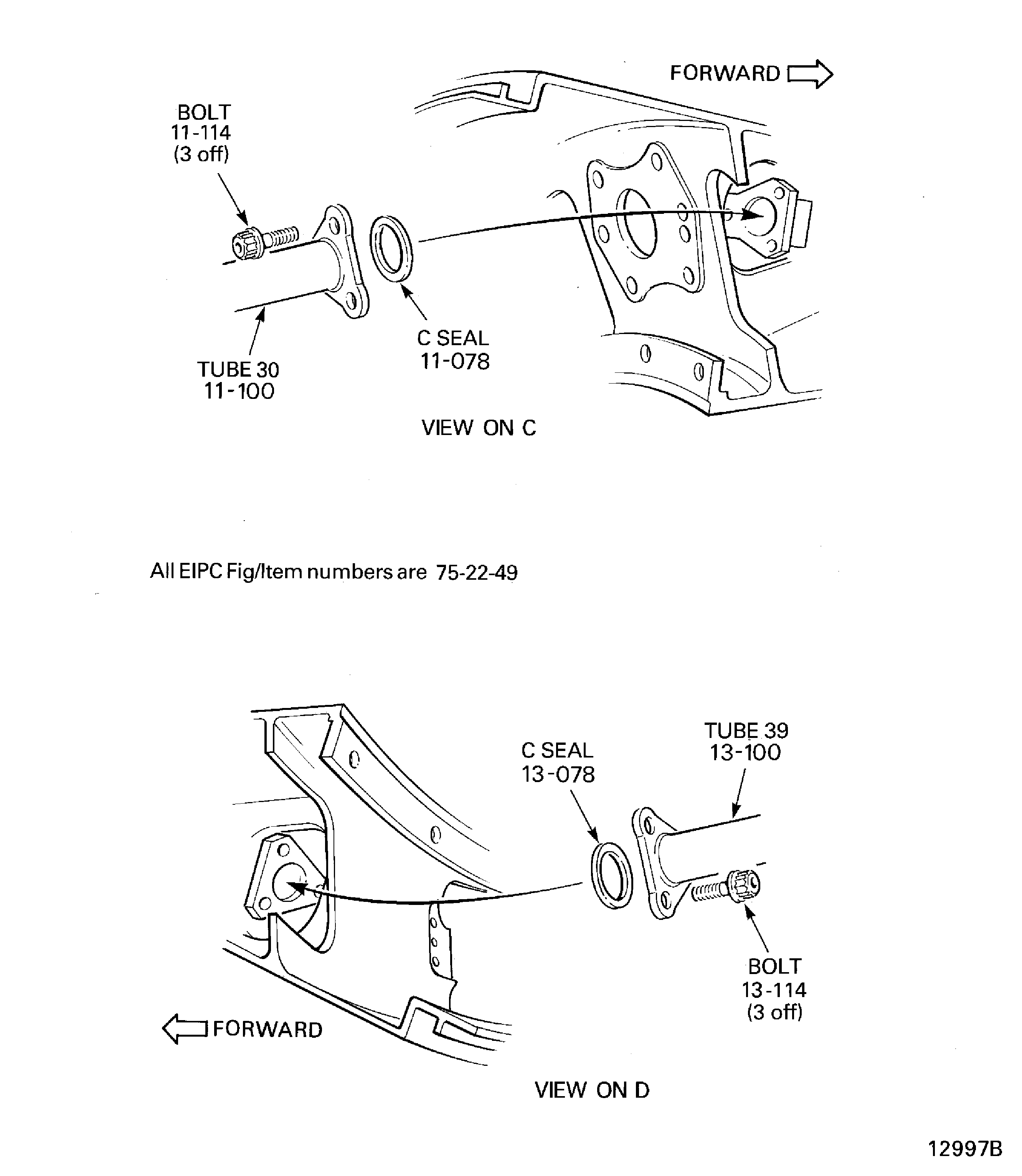

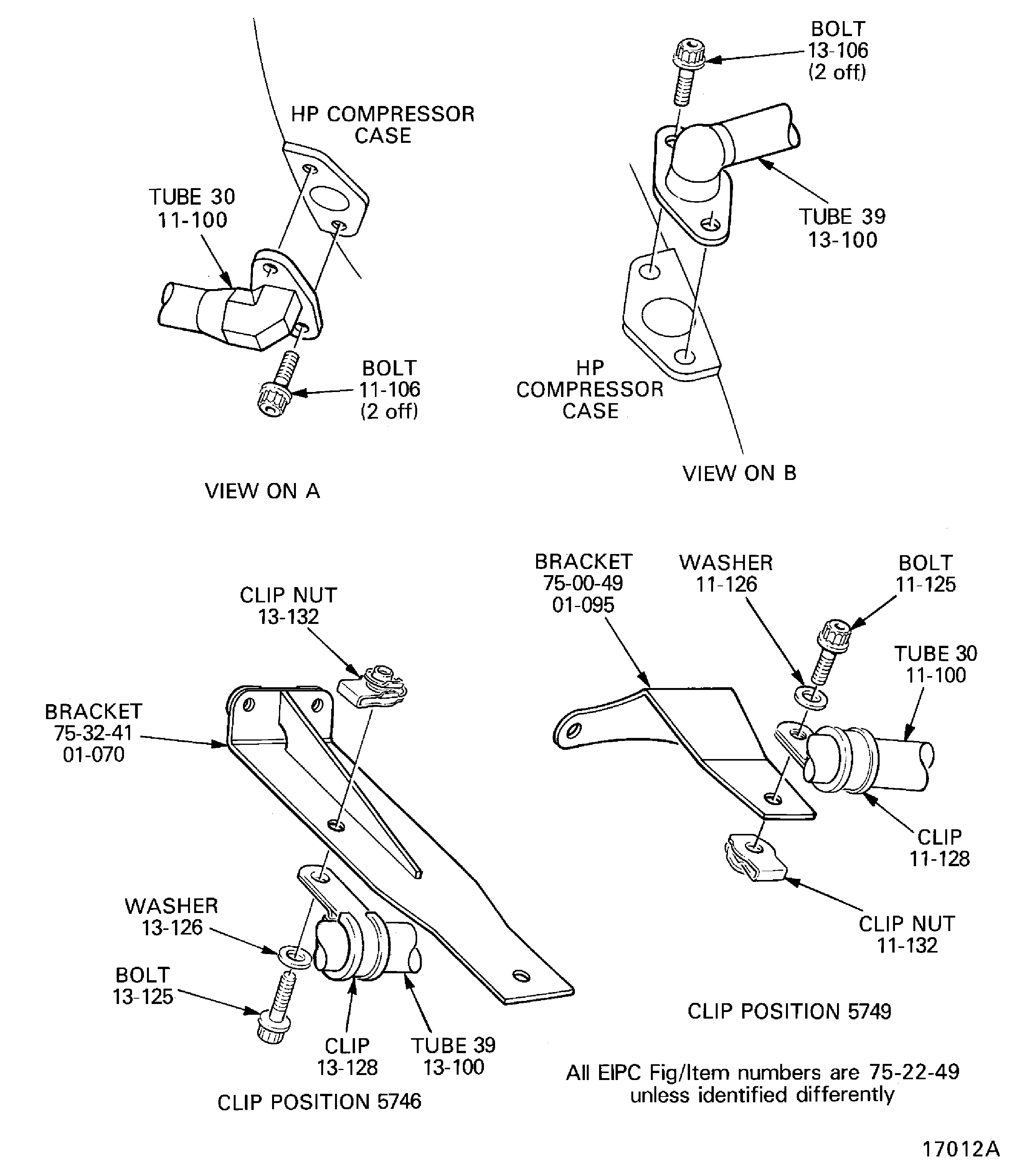

SUBTASK 72-00-40-020-085-A00 Remove the Front Bearing Buffer Air Tubes 30 and 39 (Pre SBE 75-0011 and Pre SBE 72-0132)

SUBTASK 72-00-40-020-085-B00 Remove the Front Bearing Buffer Air Tubes 30 and 39 (Pre SBE 72-0132 and SBE 75-0011)

SBE 75-0011: Air - Introduction of a support bracket for the FBC buffer air tube assembly.

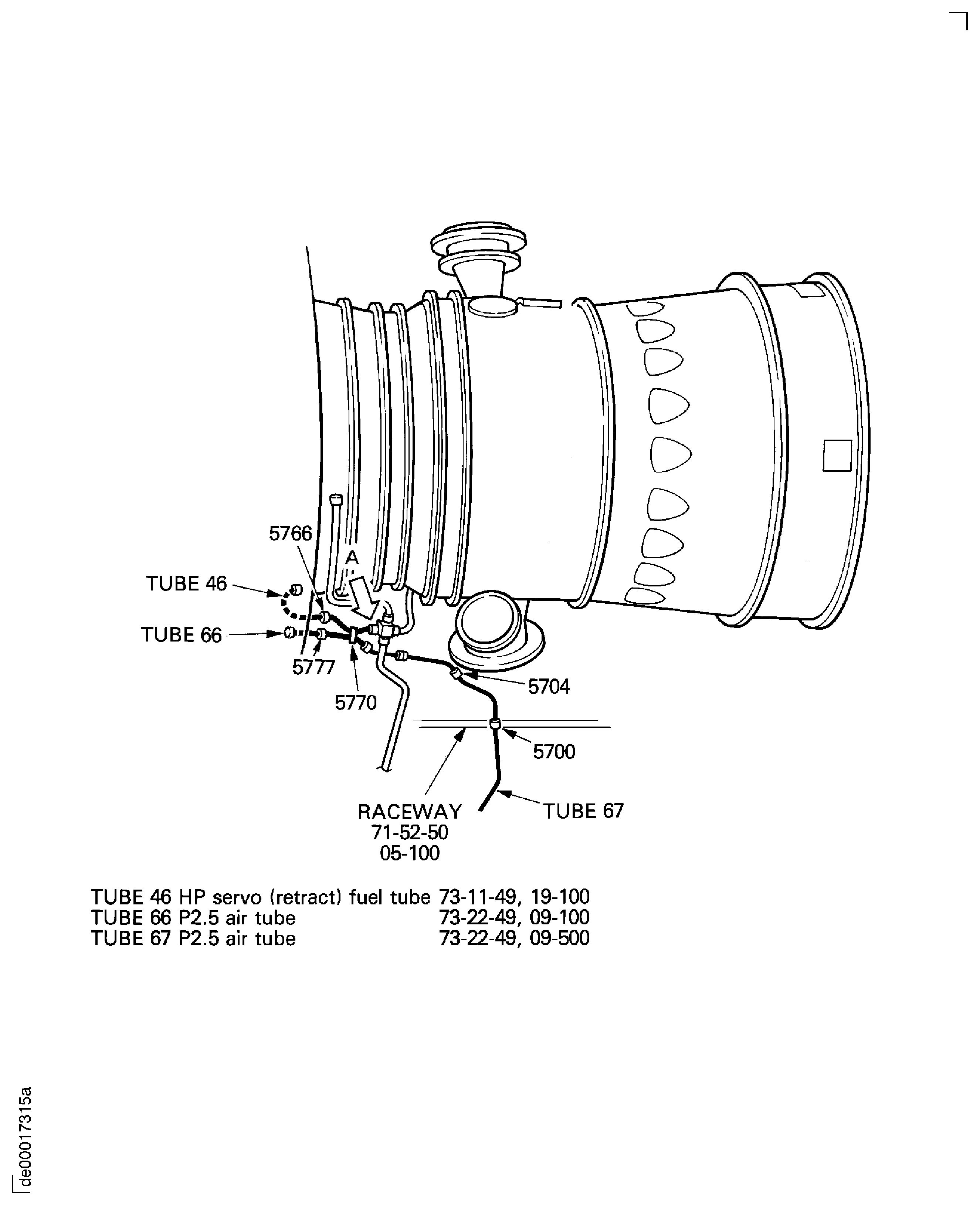

Pre SBE 79-0087: Remove the bolts, the washers, the clips and the nuts from the clip positions 5700 and 5704.

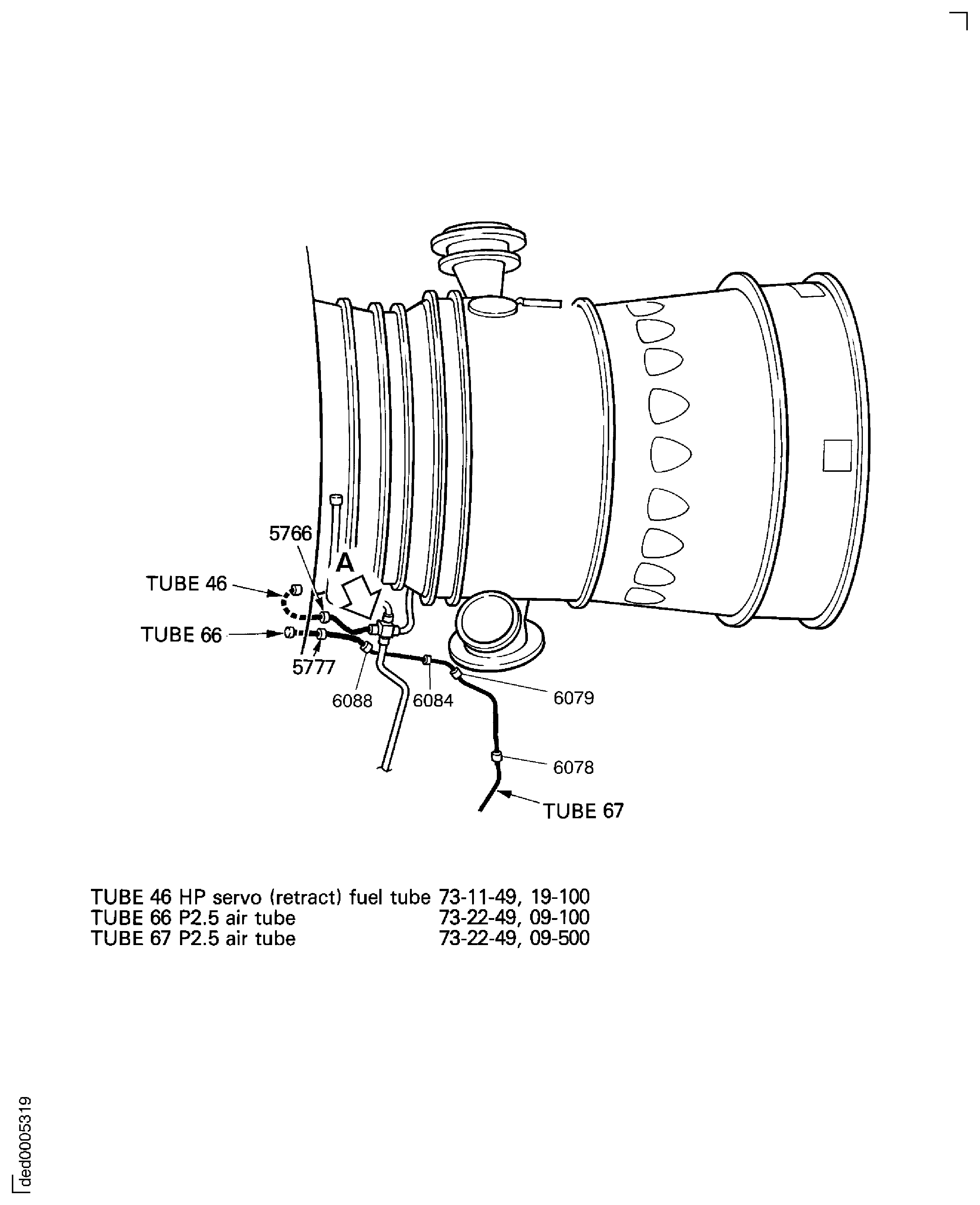

SBE 79-0087: Remove the bolts, the washers, the clips and the nuts from the clip positions 6078, 6079, 6084 and 6088.

Remove the tube 67.

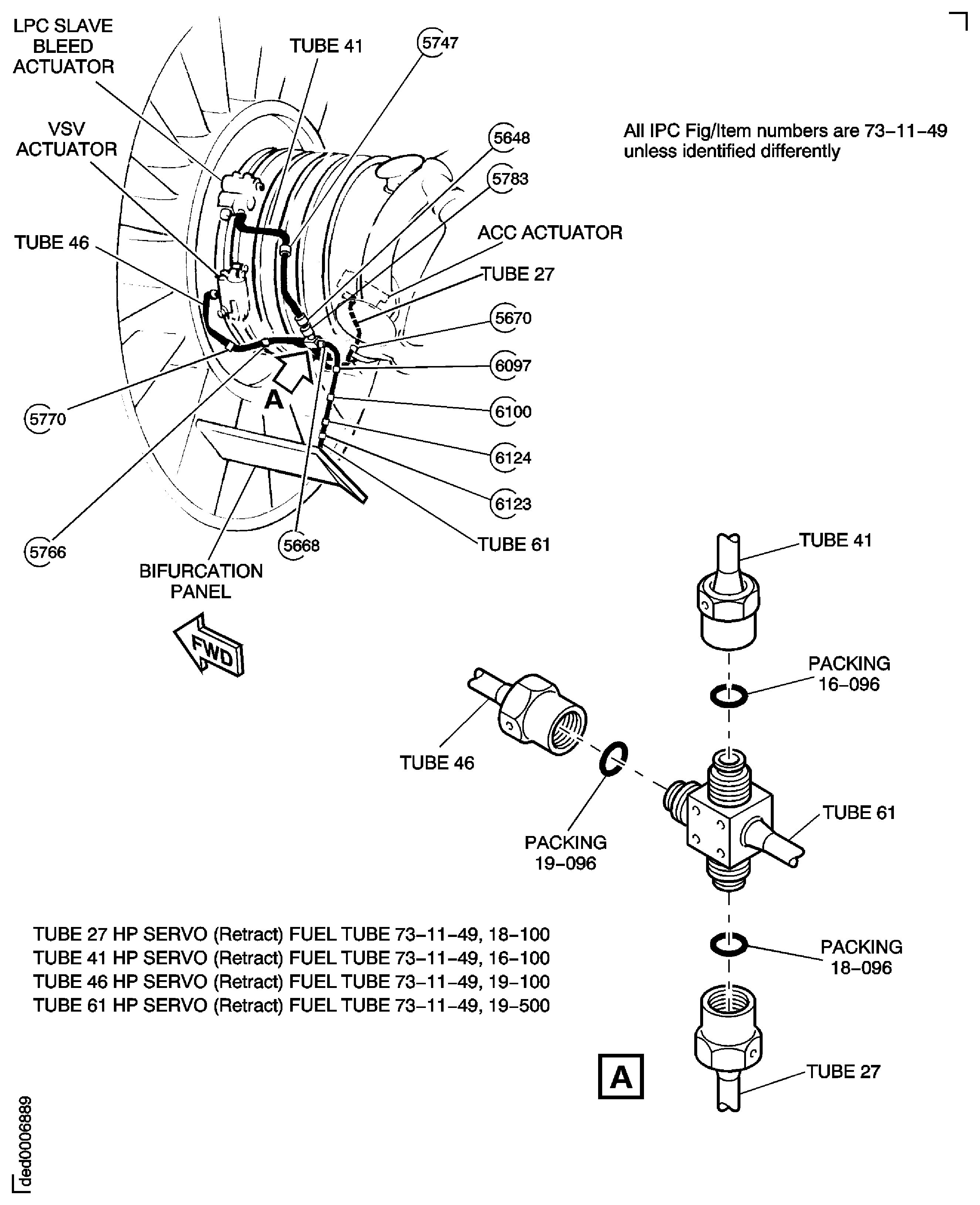

SUBTASK 72-00-40-020-126 Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67

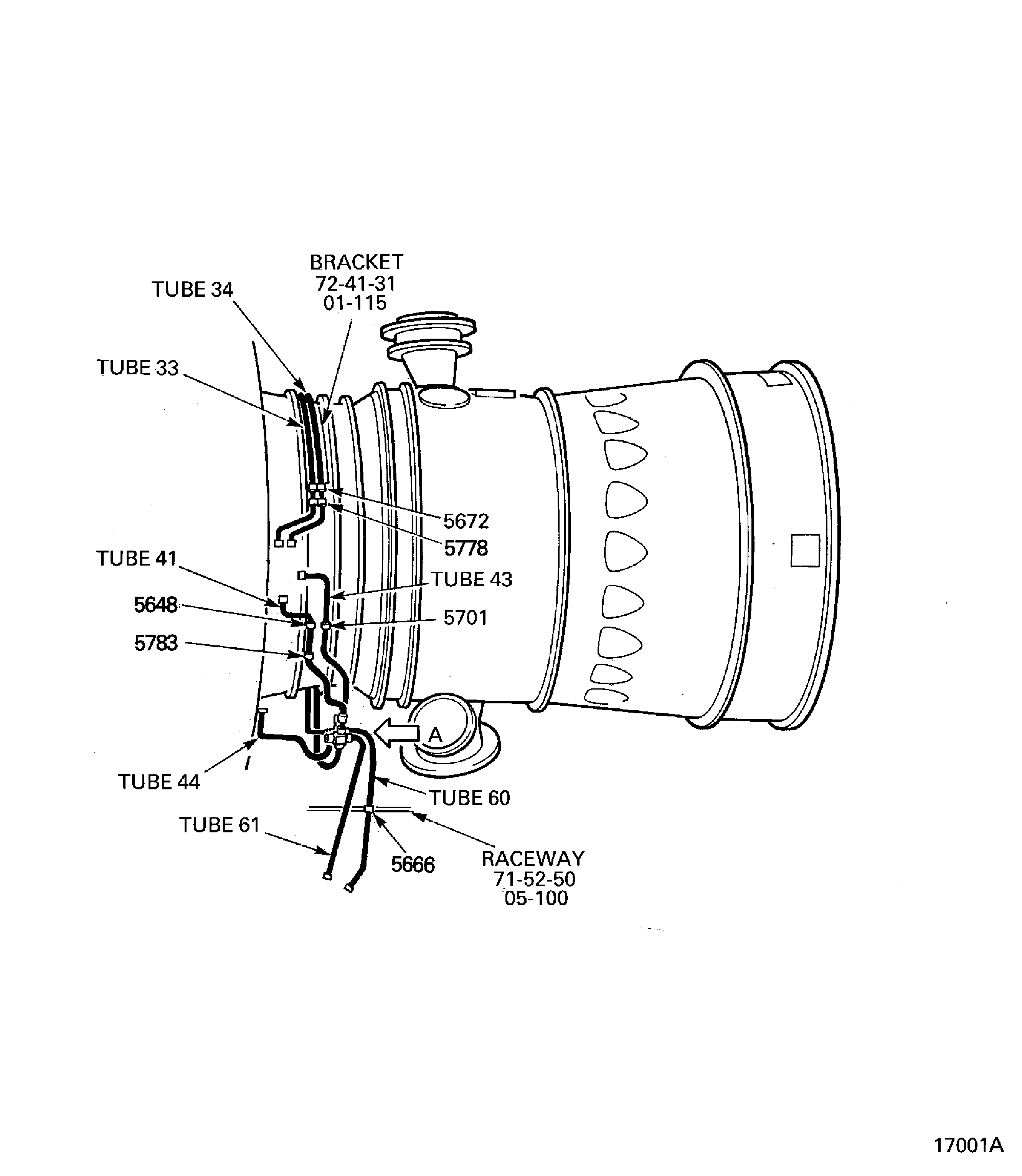

Pre SBE 79-0087: Remove the bolts, the washers, the spacer, the clips and the nuts from the clip positions 5648 and 5783.

SBE 79-0087: Remove the bolts, the washers, the spacer, the clips and the nuts from the clip positions 5648 and 5747.

Pre SBE 79-0087: Disconnect the tube 41 from the upper connection of the tube 61 and remove the tube 41 and the packing.

SBE 79-0087: Disconnect the tube 41 from the upper connection of the tube 61 and remove the tube 41 and the packing.

Remove the tube 41.

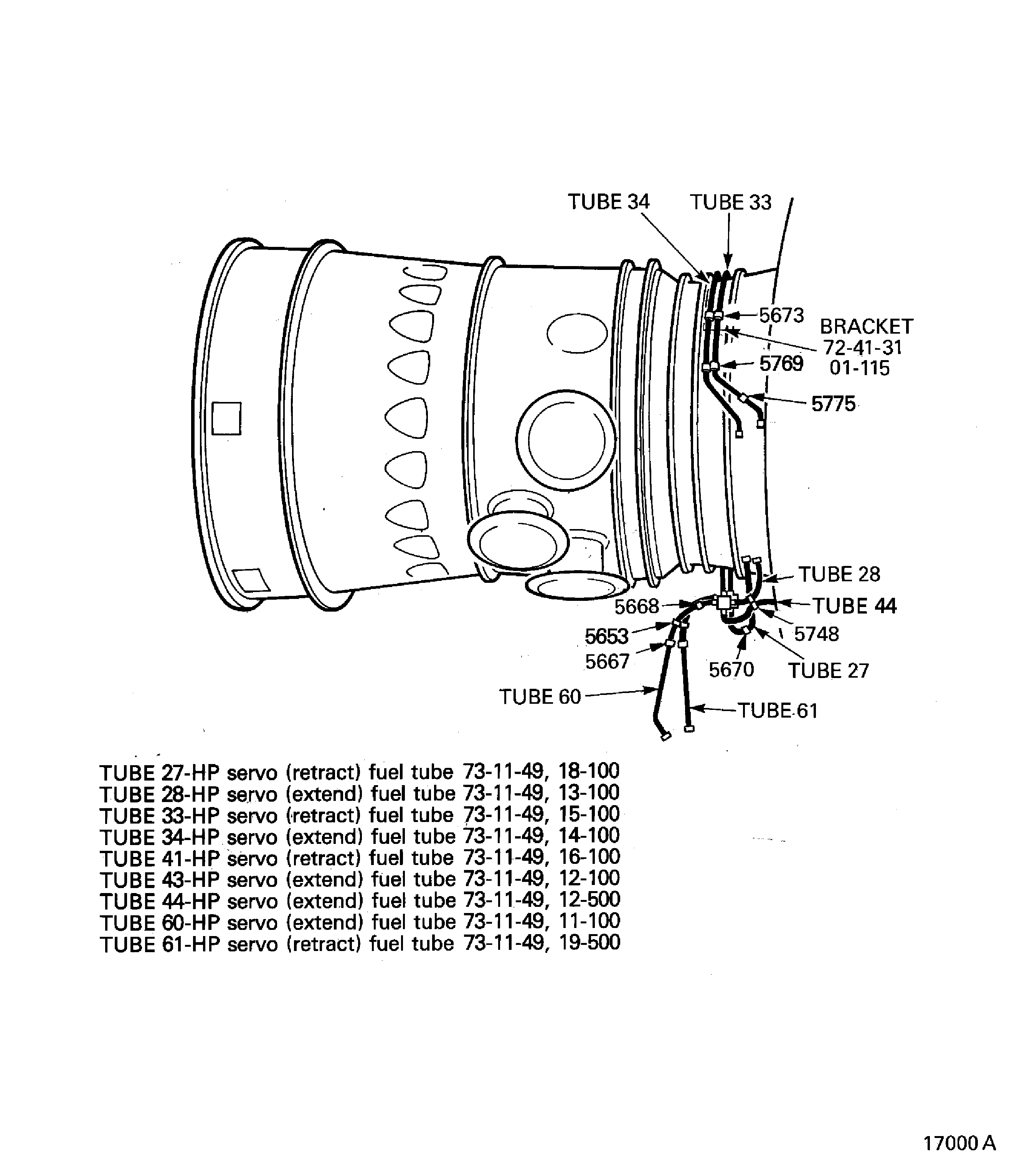

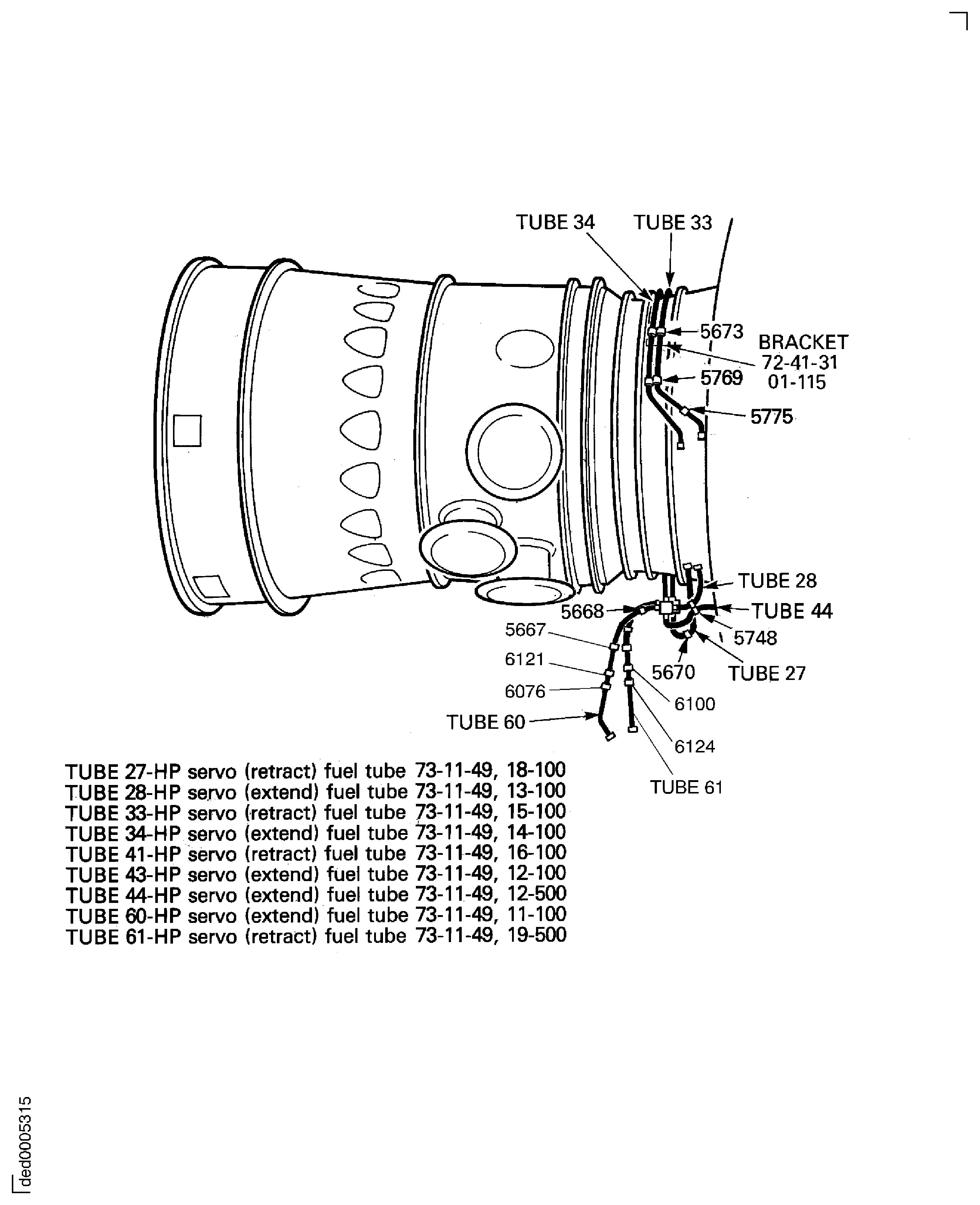

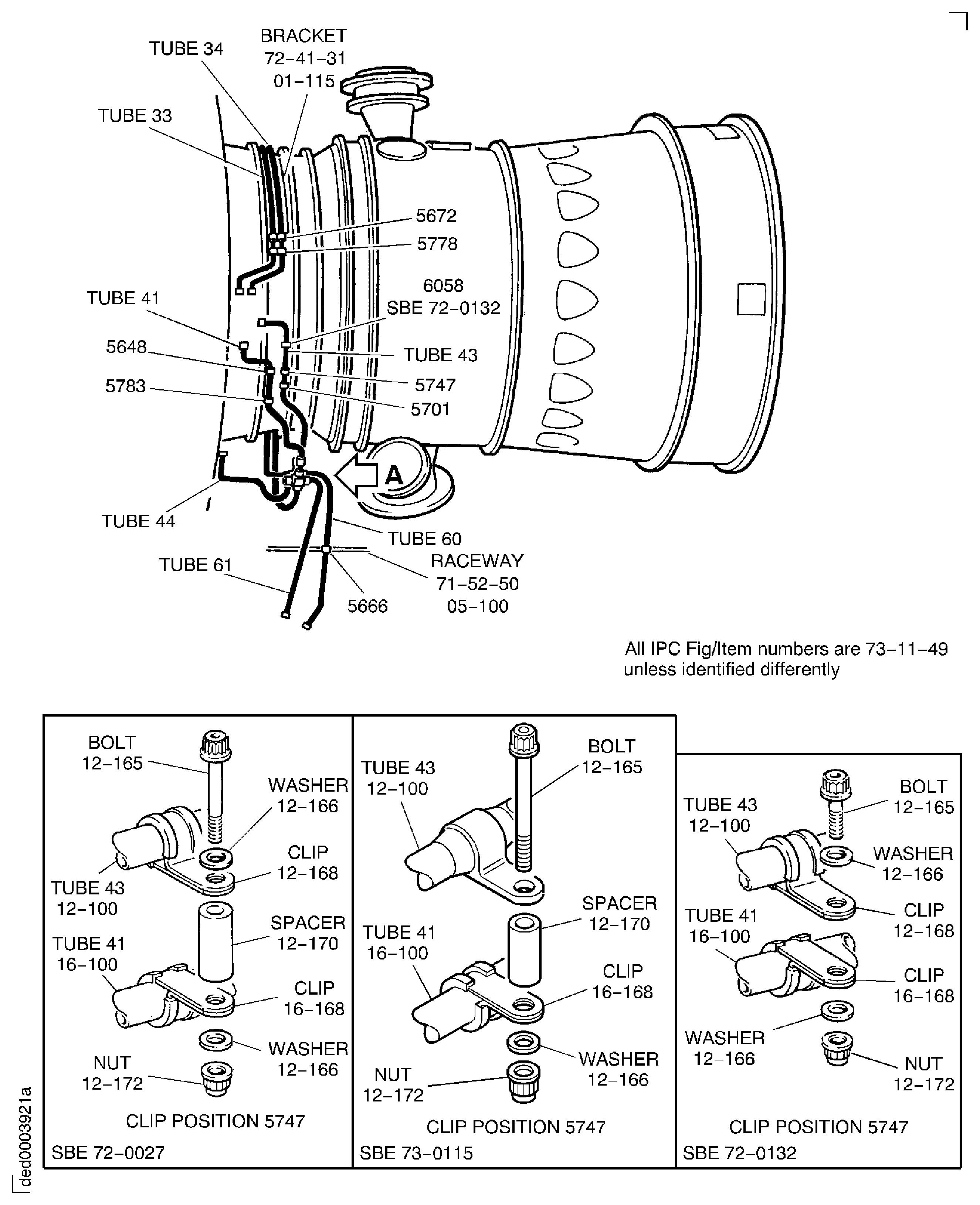

Pre SBE 79-0087: Remove the bolts, the washers, the spacers, the clips, the nuts and the clipnuts from the clip positions 5653, 5666, 5667 and 5668.

SBE 79-0087: Remove the bolts, the washers, the spacers, the clips, the nuts and the clipnuts from the clip positions 5667, 5668 and 6076.

SBE 79-0087: Remove the bolts, the washers, the spacers, the clips, the nuts and the clipnuts from the clip positions 6097, 6100, 6121, 6123 and 6124.

Remove the tubes 60 and 61.

SUBTASK 72-00-40-020-127 Remove the HP Servo Fuel Tubes

SUBTASK 72-00-40-020-206-A00 Remove the HP Servo Fuel Tube 43 (Pre SBE 72-0027, Pre SBE 72-0132, Pre SBE 73-0115 and Pre SBE 79-0087)

Pre SBE 73-0115: Remove the bolt, the washers, the clips, the spacer and the nut from clip position 5747.

SBE 73-0115: Remove the bolt, the washer, the clips, the spacer and the nut from clip position 5747.

Remove the tube 43.

SUBTASK 72-00-40-020-206-B00 Remove the HP Servo Fuel Tube 43 (SBE 72-0027, SBE 73-0115 and Pre SBE 79-0087)

SBE 72-0027: HP Compressor - Introduction of reduced weight front compressor casing

SBE 73-0115: Engine fuel and control - Fuel system tubes - Engine - Introdution of revised external fuel tube assembly with weld-in lug and amended clipping

SUBTASK 72-00-40-020-206-C00 Remove the HP Servo Fuel Tube 43 (SBE 72-0132, SBE 73-0103 and SBE 79-0087)

SBE 72-0132: LP Compressor - Removal of stage 6 buffer air system

SBE 73-0103: Engine fuel and control - Fuel system tubes - Engine - Introduction of revised clipping for the HP servo external fuel tube assembly

SBE 79-0087: Oil - Revised routing of EBU systems to allow re-routing of the oil scavenge tubes

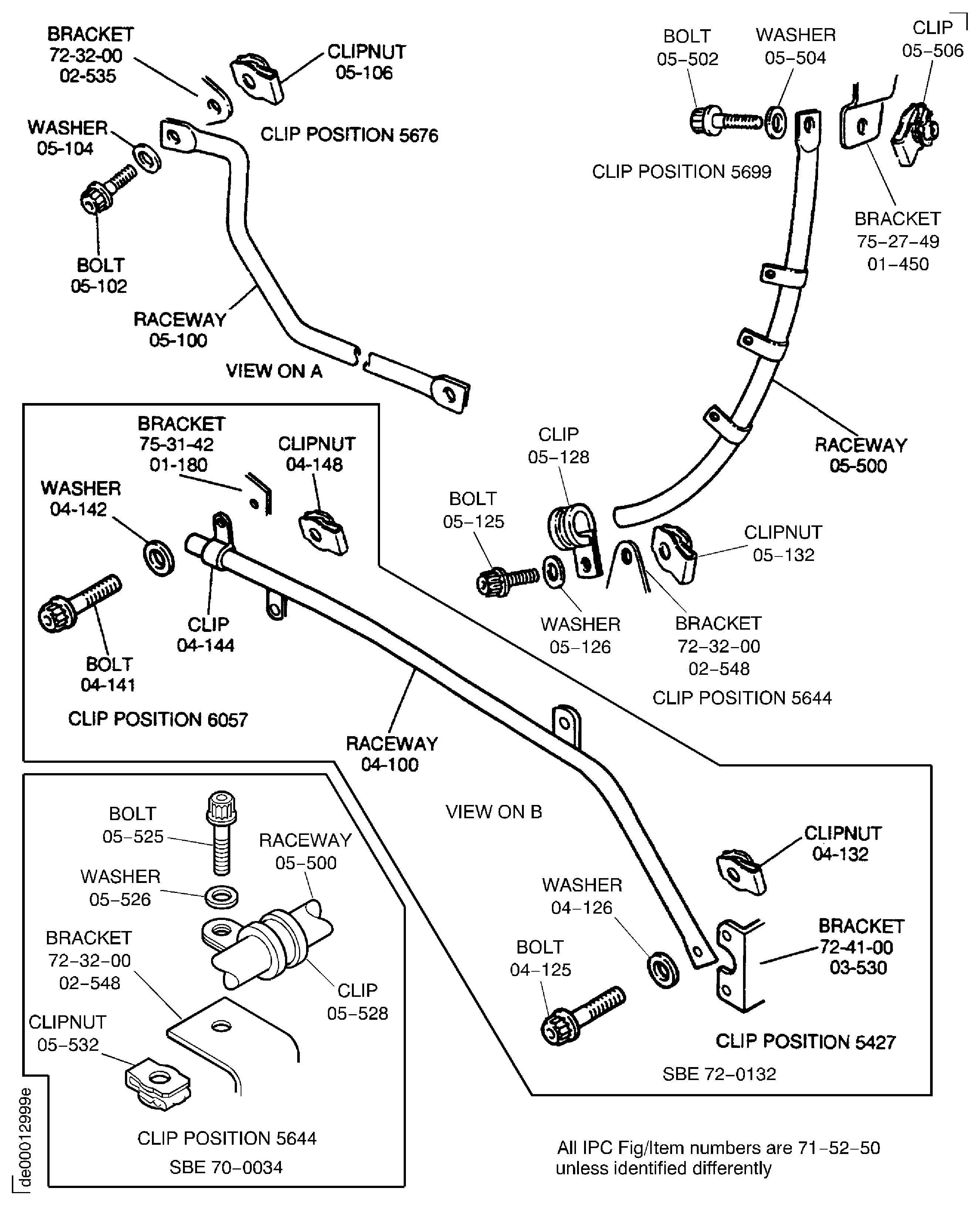

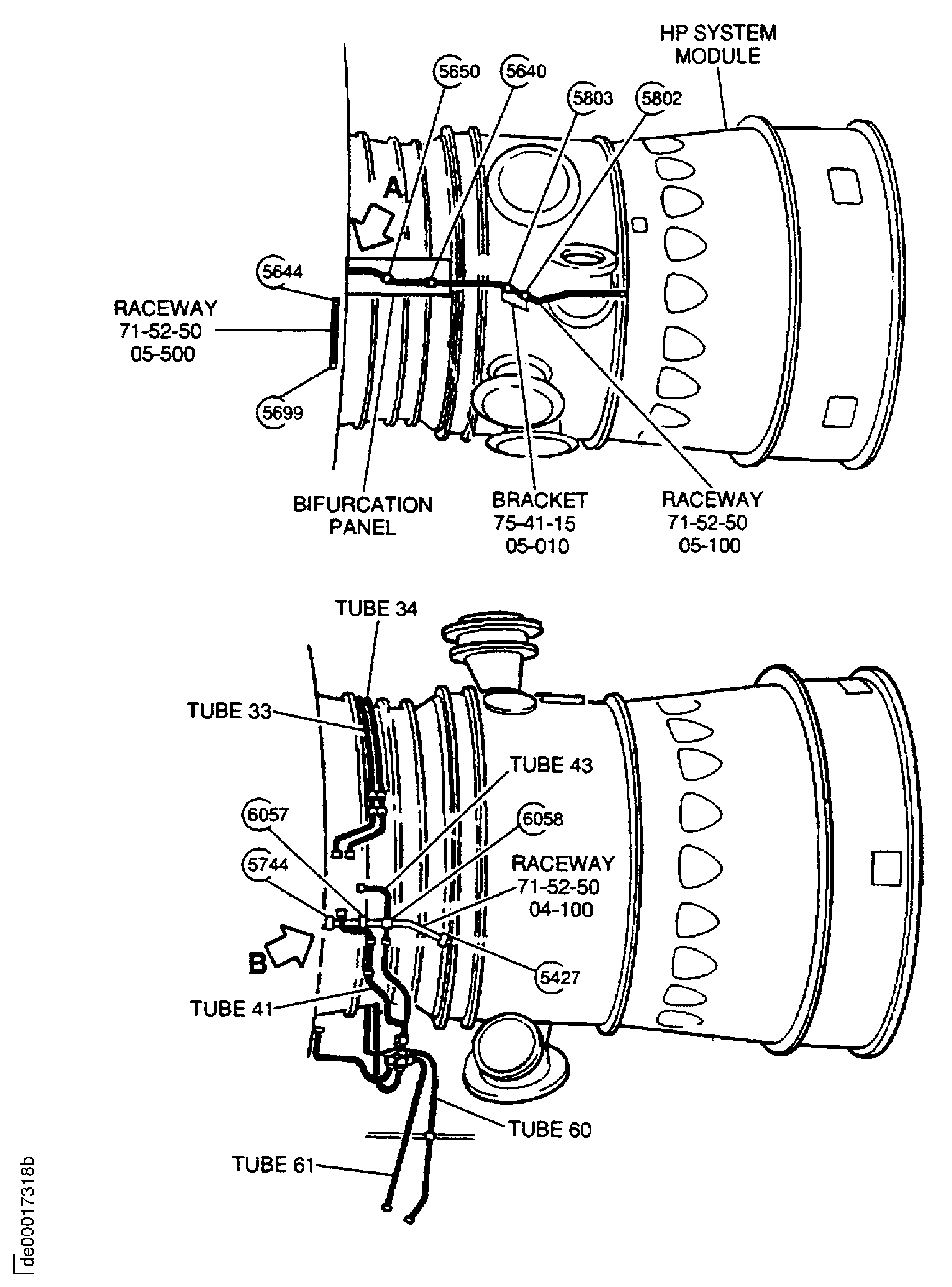

Remove the bolts, the washers, the clips and the clipnuts from the clip positions 5644 and 5699 and remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 05-500).

NOTE

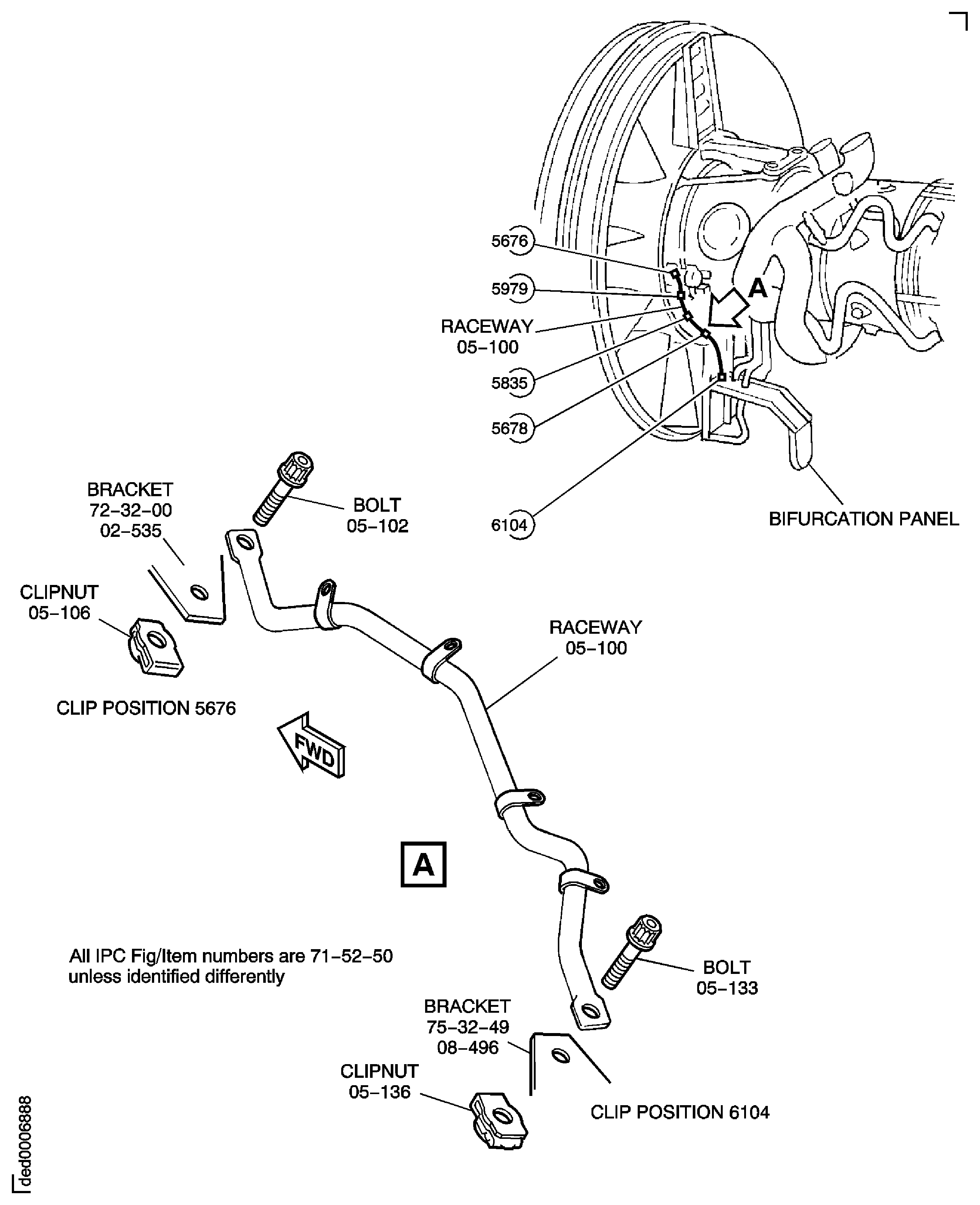

The raceways must have their maintenance completed, as given in the Component Maintenance Manual (CMM-MECH-V2500-1IA).Remove the bolts, the washers, the spacer, the clips, the nuts and the clipnut from the clip positions 5676, 5640, 5650, 5802 and 5803 and remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 05-100).

SUBTASK 72-00-40-020-114-A00 Remove the Raceways (Pre SBE 75-0016, Pre SBE 72-0132 and Pre SBE 79-0087)

Remove the bolts, the washers, the clips and the clipnuts from the clip positions 5644 and 5699 and remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 05-500).

Pre SBE 79-0087: Remove the bolts, the washers, the clips, the nuts and the clipnut from the clip positions 5676, 5650, 5802 and 5803 and remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 05-100).

SBE 79-0087: Remove the bolts, the washers, the clips, the nuts and the clipnut from the clip positions 5676 and 6104 and remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 05-100).

NOTE

The raceways must have their maintenance completed, as given in the Component Maintenance Manual (CMM-MECH-V2500-1IA).Remove the bolts, the washers, the clips and the clipnuts from the clip positions 5427, 6057 and 5746 and remove the raceway BRACKETS & RACEWAYS-HARNESS SUPPORT-CORE (71-52-50, 04-100).

SUBTASK 72-00-40-020-114-B00 Remove the Raceways (SBE 75-0016 and SBE 72-0132)

SBE 75-0016: Air - HPC bleed air tubes - Revised core engine tubes to improve clearance with harness in bifurcation area - RH side

SBE 72-0132: Engine - LP compressor - Removal of stage 6 buffer air system

Figure: Pre SBE 74-0002 and Pre SBE 74-0003: Remove the Ignition Exciters

Sheet 1

Figure: Pre SBE 74-0002 and Pre SBE 74-0003: Remove the Ignition Exciters

Sheet 2

Figure: SBE 74-0002 and SBE 74-0003: Remove the Ignition Exciters

Sheet 3

Figure: Remove the LP Compressor Bleed Actuators

Sheet 1

Figure: Pre SBE 72-0132 and SBE 72-0132: Remove the LP Compressor Bleed Actuators

Sheet 2

Figure: Remove the LP Compressor Bleed Actuators

Sheet 3

Figure: Remove the LP Compressor Bleed Actuators

Sheet 4

Figure: Pre SBE 75-0016, Pre SBE 79-0087 and SBE 75-0016: Remove the Fuel Drain Tubes

Sheet 1

Figure: Pre SBE 75-0016, SBE 75-0016 and SBE 79-0087: Remove the Fuel Drain Tubes

Sheet 2

Figure: Remove the ACC Actuator

Sheet 1

Figure: Remove the ACC Actuator

Sheet 2

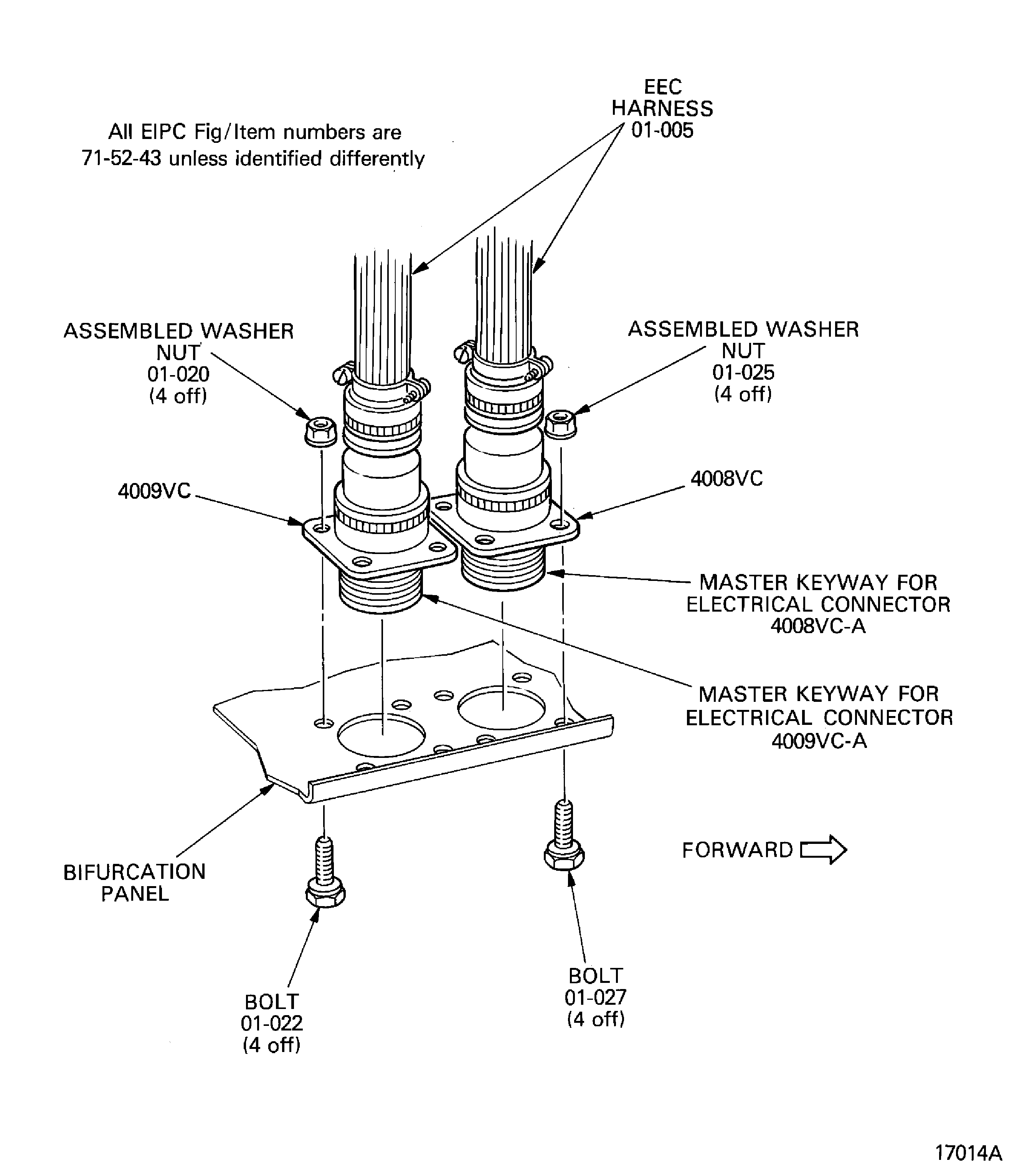

Figure: Pre SBE 72-0132 and Pre SBE 79-0087: Remove the Electrical Harnesses

Sheet 1

Figure: Pre SBE 72-0132 and SBE 79-0087: Remove the Electrical Harnesses

Sheet 2

Figure: SBE 72-0132 and Pre SBE 79-0087: Remove the Electrical Harnesses

Sheet 3

Figure: SBE 72-0132 and SBE 79-0087: Remove the Electrical Harnesses

Sheet 4

Figure: Pre SBE 72-0132, Pre SBE 79-0087, SBE 79-0087, Pre SBE 71-0303, SBE 71-0303 Pre SBE 72-0553 and SBE 72-0553: Remove the Eectrical Harnesses

Sheet 5

Figure: SBE 72-0132, SBE 79-0087, Pre SBE 71-0303, SBE 71-0303 Pre SBE 72-0553 and SBE 72-0553: Remove the Eectrical Harnesses

Sheet 6

Figure: Pre SBE 71-0303, SBE 71-0303, Pre SBE 72-0553 and SBE 72-0553: Remove the Electrical Harnesses

Sheet 7

Figure: Pre SBN 70-0151, Pre SBE 71-0145, Pre SBN 71-0272, Pre SBE 72-0132 and Pre SBE 79-0087 and SBN 70-0151: Remove the Electrical Harnesses

Sheet 8

Figure: Pre SBN 71-0272 and Pre SBE 79-0087: Remove the Electrical Harnesses

Sheet 9

Figure: Remove the Electrical Harnesses

Sheet 10

Figure: Remove the Electrical Harnesses

Sheet 11

Figure: Remove the Electrical Harnesses

Sheet 12

Figure: SBE 71-0063: Remove the Electrical Harnesses

Sheet 1

Figure: SBE 71-0063: Remove the Electrical Harness

Sheet 2

Figure: Remove the VSV actuator

Remove the VSV actuator

Figure: Disconnect the Tubes at the Bifurcation Panel

Sheet 1

Figure: Pre SBE 73-0198 and Pre SBE 79-0087: Disconnect the Tubes at the Bifurcation Panel

Sheet 2

Figure: SBE 79-0087 and Pre SBE 73-0198: Disconnect the Tubes at the Bifurcation Panel

Sheet 3

Figure: SBE 79-0087 and SBE 73-0198: Disconnect the Tubes at the Bifurcation Panel

Sheet 4

Figure: Pre SBE 73-0198 and Pre SBE 79-0087: Disconnect the Tubes at the Bifurcation Panel

Sheet 5

Figure: SBE 79-0087 and Pre SBE 73-0198: Disconnect the Tubes at the Bifurcation Panel

Sheet 6

Figure: SBE 73-0198: Disconnect the Tubes at the Bifurcation Panel

Sheet 7

Figure: Pre SBE 79-0087: Remove the No.1, 2 and 3 Bearing Oil Feed Tubes 57 and 58

Sheet 1

Figure: SBE 79-0087, Pre SBE 73-0198 and SBE 73-0198: Remove the No. 1, 2 and 3 Bearing Oil Feed Tubes 57 and 58

Sheet 2

Figure: SBE 79-0087: Remove the No. 1, 2 and 3 Bearing Oil Feed Tubes 57 and 58

Sheet 3

Figure: Remove the Front Bearing Compartment Buffer Air Tubes 30 and 39

Sheet 1

Figure: Pre SBE 72-0132: Remove the Front Bearing Compartment Buffer Air Tubes 30 and 39

Sheet 2

Figure: Pre SBE 72-0132: Remove the Front Bearing Compartment Buffer Air Tubes 30 and 39

Sheet 3

Figure: Pre SBE 79-0087: Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67

Sheet 1

Figure: SBE 79-0087: Remove the HP Servo Fuel Tube 46 and the P2.5 Air Tubes 66 and 67

Sheet 2

Figure: Remove the Fuel Distribution Feed Tube 62

Remove the Fuel Distribution Feed Tube 62

Figure: Remove the HP Servo Fuel Tubes

Sheet 1

Figure: Pre SBE 72-0132 and Pre SBE 79-0087: Remove the HP Servo Fuel Tubes

Sheet 2

Figure: SBE 79-0087: Remove the HP Servo Fuel Tubes

Sheet 3

Figure: Remove the HP Servo Fuel Tubes

Sheet 4

Figure: SBE 79-0087: Remove the HP Servo Fuel Tubes

Sheet 5

Figure: SBE 79-0087: Remove the HP Servo Fuel Tubes

Sheet 6

Figure: SBE 72-0027, SBE 73-0115 and SBE 72-0132: Remove the HP Servo Fuel Tubes

Sheet 7

Figure: Remove the Raceways

Sheet 1

Figure: SBE 79-0087: Remove the Raceways

Sheet 2

Figure: Pre SBE 79-0087, Pre SBE 72-0132 and SBE 72-0132: Remove the Raceways

Sheet 3