Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-40-020-003-A00 HP System Module - Remove The Components, Ducts, Electrical Harnesses, And Tubes From The HPC Case Vertical Splitline, Removal-003

General

This TASK gives the procedure to remove the components, ducts, electrical harnesses and tubes from the HP compressor case vertical splitline. Refer to the TASKs which follow for other related procedures.

TASK 72-00-40-020-001-A00 (REMOVAL-001, CONFIG-001) - Remove the components, the electrical harnesses and the tubes from the HP turbine,

TASK 72-00-40-020-002-A00 (REMOVAL-002, CONFIG-001) - Remove and disconnect the components, the electrical harnesses and the tubes from the front of the HP compressor case,

TASK 72-00-40-020-004 (REMOVAL-004) - Remove the remaining HP system module components, tubes and the air off-take ducts.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject the applicable Chapter/Section/Subject comes before Fig/item number.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

Remove and discard the lockwire before the tube or connector is disconnected.

When electrical connections are disconnected special plastic caps must be installed.

All the electrical harnesses removed in this procedure must have their maintenance completed as given in the Component Maintenance Manual (CMM-EHC-V2500-1IA).

All the tubes, hoses and ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

Seal all openings to prevent contamination from unwanted materials.

Discard all rubber seal rings removed in this procedure.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| ACR Torq-Set bit 212-1/4-ACR | LOCAL | Torq-Set |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | 0AM53 | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

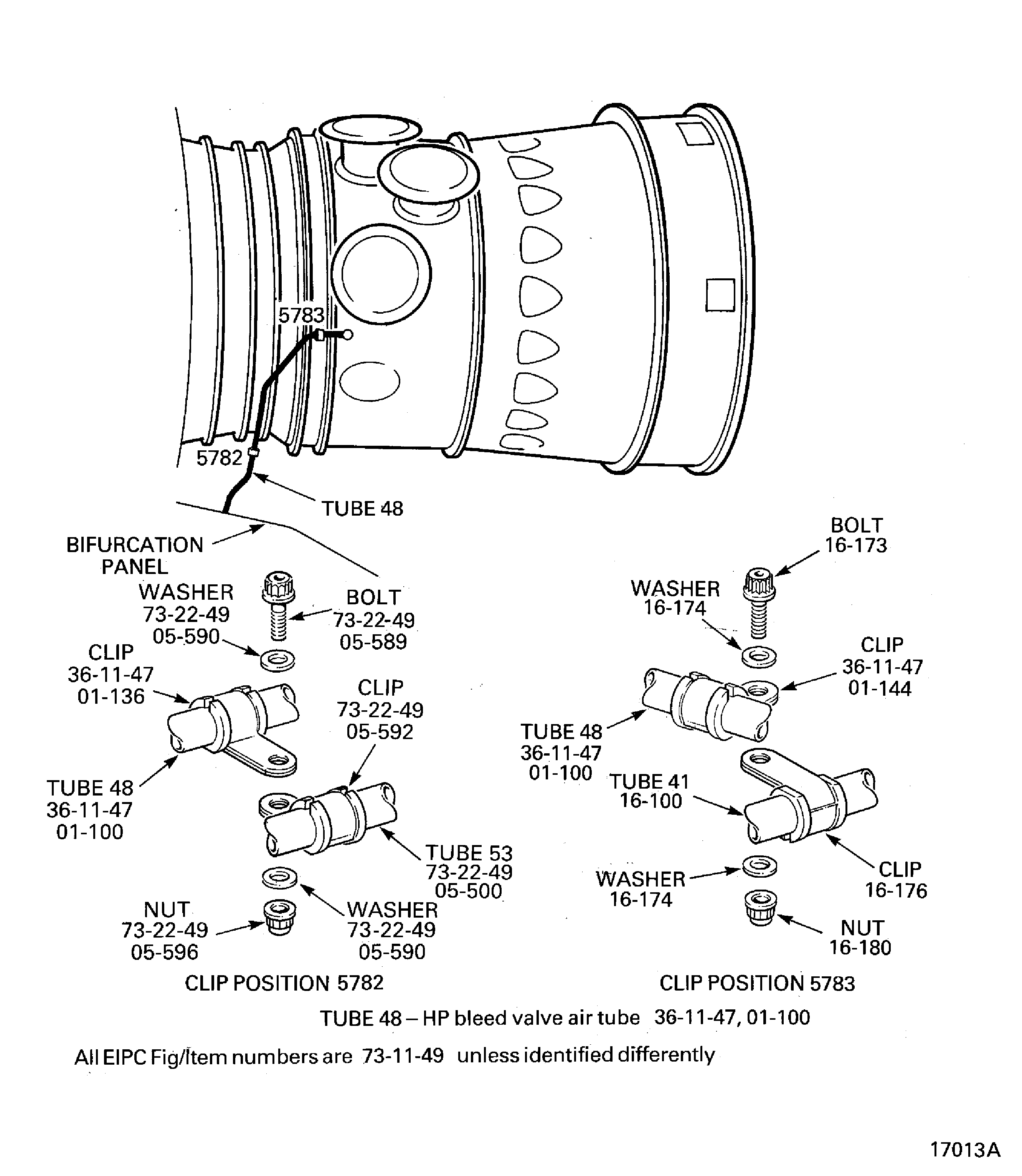

Pre SBE 79-0087: Remove the nuts, the bolts, the washers and the clips from the clip positions 5782 and 5783.

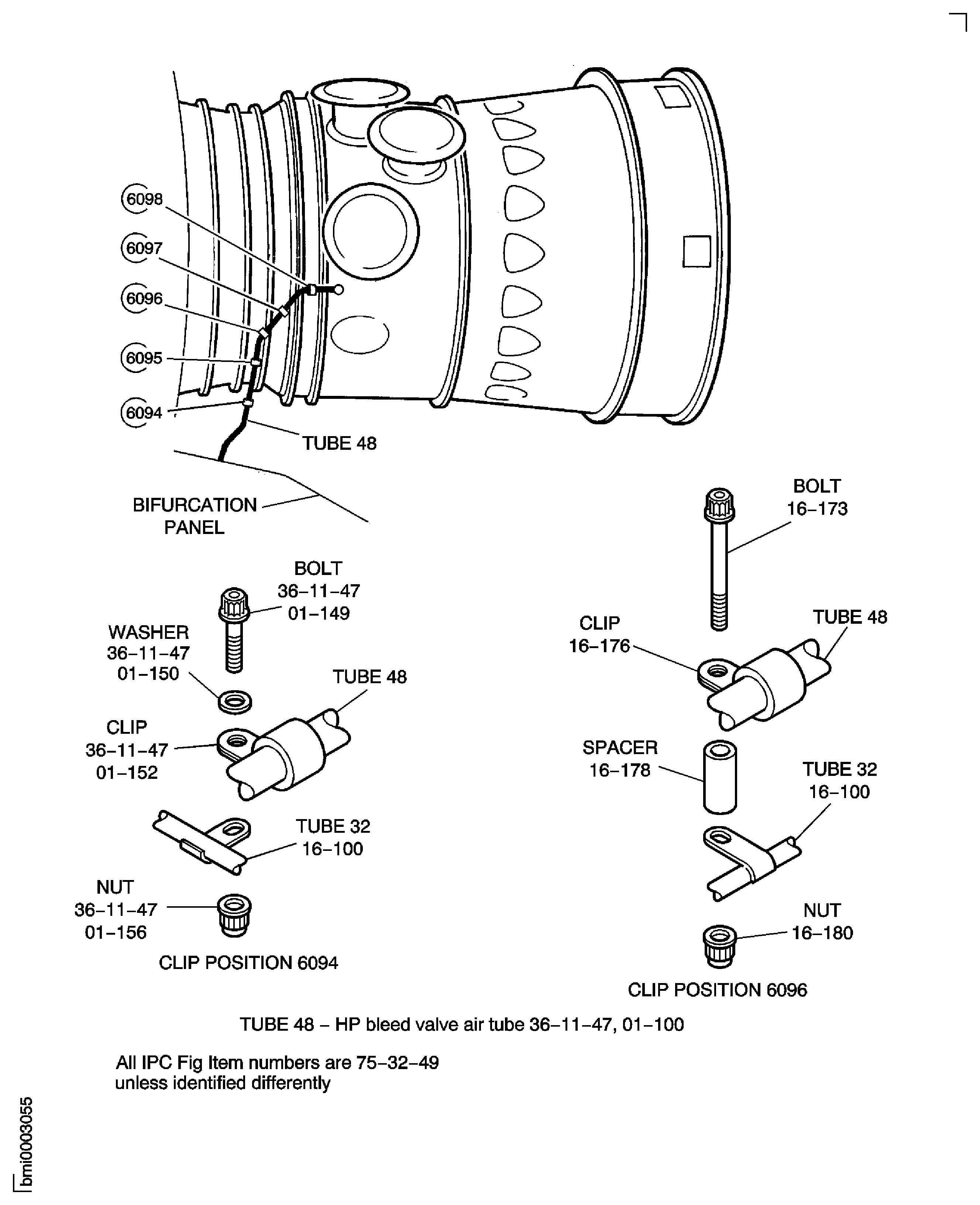

SBE 79-0087: Remove the nuts, the bolts, the washers and the clips from the clip positions 6094, 6095, 6096, 6097 and 6098.

SUBTASK 72-00-40-020-125 Remove the HP Bleed Control Air Tube (48) (Pre SBE 79-0087 and SBE 79-0087)

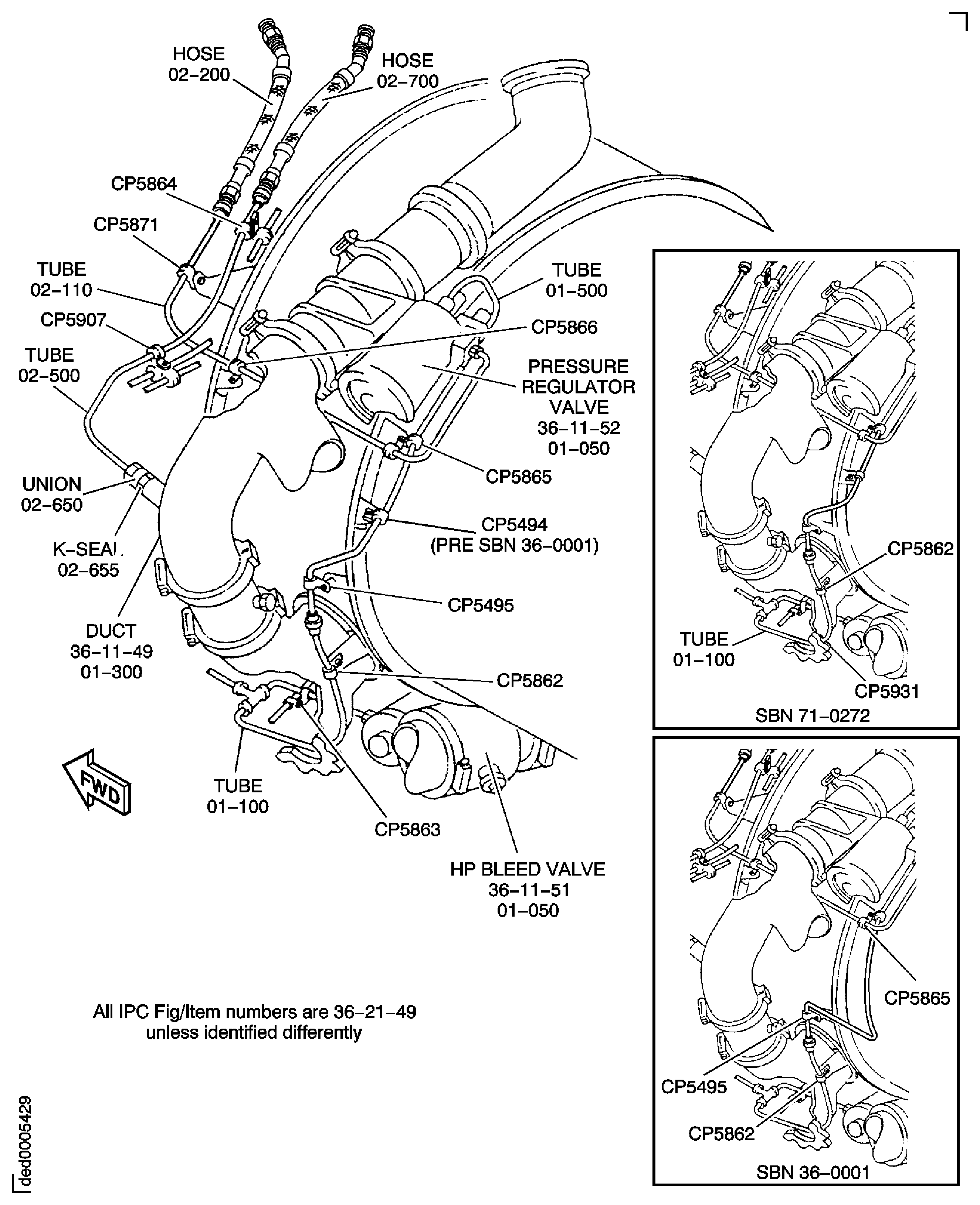

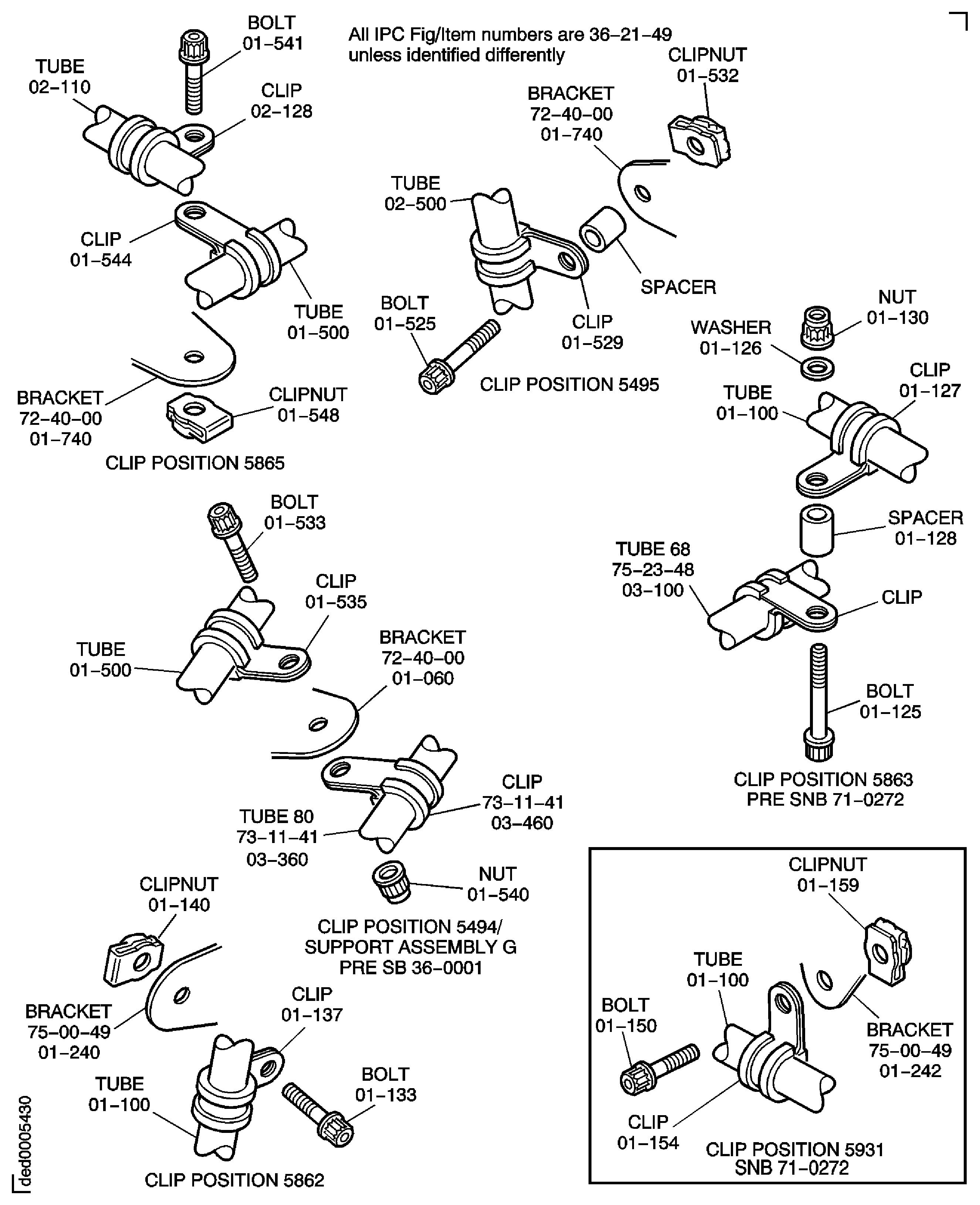

Pre SBN 71-0272: Disconnect tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) from the HP bleed valve PNEUMATIC-HP BLEED VALVE (36-11-51, 01-050) and tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500). Remove the attaching parts at clip positions 5862 and 5863 and remove the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100).

SBN 71-0272: Disconnect tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100) from the HP bleed valve PNEUMATIC-HP BLEED VALVE (36-11-51, 01-050) and tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500). Remove the attaching parts at clip positions 5862 and 5931 and remove the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100).

Disconnect the tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500 and PNEUMATIC-PRESSURE INDICATING TUBES 36-21-49, 02-110) from the pressure regulator valve.

Remove the cabin bleed air system sense tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-100).

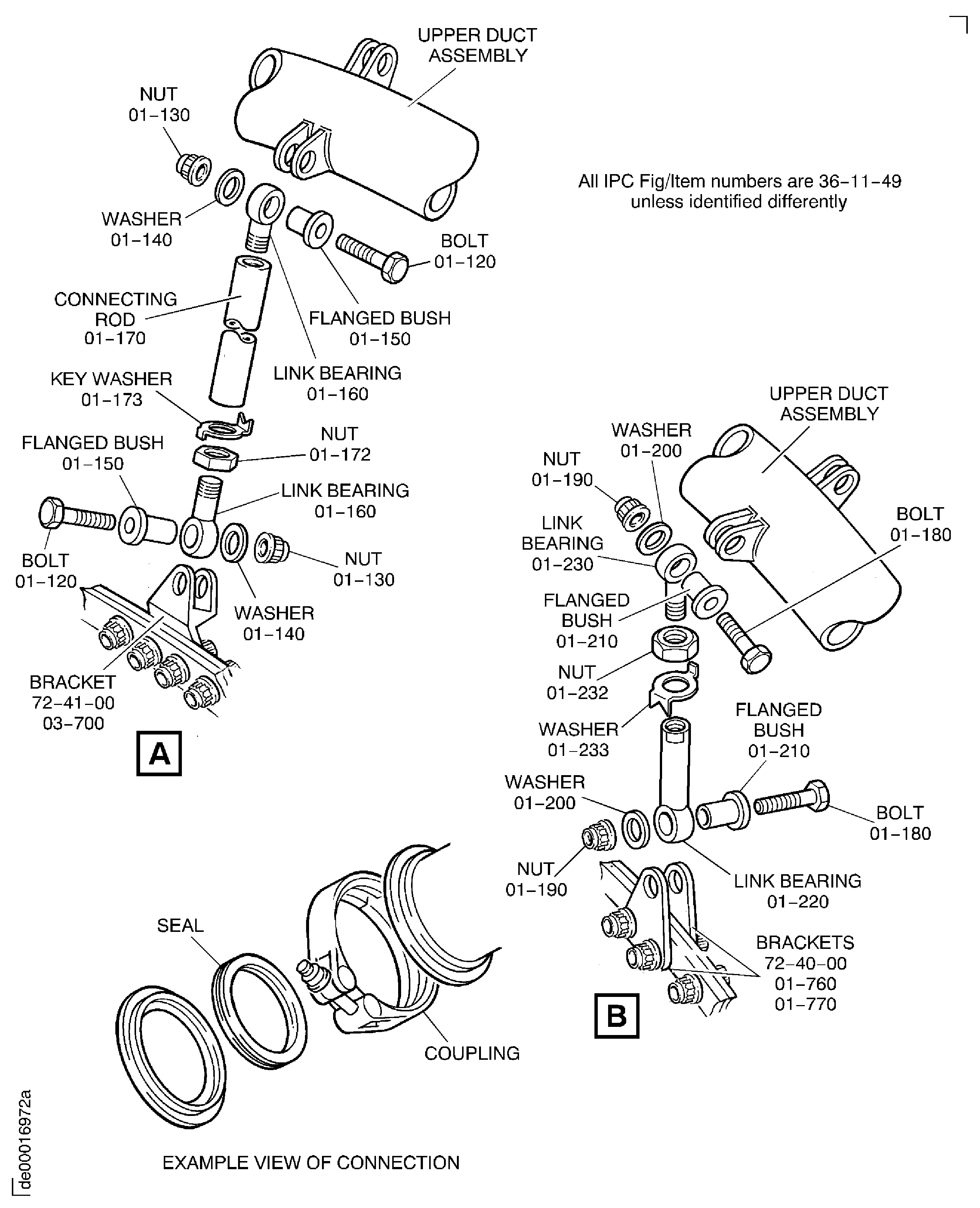

Remove the nut, the bolt and the washer that attach the connecting rod to the bracket ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 03-770).

Remove the nut, the bolt and the washer that attach the link to the brackets HPC Module - Attaching Parts (72-40-00, 01-760 and HPC Module - Attaching Parts 01-770).

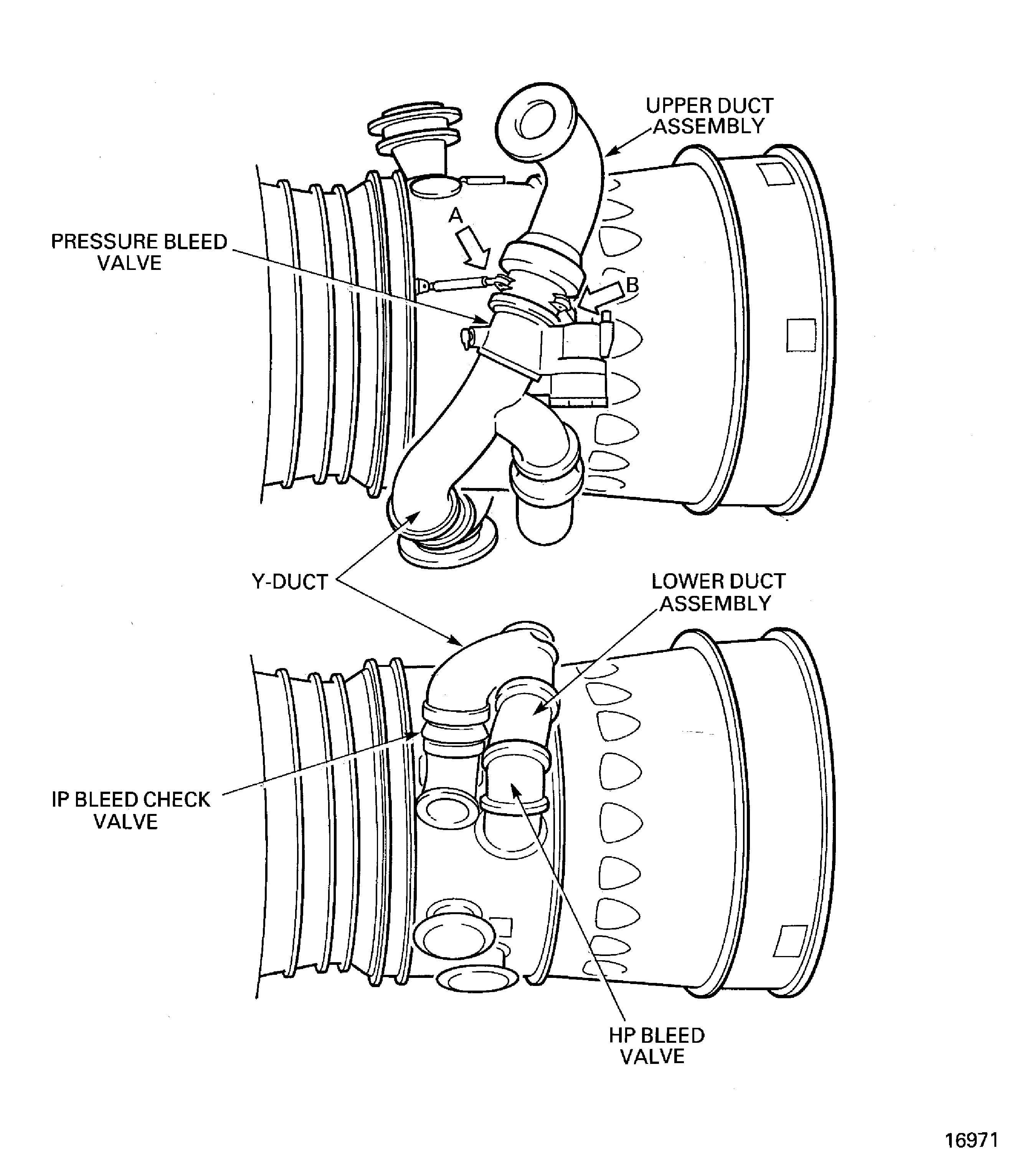

Remove the upper duct assembly.

Loosen the applicable clip positions to give sufficient clearance for tubes PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500) and PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-110).

Remove the pressure regulator valve PNEUMATIC-BLEED PRESSURE REGULATOR VALVE (36-11-52, 01-050).

Disconnect the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500) from the union PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-650). Loosen the applicable clip positions to give sufficient clearance for tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500).

Remove the union and the K-seal from the duct PNEUMATIC-BLEED AIR DUCTS (36-11-49, 01-300).

Remove the Y-duct.

SUBTASK 72-00-40-020-086 Remove the Cabin Bleed Air System Ducts, Valves and Sense Tubes (Pre SBN 71-0272 and SBN 71-0272)

Disconnect and remove the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200) from the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-110).

NOTE

The hoses PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200 and PNEUMATIC-PRESSURE INDICATING TUBES 36-21-49, 02-700) must have their maintenance completed, as given in the Marston Palmer Ltd. Component Maintenance Manual (36-21-49).Disconnect and remove the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) from the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500).

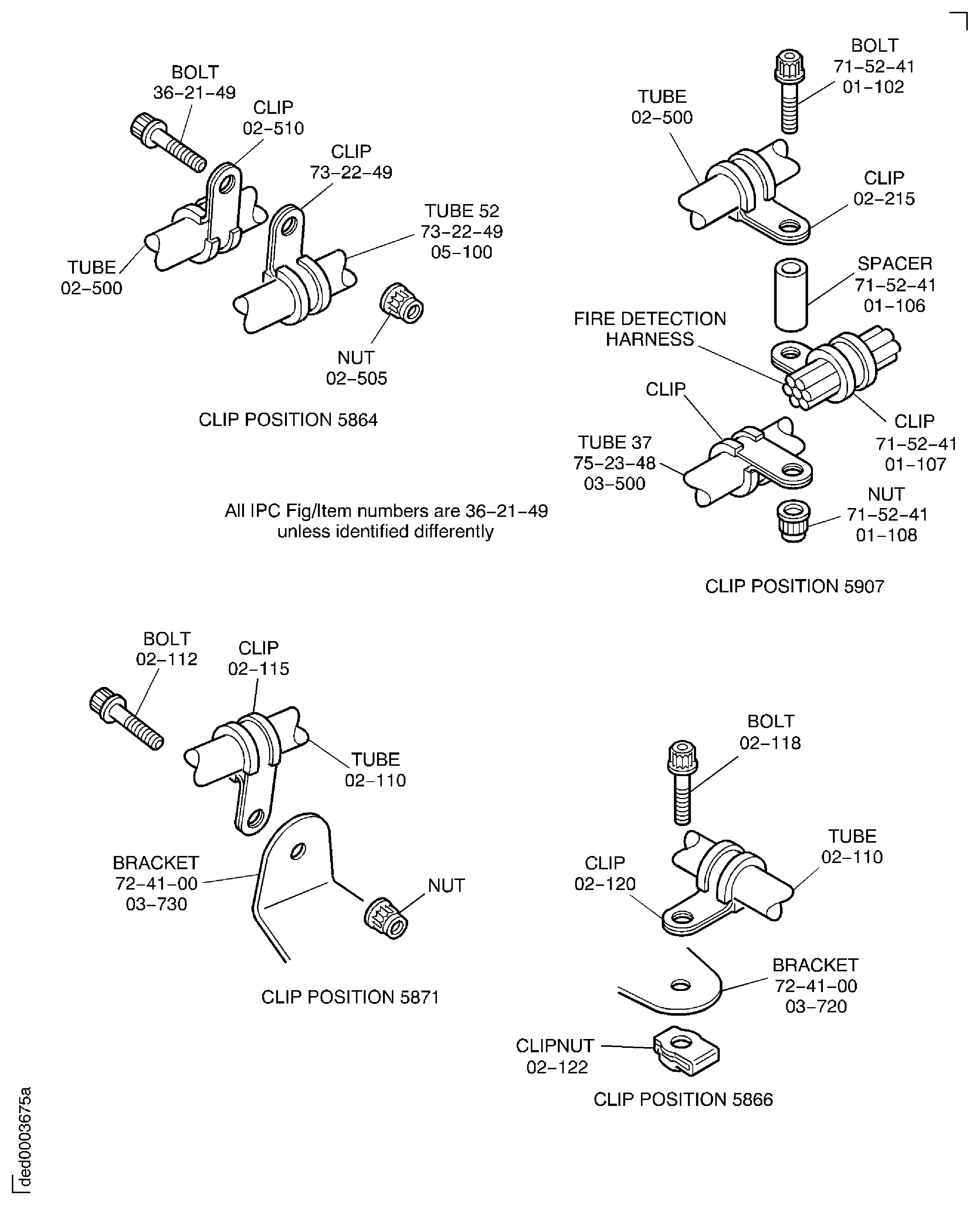

Remove the attaching parts at clip positions 5907 and 5864, remove tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500).

Remove the attaching parts at the clip positions 5865, 5494 and 5495, remove the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500).

NOTE

The cabin bleed air system sense tubes must have their maintenance completed, as given in the B.F. Goodrich Component Maintenance Manual (36-21-49).Remove the attaching parts at the clip positions 5866 and 5871, remove the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-110).

Remove the cabin bleed air system sense tubes (36-21-49).

SUBTASK 72-00-40-020-207-A00 Remove the Remaining Cabin Bleed System Sense Tubes (Pre SBN 36-0001)

Disconnect and remove the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200) from the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-110).

NOTE

The hoses PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-200 and PNEUMATIC-PRESSURE INDICATING TUBES 36-21-49, 02-700) must have their maintenance completed, as given in the Marston Palmer Ltd. Component Maintenance Manual (36-21-49).Disconnect and remove the hose PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-700) from the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500).

Remove the attaching parts at clip positions 5907 and 5864, remove tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-500).

Remove the attaching parts at the clip positions 5865 and 5495, remove the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 01-500).

NOTE

The cabin bleed air system sense tubes must have their maintenance completed, as given in the B.F. Goodrich Component Maintenance Manual (36-21-49).Remove the attaching parts at the clip positions 5866 and 5871, remove the tube PNEUMATIC-PRESSURE INDICATING TUBES (36-21-49, 02-110).

Remove the cabin bleed air system sense tubes (36-21-49).

SUBTASK 72-00-40-020-207-B00 Remove the Remaining Cabin Bleed System Sense Tubes (SBN 36-0001)

Refer to Figure.

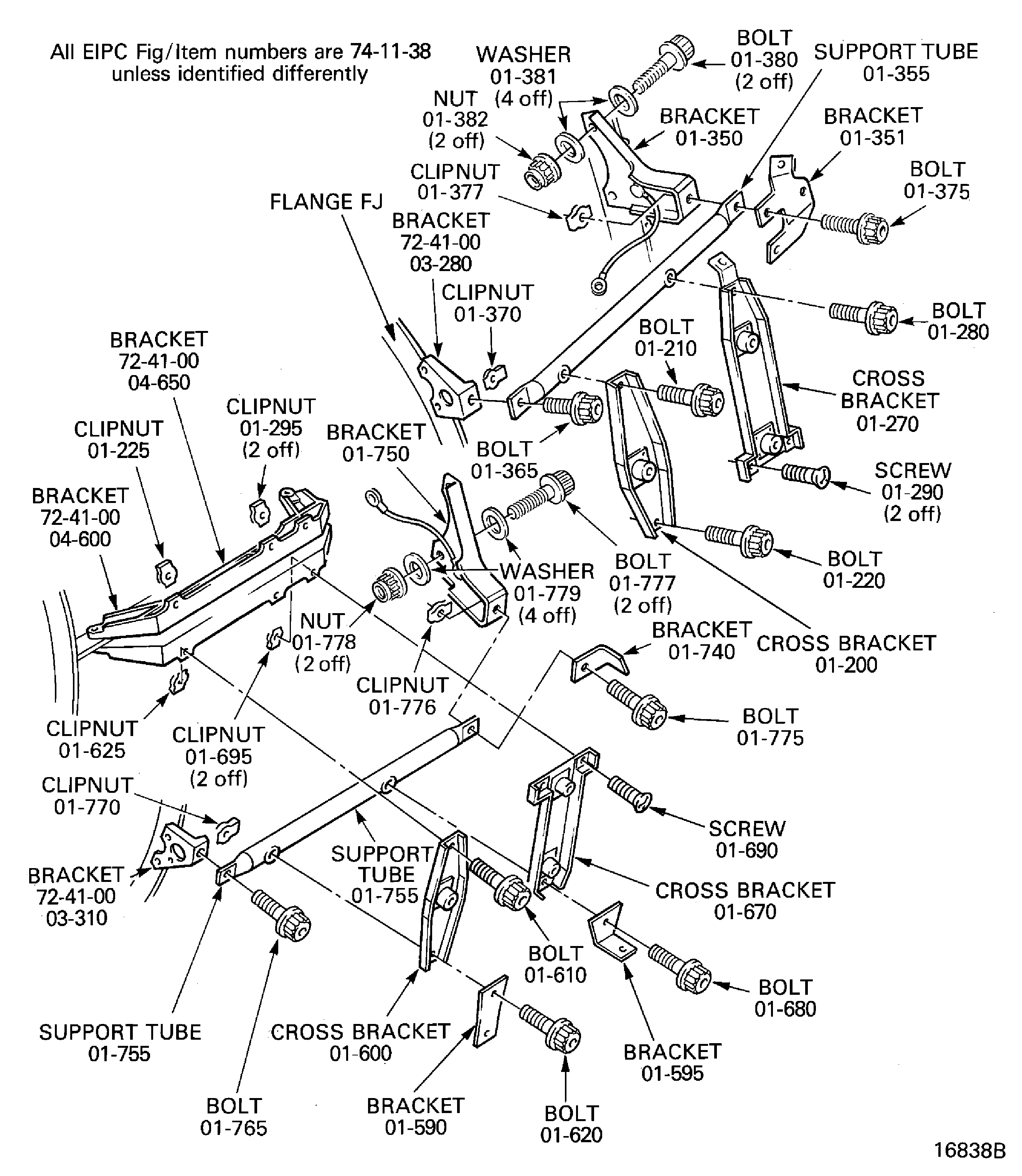

Use the ACR Torq-Set bit 212-1/4-ACR to remove the four screws from the upper and lower cross brackets.

Remove the cross brackets.

SUBTASK 72-00-40-020-128 Remove the Ignition Exciter Cross Brackets and the Support Tubes

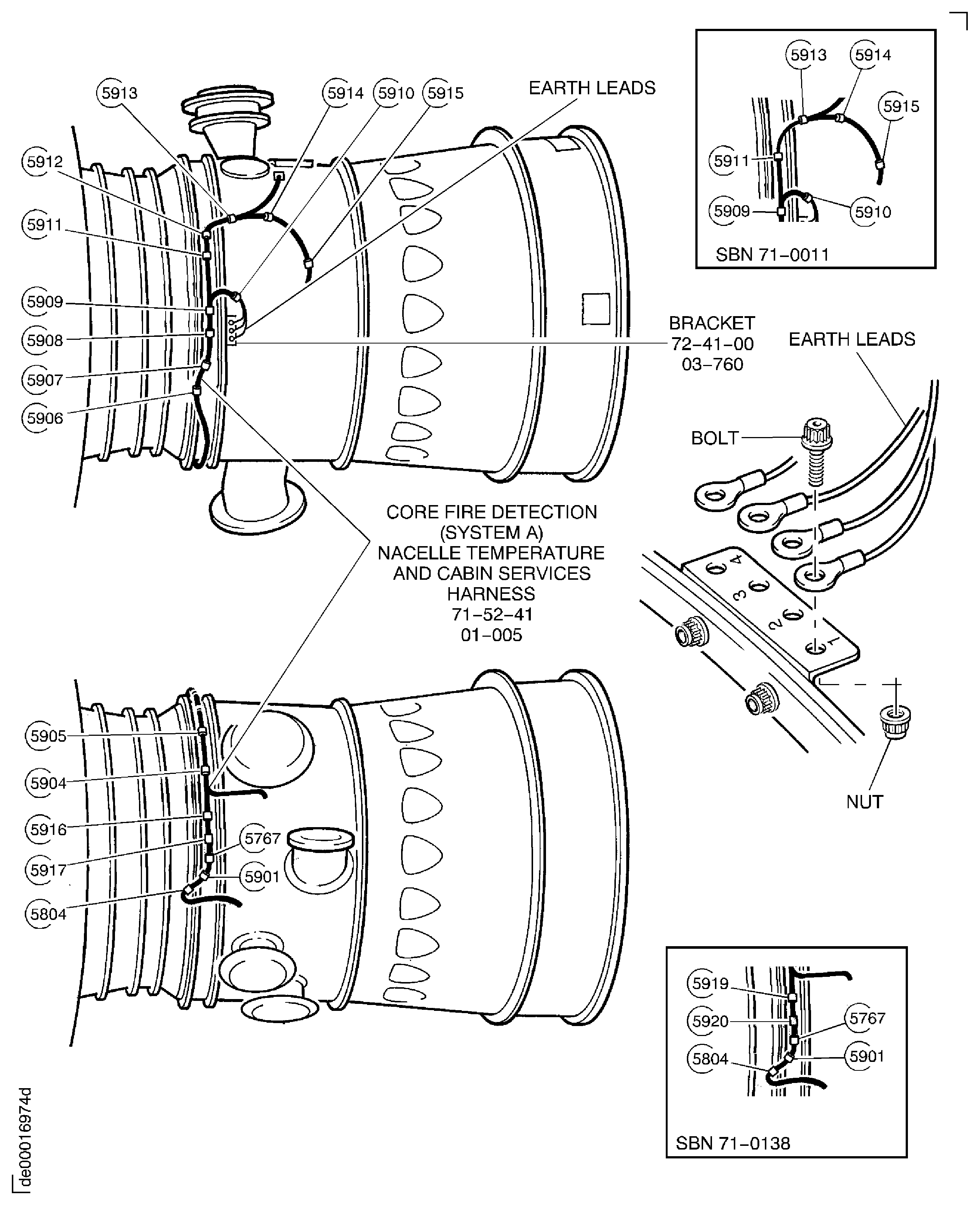

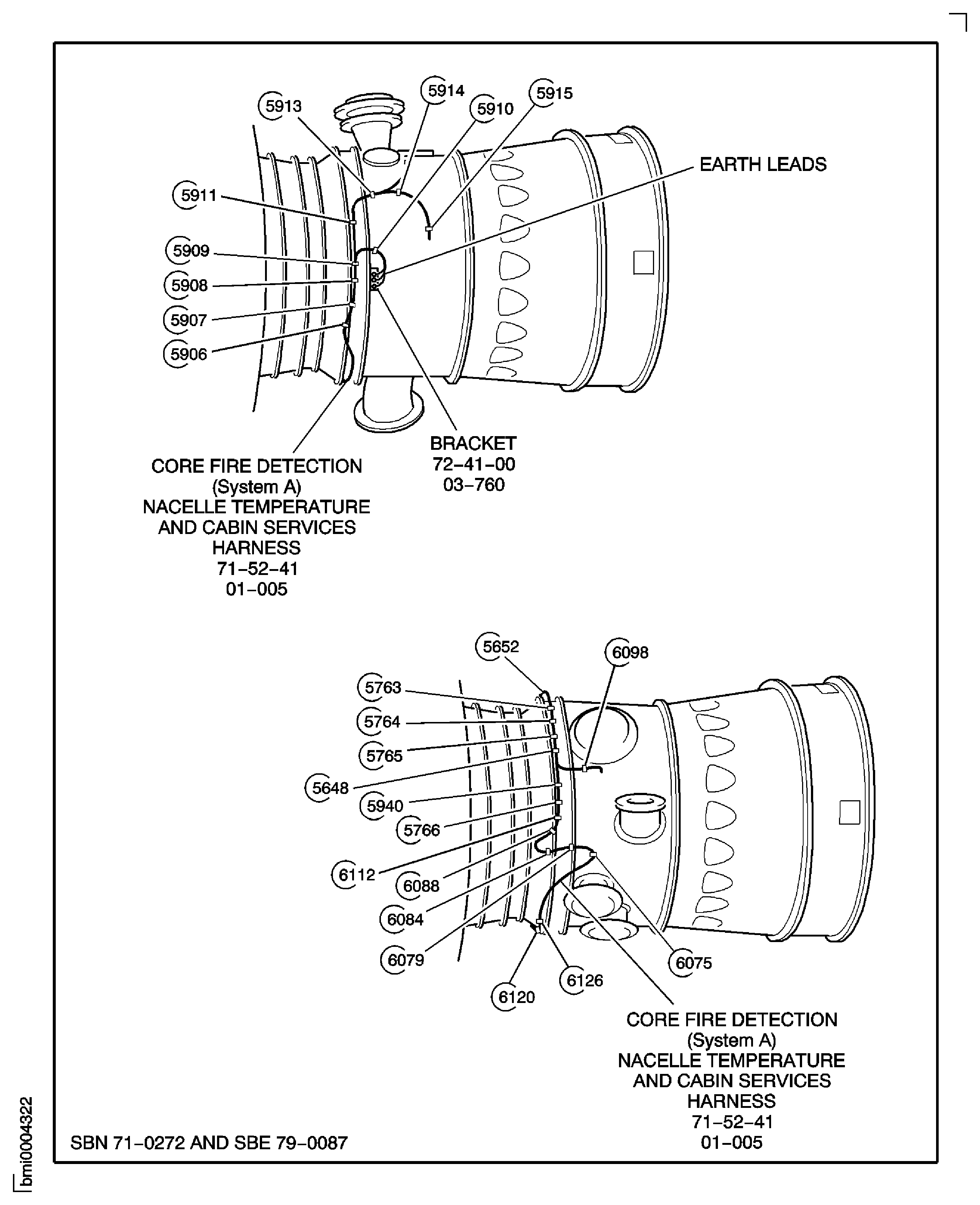

Remove the nuts and the bolts that attach the three earth leads to the bracket ENGINE-SECURING FEATURES-HP COMPRESSOR CASES (72-41-00, 03-760).

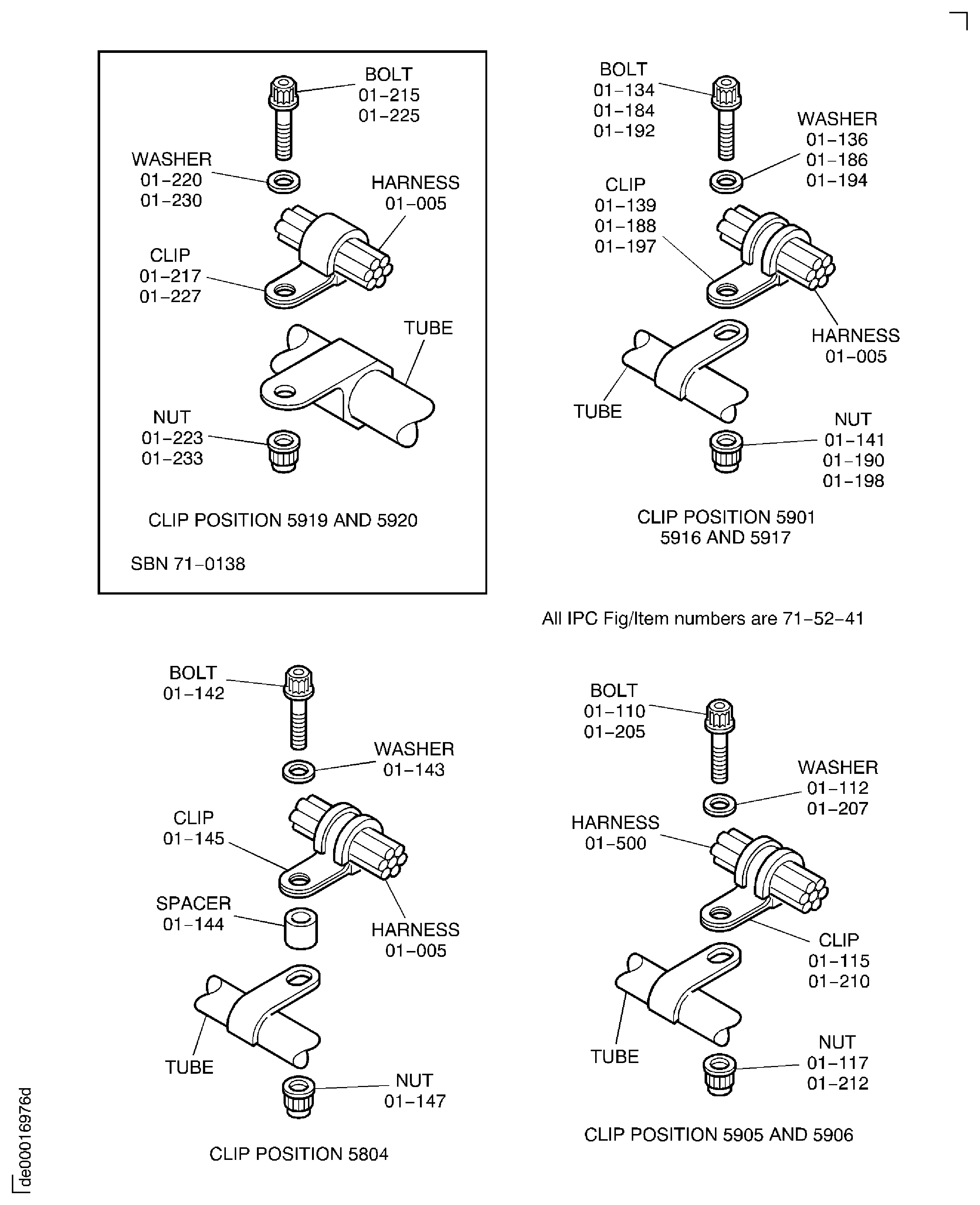

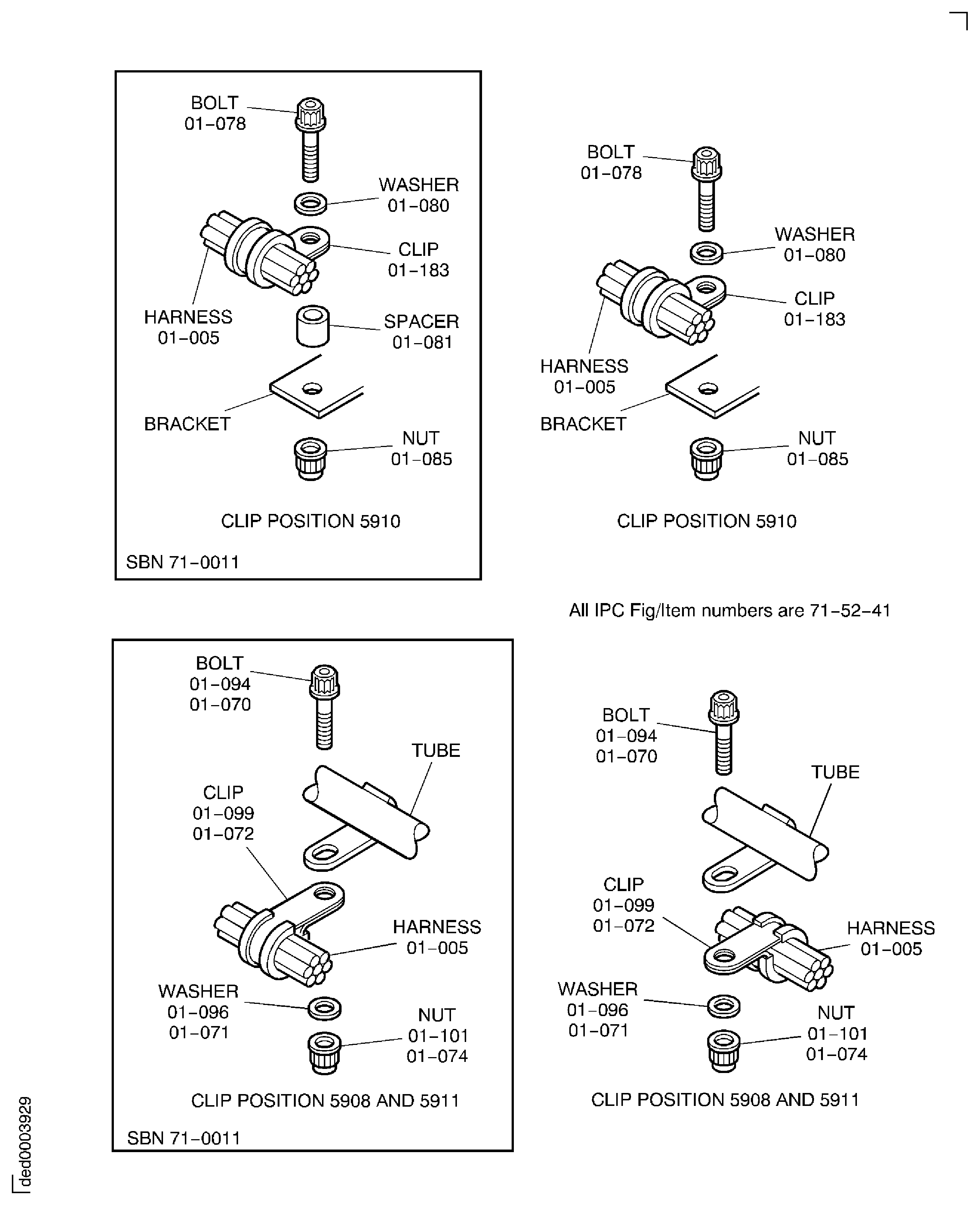

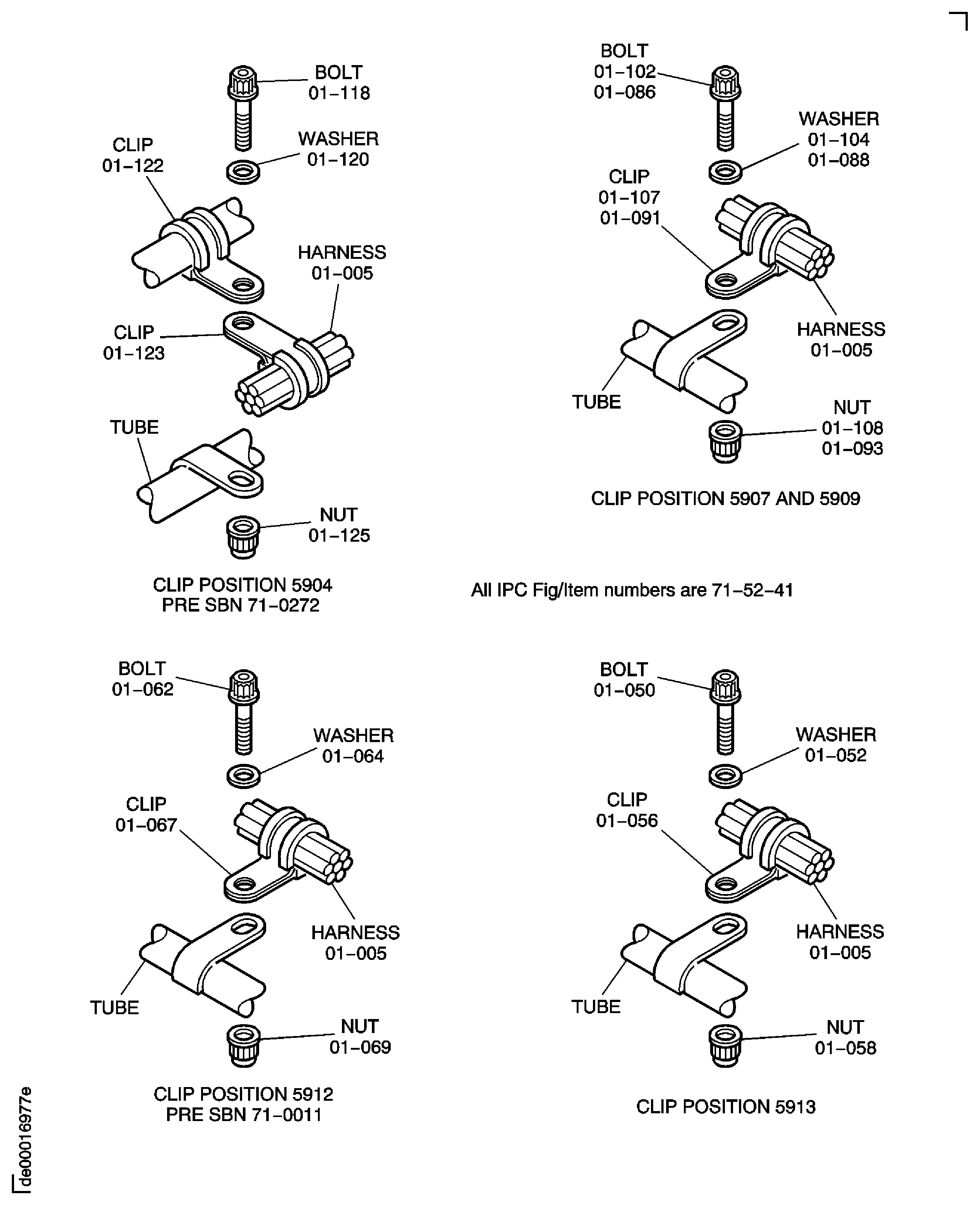

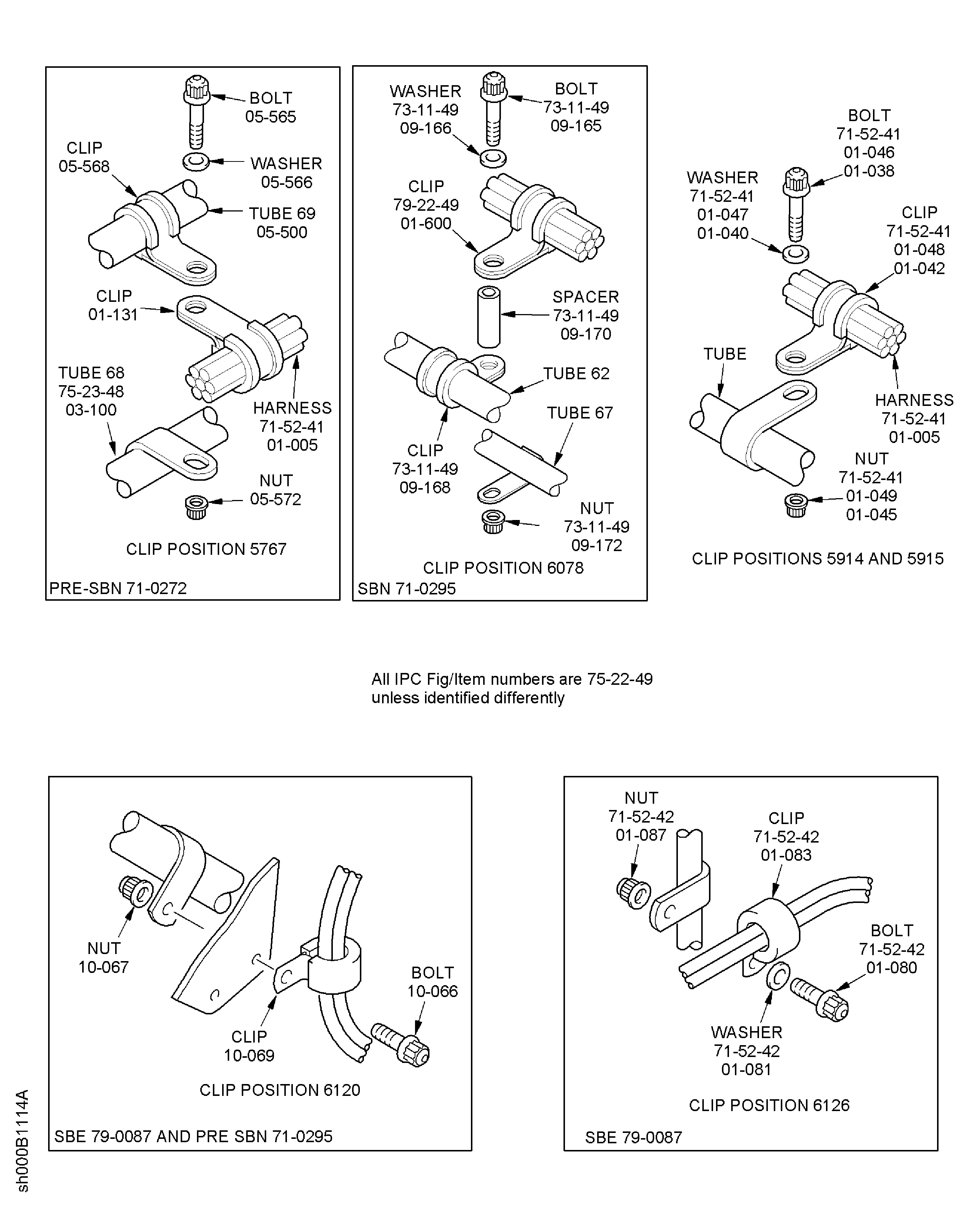

Pre SBN 71-0011: Remove the bolts, the nuts, the washers and the clips from the clip positions 5804,5901, 5767, 5917, 5916, 5904, 5905, 5906, 5907, 5908, 5909, 5911, 5912, 5913, 5914, 5915, and 5910.

SBN 71-0011 and Pre SBN 71-0138: Remove the bolts, the nuts, the washers and the clips from the clip positions 5804, 5901, 5767, 5917, 5916, 5904, 5905, 5906, 5907, 5908, 5909, 5911, 5913, 5914, 5915 and 5910.

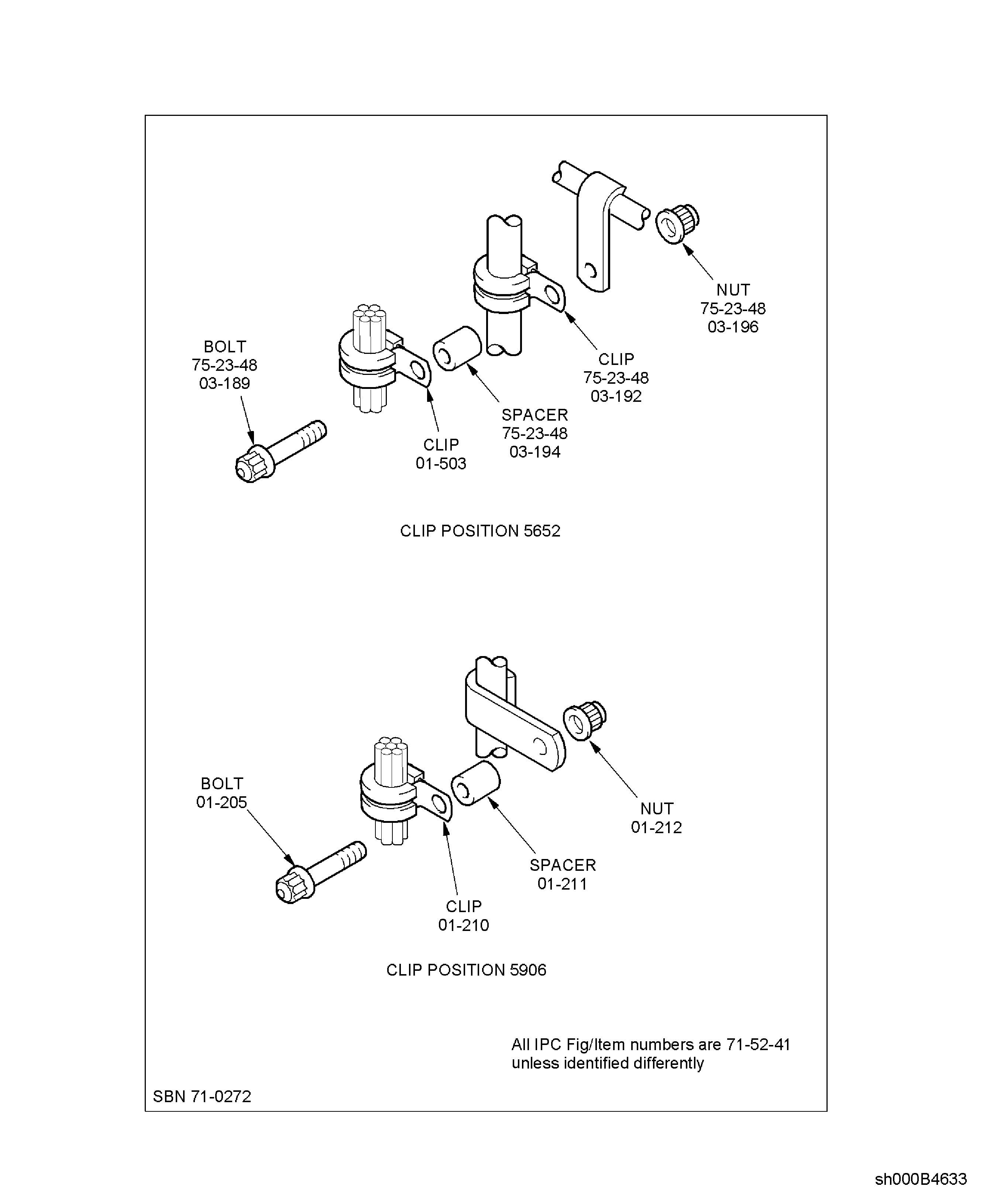

SBN 71-0011, SBN 71-0138, Pre SBN 71-0272 and Pre SBE 79-0087: Remove the bolts, the nuts, the washers and the clips from the clip positions 5804, 5901, 5767, 5919, 5920, 5904, 5905, 5906, 5907, 5908, 5909, 5911, 5913, 5914, 5915 and 5910.

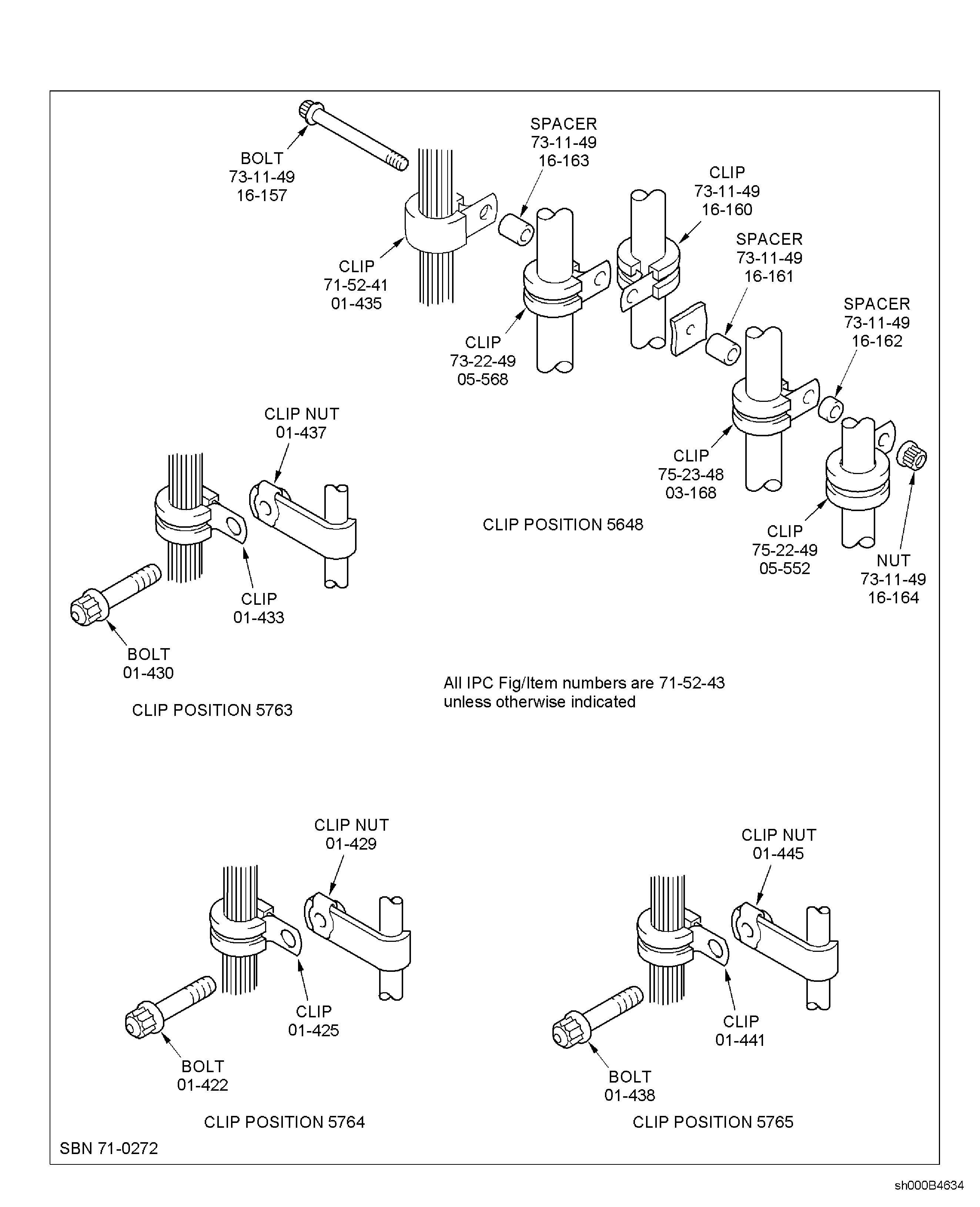

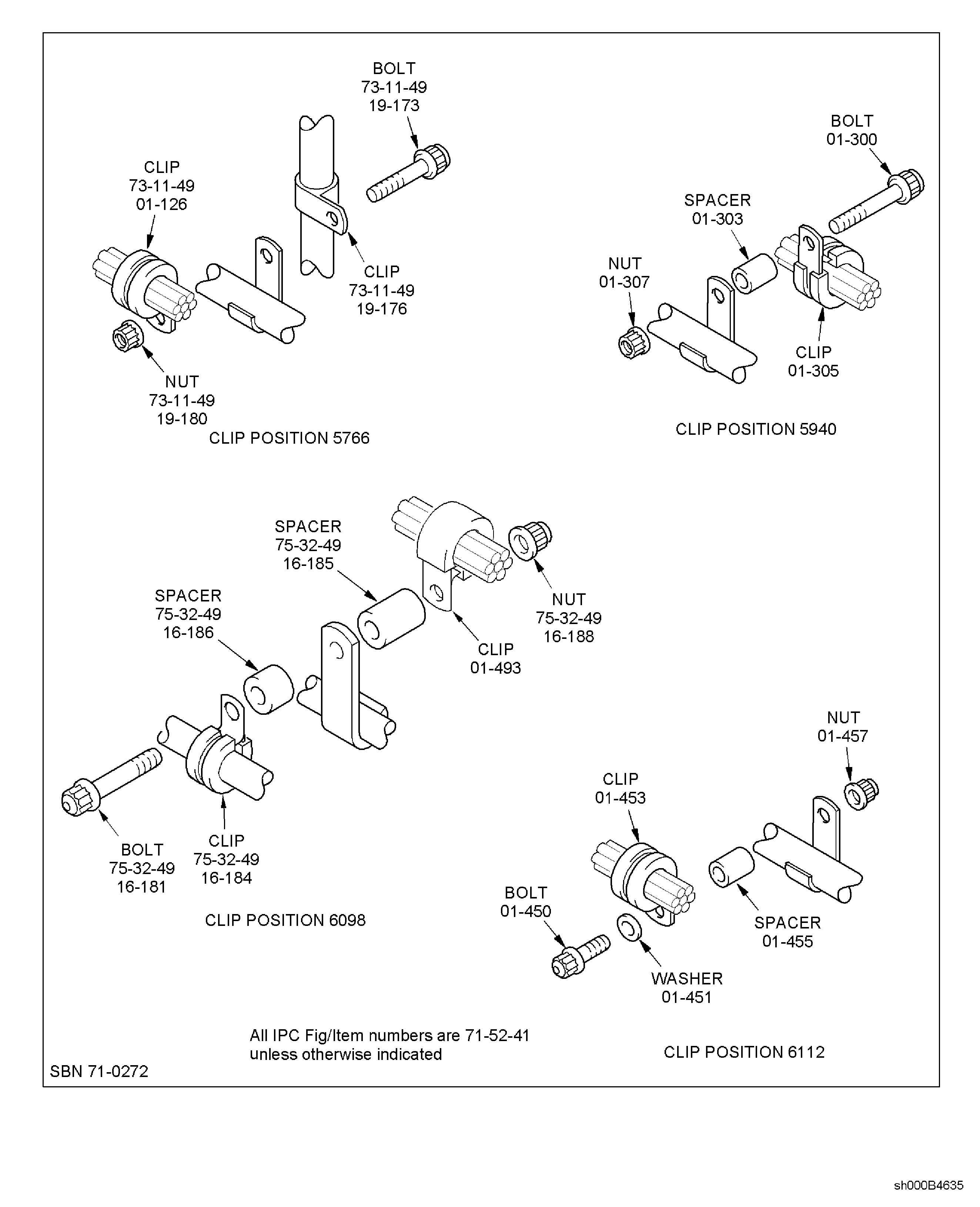

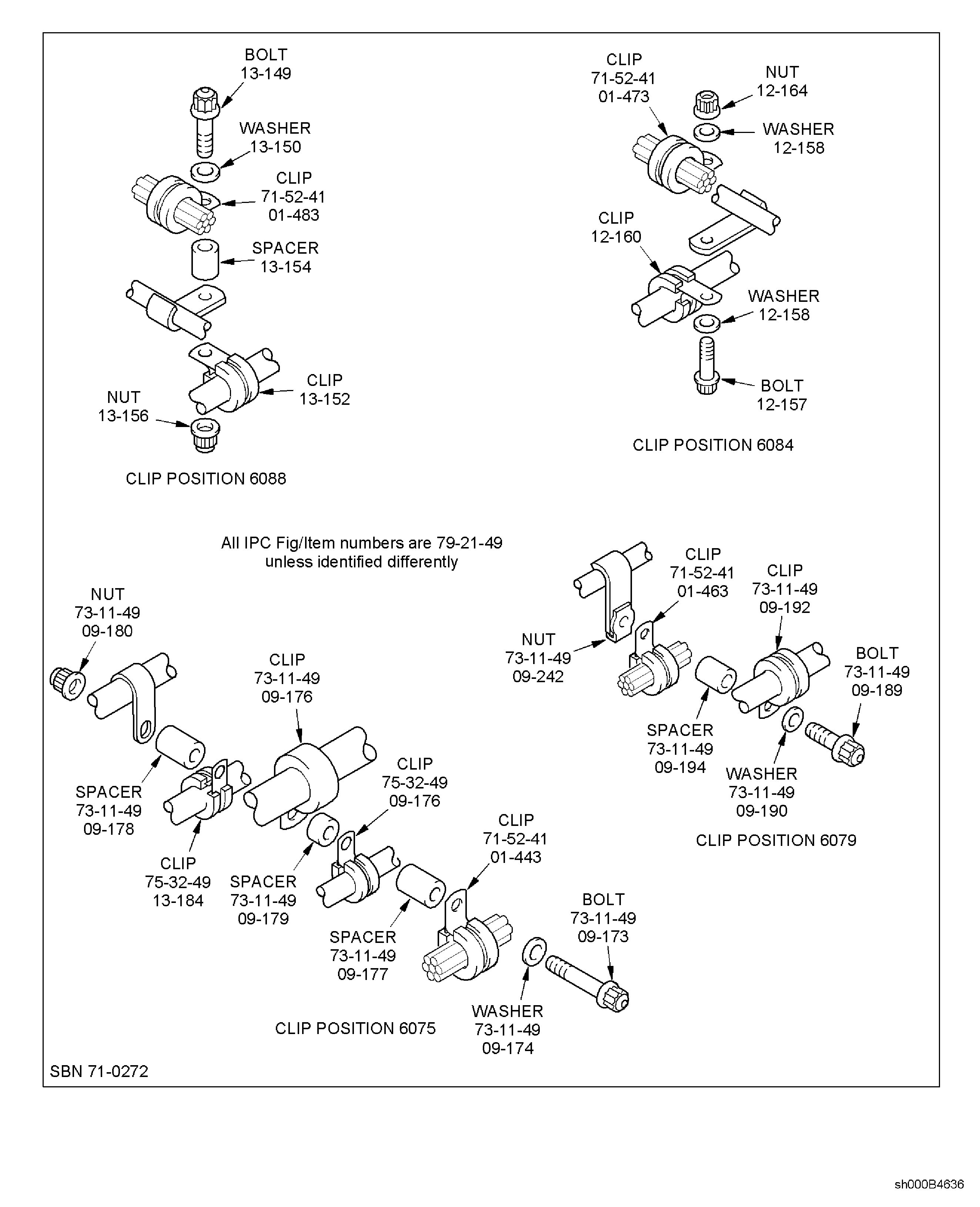

SBN 71-0272 and SBE 79-0087: Remove the bolts, the nuts, the washers, the spacers and the clips from the clip positions 6120, 6126, 6075, 6079, 6084, 6088, 6112, 5766, 5940, 5648, 5765, 5764, 5763, 5652, 5906, 5907, 5908, 5909, 5911, 5913, 5914, 5915 and the clip positions 6098 and 5910.

Remove the fire detection (system A) nacelle temperature and cabin services harness.

SUBTASK 72-00-40-020-088 Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness (Pre SBN 71-0011, Pre SBN 71-0138, Pre SBN 71-0272, Pre SBE 79-0087, SBN 71-0011, SBN 71-0138, SBN 71-0272 and SBE 79-0087)

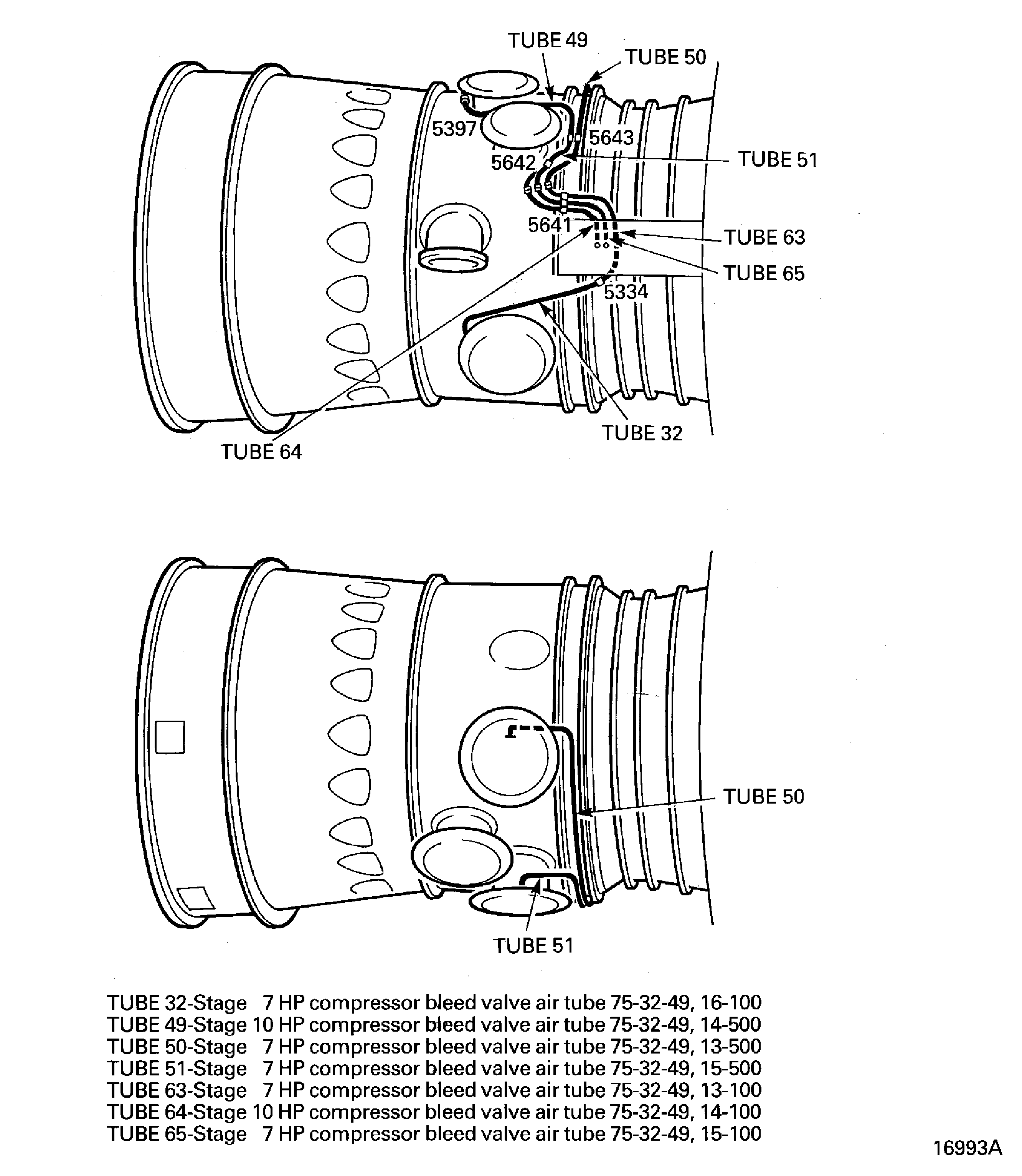

Pre SBE 79-0087: Remove the tubes 63, 64 and 65.

SBE 79-0087: Remove the tubes 63, 64 and 65.

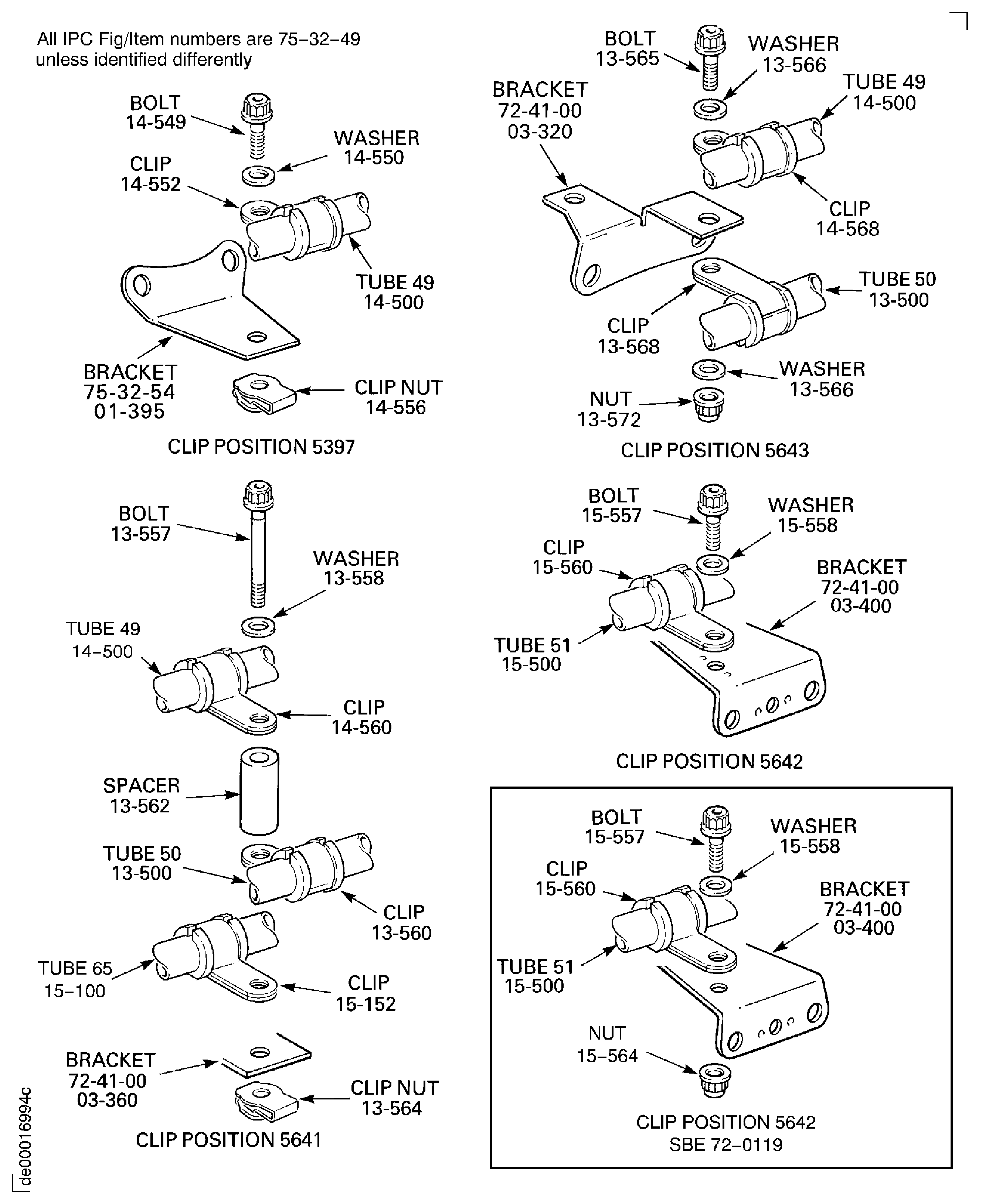

Pre SBE 72-0119: Remove the bolt, the washer and the clip from the clip position 5642.

SBE 72-0119: Remove the bolt, the washer, the nut and the clip from the clip position 5642.

Pre SBE 79-0087: Remove the tubes 49, 50 and 51.

SUBTASK 72-00-40-020-096 Remove the HP Compressor Bleed Valve Air Tubes (Pre SBE 72-0119, Pre SBE 79-0087, SBE 72-0119 and SBE 79-0087)

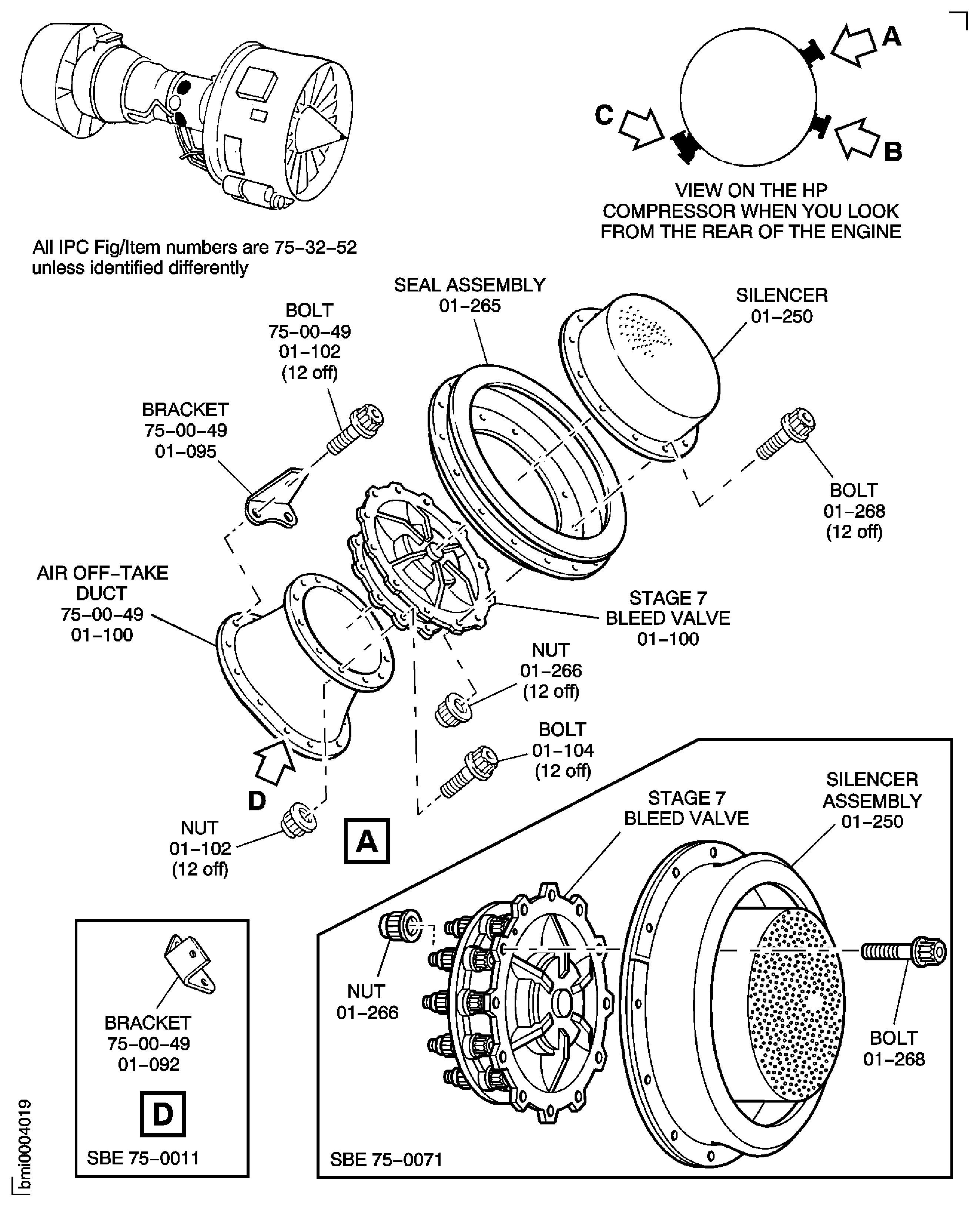

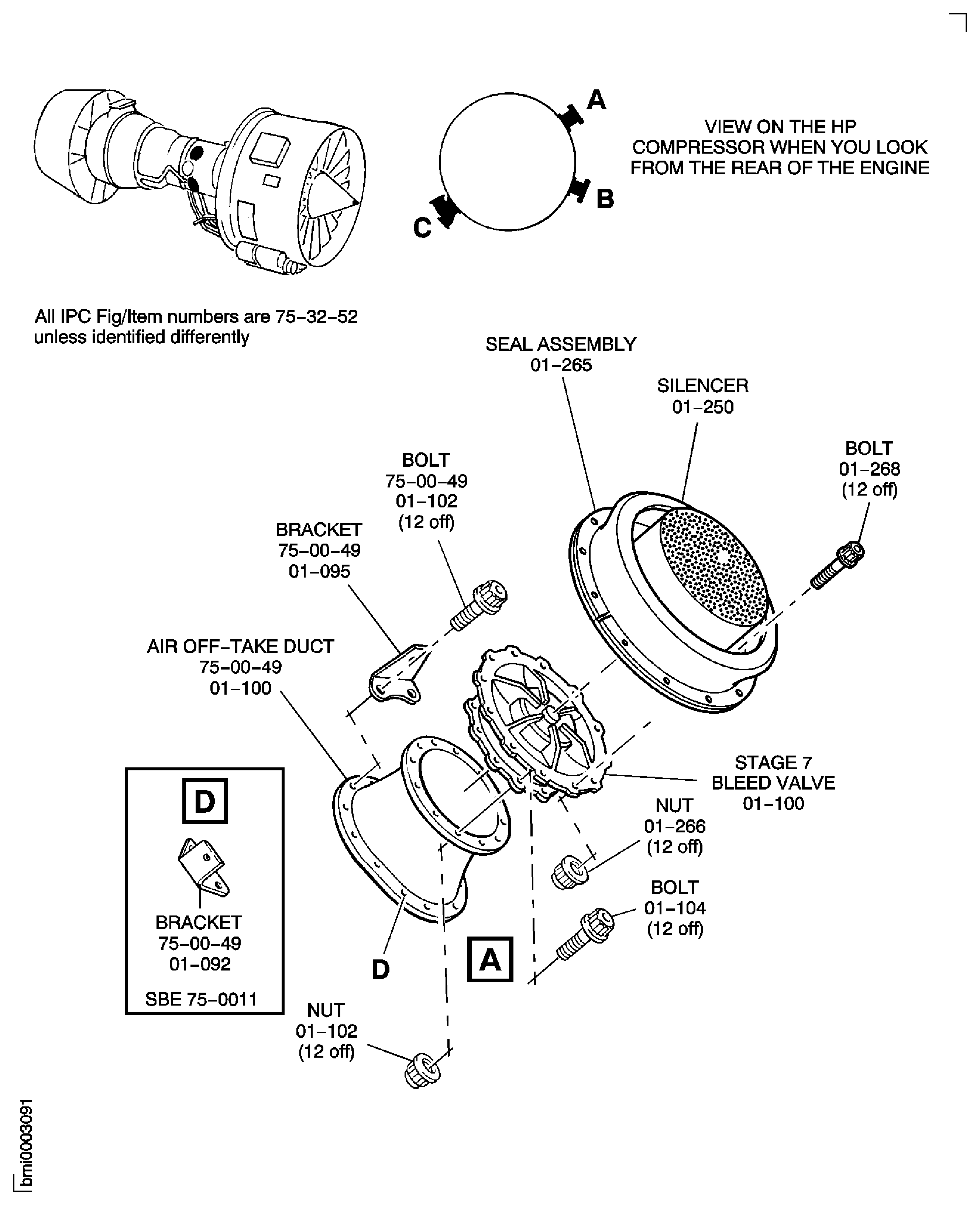

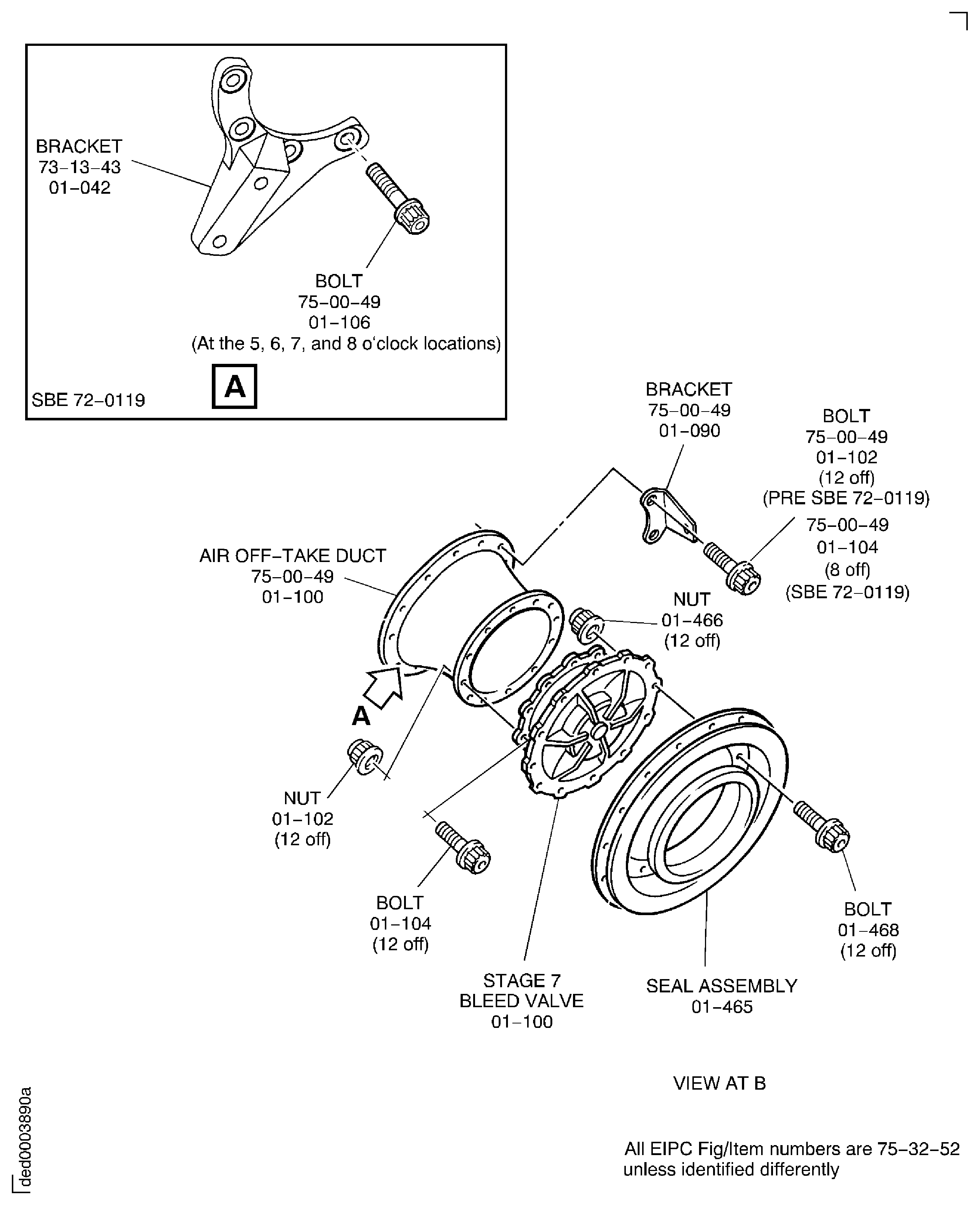

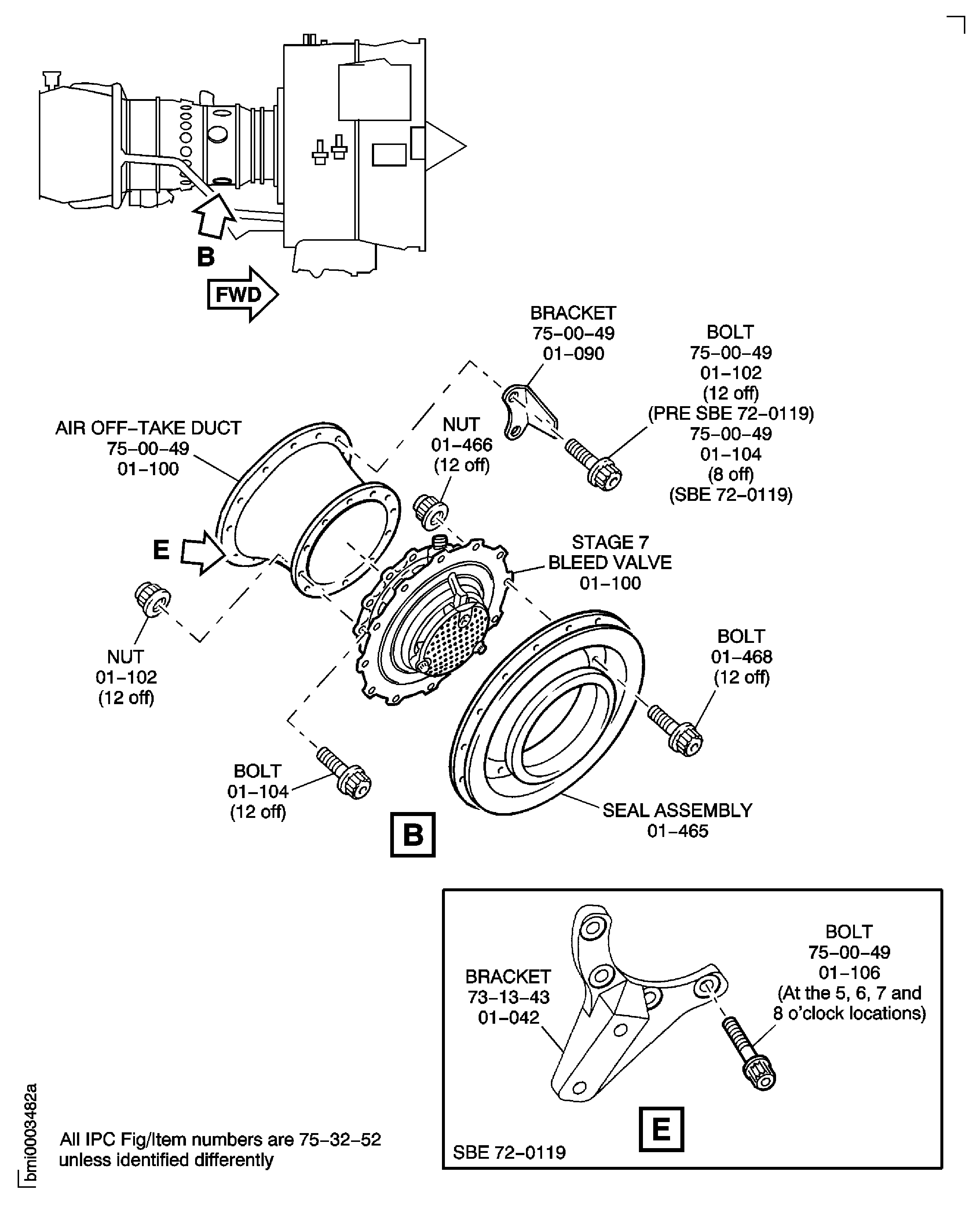

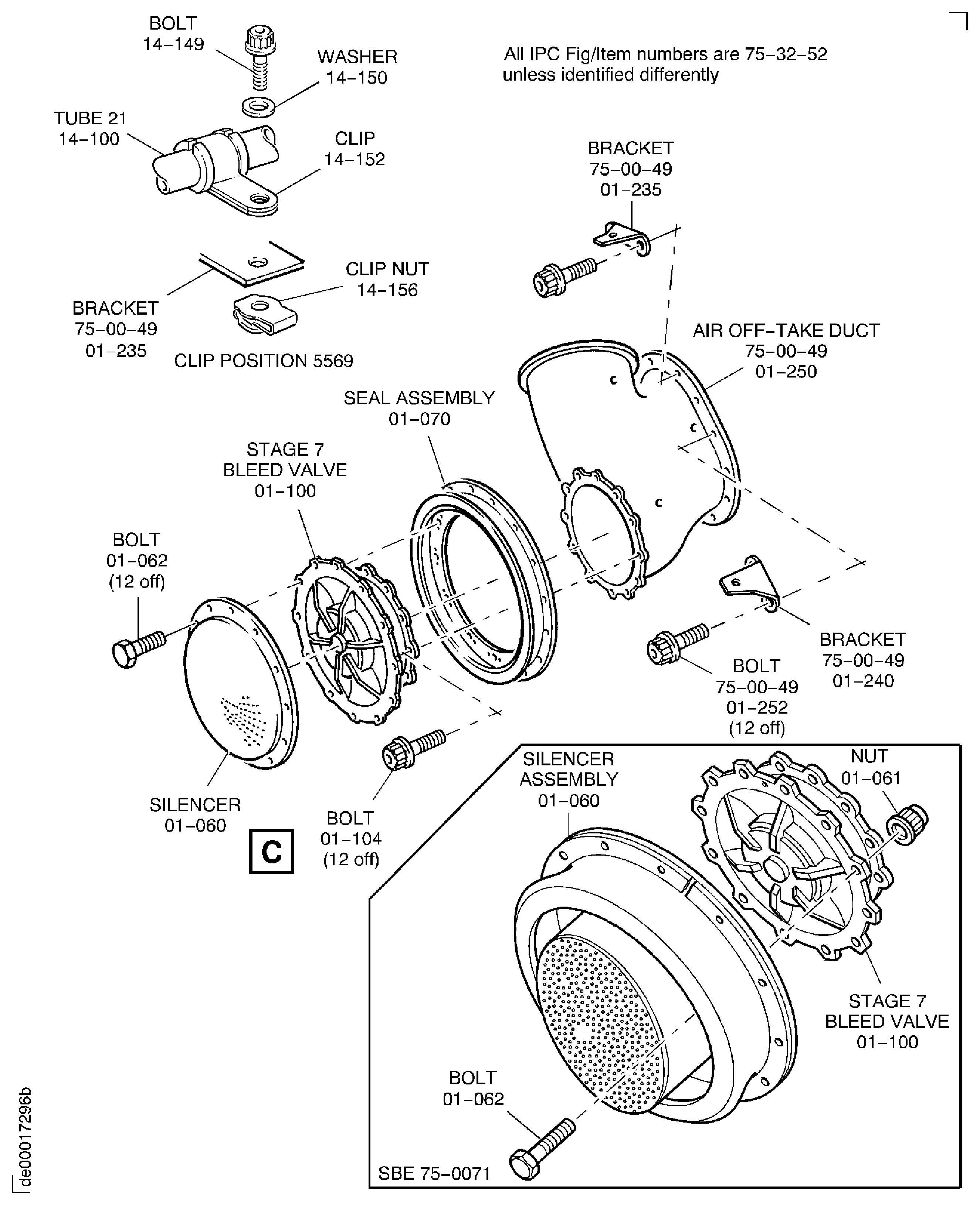

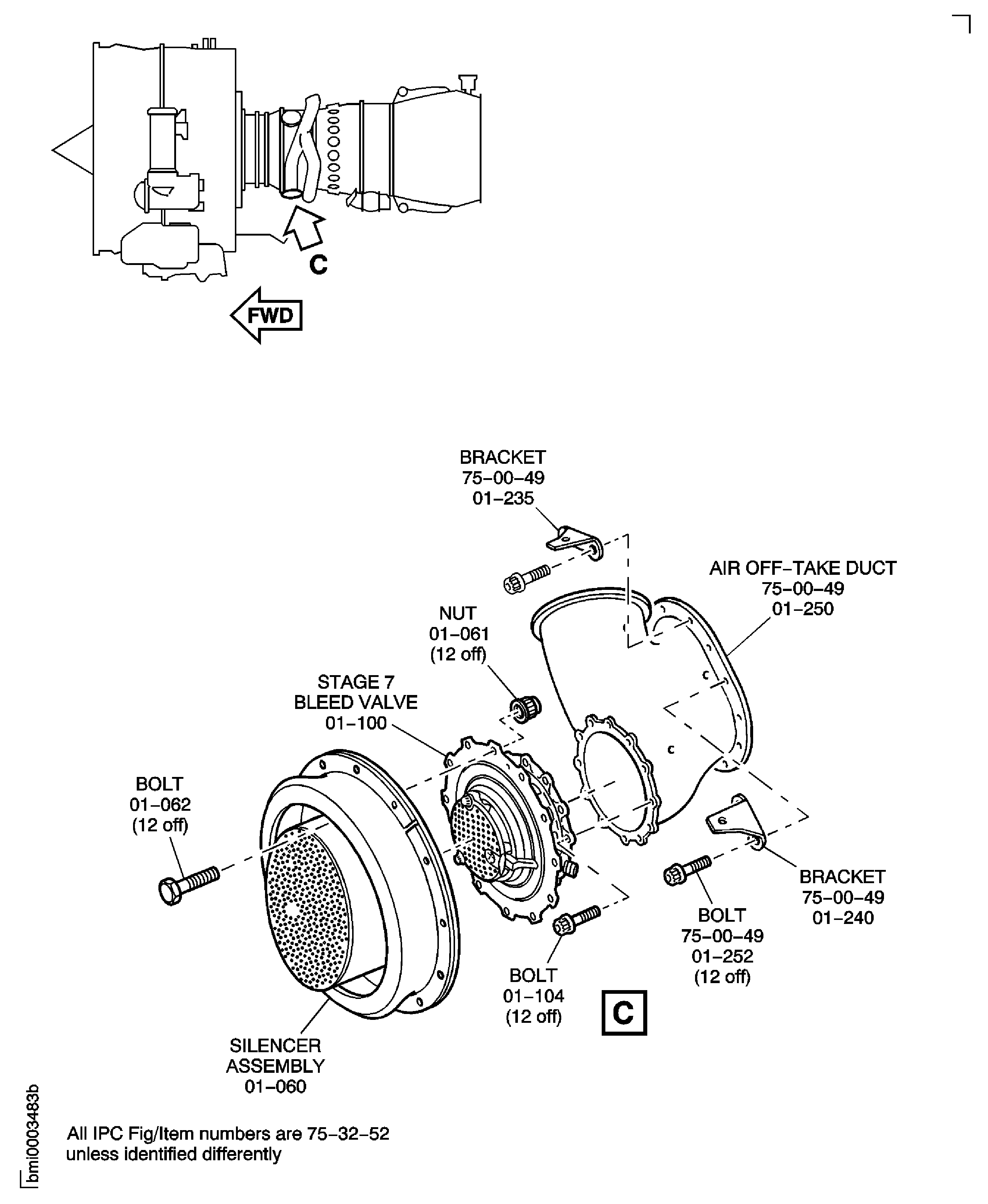

Pre SBE 75-0071: Remove the stage 7 silencer, the seal assembly and the bleed valve from the 8 o'clock position.

SBE 75-0071: Remove the stage 7 silencer assembly and the bleed valve from the 8 o'clock position.

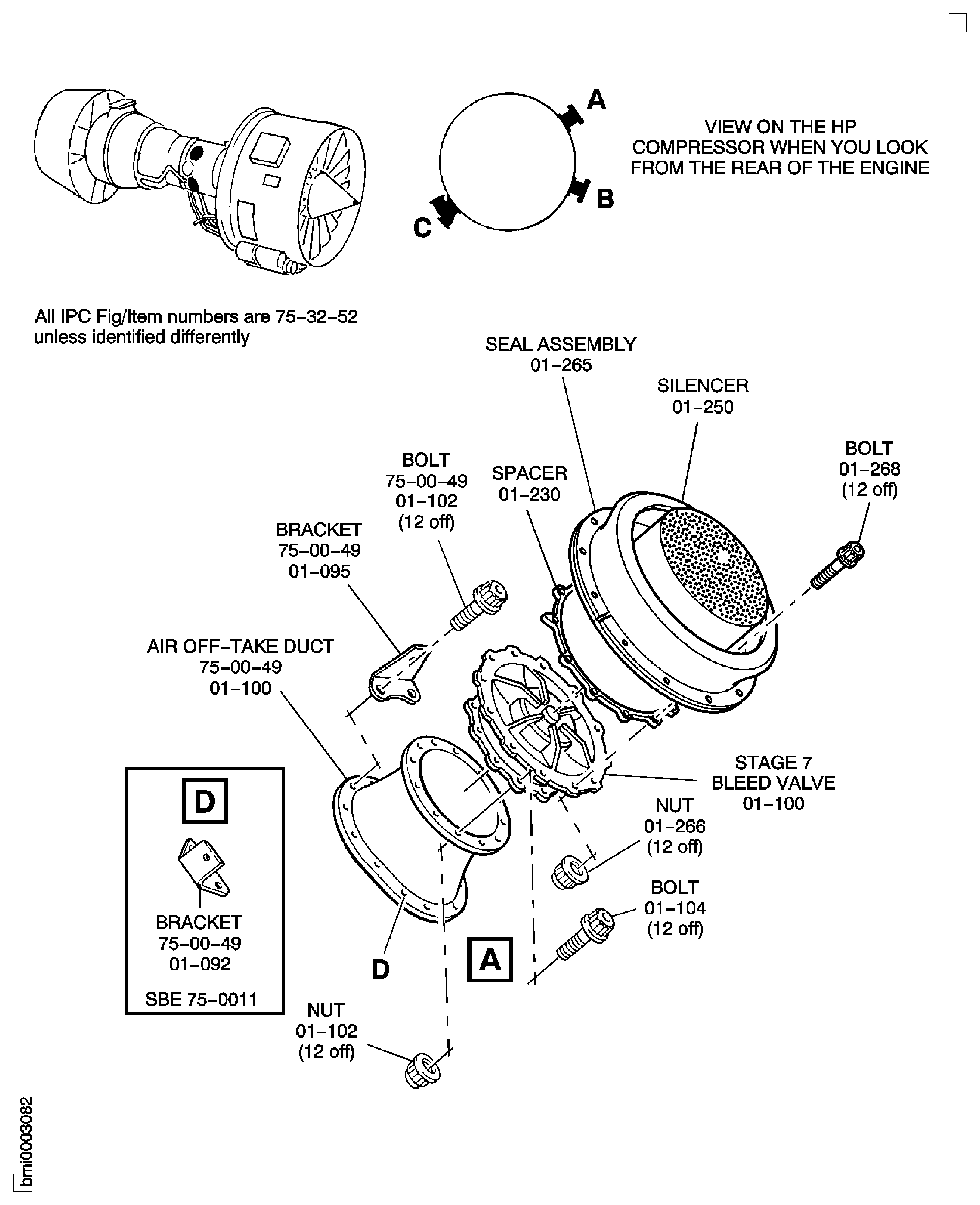

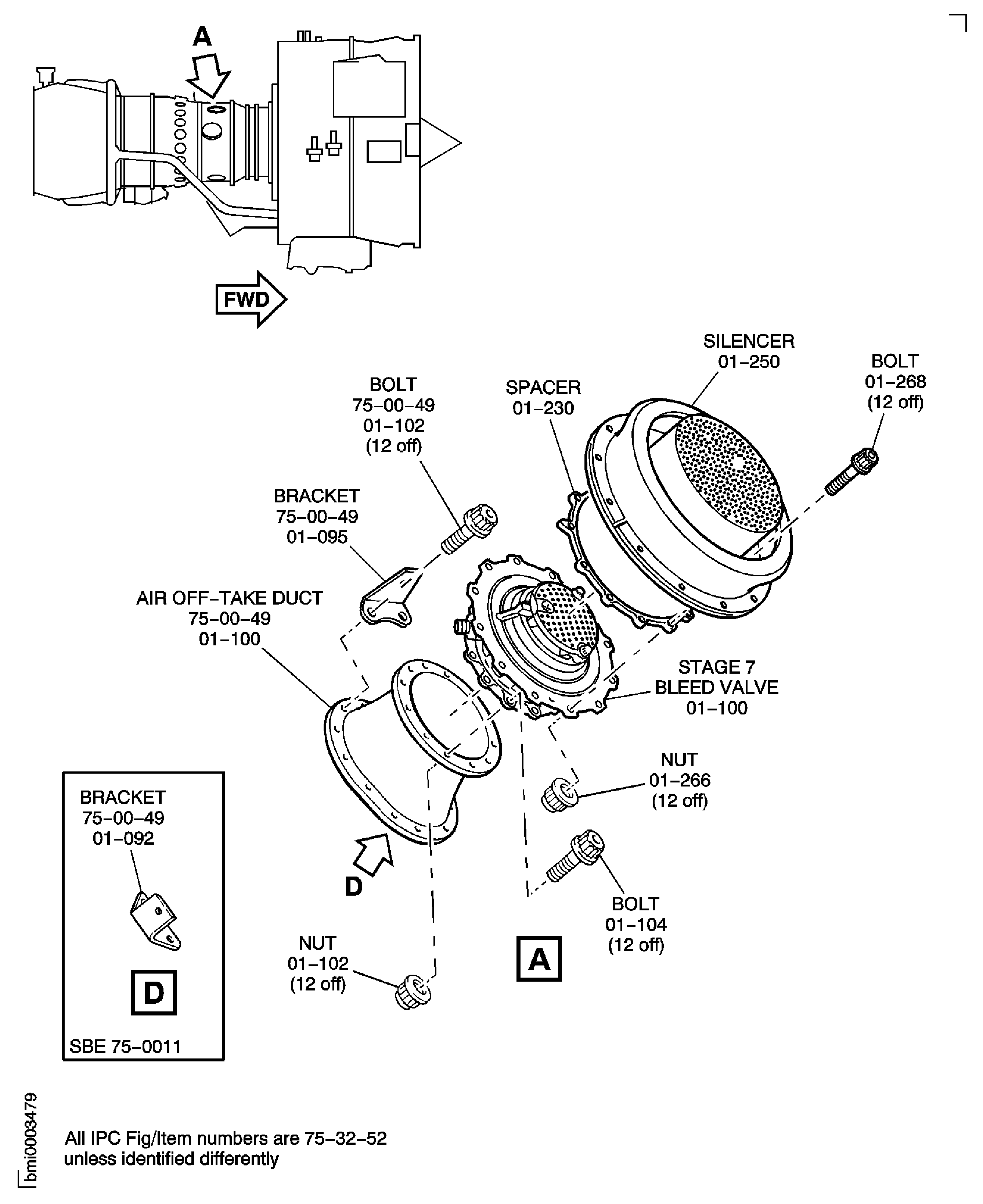

Pre SBE 75-0071: Remove the stage 7 silencer, the seal assembly and the bleed valve from the 2 o'clock position.

SBE 75-0071, Pre SBE 75-0092 and Pre SBE 75-0093: Remove the stage 7 silencer assembly and the bleed valve from the 2 o'clock position.

SBE 75-0092 and Pre SBE 75-0093: Remove the stage 7 silencer assembly, the spacer and the bleed valve from the 2 o'clock position.

SBE 75-0093: Remove the stage 7 silencer assembly and the bleed valve from the 2 o'clock position.

NOTE

The bleed valves must have their maintenance completed, as given in the Dunlop Component Maintenance Manual (75-32-52).

The silencers and seal assemblies must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA).

Remove the 12 bolts and nuts that attach the bleed valve to the air off-take duct and remove the bleed valve.

Remove the stage 7 seal assembly and bleed valve from the 4 o'clock position.

SUBTASK 72-00-40-020-103 Remove the Stage 7 Silencers, the Seal Assemblies and the Bleed Valves (Pre SBE 75-0071, Pre SBE 75-0092, Pre SBE 75-0093, Pre SBE 75-0105, SBE 75-0071, SBE 75-0092, SBE 75-0093 and SBE 75-0105)

Pre SBE 72-0119: Remove the 12 bolts (together with the bracket) that attach the stage 7 air off-take duct to the HP compressor case (at the 4 o'clock position) and remove the duct.

SBE 72-0119: Remove the 12 bolts (together with the brackets) that attach the stage 7 air off-take duct to the HP compressor case (at the 4 o'clock position) and remove the duct.

SUBTASK 72-00-40-020-105 Remove the Stage 7 Air Off-Take Ducts (Pre SBE 72-0119 and SBE 72-0119)

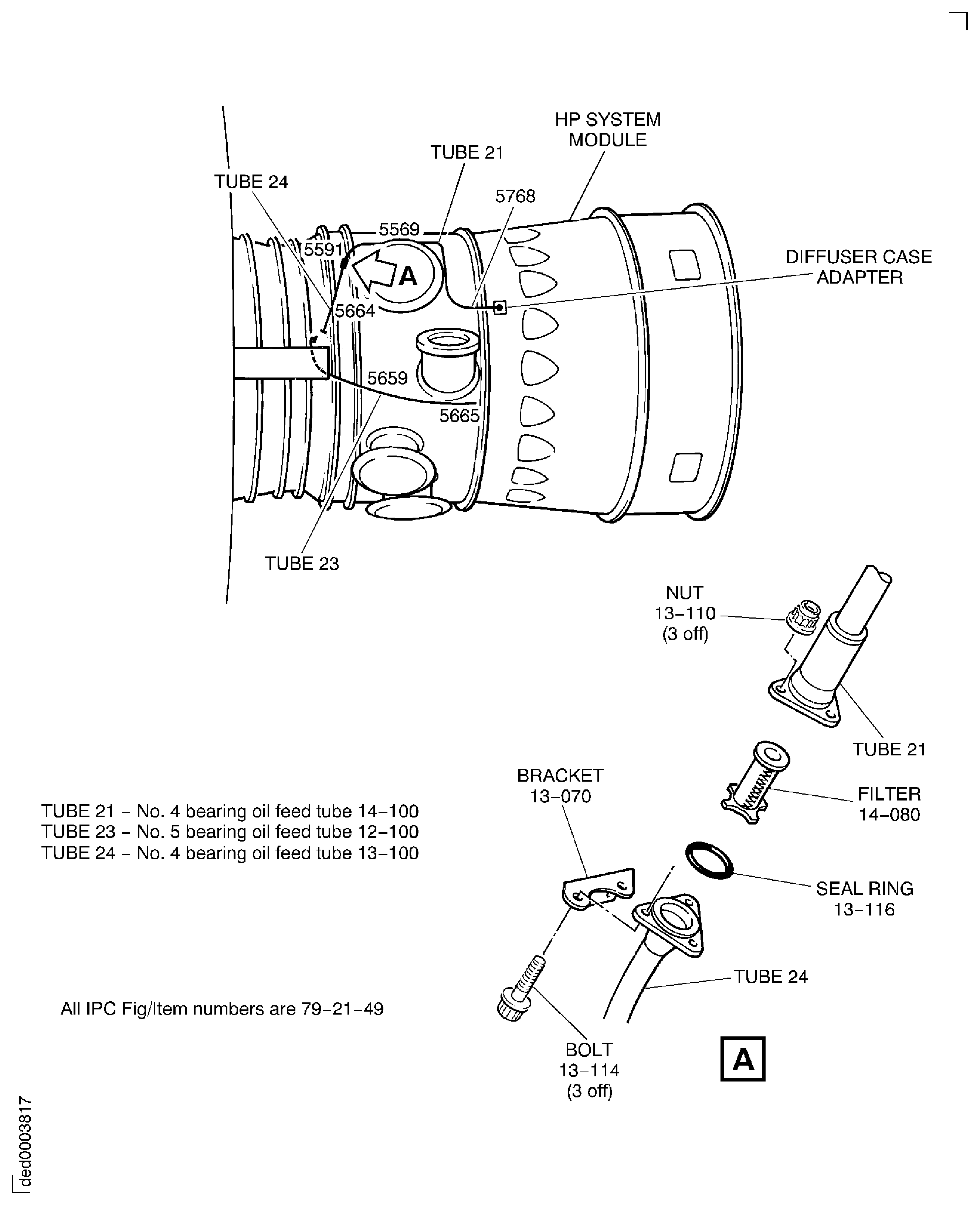

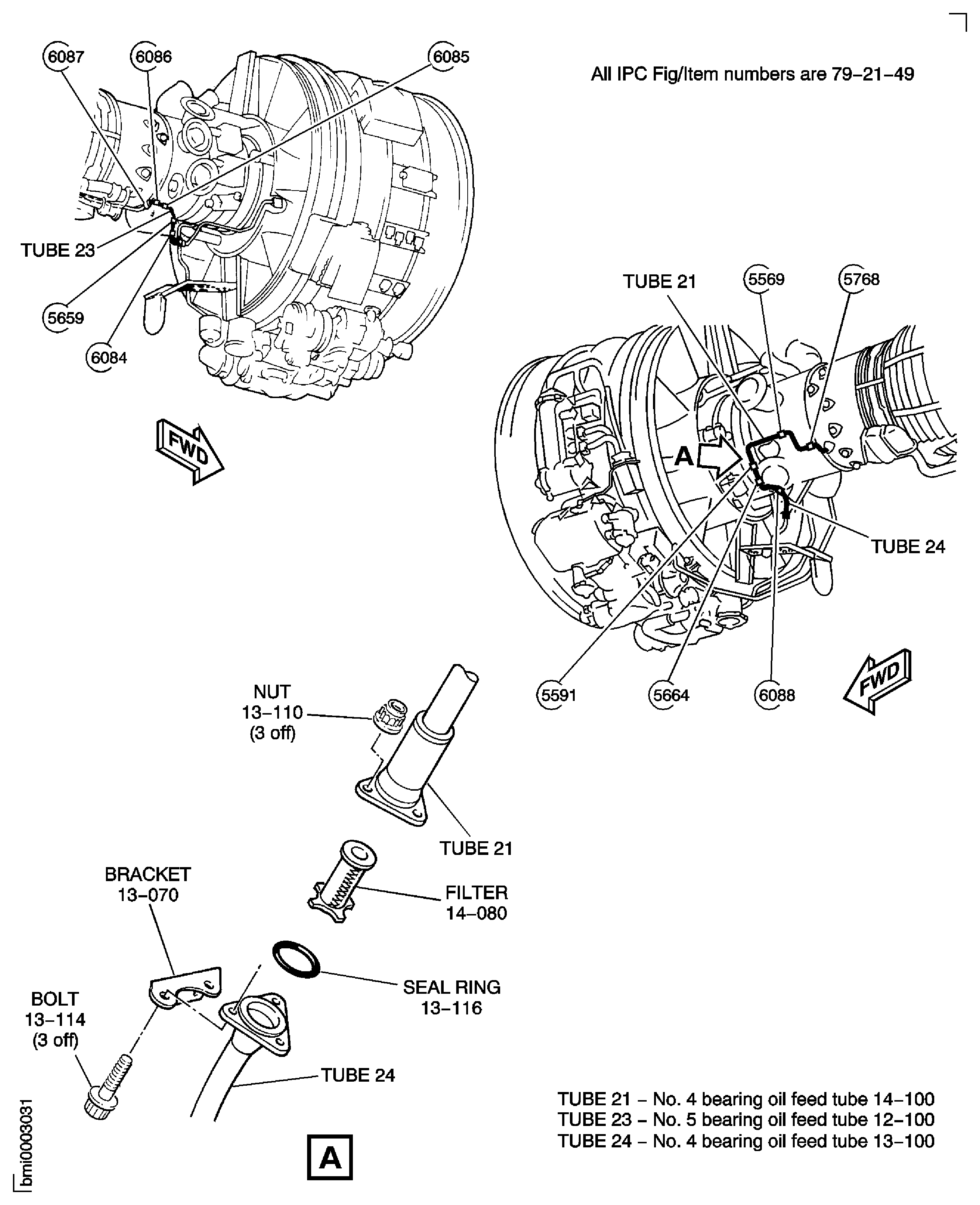

Pre SBE 79-0087: Remove the bolts, the washers, the clips and the clipnuts from the clip position 5659 and 5665.

SBE 79-0087: Remove the bolts, the washers, the spacers, the clips and the clipnuts from the clip positions 5659 and 6086.

SBE 79-0087: Remove the bolts, the washers, the clips and the clipnuts from the clip positions 6084, 6085 and 6087.

Remove the tube 23.

Remove the three nuts and the three bolts that attach the tube 21 to the tube 24 together with the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-070).

Remove the tube 21.

Pre SBE 79-0087: Remove the bolt, the washer, the clip and the clipnut from the clip position 5664.

SBE 79-0087: Remove the bolt, the clip and the nut from the clip position 5664.

SBE 79-0087: Remove the bolt, the washer, the clip, the spacer and the nut from the clip position 6088.

Remove the two nuts and the two bolts that attach the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-090) to the bracket (72-41-00 , 03-510).

Remove the bracket OIL-PRESSURE OIL TUBES-ENGINE (79-21-49, 13-090).

Remove the tube 24.

SUBTASK 72-00-40-020-099 Remove the Oil Feed Tubes (21, 23 and 24) (Pre SBE 79-0087 and SBE 79-0087)

Figure: Pre SBE 79-0087: Remove the HP Bleed Control Air Tube (48)

Sheet 1

Figure: SBE 79-0087: Remove the HPBleed Control Air Tube (48)

Sheet 2

Figure: Remove the Cabin Bleed Air System Ducts and Valves

Sheet 1

Figure: Remove the Cabin Bleed Air System Ducts and Valves

Sheet 2

Figure: Remove the Ignition Exciter Cross Brackets and the Support Tubes

Remove the Ignition Exciter Cross Brackets and the Support Tubes

Figure: Pre SBN 71-0272 and Pre SBE 79-0087: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 1

Figure: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 2

Figure: Pre SBN 71-0011 and Pre SBN 71-0272: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 3

Figure: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 4

Figure: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 5

Figure: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 6

Figure: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 7

Figure: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 8

Figure: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 9

Figure: Remove the Fire Detection Harnesses, the Nacelle Temperature and Cabin Services Harness

Sheet 10

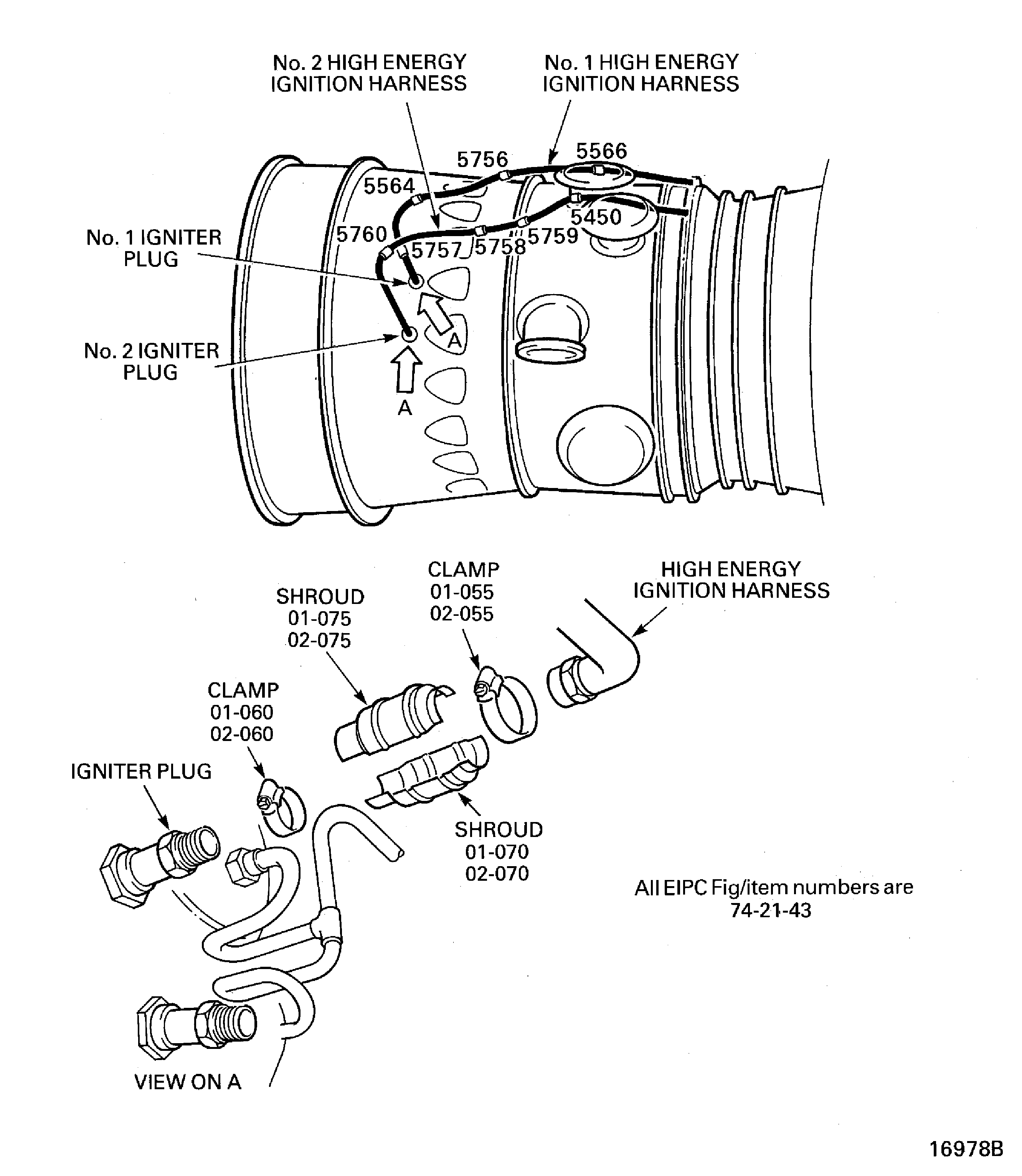

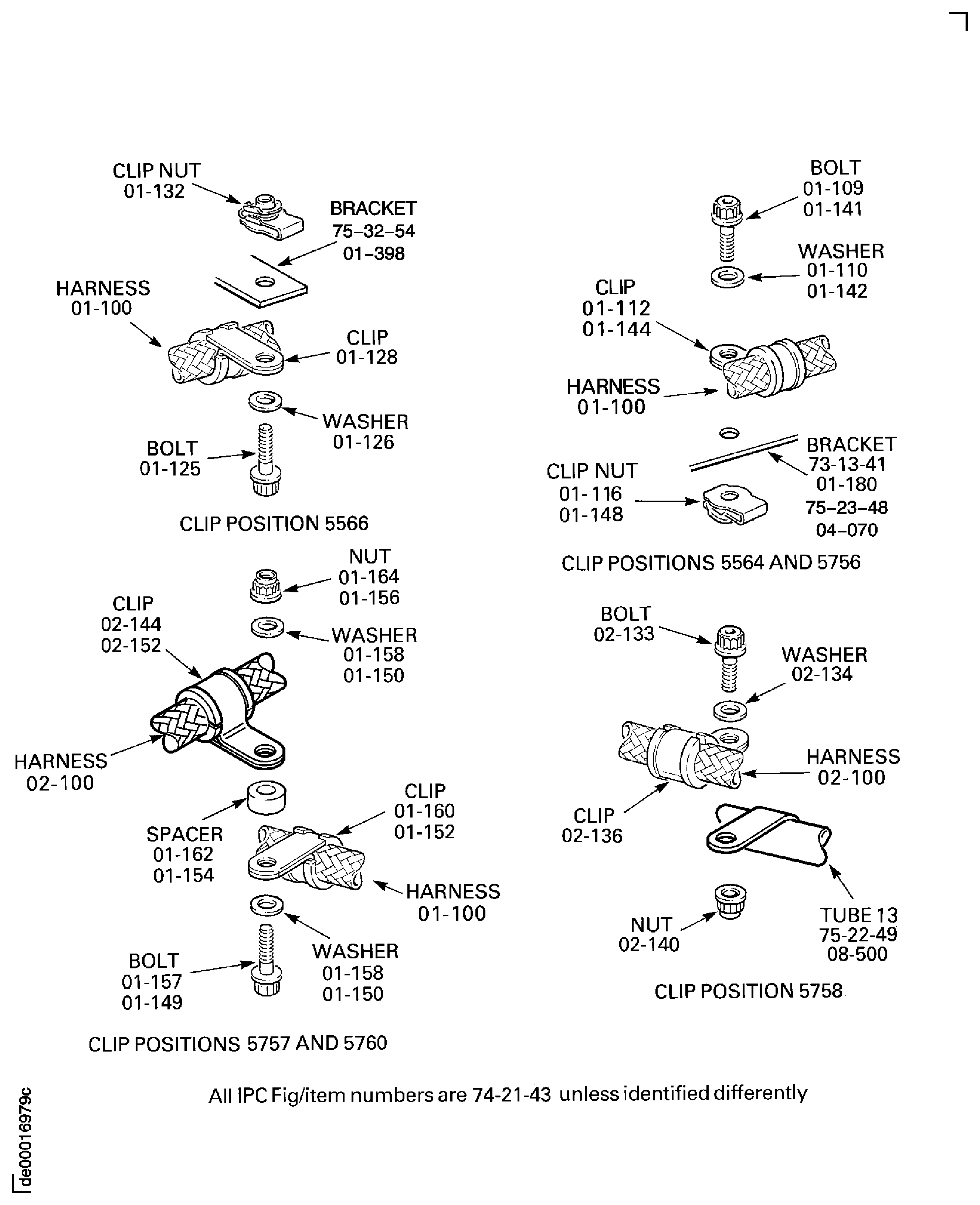

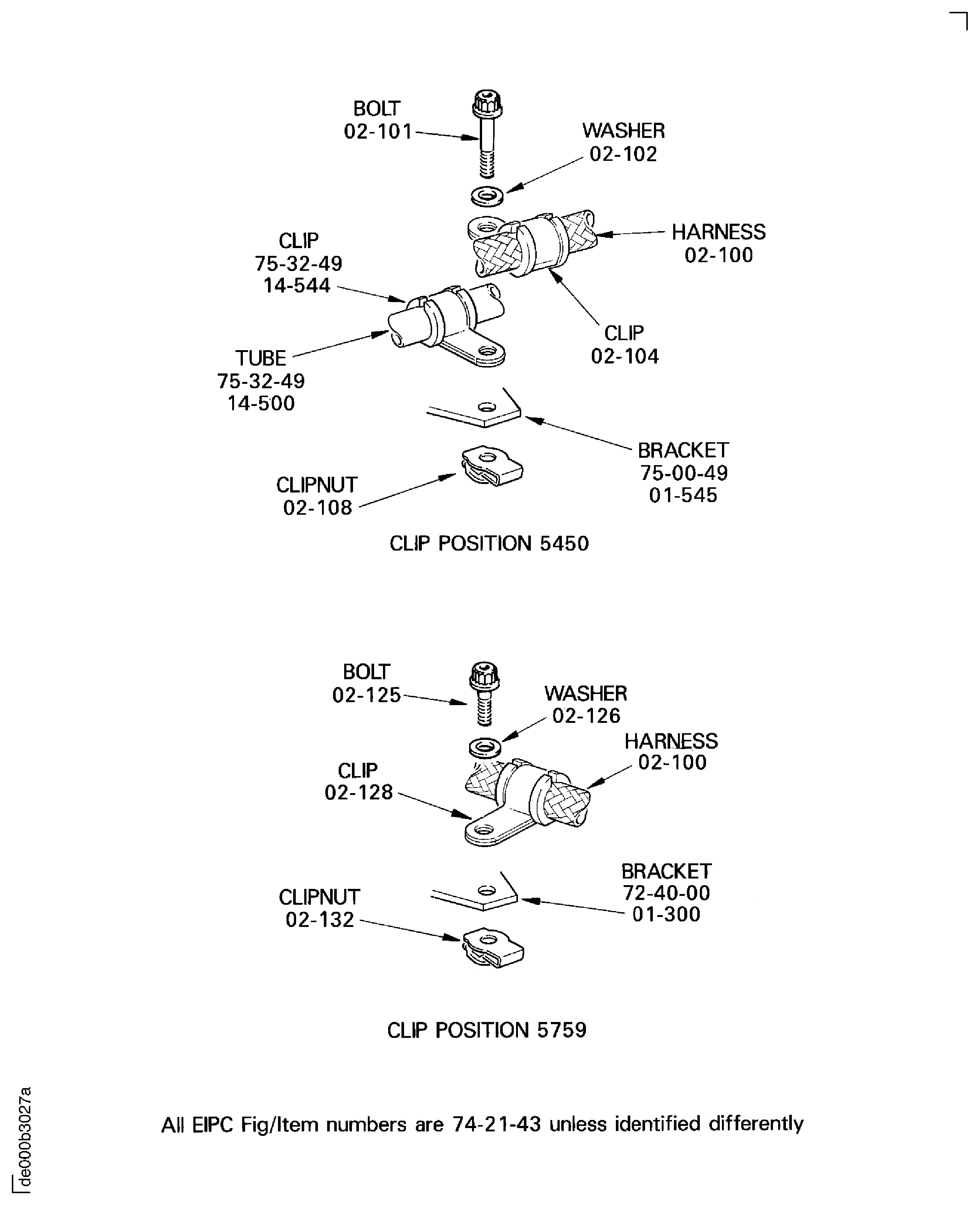

Figure: Remove the High Energy Ignition Harness

Sheet 1

Figure: Remove the High Energy Ignition Harness

Sheet 2

Figure: Remove the High Energy Ignition Harness

Sheet 3

Figure: Pre SBE 79-0087: Remove the HP Compressor Bleed Valve Air Tubes

Sheet 1

Figure: SBE 79-0087: Remove the HP Compressor Bleed Valve Air Tubes

Sheet 2

Figure: Remove the HP Compressor Bleed Valve Air Tubes

Sheet 3

Figure: Pre SBE 75-0071, SBE 75-0071, Pre SBE 75-0092 and Pre SBE 75-0105: Remove the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 1

Figure: SBE 75-0071, SBE 75-0092, Pre SBE 75-0093 and Pre SBE 75-0105: Remove the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 2

Figure: SBE 75-0071, SBE 75-0092, Pre SBE 75-0093 and SBE 75-0105: Remove the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 3

Figure: SBE 75-0071, SBE 75-0093 and Pre SBE 75-0105: Remove the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 4

Figure: SBE 75-0071, SBE 75-0093 and SBE 75-0105: Remove the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 5

Figure: Pre SBE 75-0105: Remove the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-Take Ducts

Sheet 6

Figure: SBE 75-0105: Remove the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-Take Ducts

Sheet 7

Figure: Pre SBE 75-0071, SBE 75-0071 and Pre SBE 75-0105: Remove the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 8

Figure: SBE 75-0071, SBE 75-0105: Remove the Stage 7 HP Compressor Bleed Valve Assemblies and the Air Off-take Ducts

Sheet 9

Figure: Pre SBE 79-0087: Remove the Oil Feed Tubes

Sheet 1

Figure: SBE 79-0087: Remove the Oil Feed Tubes

Sheet 2

Figure: Remove the Cabin Bleed Air System Sense Tubes

Sheet 1

Figure: Remove the Cabin Bleed Air System Sense Tubes

Sheet 2

Figure: Remove the Cabin Bleed Air System Sense Tubes

Sheet 3