Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 71-00-00-700-011-B00 Test No. 11 (A5) - Set Jumpers In Data Entry Plug (DEP), Testing-011

General

This TASK gives the procedures to set the jumper configuration in the Data Entry Plug (DEP).

Do not apply this TASK to the slave (DEP).

The DEP is used to input engine statistics to the Electronic Engine Control (EEC). Engine statistics that are input to the EEC by the DEP are:

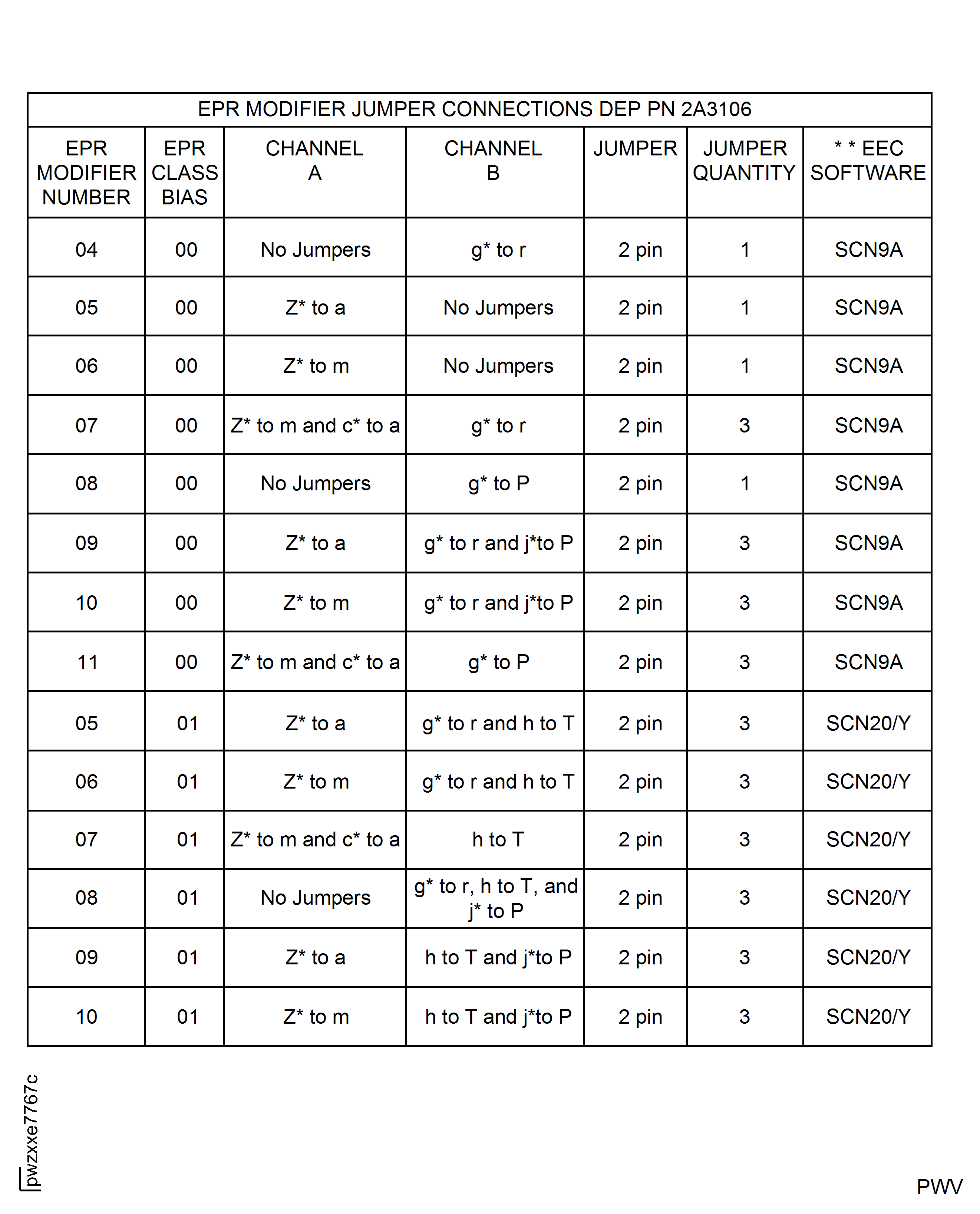

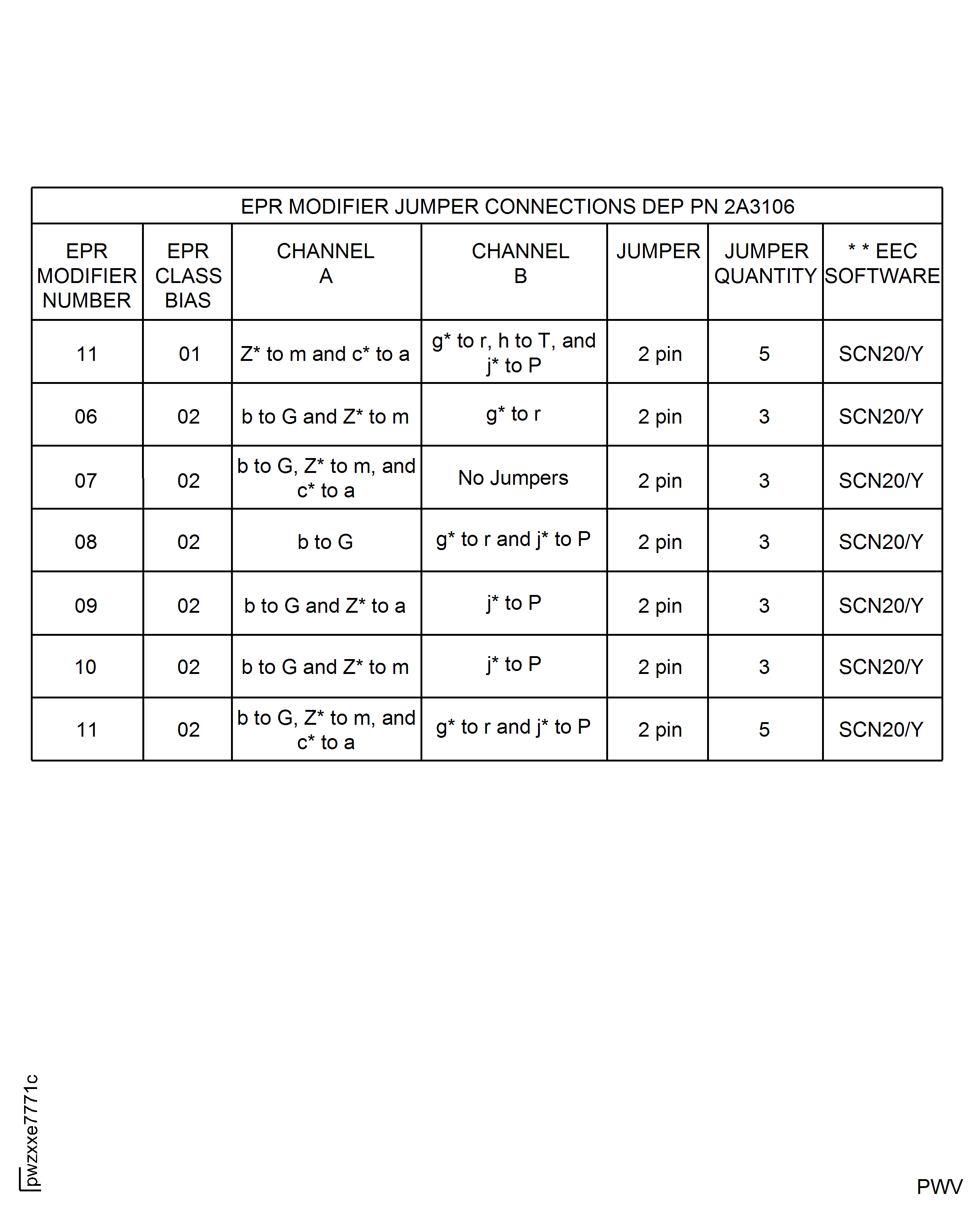

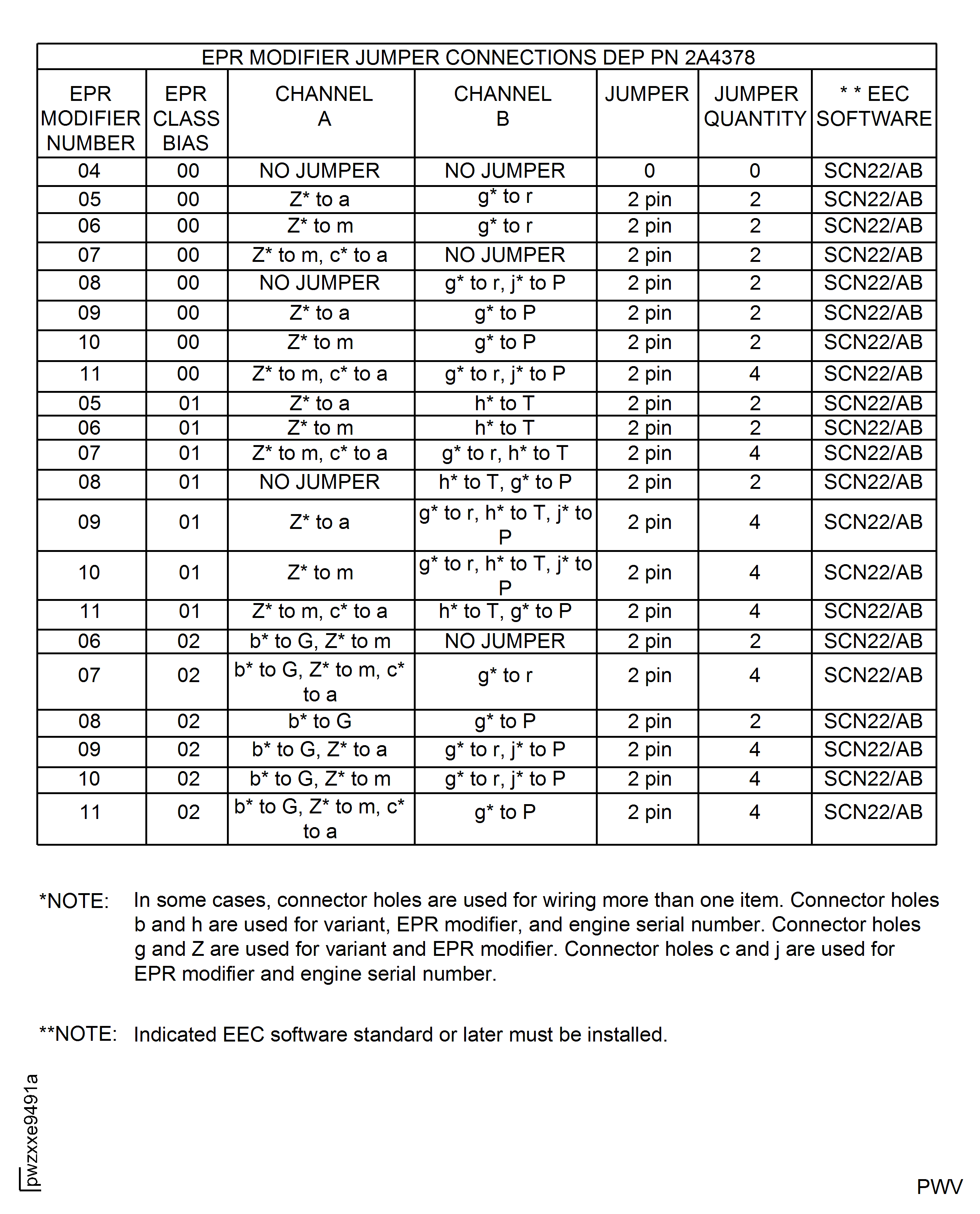

Engine Pressure Ratio (EPR) Modifier includes EPR modifier number (Class No.) and EPR class bias (SCN 20 and above)

Engine statistics (except for the engine serial number) are input to both EEC Channels A and B. Engine Take-off Rating - Enhancement/Bump No., EPR Modifier and Engine Serial Number are obtained from the engine identification plate.

Figure shows the connector of the DEP and the pin letters given to each pin hole. The upper case letters I, O and Q and the lower case letters l and o are not used. Pin holes in the connector are connected by jumpers to set the DEP with the necessary engine statistics.

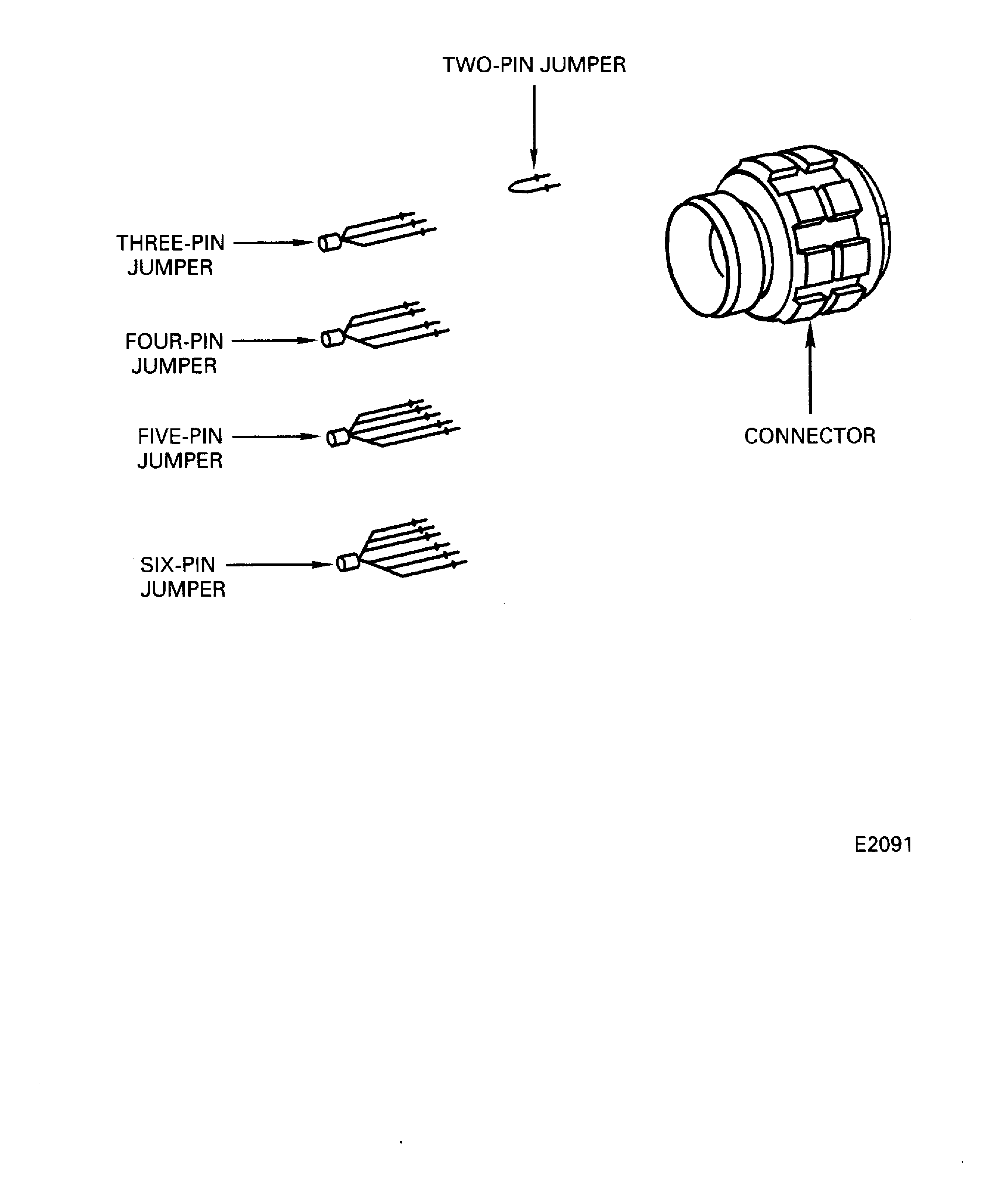

Figure shows the five types of jumpers that are used.

DEPs cannot be moved from engine to engine. Except for EPR Modifier, a DEP can be identified and jumpered again only as instructed by service bulletin. The DEP and Engine Identification Plate marks must agree in relation to DEP Part No., EPR Modifier No., Engine Serial No., and Take-off Rating - Enhancement/Bump No.

The Variant or Bump Rating of a DEP cannot be changed without approval from IAE.

If a DEP is damaged or needs replacement, the replacement DEP must be jumpered exactly like the old one.

Use Test No.10, TASK 71-00-00-700-010-B00 (TESTING-010, CONFIG-002) to:

Determine EPR modifier number and EPR class bias (SCN 20 and above).

Check the existing EPR modifier number and EPR class bias (SCN 20 and above) and make the applicable change.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For lockwire data and procedures, refer to SPM TASK 70-42-05-400-501.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Contact insertion tool | LOCAL | MS27495A20 | ||

| Contact removal tool | LOCAL | MS27495R20 | ||

| Plastic Cap | LOCAL | Plastic Cap | ||

| Soft Nose Pliers | LOCAL | Soft Nose Pliers | ||

| Strap Wrench | LOCAL | TG-70 | ||

| IAE 1R19416 EEC harness wrench | 0AM53 | IAE 1R19416 | 1 | (supersedes IAE 1R19279) |

| IAE 1R19279 EEC harness wrench | 0AM53 | IAE 1R19279 | 1 | (superseded by IAE 1R19416, supersedes IAE 1J12018) |

| IAE 1J12018 EEC harness wrench | 0AM53 | IAE 1J12018 | 1 | (superseded by IAE 1R19279) |

| IAE 1P16271 Holding fixture | 0AM53 | IAE 1P16271 | Or alternate fixture | |

| IAE 2P16369 EEC Software Loader and DEP Tester | 0AM53 | IAE 2P16369 | 1 | (superseded by IAE 2P16552) |

| IAE 2P16552 EEC Software Loader and DEP Tester | 0AM53 | IAE 2P16552 | ||

| IAE 2P16552-A EEC Software Loader and DEP Reader | 0AM53 | IAE 2P16552-A |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-138 LOCKWIRE | LOCAL | CoMat 02-138 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Jumper | 1 | (1) | ||

| Jumper | 1 | (2) | ||

| Jumper | 1 | (3) | ||

| Jumper | 1 | (4) | ||

| Jumper | 1 | (5) | ||

| Sealing plug | 1 | |||

| Contact pin | 1 |

Safety Requirements

NONEProcedure

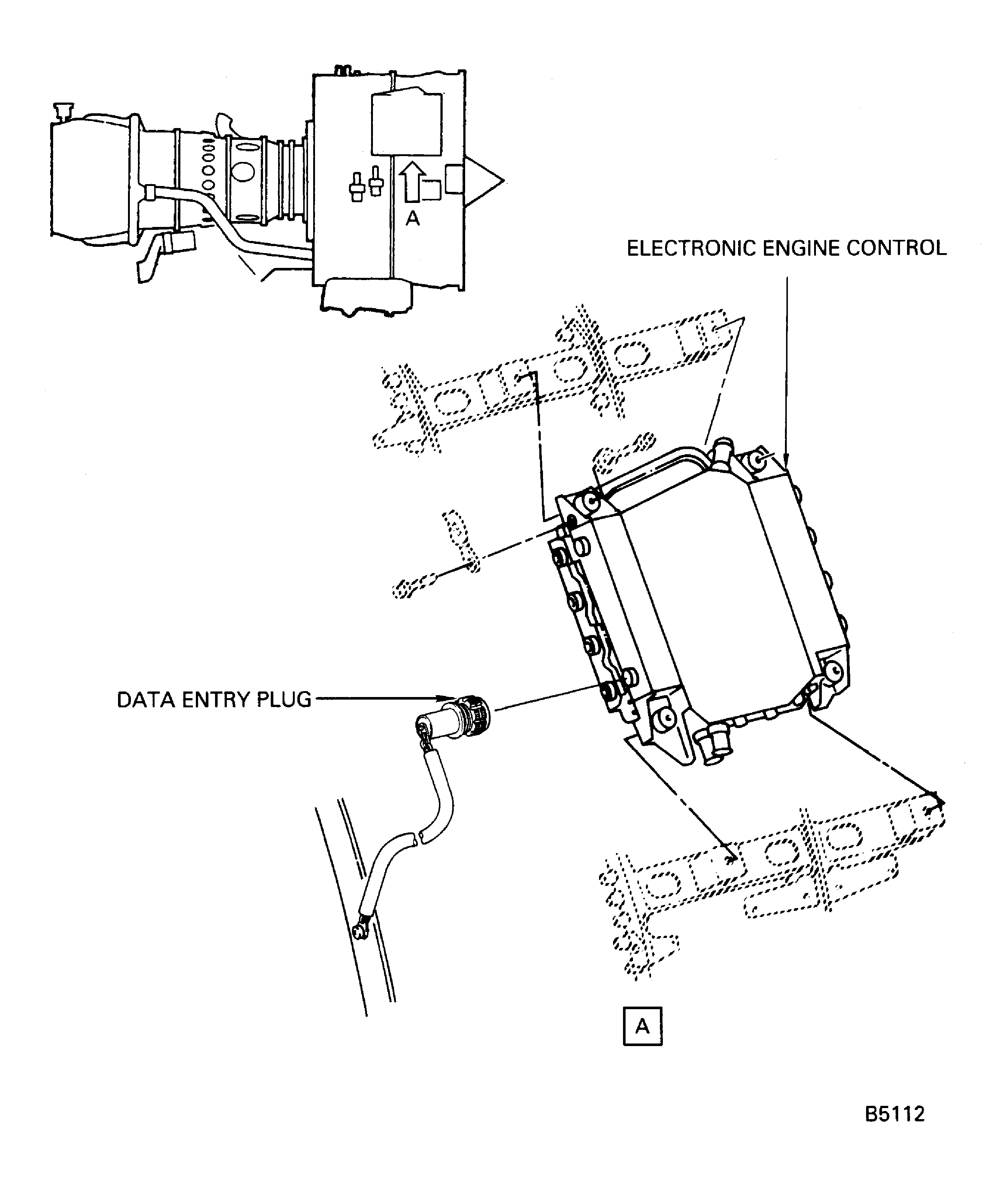

Refer to Figure.

Disconnect the DEP from the EEC connector with IAE 1R19416 EEC harness wrench 1 off.

Put the special Plastic Cap on to the EEC connectors. This gives protection from unwanted fluids or materials.

SUBTASK 71-00-00-060-055 Disconnect the Data Entry Plug (DEP) from the Electronic Engine Control (EEC)

Install the DEP onto the IAE 1P16271 Holding fixture or alternate, 1 off, as follows:

CAUTION

MAKE SURE THE BACKSHELL DOES NOT TURN WHEN YOU LOOSEN THE BACKSHELL NUT. IF THE BACKSHELL TURNS, DAMAGE TO THE JUMPER WIRES CAN OCCUR.NOTE

It is important to make sure this backshell is later installed on the same DEP connector.Remove the backshell from the DEP connector. Use a Strap Wrench 1 off or equivalent, to loosen the backshell nut.

SUBTASK 71-00-00-060-056 Remove the Backshell from the Connector of the DEP

NOTE

For engines that need only modification of the EPR Modifier as a result of doing Test No. 10, TASK 71-00-00-700-010-B00 (TESTING-010, CONFIG-002), use the procedure in Figure.

SUBTASK 71-00-00-350-056 Make a Record of the EPR Modifier No., Variant, and Engine Serial No.

NOTE

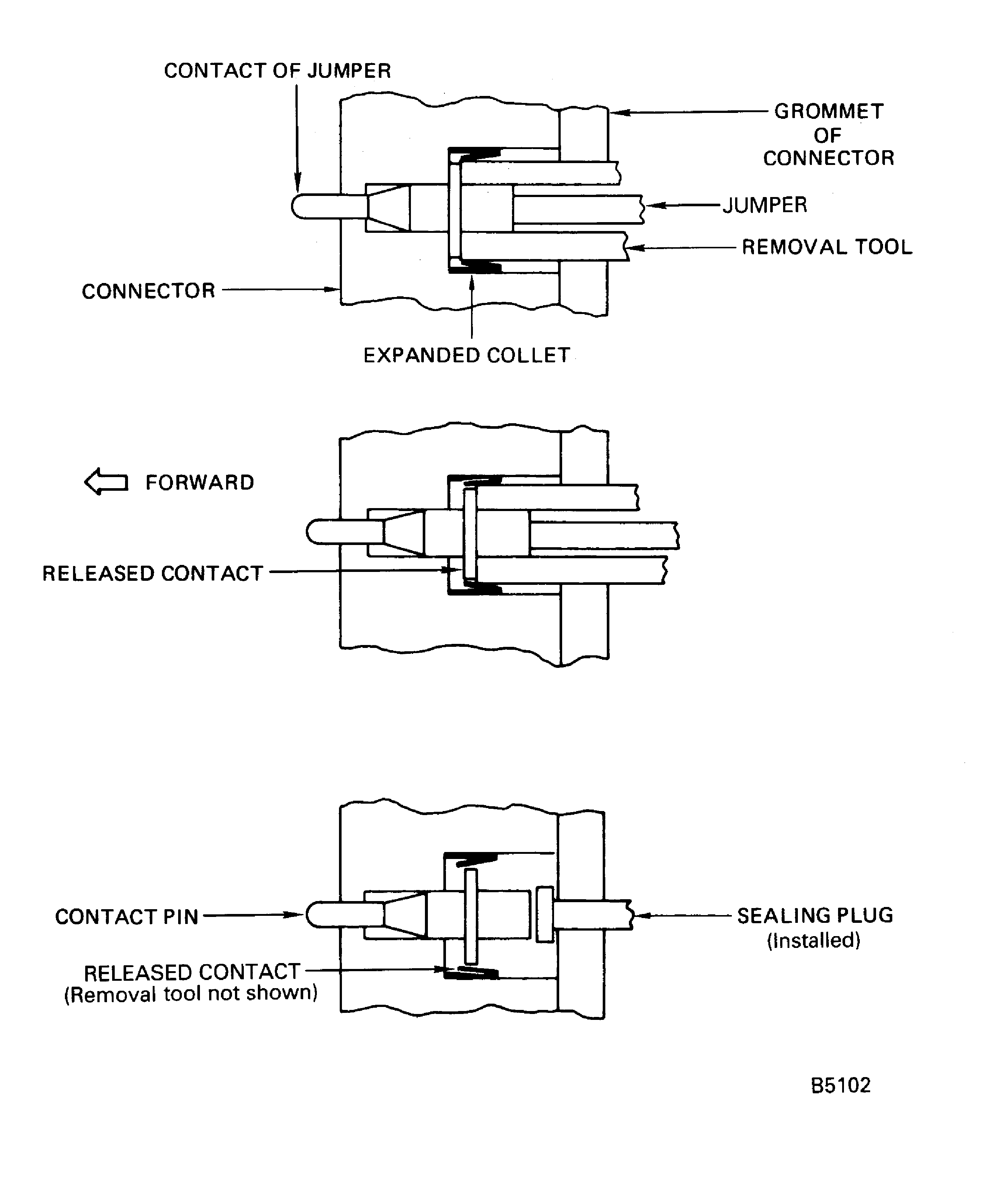

If necessary, you can cut the jumper wires so you can easily install the removal tool on the jumper. Cut the wire 0.250 in. (6.35 mm) from the top of the connector rubber seal.Remove the jumpers that do not agree with the jumpering combinations that you want from the connector with the Contact removal tool 1 off or equivalent. Refer to Figure. Discard the jumpers.

Remove the sealing plugs with your fingers or Soft Nose Pliers 1 off and discard them.

Use the Contact removal tool 1 off or equivalent and a small piece of straight wire such as a straightened paper clip.

Remove the contact pins and discard them.

SUBTASK 71-00-00-350-001 Remove the Jumpers, Sealing Plugs and Contact Pins from the Connector

Refer to Figure.

Put the jumper into the Contact insertion tool 1 off .

CAUTION

DO NOT APPLY STRONG FORCE TO THE INSERTION TOOL WHEN YOU PUSH THE JUMPER. THIS COULD CAUSE DAMAGE TO THE COLLET.NOTE

When the collet locks the contact, the collet makes a light click sound.Push one end of the jumper into the correct hole in the connector until the shoulder of the contact becomes locked by the collet.

CAUTION

DO NOT USE THE REMOVAL TOOL IN THIS SUBTASK. THE COLLET CAN NOT RETRACT AND CAN NOT LOCK THE JUMPER.Install the jumpers in to the connector (2 pin).

NOTE

When the collet locks the contact, the collet makes a light click sound.Push all of the jumper ends into the correct holes with your hand. Use the insertion tool to push the contacts into the connector until the shoulder of the contact is locked by the collet. Push each contact a little at a time.

Install the jumpers into the connector (3, 4, 5 or 6-pin).

SUBTASK 71-00-00-350-002 Install the Jumpers (73-22-35,01-145, 01-155, 01-165 and 01-175) into the Connector (73-22-35,01-200)

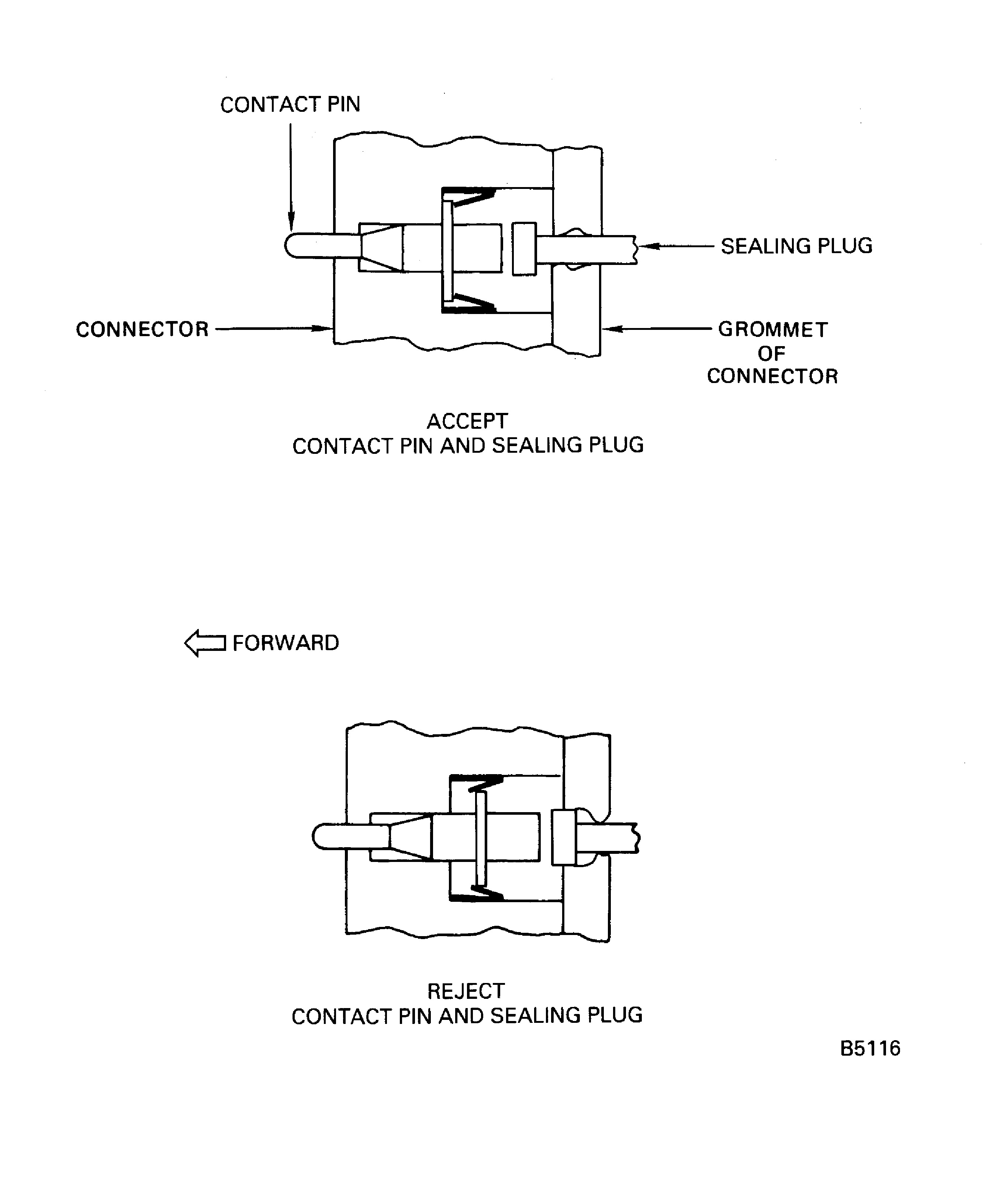

Refer To Figure.

NOTE

When the collet locks the contact, the collet makes a light click sound.Use the Contact insertion tool 1 off, or equivalent, to push the contact pin in to the unused hole until the shoulder of the contact pin becomes locked by the collet.

SUBTASK 71-00-00-350-003 Install the Contact Pins (73-22-35,01-210) and Sealing Plugs (73-22-35,01-190) in to the Remaining Open Connector Holes

NOTE

If there is no area on the backshell to make marks, replace the backshell with a new one. Make sure you mark the new backshell with the same data that is given on the old backshell.

If the DEP was reworked to a new configuration, see the service bulletin for the applicable engine identification plate instructions.

If the EPR modifier number is changed, you can vibration peen the new number on the data entry plug backshell and the engine identification plate.

If you replace the engine identification plate, see your IAE representative.

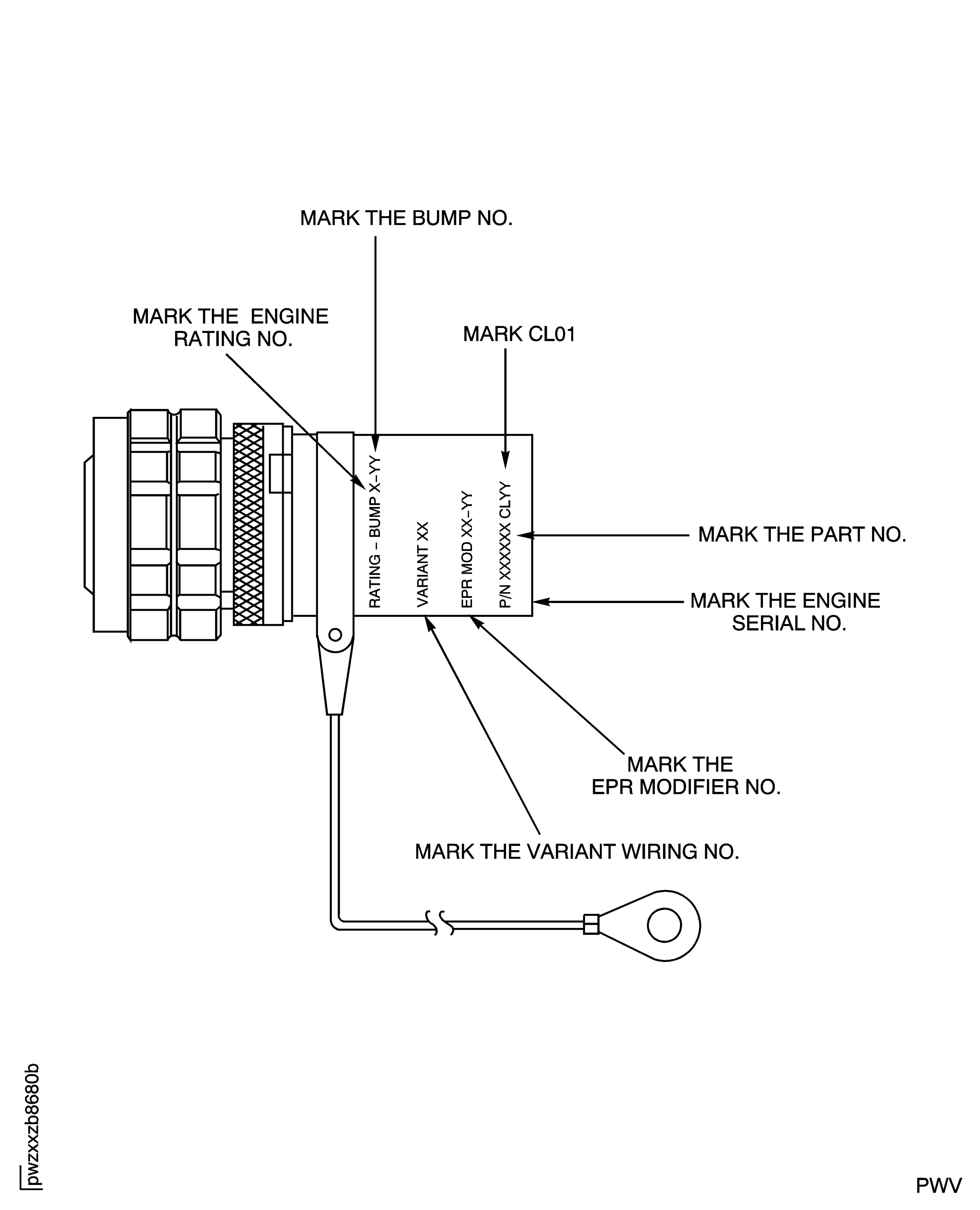

As necessary, write the Part No. and CL01, Rating - Enhancement/Bump No., EPR Modifier No., Variant and Engine Serial No. on the backshell and the engine identification plate. Use the vibration peen method. Refer to SPM TASK 70-09-00-400-501. If SCN 22 or above software is configured, make sure that the DEP PN 2A4378 is marked in both locations (Data Plate and DEP). The EPR Modifier number and EPR class bias must be marked as follows:

EPR MOD XX - YY.

Where: XX = EPR modifier number.

YY = EPR class bias.

SUBTASK 71-00-00-350-060 Make Marks on the Backshell (73-22-35,01-130) Outer Face and on the Engine Identification Plate

Install the connector on the IAE 1P16271 Holding fixture or alternate, 1 off, as follows:

CAUTION

MAKE SURE THE BACKSHELL DOES NOT TURN WHEN YOU TIGHTEN THE BACKSHELL NUT. IF THE BACKSHELL TURNS, DAMAGE TO THE JUMPER WIRES CAN OCCUR.Engage the nut of the backshell with the threads on the connector. Torque the nut to 53 to 58 lbf.in (5.988 to 6.553 Nm). Use Strap Wrench 1 off or equivalent.

Safety the nut with CoMat 02-138 LOCKWIRE. Refer to SPM TASK 70-42-05-400-501.

SUBTASK 71-00-00-460-053 Install the Backshell to the Connector

Refer to 73-0238 tooling service bulletin for instructions to update the Software loader and DEP reader to the latest configuration.

Make sure the POWER switch for the IAE 2P16552 EEC Software Loader and DEP Tester is in the OFF position.

Connect the IAE 2P16552 EEC Software Loader and DEP Tester to an external power source (110V/60Hz or 220V/50Hz).

NOTE

Do not attach the Yellow Y cable connectors to the TDS Ranger or the tester until instructed to do so, or the DEP test will not be successful.Setup of the IAE 2P16552 EEC Software Loader and DEP Tester 1 off.

Follow the instructions in the table below:

STEP

ACTION

RESULT(S)

ADDITIONAL INFORMATION

NOTE

The center of the "D-Pad" and the "Enter" key can be used interchangeably throughout the following procedure.(a)

Move the main power switch which is labeled "AC POWER INPUT" on the IAE 2P16552 EEC Software Loader and DEP Tester, to the ON position.

The orange "AC PWR ON" light will be on.

The orange light means the equipment is powered and ready for use.

(b)

Push and hold the green power button on the TDS Ranger until the word "Booting" appears at the bottom of the screen next to an arrow.

The "V2500 Front End Program" screen will be displayed.

If the unit was already on, a count down screen will appear after approximately three seconds. Wait for the countdown to reach zero. Continue to hold the green power button until the word "Booting" appears.

If the unit was off, the word "Booting" will appear after approximately two seconds.

(c)

When the "V2500 Front End Program" screen is shown, connect the Yellow Y cable to IAE 2P16552 EEC Software Loader and DEP Tester and TDS Ranger as labeled.

NOTE

If the Yellow Y Cable was already connected to the TDS Ranger before step (b), the DEP test will not be successful. Disconnect the Yellow Y Cable from the TDS Ranger and go back to step (b).The system setup is complete.

(d)

Use the "D-Pad" on the TDS Ranger and highlight "Go to Engine Support Program".

Push the ENTER key.

The "V2500 Engine Support Programs" screen will be displayed.

At this screen, there will be three options:

V2500 Loader.

DEP Tester.

Administrative Functions.

(e)

Use the "D-Pad" on the TDS Ranger and select DEP Tester.

Push the ENTER key.

The "Data Entry Plug Tester" screen will be displayed.

At this screen, there will be two options:

Test Data Entry Plug.

Data Entry Plug Tester Self Test.

(f)

Use the "D-Pad" on the TDS Ranger and select "Test Data Entry Plug".

Push the ENTER key.

The Document Property Rights Notice will be displayed.

NOTE

You must agree to the terms and conditions or it is not permissible to use this device.(g)

If you agree to the terms and conditions, use the "D-Pad" to highlight the check box, and push the ENTER key.

Use the "D-Pad" to highlight "Continue" and push the ENTER key.

The "Data Entry Plug Tester" screen will be displayed with instructions to 1. Install the Data Entry Plug and 2. Select Continue

(h)

Install the DEP on the panel marked "Data Entry Plug Tester Interface" on IAE 2P16552 EEC Software Loader and DEP Tester.

Use the "D-Pad" on the TDS Ranger and select "Continue".

Push the ENTER key.

The "Data Entry Plug Tester" screen will be displayed with radio buttons to select the applicable engine model.

(i)

Use the "D-Pad" and "Key Pad" on the TDS Ranger to highlight the applicable engine model and DEP part number.

Push the ENTER key to turn the radio button black next to the appropriate engine model and DEP part number.

Use the "D-Pad" on the TDS Ranger and select "Continue".

The detected configuration of the DEP will be displayed.

If the DEP wiring configuration is not recognized, "Unknown DEP Jumper Connection" will be displayed. Use the "D-Pad" on the TDS Ranger to select "Continue" and push the ENTER key.

Continue with step (l).

Otherwise, go to step (j).

(j)

If the configuration displayed is the setting you want, use the "D-Pad" on the TDS Ranger to select "Yes".

If the configuration displayed is not the setting you want, use the "D-Pad" on the TDS Ranger to select "Yes".

Push the ENTER key.

If "Yes" is selected, the DEP configuration will be displayed. Go to step (k).

If "No" is selected, you will be asked to enter the DEP configuration you want. Go to step (l).

(k)

Use the "D-Pad" on the TDS Ranger to select "Finish".

Push the ENTER key.

The "V2500 Engine Support Programs" menu will be displayed.

You should be at step (k) if the DEP was wired correctly, and you selected "Yes" at step (j). Otherwise, go to step (l).

(l)

If an unknown DEP jumper connection was detected, or if the configuration you detected was not the configuration you wanted, the words "Enter Desired" will be displayed, followed by several empty boxes.

Use the "D-Pad" ENTER key, TAB key, and keypad to enter the configuration you want.

Use the "D-Pad" to select "Continue".

The results you wanted will be displayed alongside the results you got.

When you enter the Engine Serial Number, enter the number without a "V" before it.

(m)

Remove the DEP from the panel that says "Data Entry Plug Tester Interface" on IAE 2P16552 EEC Software Loader and DEP Tester.

For each row on the TDS Ranger that show "Fail" in the right column, correct the wiring as necessary.

Install the DEP on the panel that says "Data Entry Plug Tester Interface" on IAE 2P16552 EEC Software Loader and DEP Tester.

Use the "D-Pad" on the TDS Ranger to select "Continue".

Push the ENTER key.

The words "Do you want to retest this plug?" will be displayed.

It is possible to go back to the wiring display screen by using the "D-Pad" on the TDS Ranger to select "back" and pushing the ENTER key.

(n)

Use the "D-Pad" on the TDS ranger to select "Yes".

Push the ENTER key.

A screen will be displayed with instructions to select "DEP P/N to be tested". Go back to step (i) for instructions to continue with the DEP test.

If you selected "No", the "V2500 Engine Support Programs" menu will be displayed.

Do a test of the DEP wiring.

Make sure the power switch for IAE 2P16552 EEC Software Loader and DEP Tester is in the OFF position.

Disconnect the Yellow Y Cable from IAE 2P16552 EEC Software Loader and DEP Tester and TDS Ranger.

Disconnect the Data Entry Plug from the panel that says "Data Entry Plug Interface" on IAE 2P16552 EEC Software Loader and DEP Tester.

Do an electrical wiring test on the DEP plug assembly. Use the IAE 2P16552 EEC Software Loader and DEP Tester 1 off.

SUBTASK 71-00-00-750-115 Do an Acceptance Test

Refer to Figure.

Connect the DEP to the EEC connector with IAE 1R19416 EEC harness wrench 1 off. Torque to 32 lbf.in (3.616 Nm). Refer to SPM TASK 70-43-01-400-501.

Connect the DEP to the EEC connector.

SUBTASK 71-00-00-450-053 Connect the DEP to the EEC

Figure: Contact Hole Locations

Contact Hole Locations

Figure: Types of Jumpers

Types of Jumpers

Figure: Data Entry Plug Pin Selection Procedure for EPR Modifier

Data Entry Plug Pin Selection Procedure for EPR Modifier

Figure: Data Entry Plug Pin Selection Procedure for EPR Modifier

Data Entry Plug Pin Selection Procedure for EPR Modifier

Data Entry Plug Pin Selection Procedure for EPR Modifier

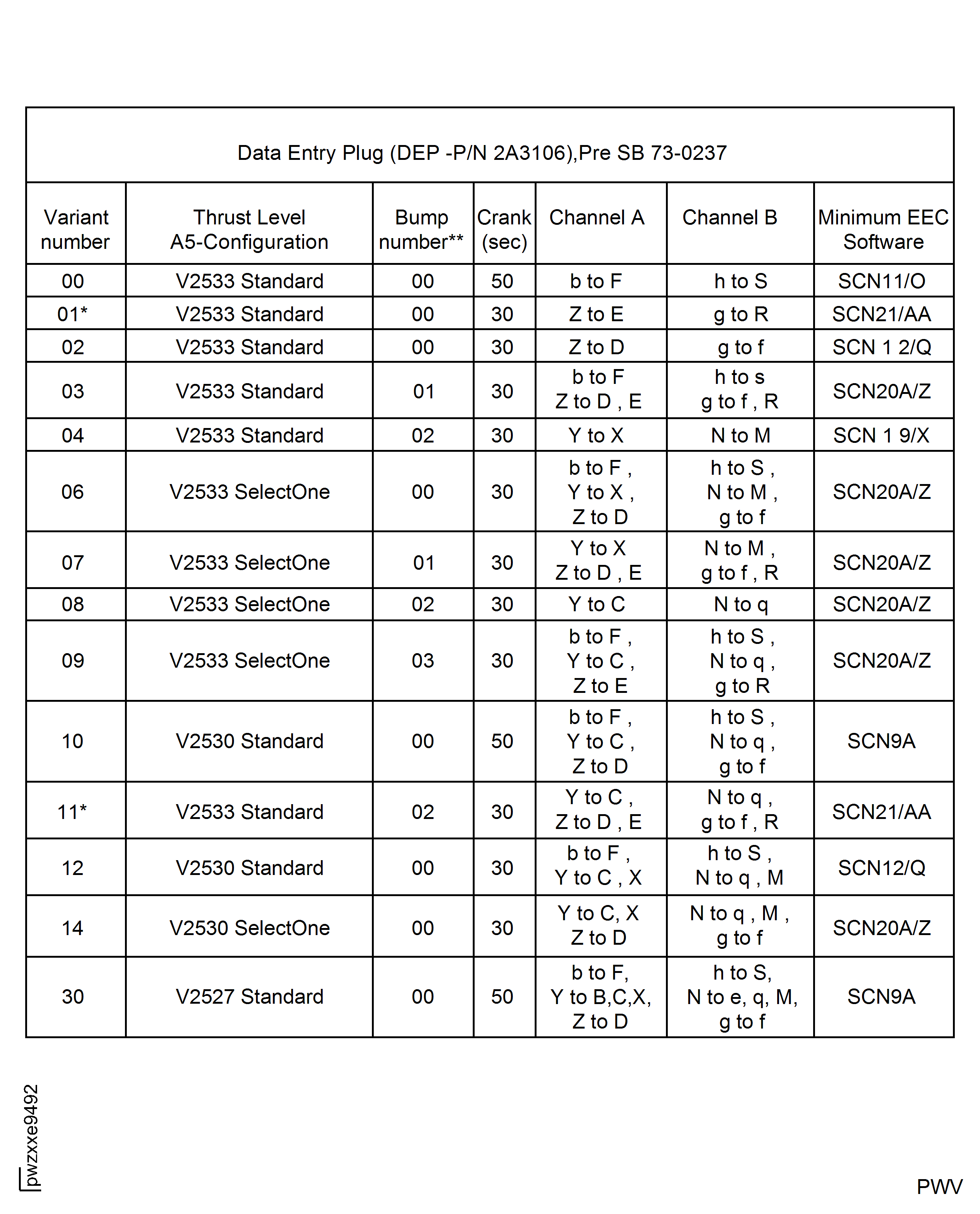

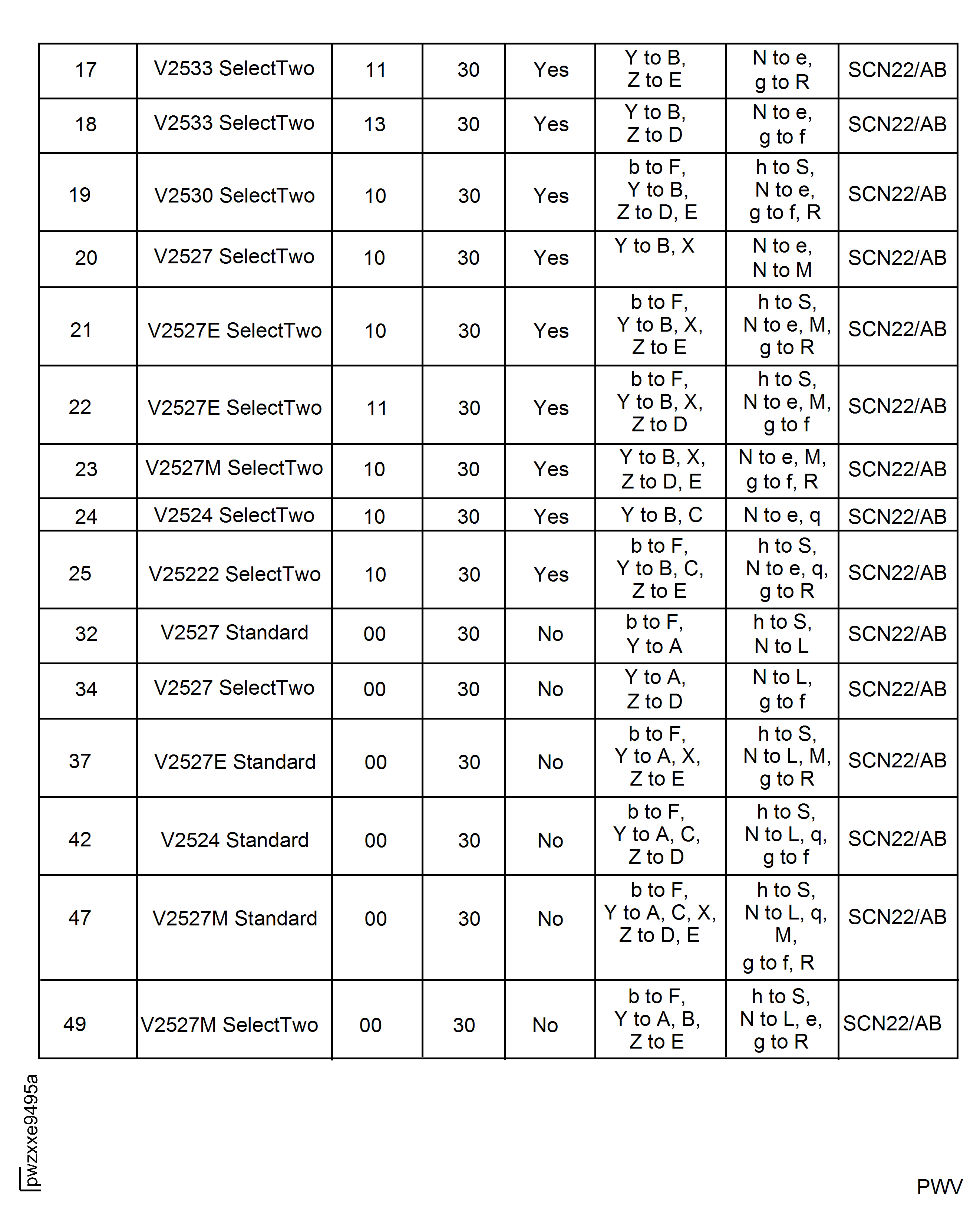

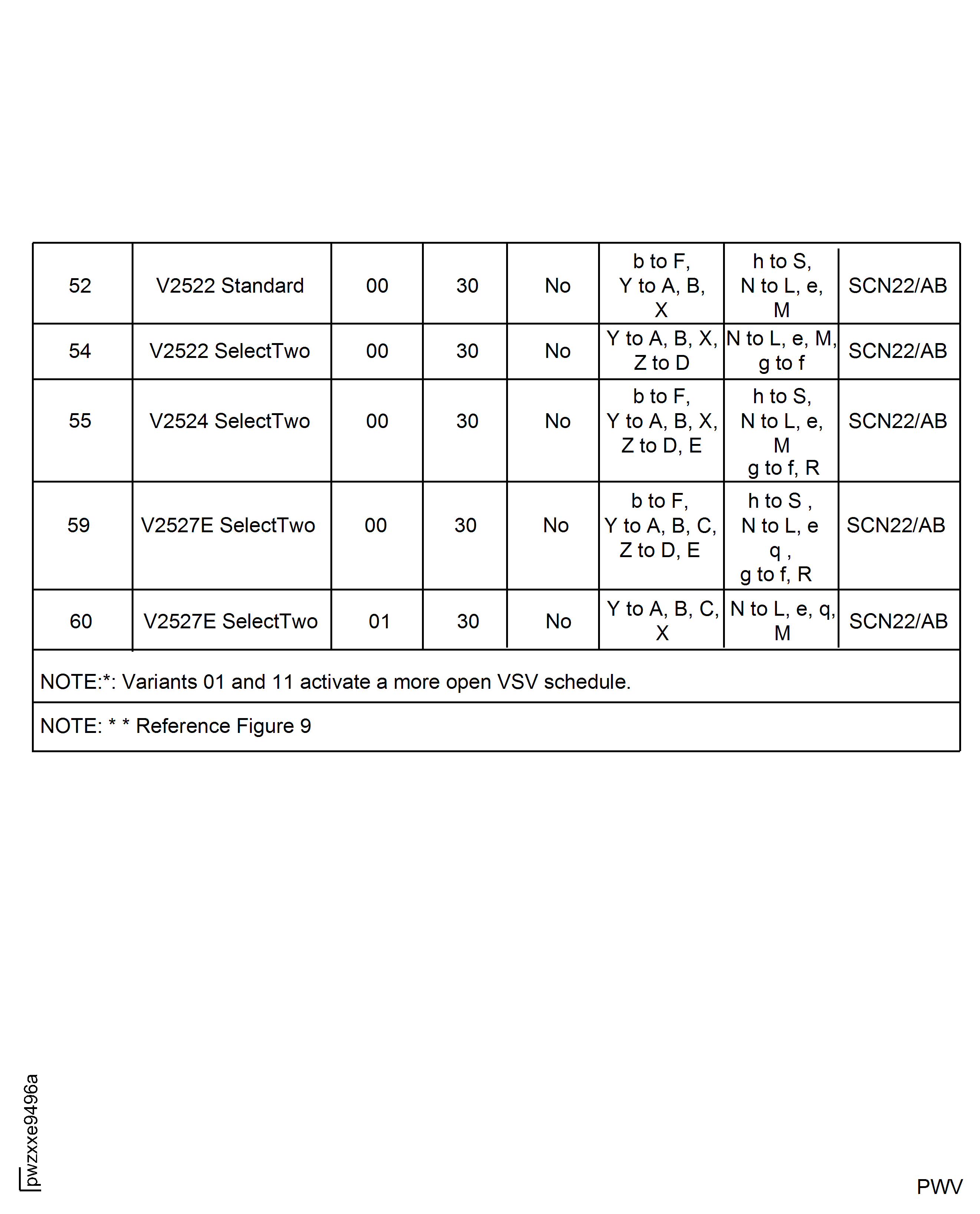

Figure: Data Entry Plug Pin Selection for Engine Variant-Bump No.

Data Entry Plug Pin Selection for Engine Variant-Bump No.

Data Entry Plug Pin Selection for Engine Variant-Bump No.

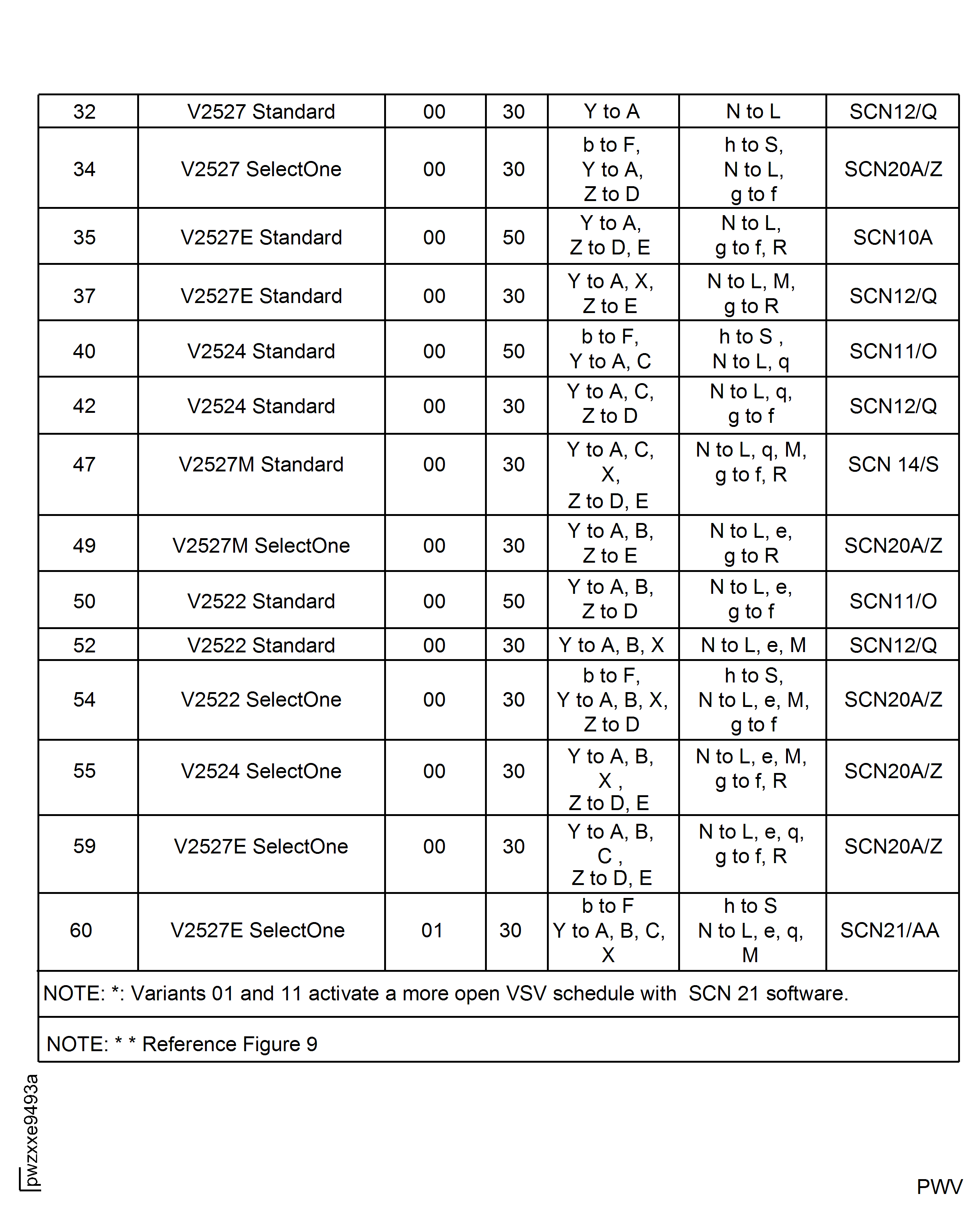

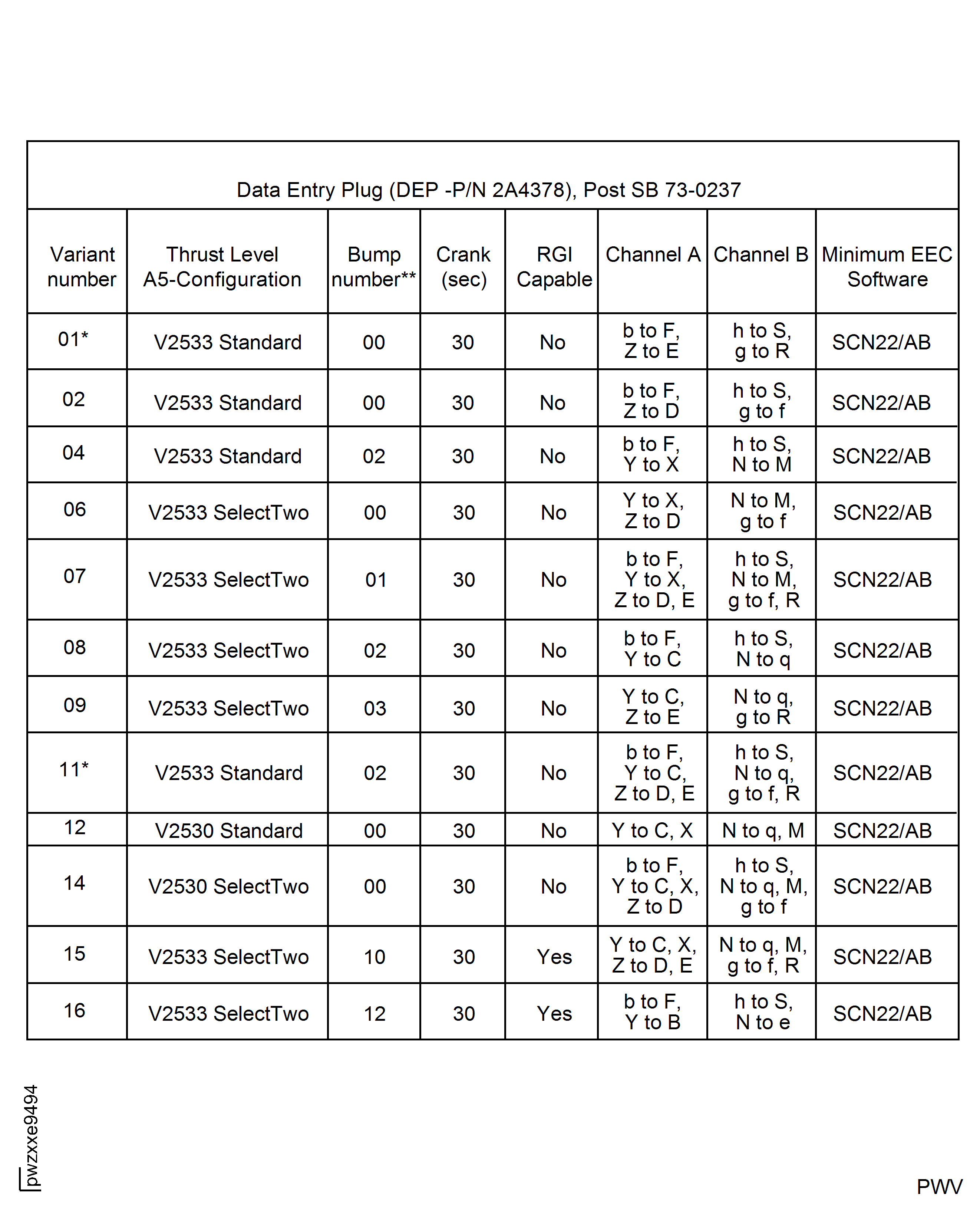

Figure: Data Entry Plug Pin Selection for Engine Variant-Bump No.

Data Entry Plug Pin Selection for Engine Variant-Bump No.

Figure: Data Entry Plug Pin Selection for Engine Variant-Bump No.

Data Entry Plug Pin Selection for Engine Variant-Bump No.

Figure: Data Entry Plug Pin Selection for Engine Variant-Bump No.

Data Entry Plug Pin Selection for Engine Variant-Bump No.

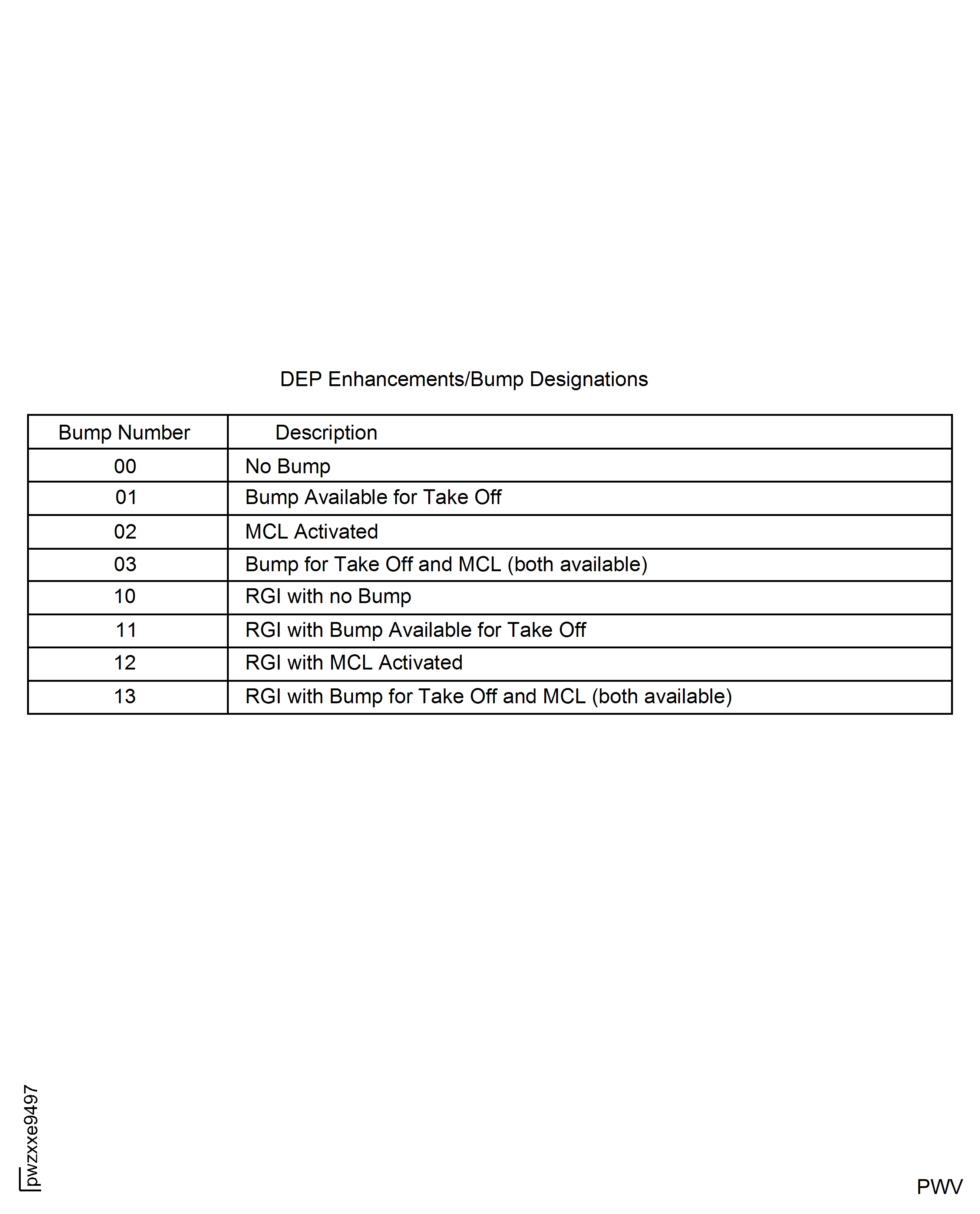

Figure: Bump No. Thrust Enhancements

Bump No. Thrust Enhancements

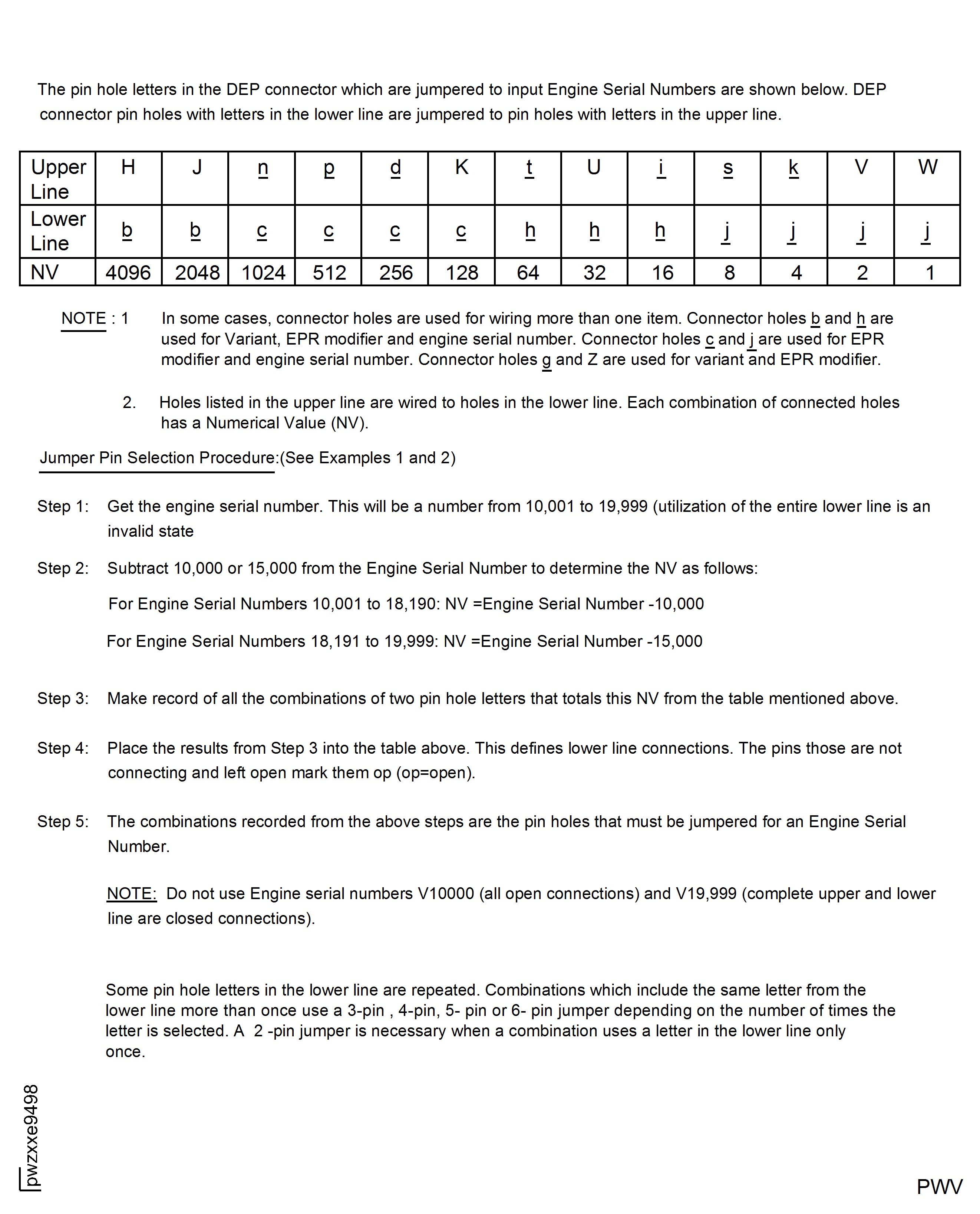

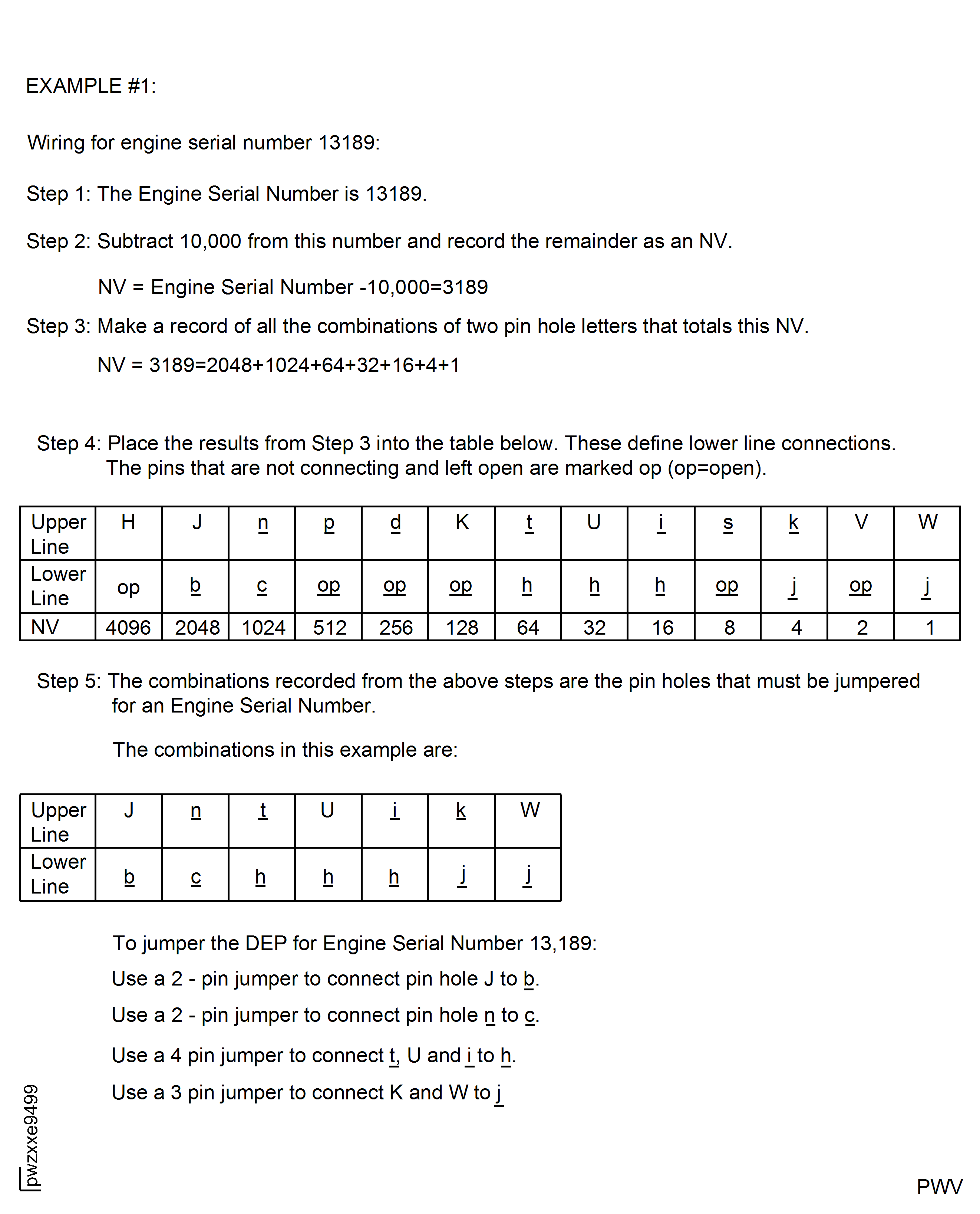

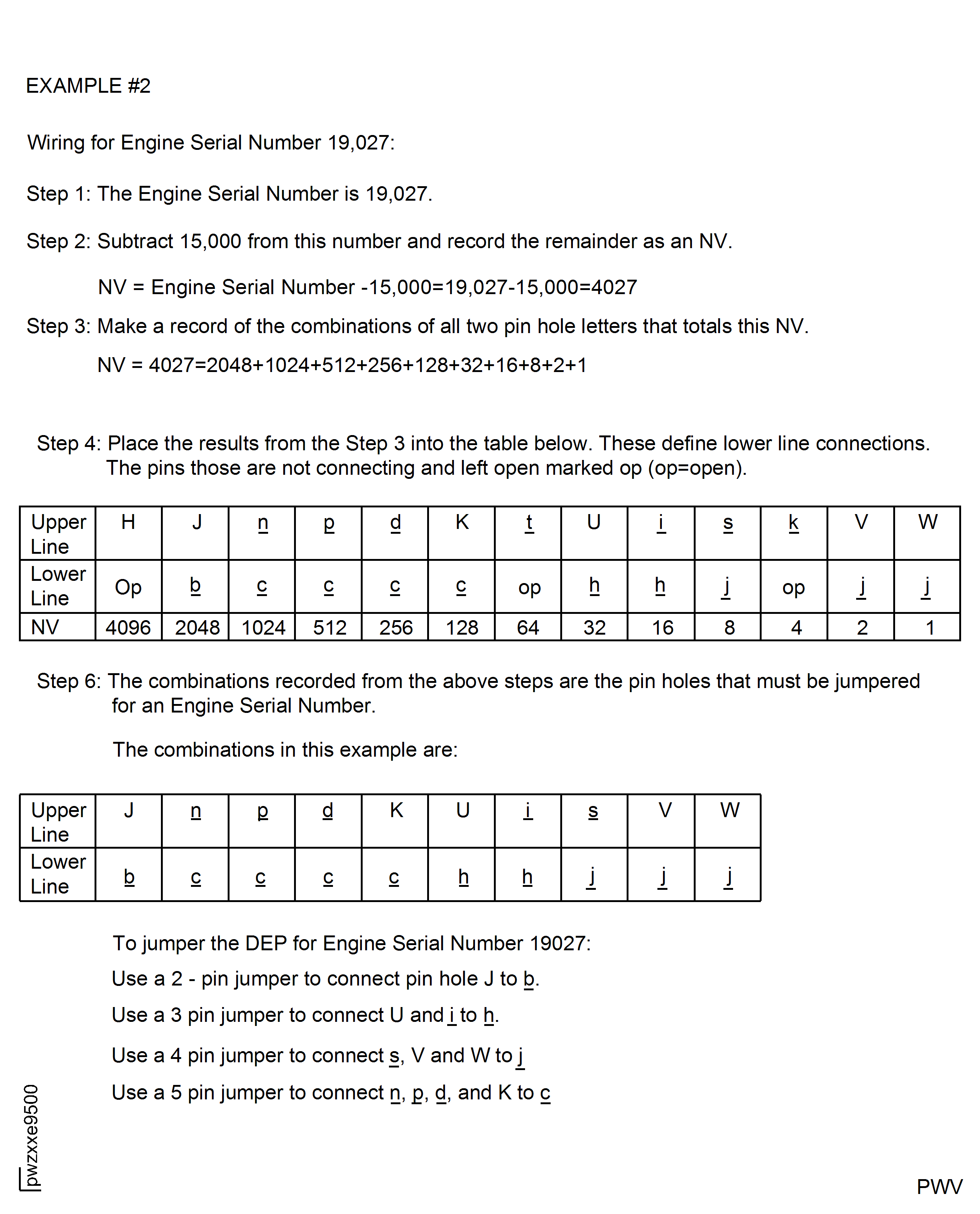

Figure: Data Entry Plug Pin Selection Procedure for Engine Serial No.

Data Entry Plug Pin Selection Procedure for Engine Serial No.

Figure: Data Entry Plug Pin Selection Procedure for Engine Serial No.

Data Entry Plug Pin Selection Procedure for Engine Serial No.

Figure: Data Entry Plug Pin Selection Procedure for Engine Serial No.

Data Entry Plug Pin Selection Procedure for Engine Serial No.

Figure: Disconnect/Connect the DEP

Disconnect/Connect the DEP

Figure: Remove/Install the Backshell

Remove/Install the Backshell

Figure: IAE 1P16271 Data Entry Plug Holding Fixture

IAE 1P16271 Data Entry Plug Holding Fixture

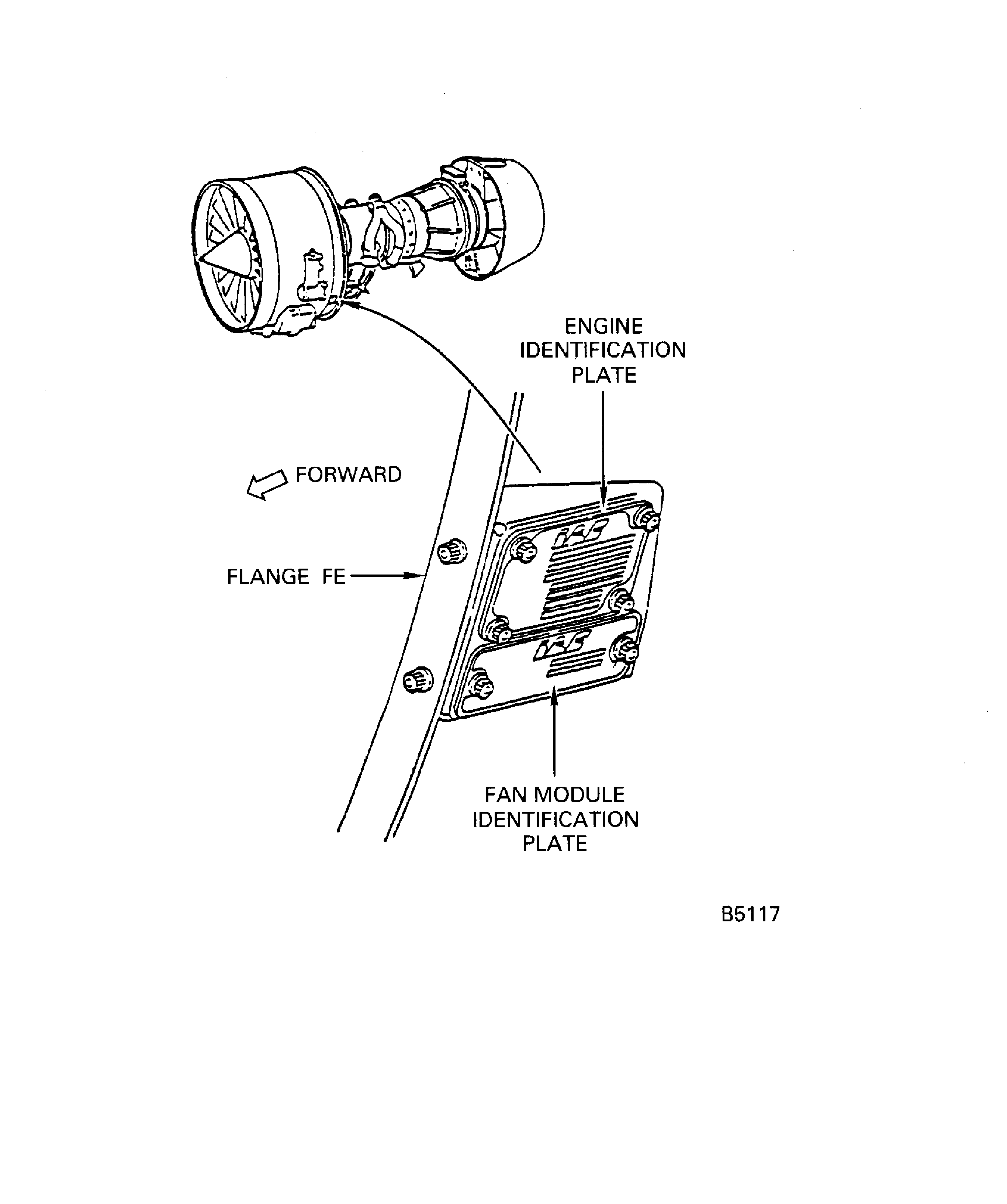

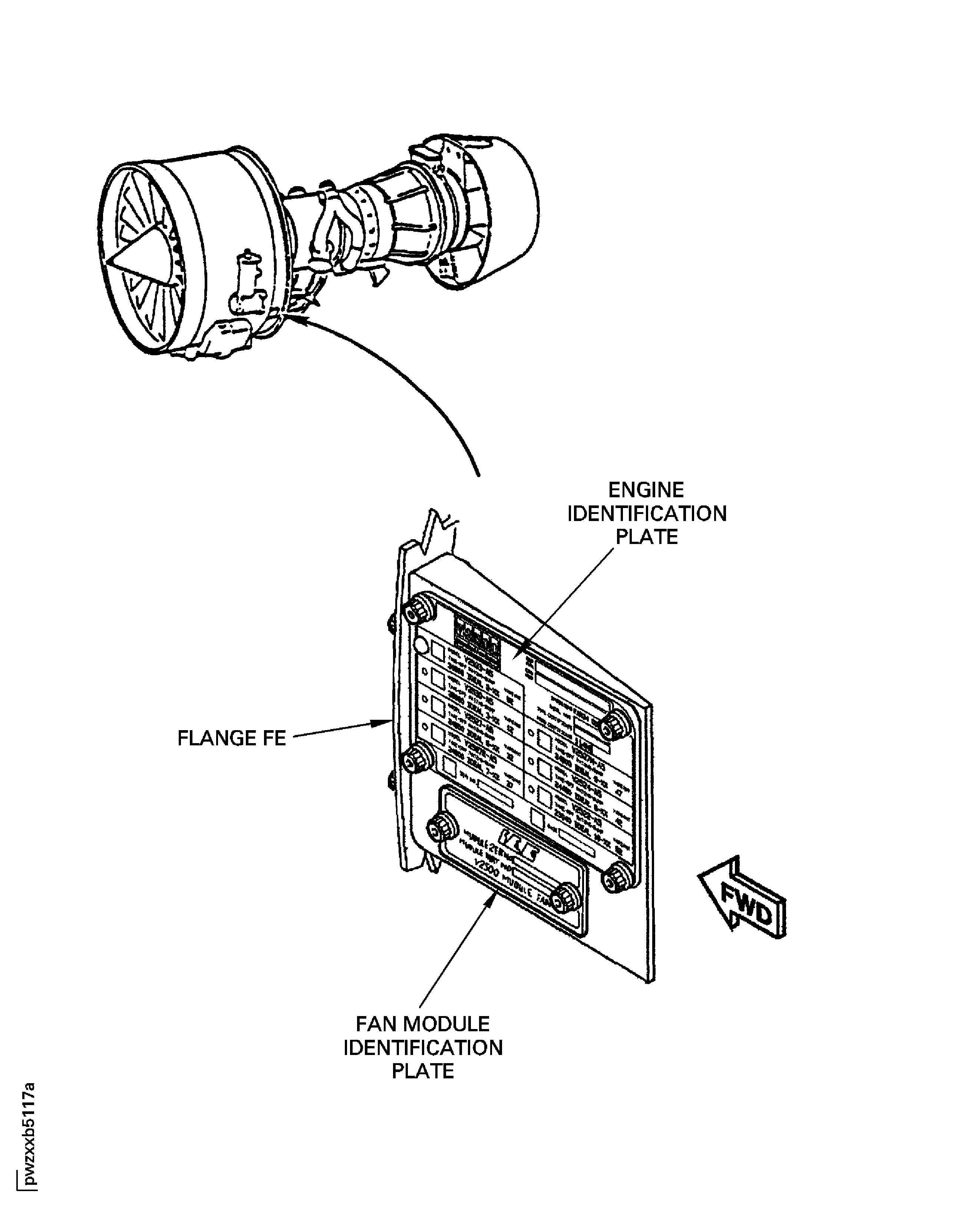

Figure: Pre SBE 72-0378: Engine and Module Identification Plates

Pre SBE 72-0378: Engine and Module Identification Plates

Figure: SBE 72-0378: Engine and Module Identification Plates

SBE 72-0378: Engine and Module Identification Plates

Figure: Remove the Jumpers or Pins from the Connectors

Remove the Jumpers or Pins from the Connectors

Figure: Install the Jumpers into the Connector

Install the Jumpers into the Connector

Figure: Install the Sealing Plug into the Connector

Install the Sealing Plug into the Connector

Figure: IAE 2P16369 Data Entry Plug Tester

IAE 2P16369 Data Entry Plug Tester

Figure: Make Marks on the Outer Face of the Backshell

Make Marks on the Outer Face of the Backshell