Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-00-00-700-010-B00 Test No. 10 - Performance Test, Testing-010

General

For general information refer to Engine Safety Precautions and Engine Operation Limits, Guidelines, and Special Procedures. Refer to TASK 71-00-00-700-050-B00 (TESTING-000) and TASK 71-00-00-700-051-B00 (TESTING-000).

Use this test to make a performance analysis of an engine that has had a complete overhaul or a module/section replaced.

If you did not operate the engine before, do Test No.3, the Idle Leak Check before you do this test. Refer to TASK 71-00-00-700-003-B00 (TESTING-003).

You can do other tests which are not done in the performance test, during engine operation before this test.

The applicable test data must be corrected by the specified test cell correction (before you use the curves and/or limits given in the test procedure).

Refer to TEST No.20 for the installation of the seal drain bottles needed for this test.

Necessary Information

The engine must have instrumentation at the locations which follow:

P2/T2 probe

N1

N2

P2.5 (P25)

PB or PS3

P4.9 (P49)

Delta Main Oil Pressure (DMOP)

Main Oil Temperature

Oil Filter Differential Pressure

Fuel Pump Inlet Pressure

PAMB

T2.5

T3

Vibration: Fan Case

T4.9 Harness Average (EEC output)

Thrust

Fuel Flow

P12.5

T Fuel

No.4 Bearing Compartment Scavenge Pressure (P4SCAV)

Oil Tank Temperature

Specific Ratings

The thrust and the thrust specific fuel consumption (TSFC) ratings at sea level standard conditions are:

Take-off, V2533-A5

Corrected Jet Thrust (lbs) - 30,650 lbs (136,337 N)

TSFC (pounds per hour for each pound of thrust) - 0,3746

Take-off, V2530-A5

Corrected Jet thrust (lbs) - 29,050 lbs (129,220 N)

TSFC (pounds per hour for each pound of thrust) - 0.3627

Maximum continuous

Corrected Jet thrust (lbs) - 26,220 lbs (116,632 N)

TSFC (pounds per hour for each pound of thrust) - 0.3506

50 percent take-off

Corrected Jet thrust (lbs) - 14,525 lbs (64,610 N)

TSFC (pounds per hour for each pound of thrust) - 0.3409

NOTE

Definitions

The definitions given below will be used in this procedure

EPR-O | - | The engine pressure ratio from the Electronic Engine Control instrumentation system (with a null EPR modifier data entry plug installed in the Electronic Engine Control). |

EPR | - | The engine pressure ratio from the Electronic Engine Control instrumentation system (with the EPR modifier to be found by this test). |

EPR Modifier | The combination of EPR modifier number and the EPR class bias (SCN 20 and above) |

Operation Procedures - General

All engines must be tested to either the V2530-A5 or the V2533-A5 rating regardless of the model displayed on the engine identification plate. Engines with 27E Bump Rating must be tested to the V2533-A5 rating. All engines must also be equipped with an EEC configured for either V2530-A5 or the V2533-A5 rating (null EPR modifier) to make sure the correct DEP class is determined. For engines tested with software version SCN22 and above use PW P/N 2A4378. For engines tested with earlier versions of the software, use part number PW P/N 2A3106. The DEP class determination is valid for all lower rated models. If the test engine is not equipped with a high flow FMU then one must be installed before test to make sure that sufficient fuel flow availability. Examples of high flow FMUs are Lucas 530MKII and 570 or Woodward 8061-632 and -637. This FMU is to remain on the engine for the duration of the test and is to be replaced by the appropriate FMU upon conclusion of the test based on the engine model on the engine identification plate. After the appropriate FMU is installed, either TEST 2 or TEST 3 must be performed. Refer to Wet Motor Leak Check TASK 71-00-00-700-002 (TESTING-002) or Idle Leak Check TASK 71-00-00-700-003-A00 (TESTING-003) and TASK 71-00-00-700-003-B00 (TESTING-003).

Engines with serial number V10197 and below are to be tested to the V2530-A5 rating requirements.

Engines with serial number V10198 and above, including SelectOne(TM) and SelectTwo(TM) engines may be tested to either the V2530-A5 or the V2533-A5 rating requirements. Engines with serial number V10198 and above, including SelectOne(TM) and SelectTwo(TM) engines, accepted to the V2530-A5 rating requirements, must meet the following requirements:

The V2533-A5 rating must be crossed-out (X) on the engine data plate (reference the SPM, Section 70-09-00, Marking of Parts).

Engines tested or accepted to the V2530-A5 requirements are limited to operation at the V2530-A5 rating or lower until the engine is next tested and accepted to a higher rating (and a new data plate installed) at an overhaul facility.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

CAUTION

Procedure

Do the necessary steps by the instructions in Pre-Rig the Engine for Testing. Refer to TASK 71-00-00-700-020 (TESTING-020).

Prepare and start the engine by the Normal Engine Automatic Start Procedure or the Normal Engine Manual Start Procedure. Refer to TASK 71-00-00-700-053-B01 (TESTING-000) or TASK 71-00-00-700-053-B02 (TESTING-000).

Let the engine become stable at MIN IDLE for three minutes.

Do not continue to operate the engine if any indications are unusual.

Make a record of the EEC status. Refer to the Fault Isolation V2500-A0-71-00-0000-01A-009A-B (FAULT ISOLATION-000) for more information on faults.

Do a shutdown of the engine by the Discontinued Start and Shutdown Procedure. Refer to TASK 71-00-00-700-054-B00 (TESTING-000).

Do not add oil during the performance test.

Fill the oil tank to the top of the overflow (5-25 minutes after shutdown) to find the engine oil consumption after the test. Record the oil tank temperature. Refer to TASK 71-00-00-700-064-B00 (TESTING-000).

If necessary, make sure all the seal drain bottles are empty for the performance test.

Operation of the Engine Before the Performance Test

NOTE

Do all the thrust lever movements by the instructions given in the Engine Safety Precautions unless specified differently. Refer to TASK 71-00-00-700-050-B00 (TESTING-000).The date of the engine performance test.

The engine serial number.

The serial number of the modules (to use for module history analysis).

The fuel specific gravity.

The fuel lower heat value (you can do this after the test).

The ambient atmospheric conditions (the true barometer wet and dry bulb temperature).

Make a record of the information which follows before you do the performance test.

Time

* Observed and corrected N1 and N2 speeds

Observed and corrected thrust (FN)

Observed and corrected fuel flow (WF)

* Engine inlet total temperature (T2)

* Fan inlet total pressure (P2)

** Turbine discharge total temperature (T4.9 harness average) Channel A and B

* Turbine discharge total pressure (P4.9)

* Calculated engine pressure ratio (P4.9/P2)

* Engine pressure ratio from EEC (EPR-O)

Fuel inlet pressure

Delta main oil pressure

Oil temperature

Vibration amplitude

* Burner pressure (PB or PS3) (Optional)

* HPC inlet pressure (P2.5) (Optional)

Ambient temperature (TAMB)

Ambient pressure (PAMB)

* HPC inlet temperature (T2.5) (Optional)

* HPC exit temperature T3

* Fan exit pressure (P12.5) (Optional)

* 2.5 bleed valve position indicator

No.4 bearing Compartment Scavenge Pressure (P4SCAV)

* ARINC data

Fuel temperature (T fuel)

* EEC outputs

** For SCN21 and below only: As a guideline it is recommended that the EGT level between Channels A and B must be within 10 deg F (5.6 deg C) of each other. Differences that are greater than this level should be investigated to be sure that there are no indication problems. If, after you replace individual EGT probes and wiring harness to the probes, the EGT level continues to be greater than 10 deg F (5.6 deg C) between channels A and B, as determined by engine test, then you can accept the engine data.

Make a record of and/or calculate all of the indications that follow, but the EEC outputs.

Be prepared to make a record of the data at all the test points when the engine is stable (before you move the thrust lever to the subsequent point).

If the scavenge pressure limit is exceeded at any time, you must shut down the engine as given in TASK 71-00-00-700-054-B00 (TESTING-000).

Disconnect the No. 4 bearing compartment external scavenge elbow.

Check and record signs of leaks from the gasket.

Replace the gasket. Refer to TASK 72-42-00-430-001 (ASSEMBLY).

Do the Performance Test again to check for correct No. 4 bearing compartment scavenge pressure. Refer to TASK 71-00-00-700-010-B00 (TESTING-010, CONFIG-002).

Inspect the gasket for leaks at the interface between the No. 4 bearing compartment external scavenge elbow and internal scavenge line. (A leak gasket usually increases P4 scavenge pressure in the 130 to 160 psig (896.3 to 1103.2 kPa) band).

If the P4SCAV limit is more than the maximum permitted limits, do the check that follows. If the Band A pressure limit is below 55 psig (379.2 kPa), then you continue to step 8. D. (3). (d).

If the vacuum check is more than 17 pph, disassemble, inspect and assemble the No. 4 bearing compartment.

If the vacuum check is less than 17 pph, contact IAE Technical Services for instructions.

If the scavenge pressure is still not normal, do a No. 4 Bearing Compartment Vacuum Check. Refer to TASK 72-00-43-420-001 (INSTALLATION), SUBTASK 72-00-43-720-051.

If you find signs of oil or wetness from weep hole, examine the Turbine Exhaust Case and reject the engine.

If you find the quantity of oil consumed during the test run is in operational limits. Refer to Engine Manual, TASK 71-00-00-700-051.

Do a check on the Test Cell Transducer to make sure that for correct functionality.

Check the scavenge line from the compartments to the scavenge valve. Make sure that all connections, fittings and fasteners are attached and installed correctly, and make sure that no leakage is permitted.

Do a borescope examination of the No.4 Scavenge Tube inside the diffuser case for all blockages due to oil coking, debris etc.

Do a vacuum check for No.4 bearing compartment. Refer to TASK 72-00-43-420-001 (INSTALLATION-001) SUBTASK 72-00-43-720-051.

1

If the vacuum check is not more than 17 pph

Accept

Continue for step 8. D. (3). (d). (vii).

2

If the vacuum check is more than 17 pph but not more than 21 pph

Accept, if the engine has no leaks out of the No. 4 oil weep during pass-off testing, the engine has no abnormal oil system indications (MOP, Oil consumption, external oil leaks) since the last shop visit. Continue to step 8. D. (3). (d). (vii).

3

If the vacuum check is more than 21 pph

Reject the engine and contact IAE Tech services for instructions

Examine the scavenge valve. Replace if necessary. Refer to Engine Manual, TASK 72-00-60-050-004 (REMOVAL-008) and TASK 72-00-60-450-004 (INSTALLATION-008).

Check the No. 4 compartment cooling air system. Refer to Engine Manual TASK 72-00-44-420-001-002 (INSTALLATION-002), SUBTASK 72-00-44-720-052.

Do a visual inspection of the HPC stage 10 air supply line to the scavenge valve.

Remove the Air Cooled Air Cooler (ACAC). Refer to Engine Manual TASK 72-00-50-050-003 (REMOVAL-012). Visually examine the ACAC and the ACAC outlet duct for any obstructions or blockages which can restrict airflow. Re-install the ACAC. Refer to Engine Manual TASK 72-00-50-450-003 (INSTALLATION-012).

Examine the scavenge pump for jammed gears. Replace if necessary. Refer to Engine Manual TASK 72-00-60-050-007 (REMOVAL-011) and TASK 72-00-60-450-007 (INSTALLATION-011).

If the P4SCAV Band A pressure limit is below 55 psig (379.2 kPa), do an inspection by the procedure that follows:

Make sure at all power conditions that the No. 4 bearing compartment scavenge pressure is not more than the limits that follow:

Maximum Allowable Transient Limit:

All testing conditions: 205 psig (1413.4 kPa)

Maximum Allowable Steady-State Limit (3 Minutes Stabilization Or More):

Idle and Approach Idle: 9 psig (62.1 kPa)

Band D:

Band B and C:

Band A:

17 psig (117.2 kPa)

145 psig (999.7 kPa)

Minimum: 55 psig (379.2 kPa)

Maximum: 145 psig (999.7 kPa)

Do the Normal Engine Automatic Start Procedure or the Normal Engine Manual Start Procedure. Refer to TASK 71-00-00-700-053-B01 (TESTING-000, CONFIG-002) and TASK 71-00-00-700-053-B02 (TESTING-000, CONFIG-002).

Make a record of the data after five minutes at MIN IDLE. Refer to Figure.

Make sure that there are no faults in the EEC in Channel A and Channel B.

Do the break-in of a newly overhauled engine/module, Test No. 7. Refer to TASK 71-00-00-700-007-B00 (TESTING-007, CONFIG-002).

NOTE

Test No.7 must be completed for a newly overhauled engine before you continue.Refer to Test No. 8 (Vibration Survey) or Testing-00 (Engine operating limits).

Make a selection of APPROACH IDLE and operate at APPROACH IDLE for 3 minutes. Refer to Figure.

Make sure that the EEC operates in the EPR mode.

Make a record of the time to go from the start of the thrust lever movement to 90 percent of the lower line of Band A thrust. Refer to Figure.

The acceleration time cannot be more than 6.6 seconds or less than 5.3 seconds for the V2533-A5 model and not more than 6.2 seconds or less than 4.9 seconds for the V2530-A5 model.

Let the engine become stable for one minute before you continue.

Do a snap acceleration (as quickly as the thrust lever will move) from APPROACH IDLE to Band A. Refer to Figure.

Make a record of the time from the start of the thrust lever movement to a corrected thrust of 8166 plus or minus 30 lbs.

The deceleration time cannot be more than seven seconds.

NOTE

During subsequent acceleration and deceleration (step (12) thru (16)), check and record the position of the No. 4 bearing scavenge valve for the correct operation. Refer to Figure.

Do a snap deceleration (as quickly as the thrust lever will move) from Band A to MIN IDLE. Refer to Figure.

Operate the engine for five minutes with the thrust lever set in one position. Make a record of the data.

If the minimum required corrected take-off thrust or EPR for Band A is not shown at full TLA and PAMB is more than 14.696 PSIA, the correction method that follows must be used:

FNTR2 (Modified Band A) = (FNTR2 Band A)/(PAMB/14.696), where FNTR2 is obtained from Figure.

If you do not get the minimum required take-off thrust (after you apply the correction if necessary), stop the test and tell the test engineer.

Slowly increase the engine speed and set the thrust of Band A. Refer to Figure.

Operate the engine for three minutes with the thrust lever set in one position.

Make a record of the data.

Set the thrust of Band B. Refer to Figure.

Operate the engine for three minutes with the thrust lever in one position.

Make a record of the data.

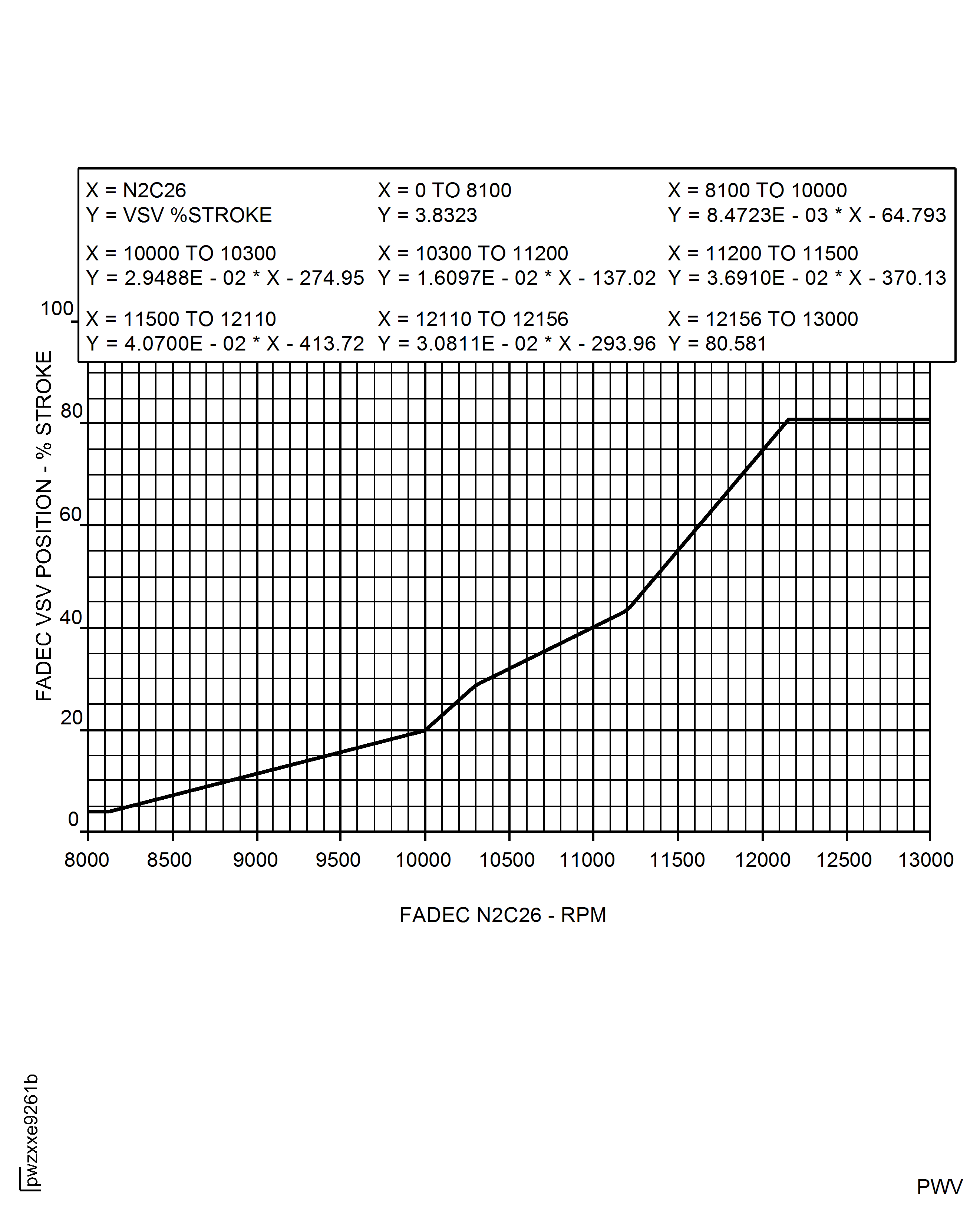

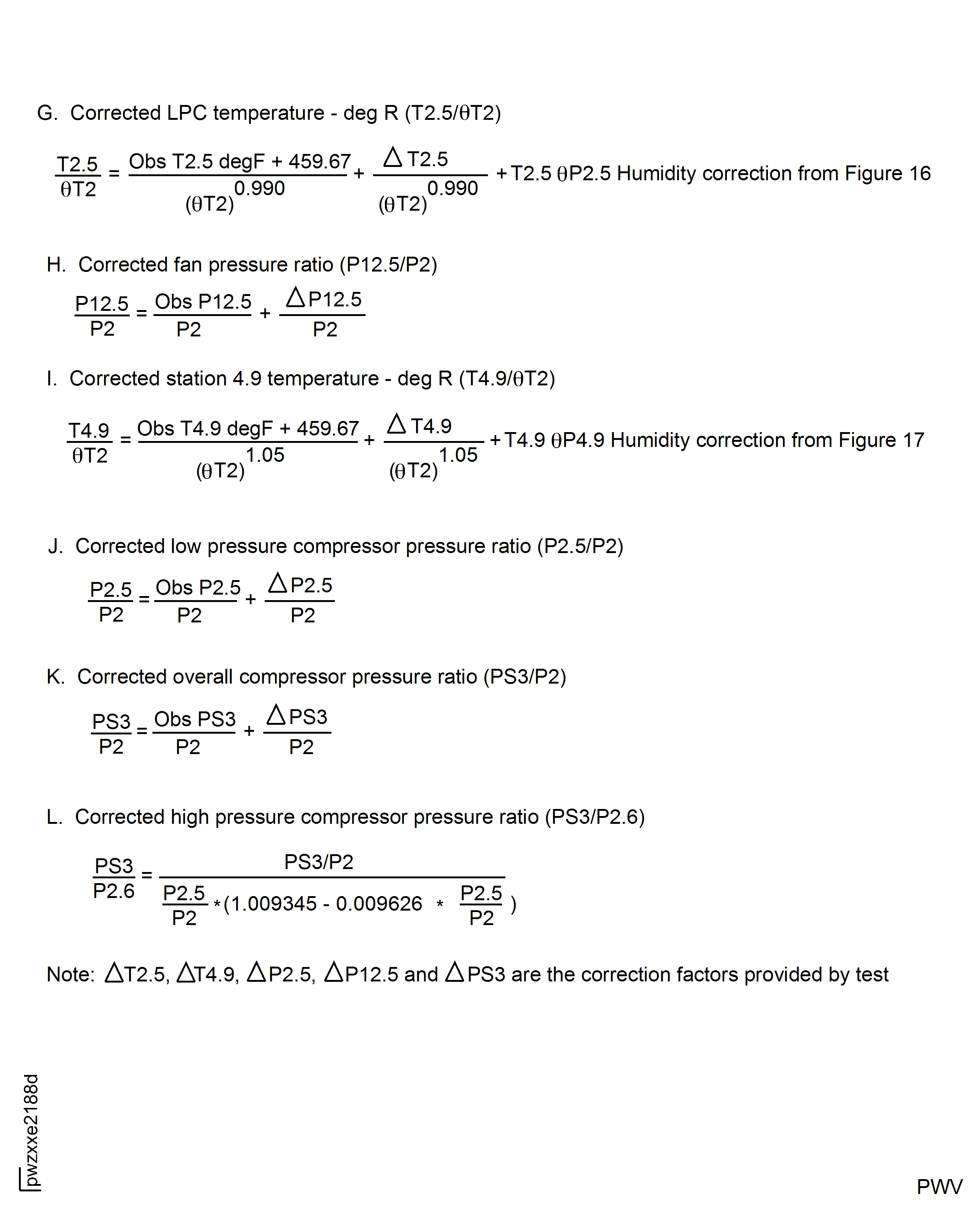

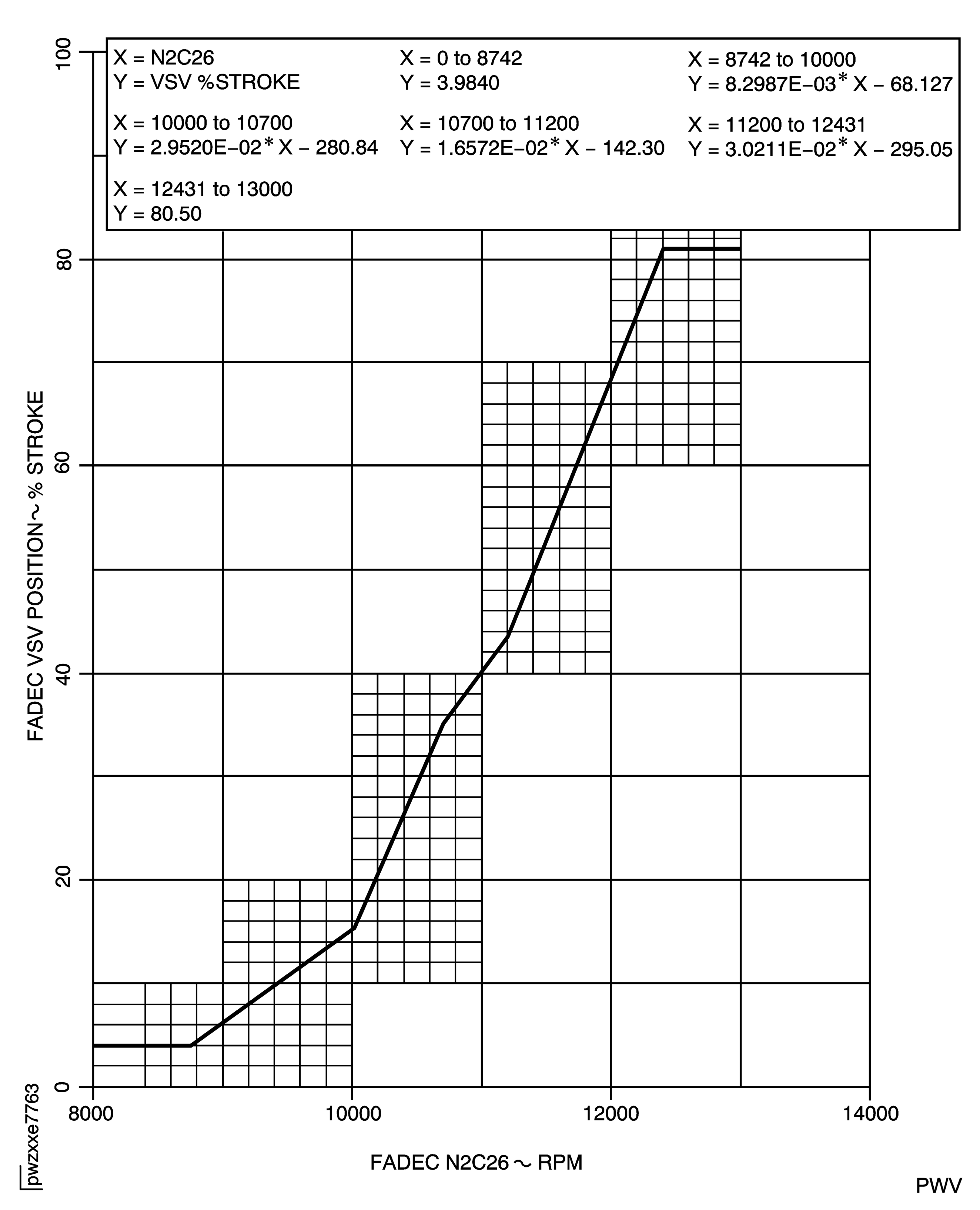

Refer to Figure for all SCN (including most current) versions with Standard A5 engine configuration.

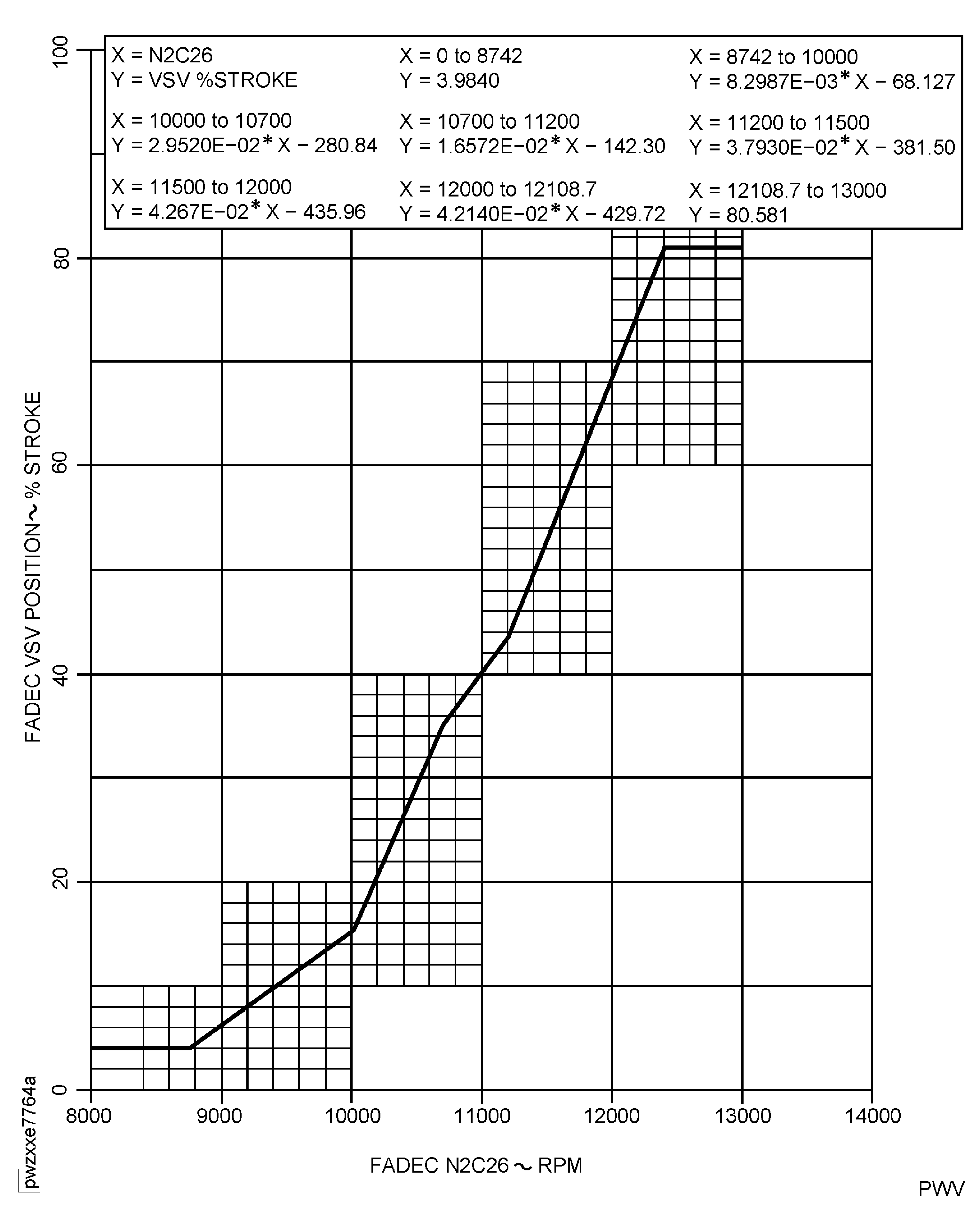

Refer to Figure for Pre-SCN-21 SelectOne(TM) engine configuration, i.e., engines with serial numbers V15001 and above or that have incorporated SBE 72-0560 and SBE 72-0562.

Refer to Figure for SCN-21 SelectOne(TM) and SelectTwo(TM) engine configurations, i.e., engines with serial numbers V15001 and above or that have incorporated SBE 72-0560 and SBE 72-0562.

Confirm engine test software is appropriate for the engine configuration (Standard A5, SelectOne(TM) or SelectTwo(TM)) by checking the EEC output parameters from the Variable Stator Vane Schedule. Compare the recorded values for FADEC N2C26 (rpm) and FADEC VSV Position (Percent Stroke) using the appropriate figure as follows:

At Band C, data should fall on the schedule within plus or minus two percent stroke at VSV position. If the engine is not operating on the proper schedule stop the test and tell the test engineer. Implement correct schedule and start test at Section 8. D. (9) Snap Acceleration evaluation, and run again with the correct test software to evaluate of all engine limits.

Set the thrust lever of Band C. Refer to Figure.

Operate the engine for three minutes with the thrust lever set in one position.

Make a record of the data.

Set the thrust of Band D. Refer to Figure.

Let the engine become stable for five minutes.

Make a record of the data.

During the five minutes, do a check of the EEC fault messages.

Decrease the engine speed to MIN IDLE.

Do a shutdown by the Discontinued Start and Shutdown Procedure. Refer to TASK 71-00-00-700-054-B00 (TESTING-000, CONFIG-002).

The information which follows gives the instructions for operation of the engine during the performance test.

Performance Test

Fill the oil tank to the top of the overflow. Refer to TASK 71-00-00-700-064-B00 (TESTING-000, CONFIG-002).

Use a device with graduations to measure the quantity of oil added.

Make a record of the quantity of oil added.

Find the oil consumption in gal/hr (1 hr) and make a record of the quantity used during the performance test.

After shutdown, look at the oil tank temperature until it is within 15 deg F of the temperature recorded in step 7.G.

Fuel Units:

LOCATION: Fuel Pump Seal Drain, LIMIT 30 cc/hr of fuel only or 10 cc/hr of fuel/oil mixture or 10 cc/hr of oil only

LOCATION: Common Core Seal Drain, LIMIT 10 cc/hr of fuel

LOCATION: All Others, Limit 0 cc/hr of fuel

Hydraulic Unit:

LOCATION: Hydraulic Pump Seal Drain, LIMIT 10 cc/hr of oil

Oil Units:

LOCATION: Starter Seal Drain, LIMIT 10 cc/hr of oil

LOCATION: IDG Seal Drain, LIMIT 10 cc/hr of oil

Compare the quantity of fluid to the following limits:

Check the seal drain hole on the fuel-cooled oil cooler (FCOC). Leaks of fuel or oil are not allowed.

Examine all the seal drain bottles and make a record of the quantity and type of fluid collected.

Do a borescope inspection. Refer to TASK 72-00-00-200-000 (INSPECTION/CHECK-000).

Remove all of the chip detectors, do an inspection of them and install them again. Refer to TASK 72-00-00-200-008 (INSPECTION/CHECK-008).

Remove the scavenge oil filter, inspect it, and install it again.

Remove the pressure oil filter, inspect it, and install it again.

Remove the fuel filter, inspect it and install it again.

After you complete the engine operation do the Engine Preservation and Inhibiting Procedure. Refer to TASK 72-00-00-550-001 (STORAGE-001).

Do the necessary steps by the instructions in De-Rig the Engine after Testing. Refer to TASK 71-00-00-700-021 (TESTING-021).

Procedure to be Done After Completion of the Performance Test

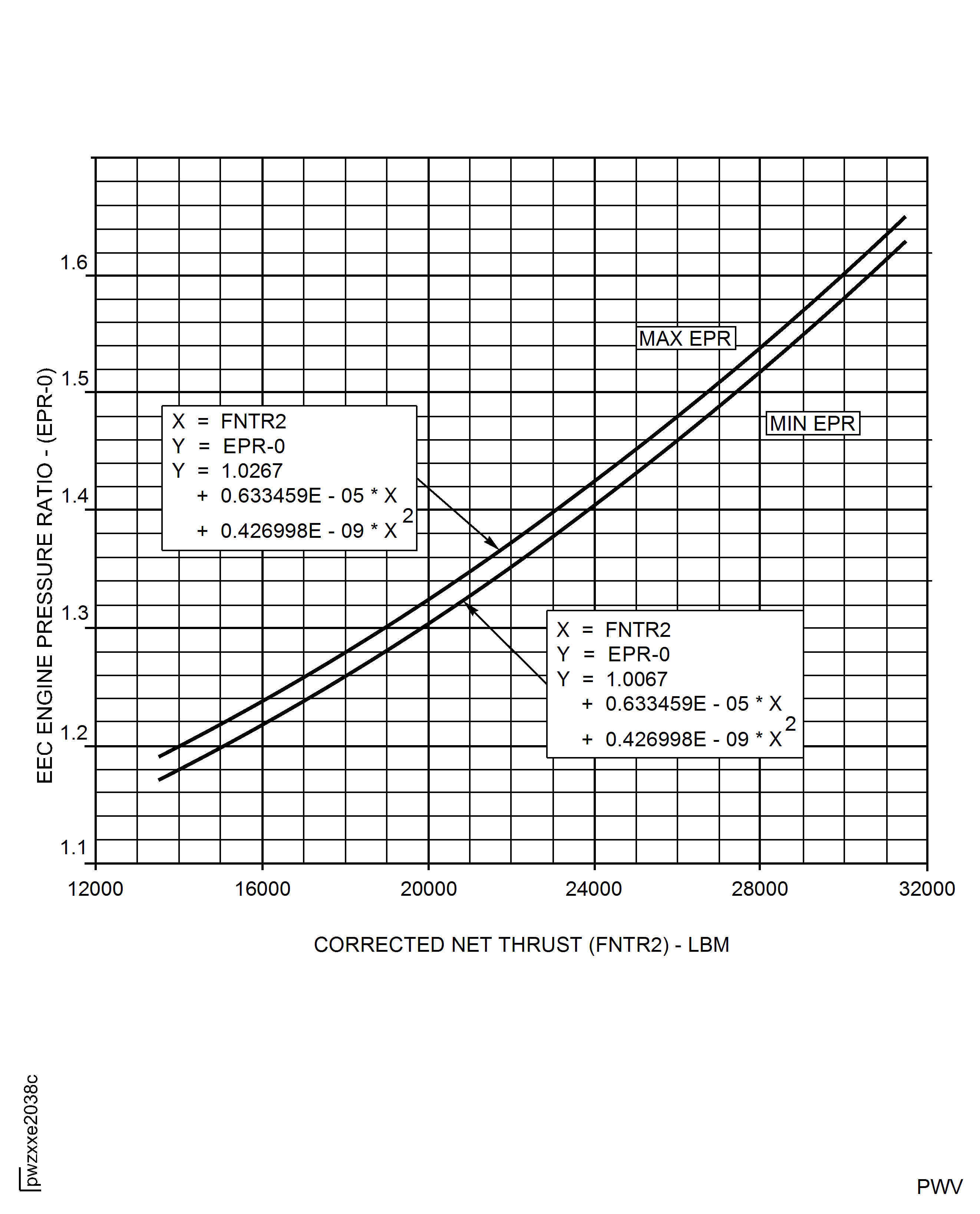

The guidelines are when EPR-O is the EEC EPR indication with a null data entry plug installed.

The lines on this figure are only to be used as guidelines and are not limits.

If possible the values of FN/ST2 versus corrected EPR-O will be within the guidelines of the figures. Refer to Figure.

Do a check of corrected thrust specific fuel consumption (TSFC) by the specific ratings given.

Check the vibration for the correct operating limits.

Do a Check of the Corrected Data

The EPR modifier selection will provide the correct relation between the EPR and the thrust.

Curve fit measured EEC EPR (EPR-O versus measured correct thrust. Use a second order/degree least square fit (Band A, B, C and D only).

Evaluate the curve fit at the corrected net thrust gates in the table that follows to find EPR.

The selection of the EPR modifier number is found by:

Find the delta EPR at each gate as follows:

Subtract each evaluated EPR, rounded to three decimal places, from the related max EPR in the table above.

delta EPR = max EPR - evaluated EPR 3

Find the highest EPR modifier number (which will give the highest thrust) with a delta EPR modifier which will give an EPR of plus 0.000/minus 0.002 of the max EPR at each gate.

EPR = evaluated EPR plus delta EPR modifier - 0.002 < EPR - max EPR < plus 0.000

For EEC software SCN 19 and below, make a selection of the highest EPR modifier of all gates. Modified EPR is the sum of the measured EPR-O plus the delta EPR modifier for the selected EPR modifier number. Do not do steps (d) and (e).

Subtract the highest EPR modifier number of gates 1 and 2 from the highest EPR modifier number of all gates to find the EPR class bias.

Set the EPR class bias equal to zero if less than zero and equal to two if greater than two.

Find the delta EPR bias. Multiply the EPR class bias by 0.003.

EPR class bias = (highest EPR modifier number of all gates) - (highest EPR modifier number of gates 1 and 2)

0 ≤ EPR class bias ≤ 2

delta EPR bias = (EPR class bias) x 0.003

NOTE

The EPR class bias is limited to 0 (no adjustment), 1 (one), or 2 (two). The EPR class bias is set to zero when the highest numerical EPR modifier number at gates 1 and 2 is equal to the highest EPR modifier number from all eight gates.

For EEC software SCN 20 and above, a two-point EPR classification is available. This reduces the risk of over-boost on 30K and 33K rated engines when the EPR modifier number is set by the lower thrust ratings.

For EPR-O ≤ 1.477, the modified EPR is the sum of the measured EPR-O and the delta EPR modifier for the highest EPR modifier number of all the gates.

EPR = EPR-O plus delta EPR modifier

For EPR-O ≥ 1.562, the modified EPR is the sum of EPR-O, the delta EPR modifier from the highest EPR modifier number of all the gates and the delta EPR bias.

EPR = EPR-O plus delta EPR modifier plus delta EPR bias

For EPR-O between 1.477 and 1.562, do a linear interpolation between the two steps above.

EPR = EPR-O plus delta EPR modifier plus delta EPR bias x (EPR-O - 1.477)/0.085.

For EEC software SCN 20 and above, find EPR as follows:

Gate No.

Description

Thrust, Lbf (FNTR2)

Max. EPR 33K Tested Engines

Max. EPR 30K Tested Engines

1

33K MTO

*30650

1.613

Not applicable

2

30K MTO

29050

1.562

1.559

3

30K MCT

*26220

1.477

1.477

4

27K MTO

24200

1.422

1.422

5

24K MTO

23930

1.414

1.414

6

22K MTO

22500

1.376

1.376

7

27K MCT

*21750

1.357

1.357

8

17100

1.251

1.251

NOTE

The V2500-A5 engine model can be used at lower thrust ratings, so it is necessary to use a larger range of thrust levels to find the correct Data Entry Plug (DEP) that will give sufficient thrust at all of these ratings.* Shows the points that are necessary to run to curve fit the data. The other points can be interpolated (Band D is not shown). Use only the points with a max EPR value to find the DEP class.Find the EPR modifier number (EPR class) at each gate.

Gate No.

Corrected Net Thrust (lbs)

Max. EPR

Evaluated EPR

Delta EPR

EPR Modifier No.

1

30650

1.613

1.605

plus 0.008

06

2

29050

1.562

1.555

plus 0.007

06

3

26220

1.477

1.472

plus 0.005

07

4

24200

1.422

1.416

plus 0.006

06

5

23930

1.414

1.409

plus 0.005

07

6

22500

1.376

1.372

plus 0.004

07

7

21750

1.357

1.354

plus 0.003

07

8

17100

1.251

1.250

plus 0.001

08

For EEC software SCN 19 and below, the correct data entry plug EPR modifier number for this example is 08, because it is the highest modifier number which gives the highest thrust.

Gate 8 has class 8 and gates 1 and 2 have class 6. Thus, EPR class bias is 8 - 6 = 2.

Delta EPR bias is EPR class bias of 2 multiplied by 0.003 : 0.006.

For EEC software SCN 20 and above, make a selection of the highest EPR modifier number of all gates (1 - 8) and compare to the highest EPR modifier number of gates 1 and 2 to find the EPR class bias.

For SCN 20 and above:

Band

EPR-O

EPR Mod No.

Delta EPR Modifier

EPR Class Bias

Delta EPR Bias

EPR

A

1.622

08

0.000

2

0.006

1.628

B

1.486

08

0.000

2

0.006

1.487

C

1.365

08

0.000

1.365

D

1.224

08

0.000

1.224

NOTE

For Band A with EPR-O = 1.622, EPR = 1.622 plus 0 plus 0.006 = 1.628For Band B with EPR-O = 1.486, EPR = 1.486 plus 0 plus 0.006 x (1.486 - 1.477)/0.085 = 1.487For Band C with EPR-O = 1.365, EPR = 1.365 plus 0 = 1.365

An example calculation of an engine tested to the V2533 rating follows:

Apply a second order/degree curve fit through the measured corrected thrust versus measured EEC EPR.

Band

Corrected Net Thrust (lbs)

Measured EPR-O

A

31148

1.6215

B

26715

1.4858

C

22183

1.3646

D

15830

1.2244

Make a selection of the data entry plug.

You must make a mark of the Data Entry Plug EPR Modifier number and EPR class bias on the engine identification plate and the data entry plug backshell (if it is different from the current labeling). Make the mark as follows:

EPR MOD XX-0Y

Where: XX = EPR modifier number

Y = EPR class bias

NOTE

The engine data plate location is labeled EPR modifier.If necessary, set the Data Entry Plug pins to the necessary EPR modifier number and EPR class bias by TASK 71-00-00-700-011-B00 (TESTING-011, CONFIG-002).

Engine Pressure Ratio Classification

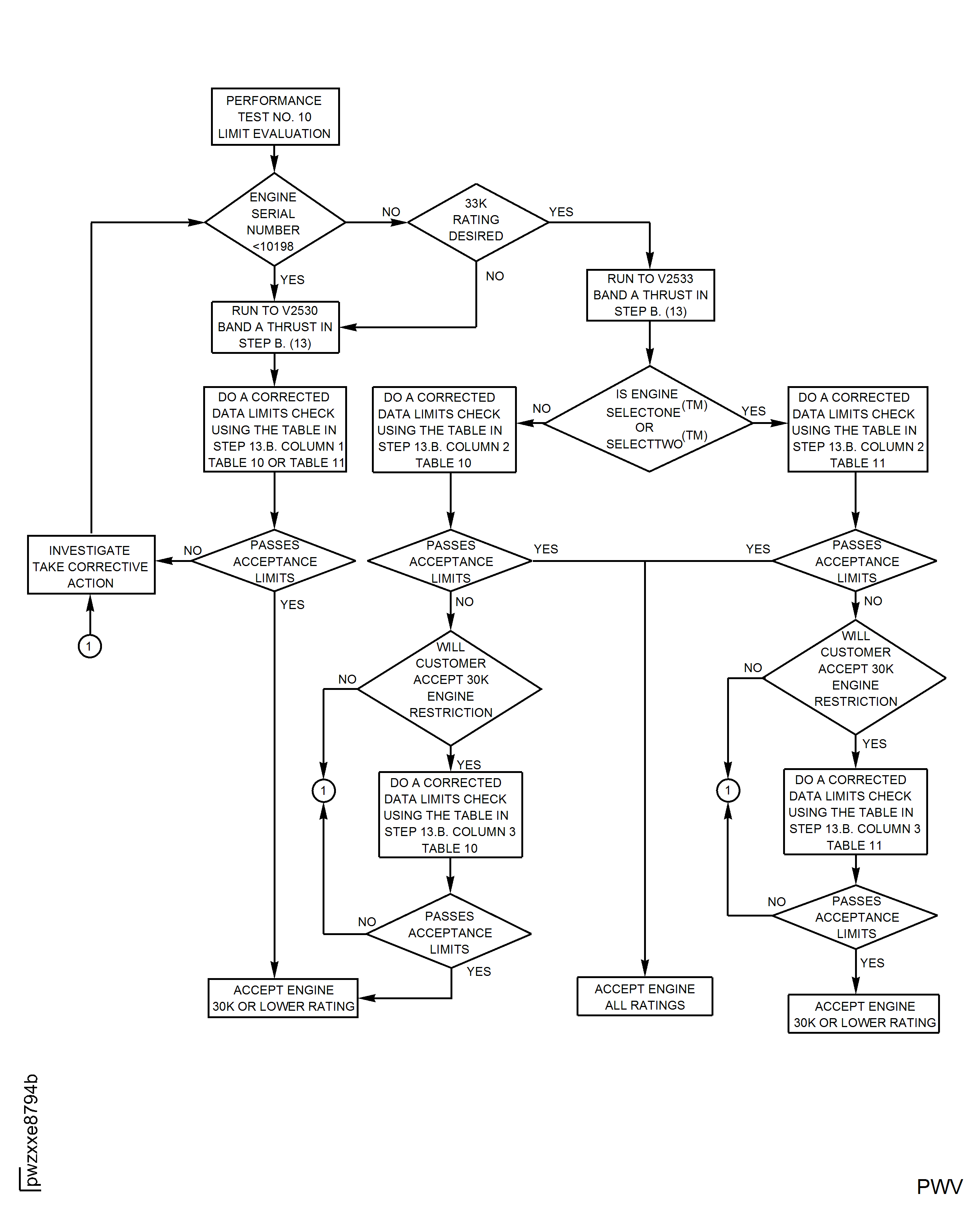

The flowchart in Figure is used to show the limit and rating selection for the different thrust ratings.

The corrected N1 and N2 level must not be more than the limits specified below. The value is obtained by plotting a graph of EPR versus corrected N1 or N2 with a second degree fit interpolating the graph at the specified EPR in the table below. Engines that are to be tested to the V2533-A5 rating are defined in paragraph 6B of test No. 10.

The acceptance rotor speeds (N1 and N2) and EGT margin criteria for Standard A5 (Table), SelectOne(TM) and SelectTwo(TM) (Table) are as follows:

Table 10. Standard A5 Column 1

Column 2

Column 3

Column 4

Standard V2500-A5 engine acceptance limit

Tested to the V2530-A5 rating

Tested to the V2533-A5 Rating

Tested to the V2533-A5 Rating

V2533-A5 rating

V2530-A5 rating (*)

V2533-A5 rating with more open VSV schedule (**)

Corrected N1 limit, rpm

5287 at 1.56 EPR

5440 at 1.61 EPR

5287 at 1.56 EPR

5440 at 1.61 EPR

Corrected N2 limit, rpm

13820 at 1.40 EPR

13765 at 1.40 EPR

13820 at 1.40 EPR

13820 at 1.40 EPR

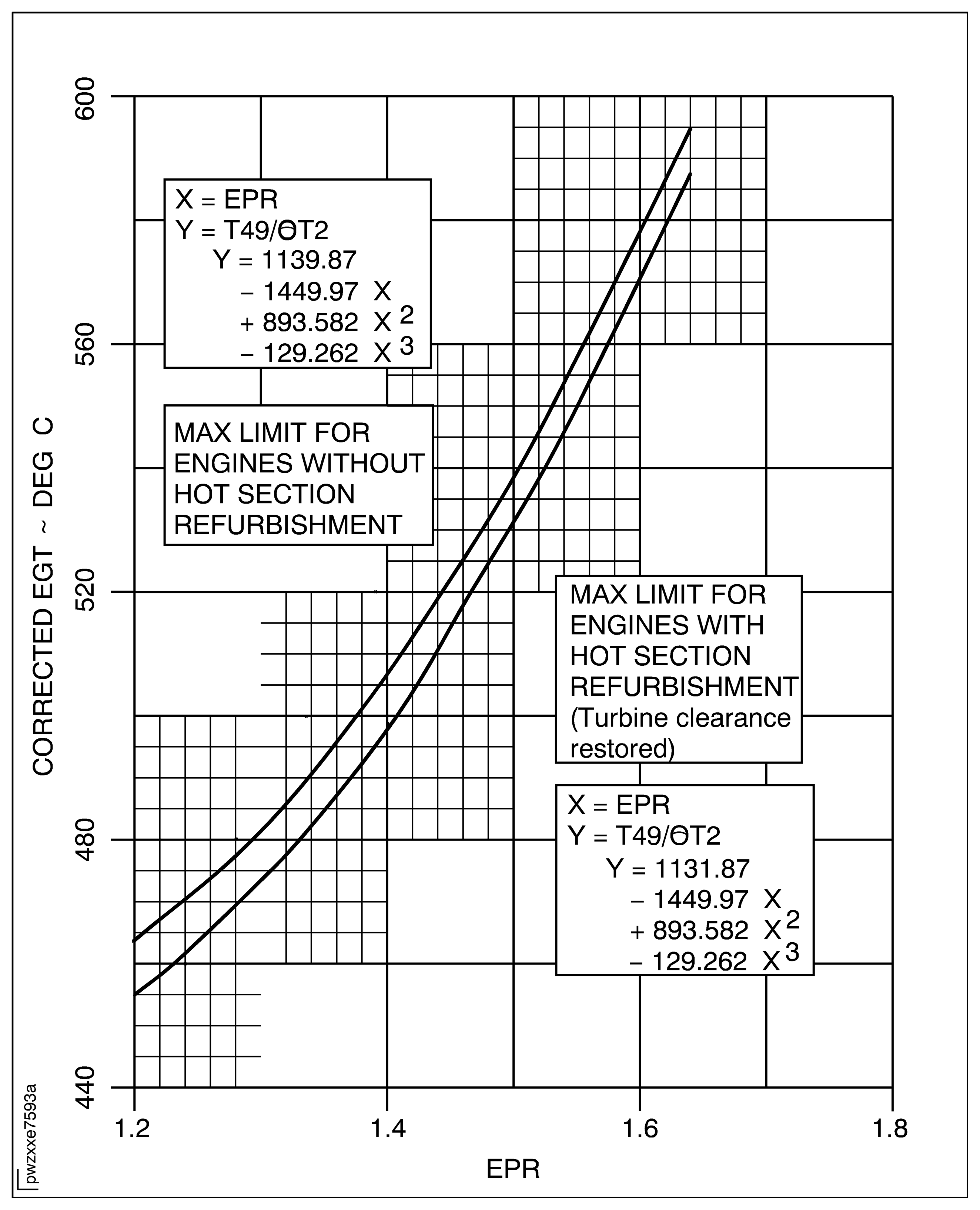

Corrected EGT limit, deg C

Figure at 1.4 EPR

Figure at 1.4 EPR

Figure at 1.4 EPR

Figure at 1.4 EPR

Table 11. SelectOne(TM) and SelectTwo(TM) Column 1

Column 2

Column 3

SelectOne(TM) and SelectTwo(TM) engine acceptance limit

Tested to the V2530-A5 rating

Tested to the V2533-A5 Rating

V2533-A5 rating

V2530-A5 rating (*)

Corrected N1 limit, rpm

5287 at 1.56 EPR

5410 at 1.61 EPR

5287 at 1.56 EPR

Corrected N2 limit, rpm

13820 at 1.40 EPR

13725 at 1.40 EPR

13820 at 1.40 EPR

Corrected EGT limit, deg C

Figure at 1.4 EPR

Figure at 1.4 EPR

Figure at 1.4 EPR

NOTE

(*) All Standard A5, SelectOne(TM) and SelectTwo(TM) engines tested to the V2533-A5 rating that do not meet the V2533-A5 rating acceptance limits, but meet the V2530-A5 rating acceptance limits, may be released for service operation at the V2530-A5 and lower ratings if the conditions listed above in paragraph Step are met.(**) Standard A5 engines with a corrected N2 rotor speed (rpm) more than 13765 @ 1.4 EPR, but less than 13820 @ 1.4 EPR can be released with V2533-A5 rating capability if the engine has implemented the revised HPC R4 Blade (SB 72-0295) and SCN-21 (SB 73-0222) and onward software. Make a record that the engine requires the more open VSV schedule. If the engine will be shipped with the V2533-A5 rating, modify the DEP per SB 73-0225.Tell the test engineer if any acceptance limits are exceeded.

Always use the higher EGT limit curve (unless you do the performance test after you do a complete overhaul of the hot section).

Only use the lower EGT limit curve after you complete a hot section overhaul and the turbine clearances are put back to initial condition or the engine has not flown with the active clearance control (ACC) system on.

The EGT limit curve contained in Figure is based on takeoff worst case operating condition. Sea level, 131 deg F (55 deg C) outside air temperature (OAT). If it is necessary to determine EGT margin at conditions other than worse case reference, refer to SIL-057.

Figure gives two maximum EGT limit curves.

Do a Corrected Data Limits Check

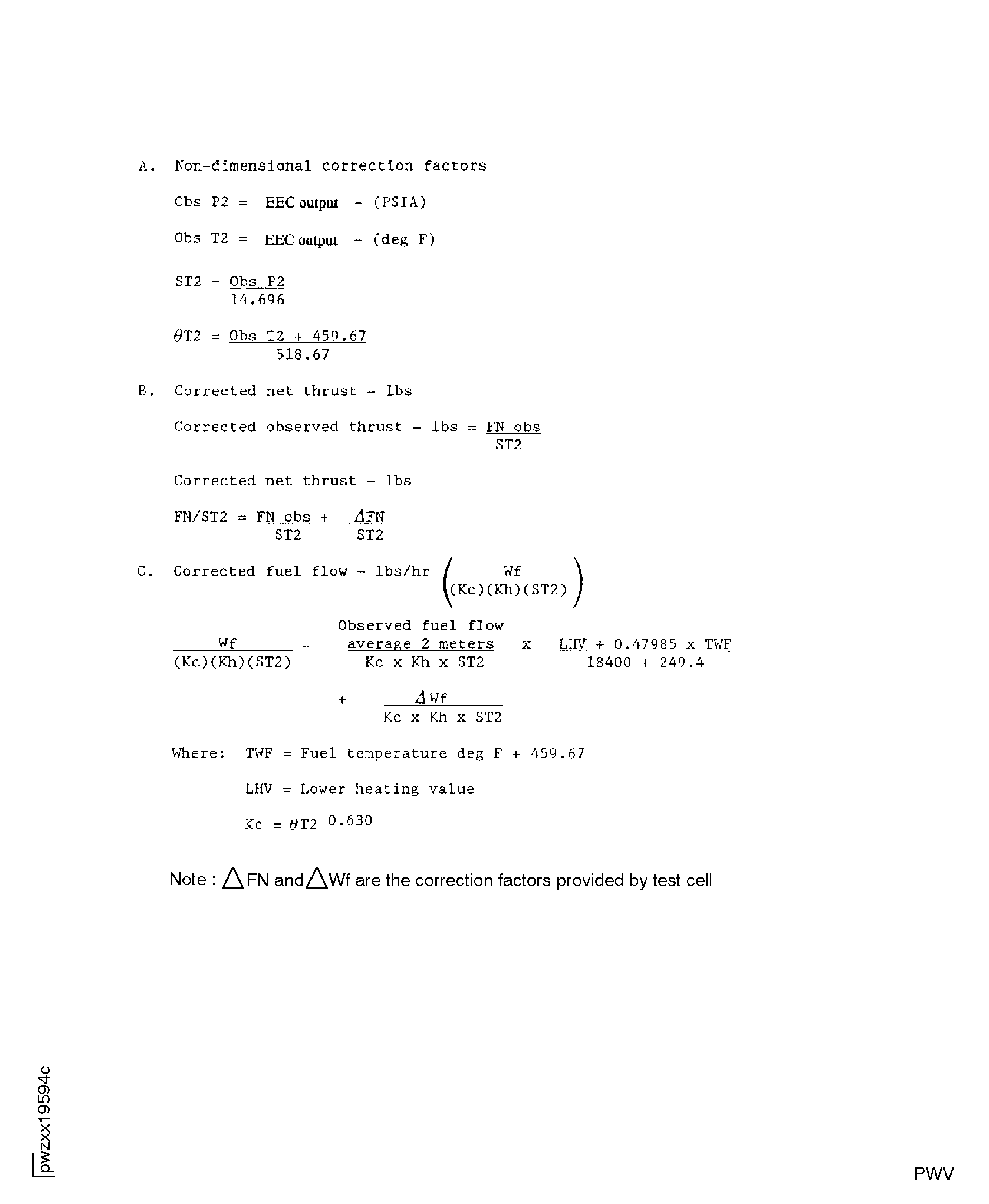

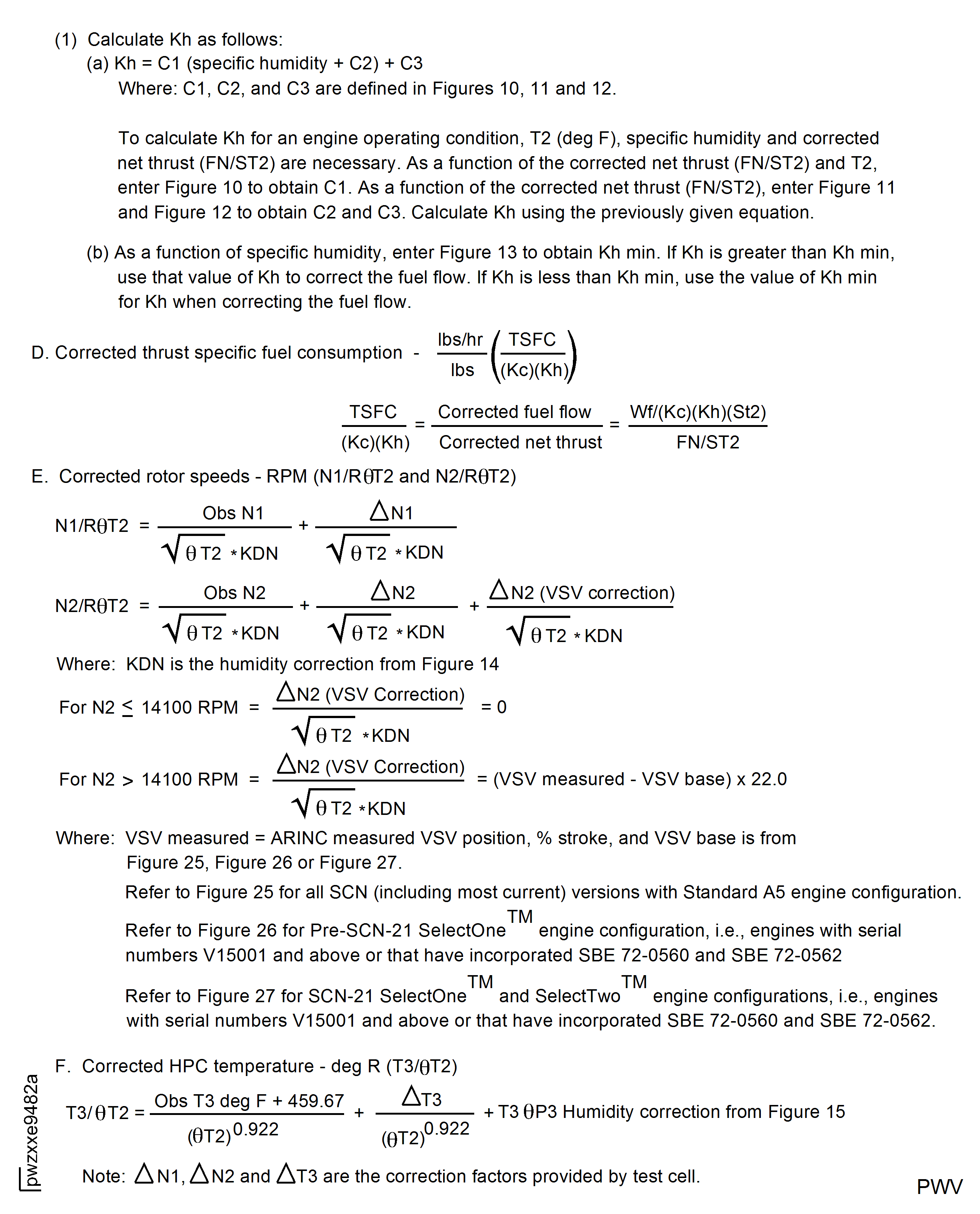

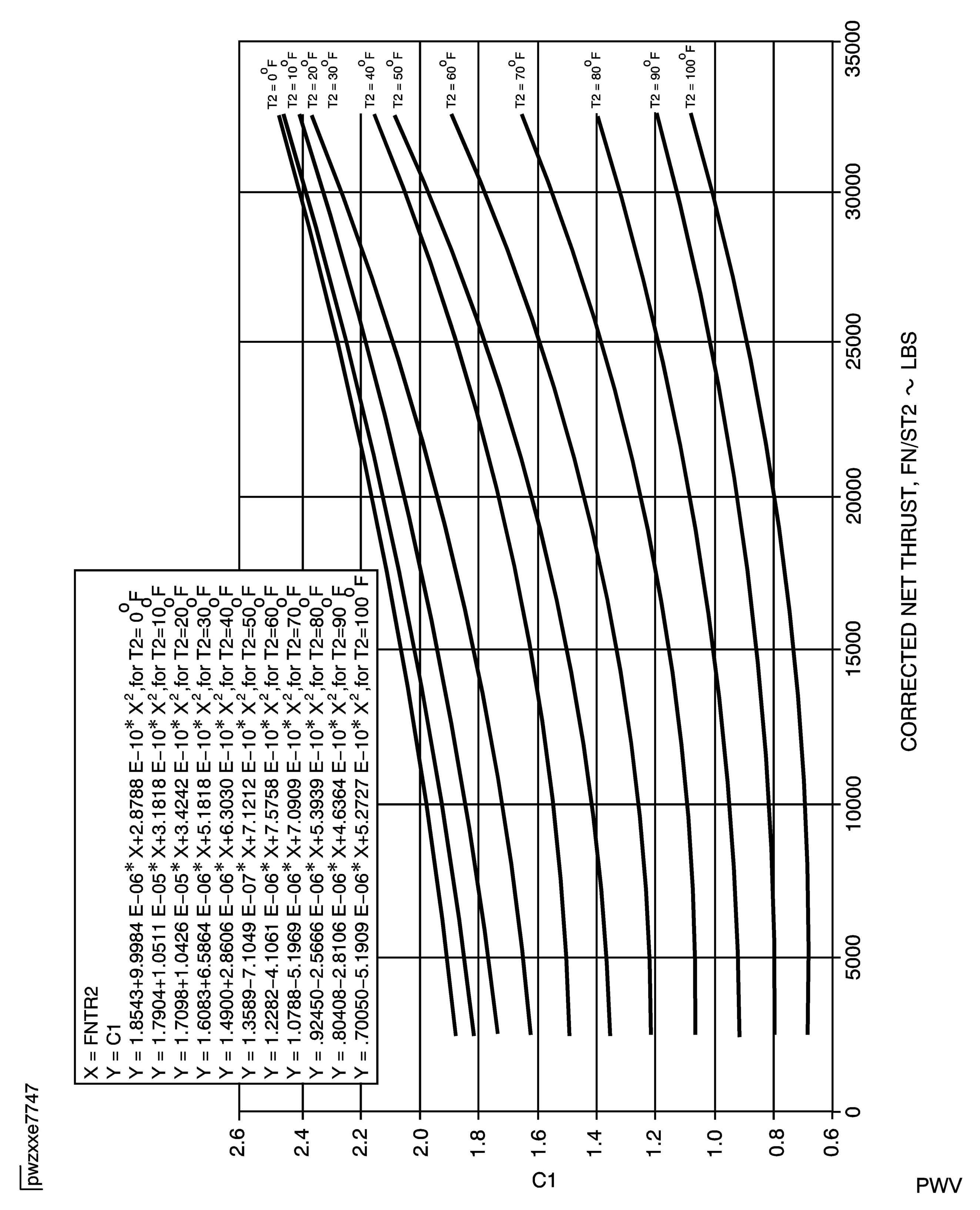

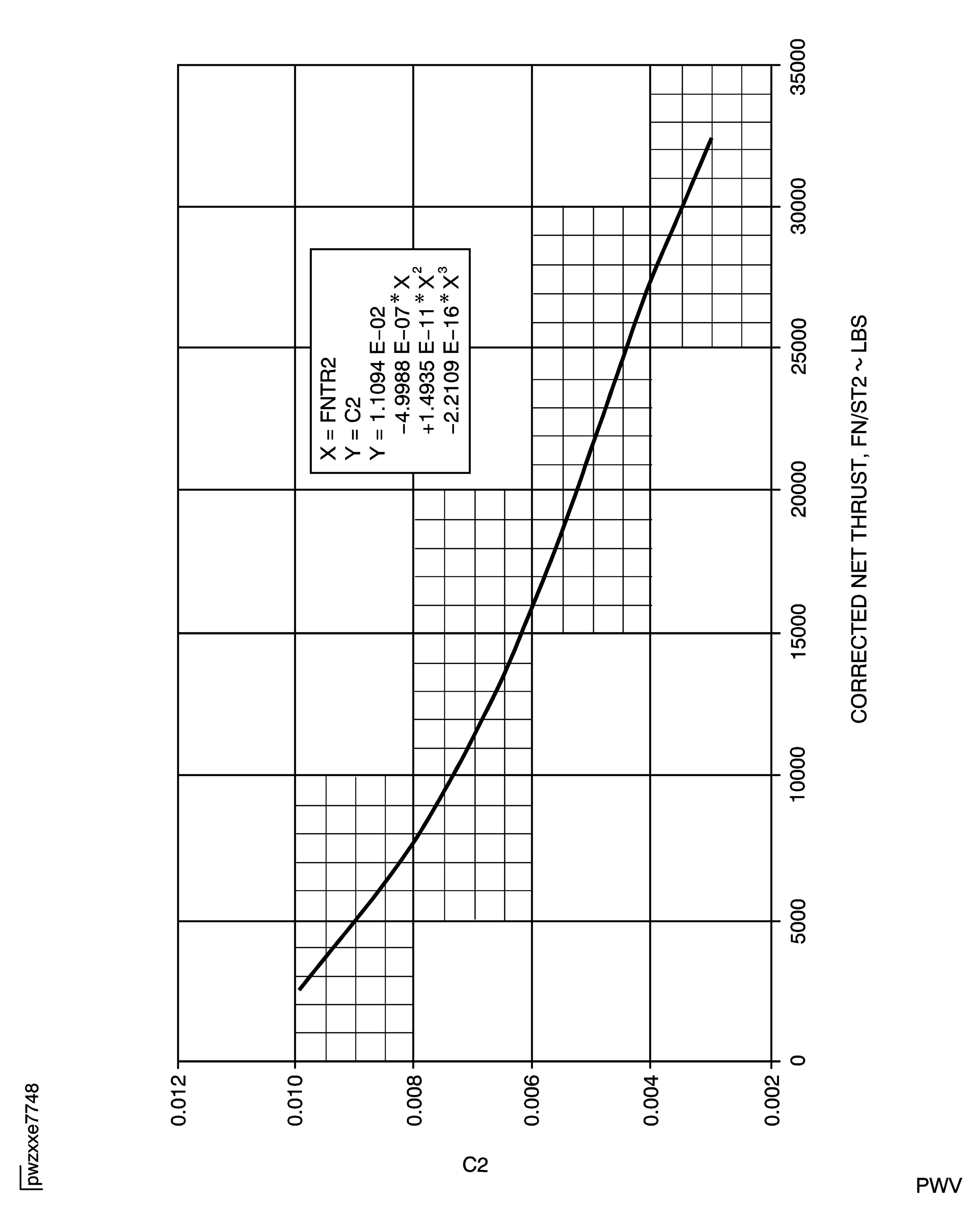

Figure: Data Calculation and Correction

Data Calculation and Correction

Figure: Data Calculation and Correction

Data Calculation and Correction

Figure: Data Calculation and Correction

Data Calculation and Correction

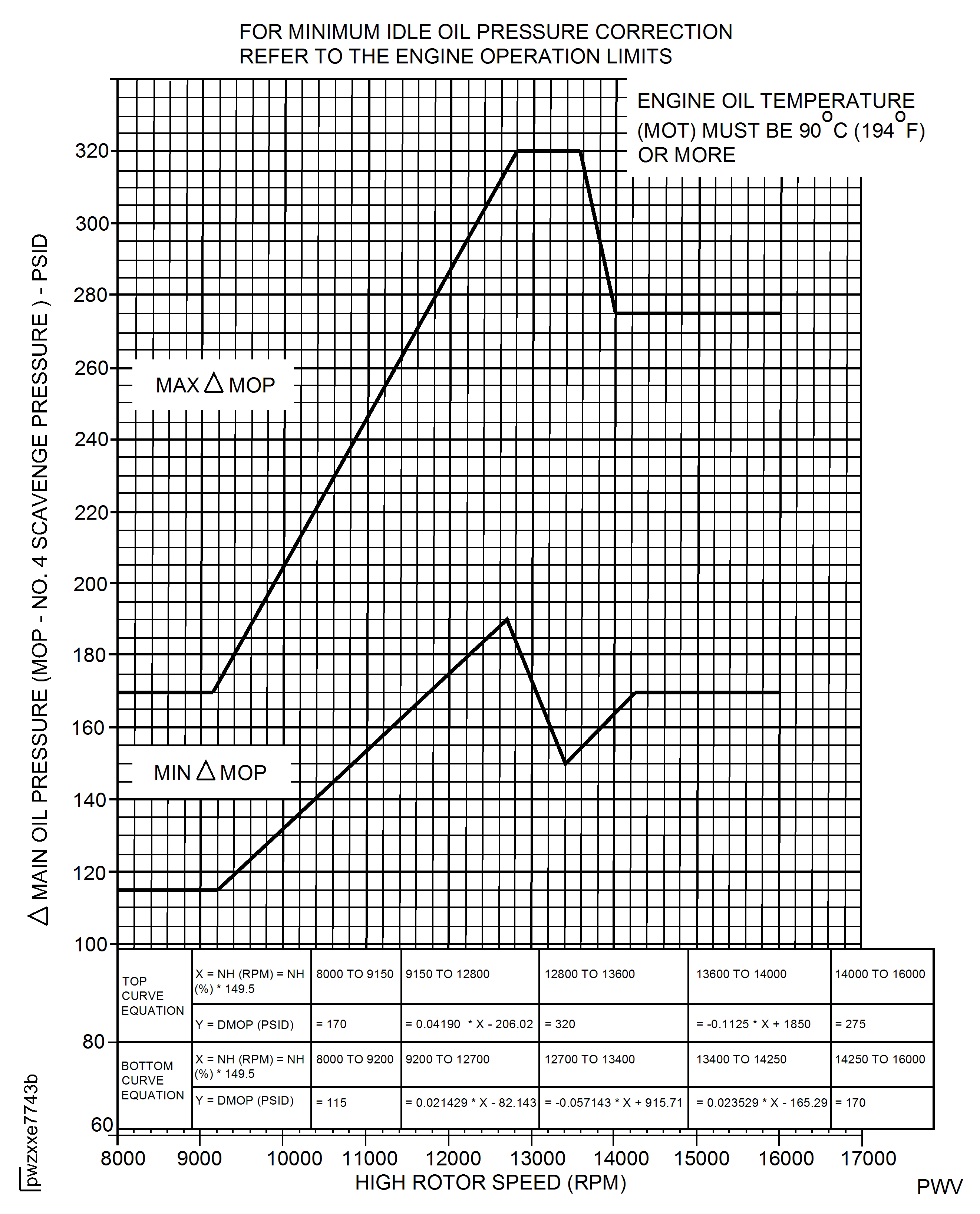

Figure: Minimum Allowable Delta MOP Versus N2

Minimum Allowable Delta MOP Versus N2

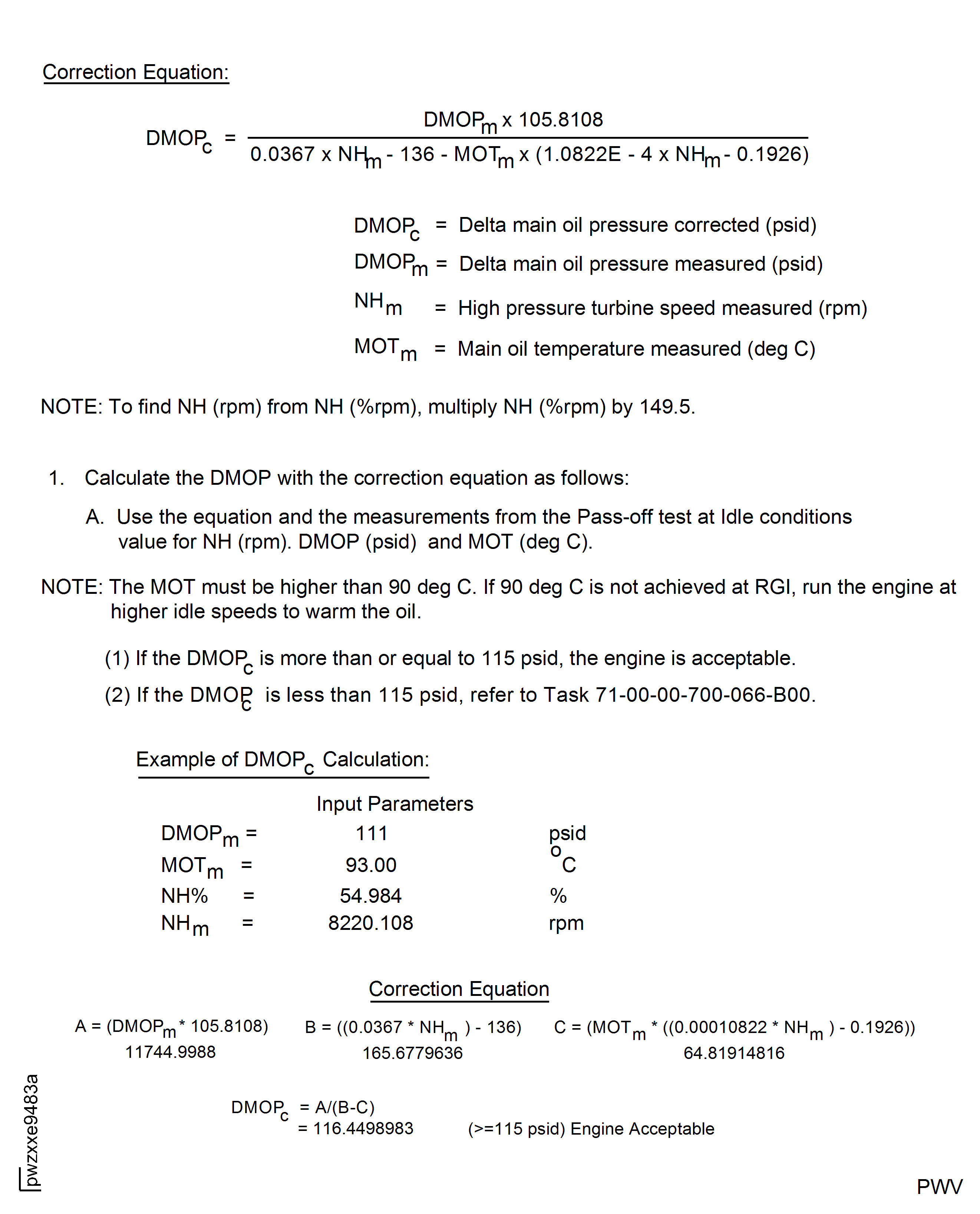

Figure: Delta Main Oil Pressure (DMOP) Idle Correction Equation

Delta Main Oil Pressure (DMOP) Idle Correction Equation

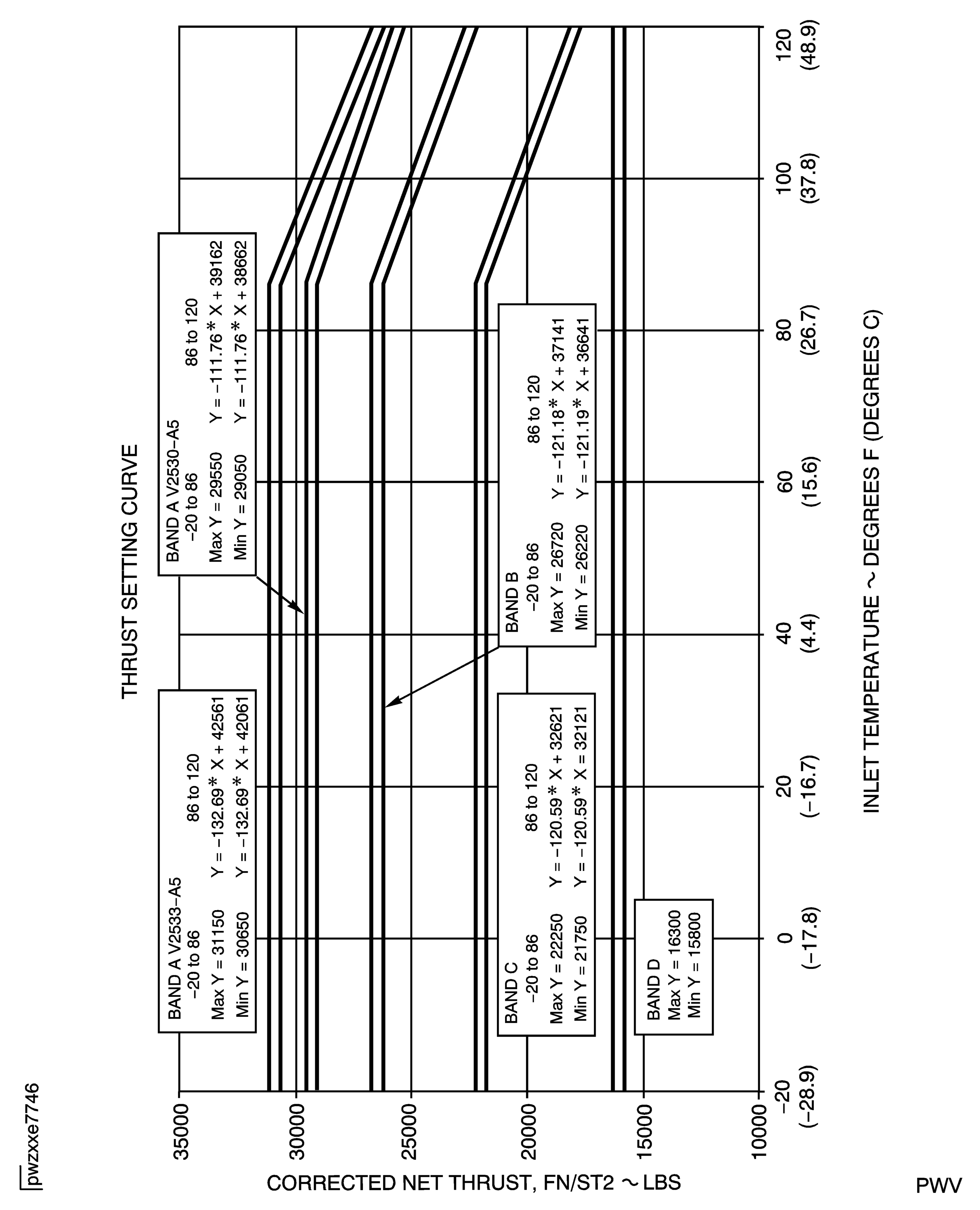

Figure: Thrust Setting Curve

Thrust Setting Curve

Figure: Gas Generator Guidelines Curve

Gas Generator Guidelines Curve

Figure: EGT Limit Curve

EGT Limit Curve

Figure: Limit and Rating Selection for Different Thrust Ratings

Limit and Rating Selection for Different Thrust Ratings

Figure: C1 Humidity/Condensation Correction Factor for WF

C1 Humidity/Condensation Correction Factor for WF

Figure: C2 Humidity/Condensation Correction Factor for WF

C2 Humidity/Condensation Correction Factor for WF

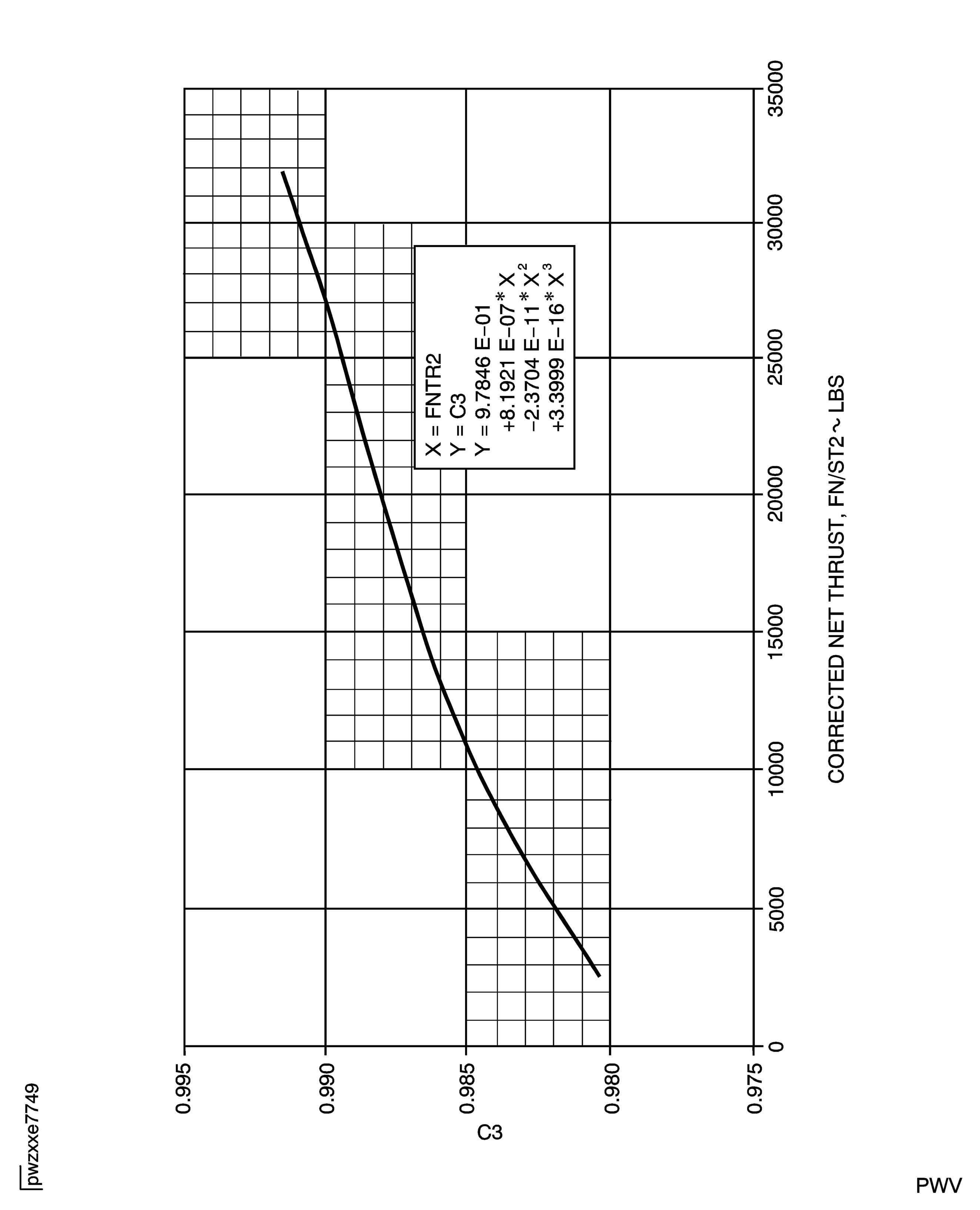

Figure: C3 Humidity/Condensation Correction Factor for WF

C3 Humidity/Condensation Correction Factor for WF

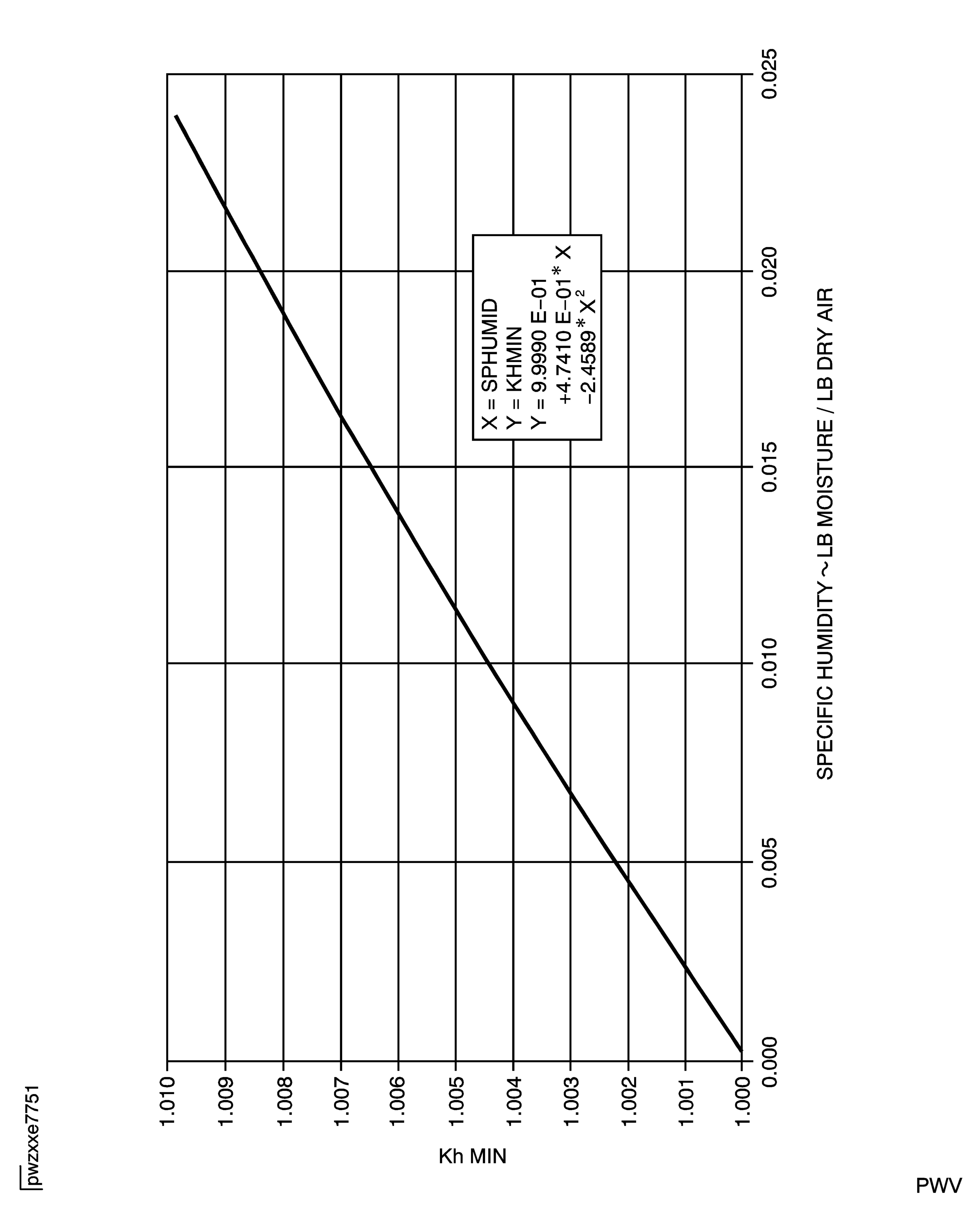

Figure: Kh MIN - Humidity/Condensation Correction Factor for WF

Kh MIN - Humidity/Condensation Correction Factor for WF

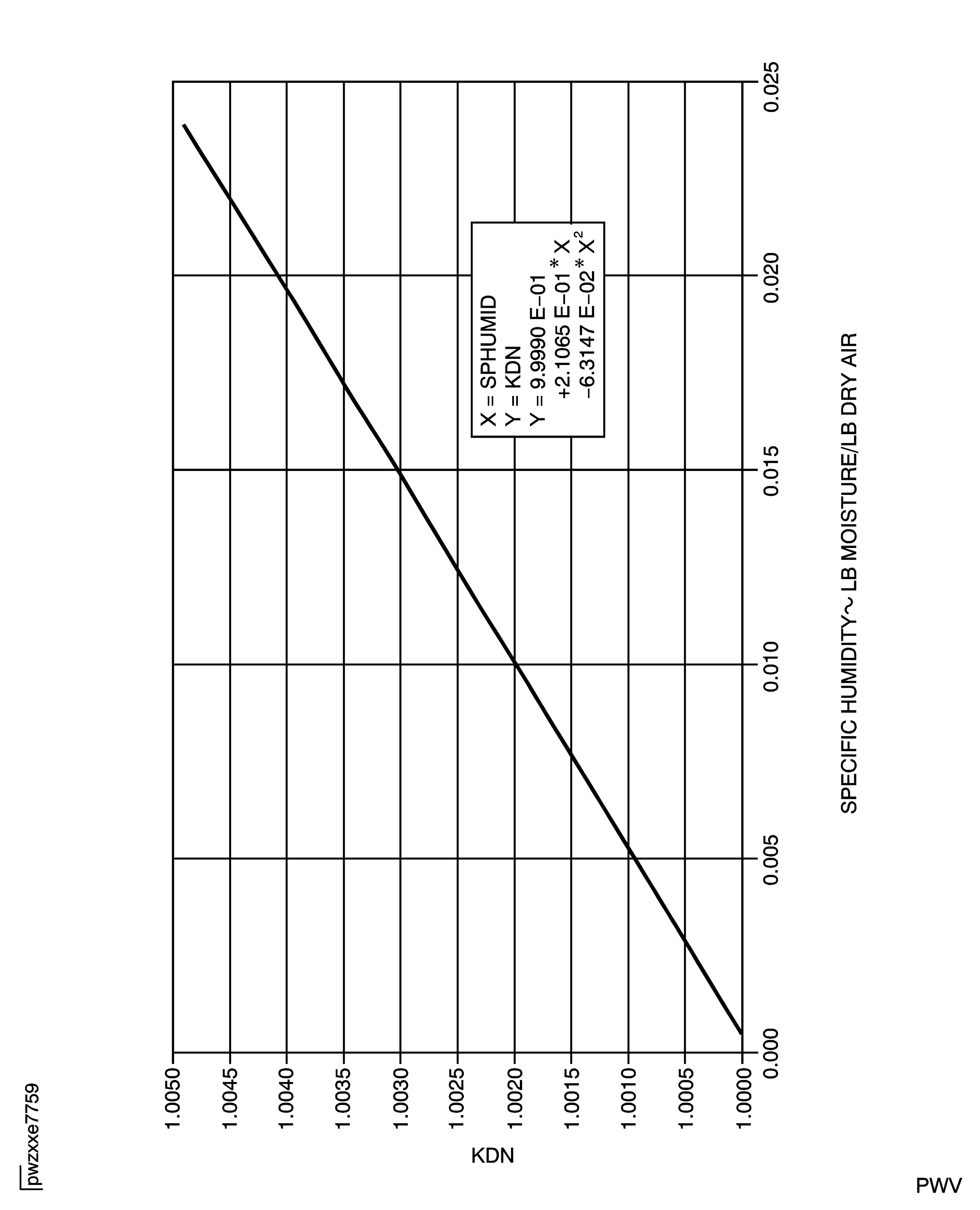

Figure: Humidity Correction Factor for N1 and N2 Rotor Speeds

Humidity Correction Factor for N1 and N2 Rotor Speeds

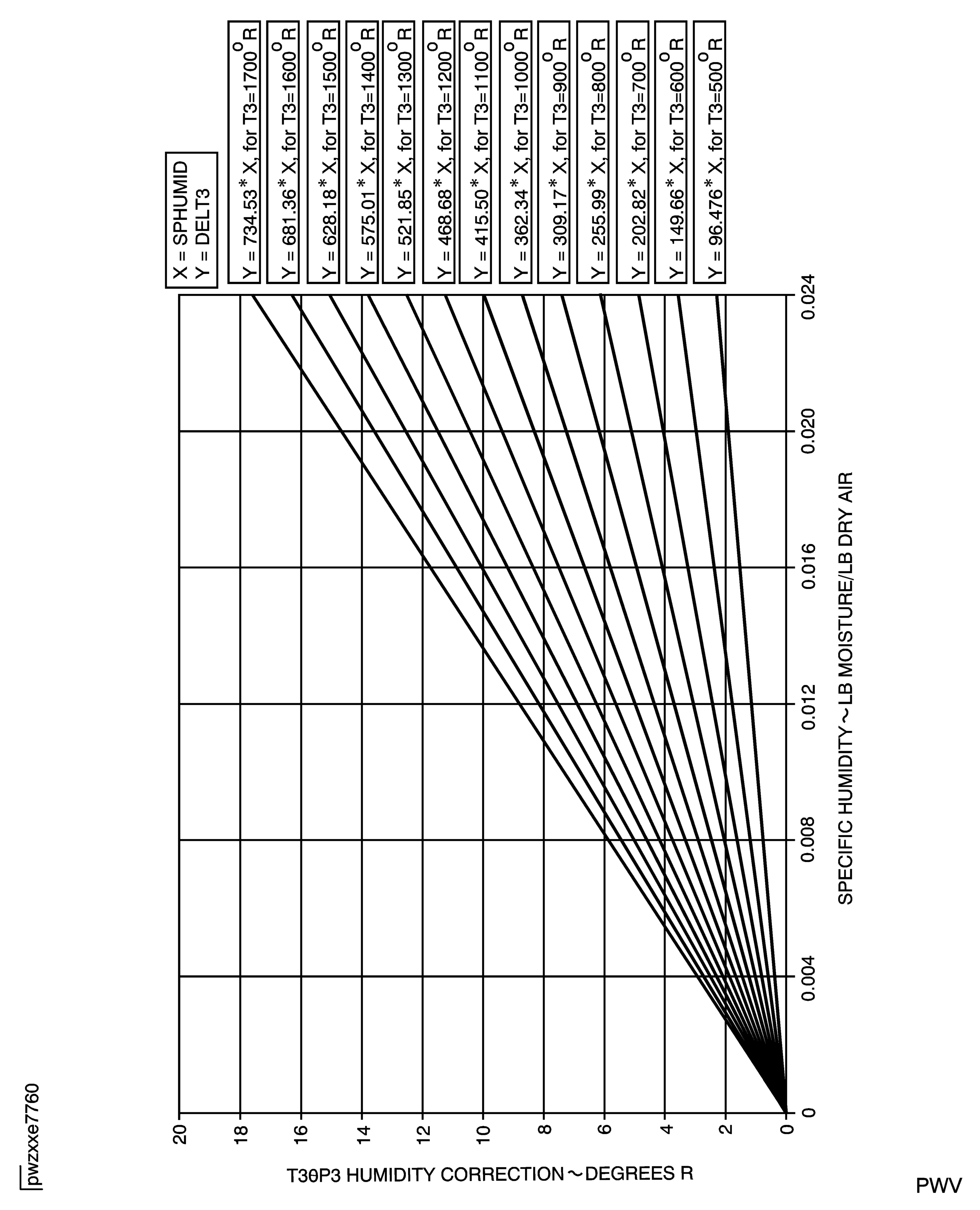

Figure: Humidity Correction Factor for T3

Humidity Correction Factor for T3

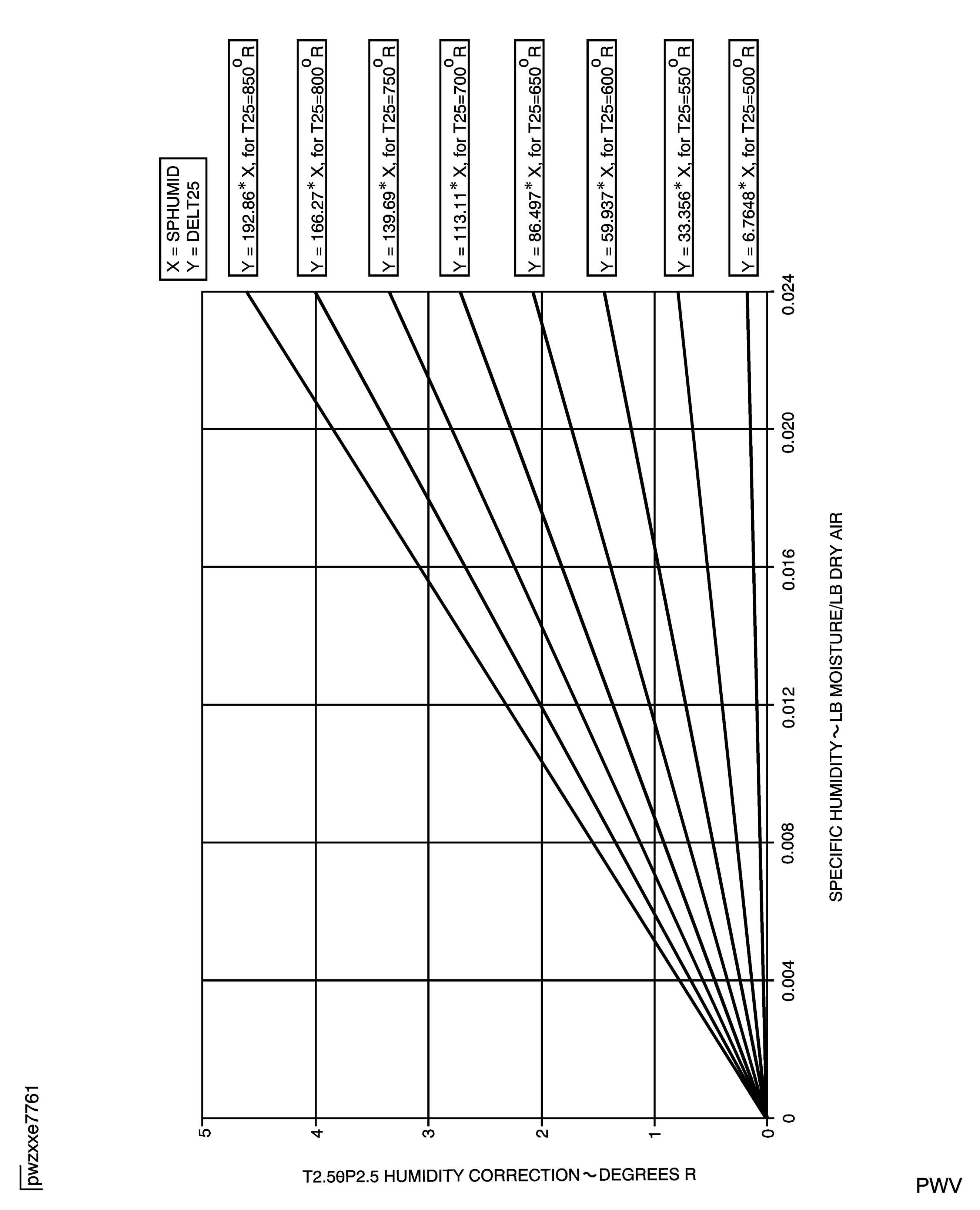

Figure: Humidity Correction Factor for T2.5

Humidity Correction Factor for T2.5

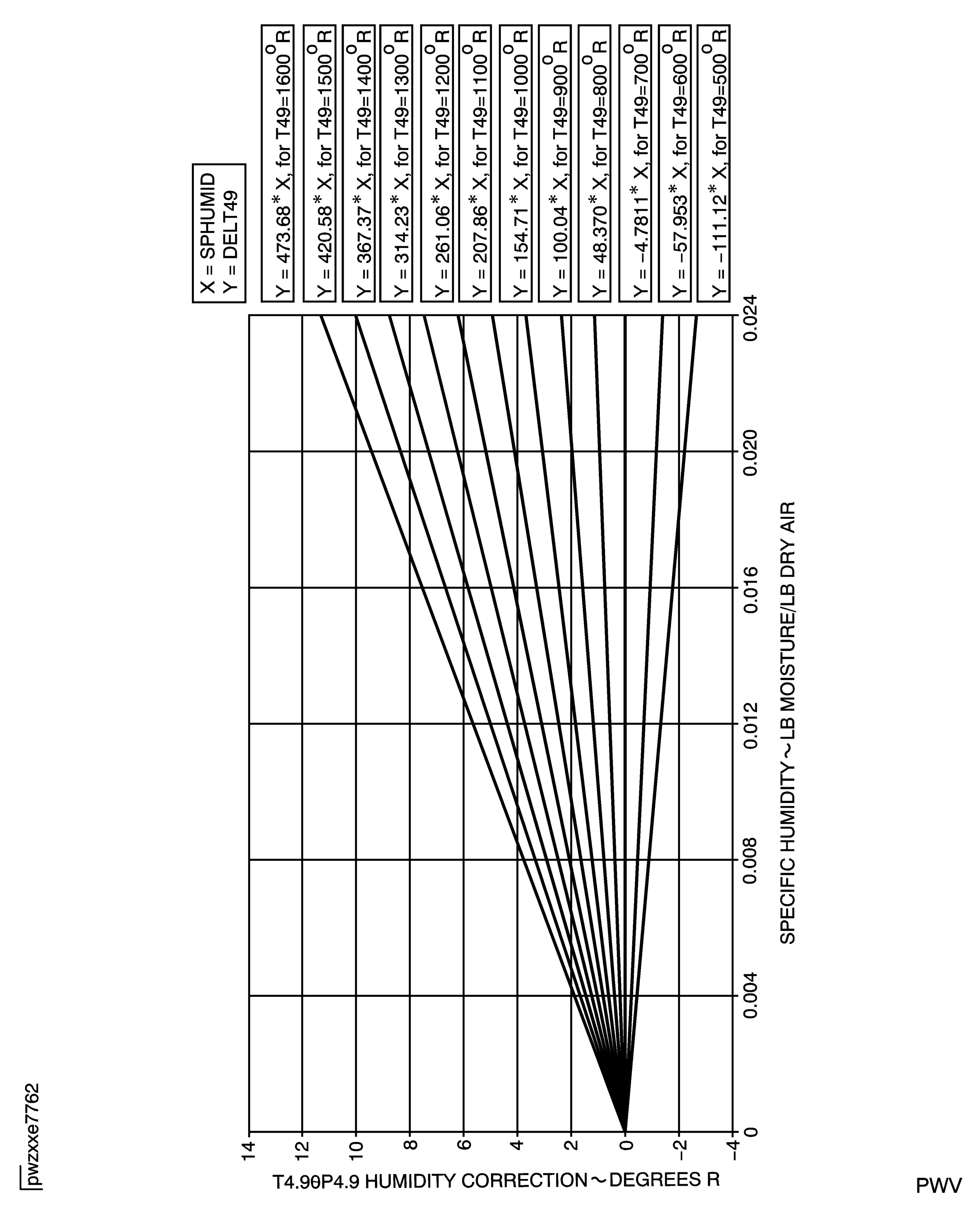

Figure: Humidity Correction Factor for T4.9

Humidity Correction Factor for T4.9

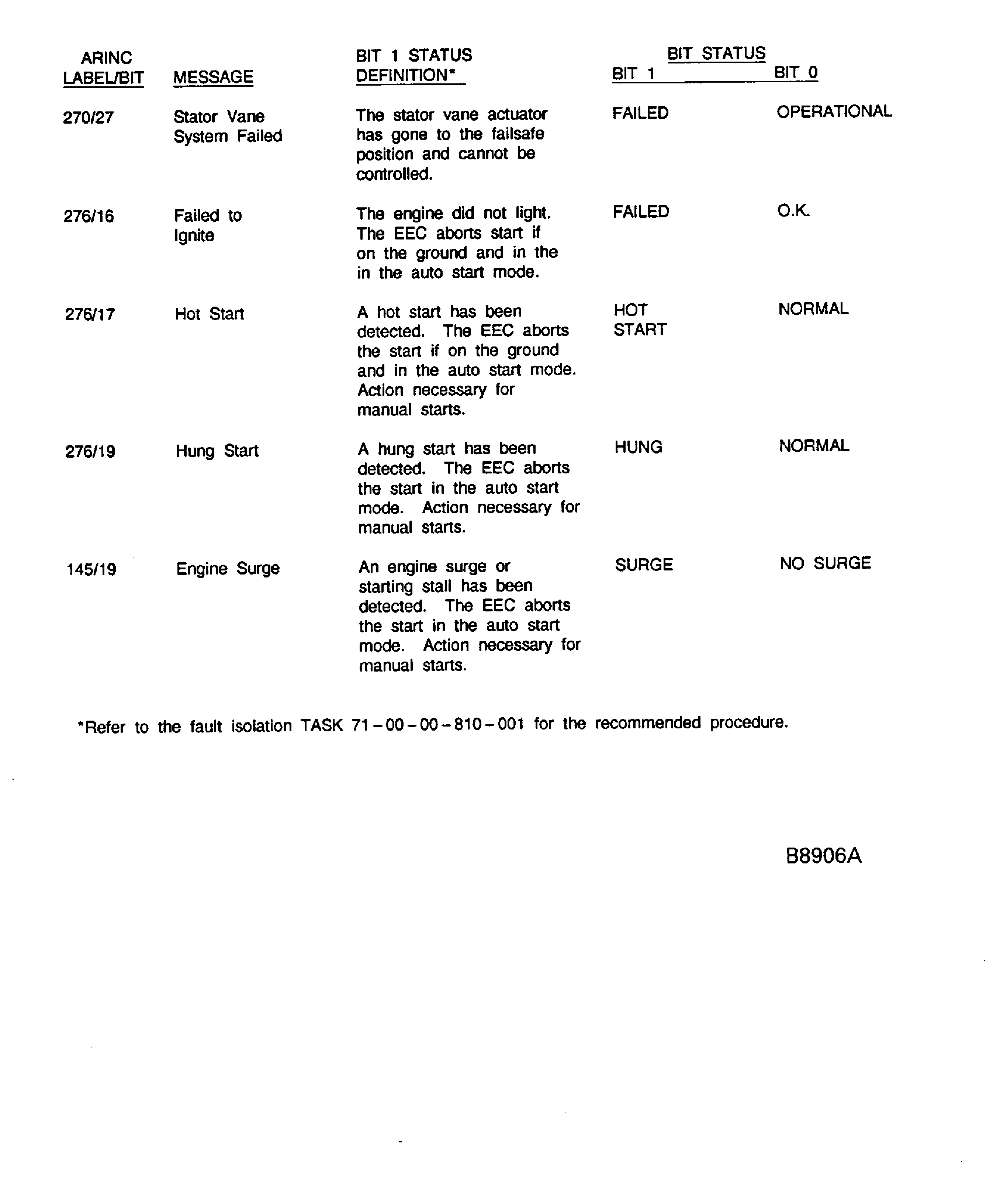

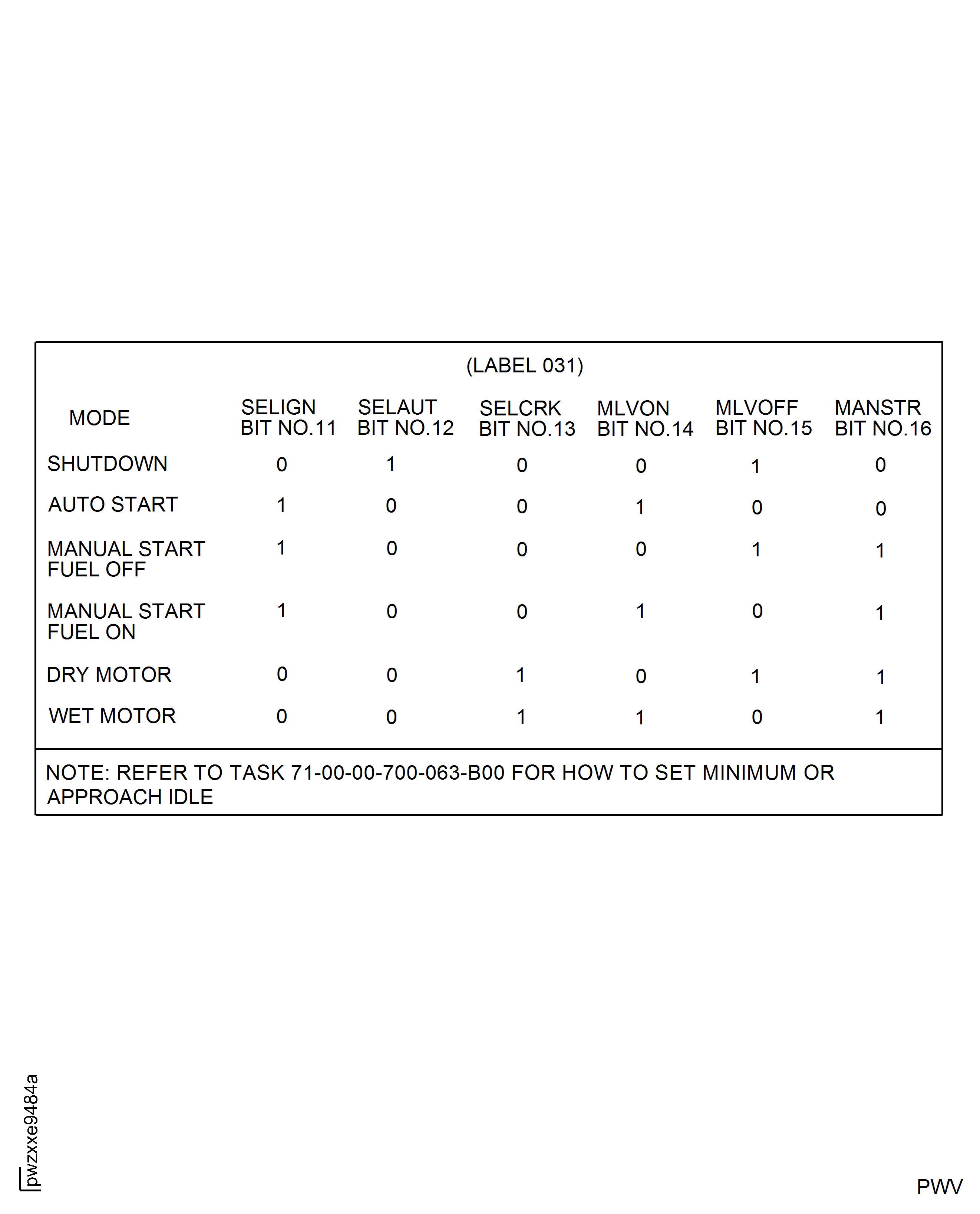

Figure: EEC Output Status Messages

EEC Output Status Messages

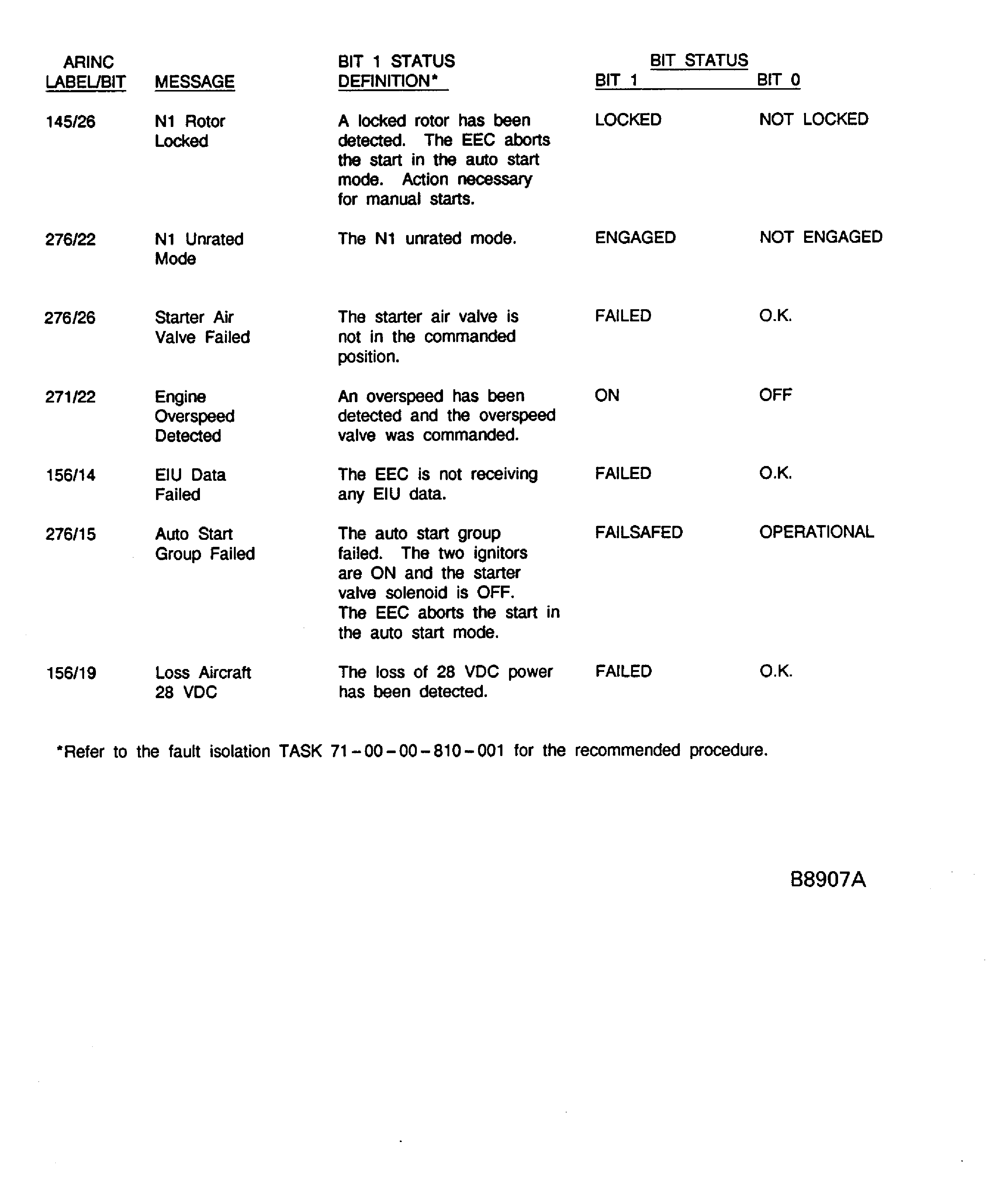

Figure: EEC Output Status Messages

EEC Output Status Messages

Figure: EEC Output Status Messages

EEC Output Status Messages

Figure: EEC Output Status Messages

EEC Output Status Messages

Figure: EIU Inputs

EIU Inputs

Figure: No.4 Bearing Scavenge Valve Position

No.4 Bearing Scavenge Valve Position

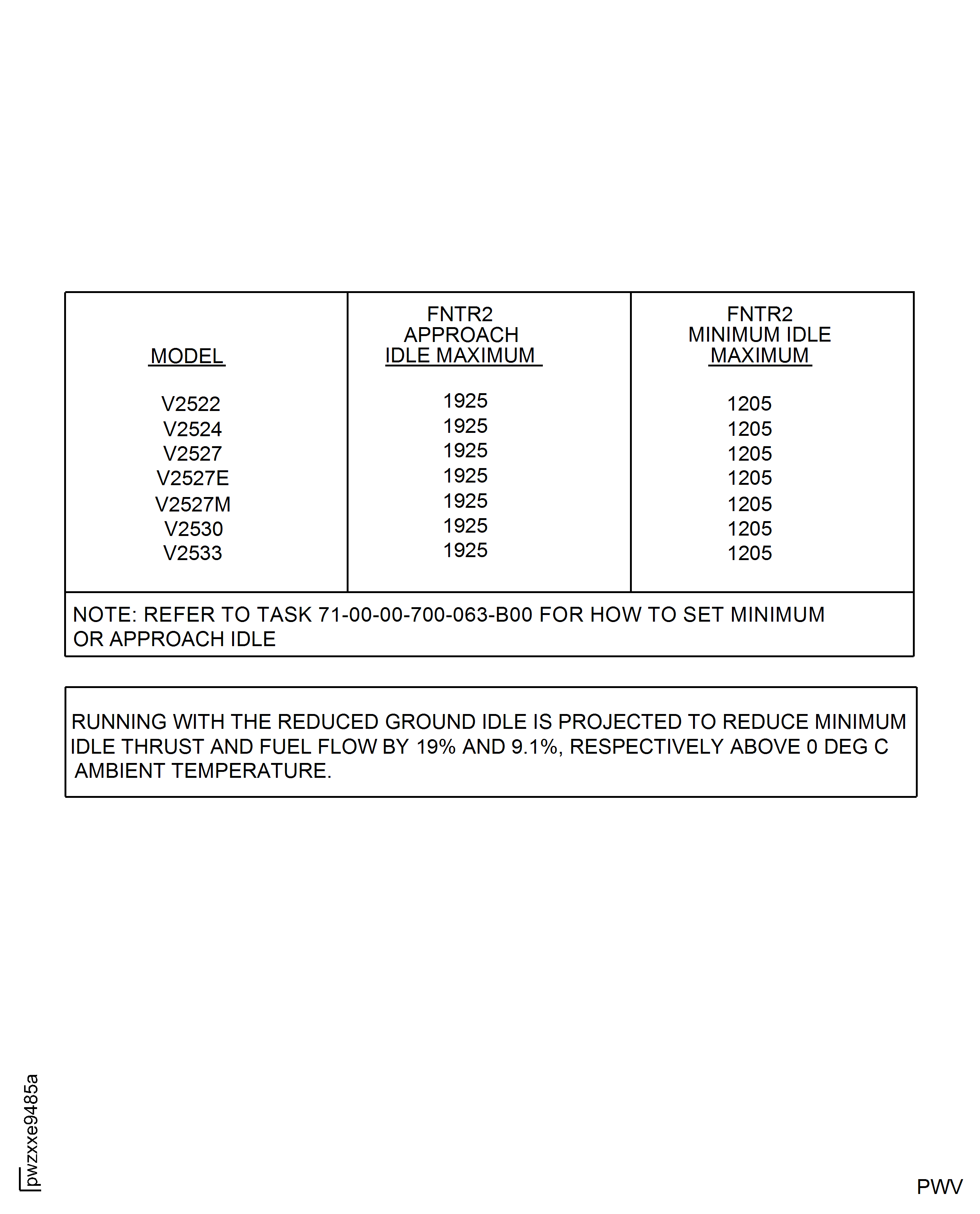

Figure: Approach and Minimum Idle Settings

Approach and Minimum Idle Settings

Figure: Standard A5 Base Variable Stator Vane Schedule

Standard A5 Base Variable Stator Vane Schedule

Figure: SelectOne(TM) Base Variable Stator Vane Schedule Pre - SCN 21

SelectOne(TM) Base Variable Stator Vane Schedule Pre - SCN 21

Figure: SCN21 SelectOne(TM) and SelectTwo(TM) Base Variable Stator Vane Schedule

SCN21 SelectOne(TM) and SelectTwo(TM) Base Variable Stator Vane Schedule