Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 71-00-00-700-053-B02 Normal Engine Manual Start Procedure, Testing-000

Normal Engine Manual Start Procedure

General

If the engine was shutdown for more than 10 hours, motor the engine with the starter for a minimum of two minutes. Check the oil level after the rotor stops. Fill the oil tank as necessary. Refer to TASK 71-00-00-700-064-B00 (TESTING-000, CONFIG-002).

If the engine was shutdown for less than 10 hours, check the oil level. Fill the oil tank as necessary. Refer to TASK 71-00-00-700-064-B00 (TESTING-000, CONFIG-002).

Before the first start after an overhaul, or if you drained the fuel or oil compartments to repair the engine, prime the oil and fuel systems. Refer to TASK 71-00-00-700-061-B00 (TESTING-000, CONFIG-002).

Before you start the engine, refer to procedure for a Bowed Rotor Start Prevention. Refer to TASK 71-00-00-700-065-B00 (TESTING-000, CONFIG-002).

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

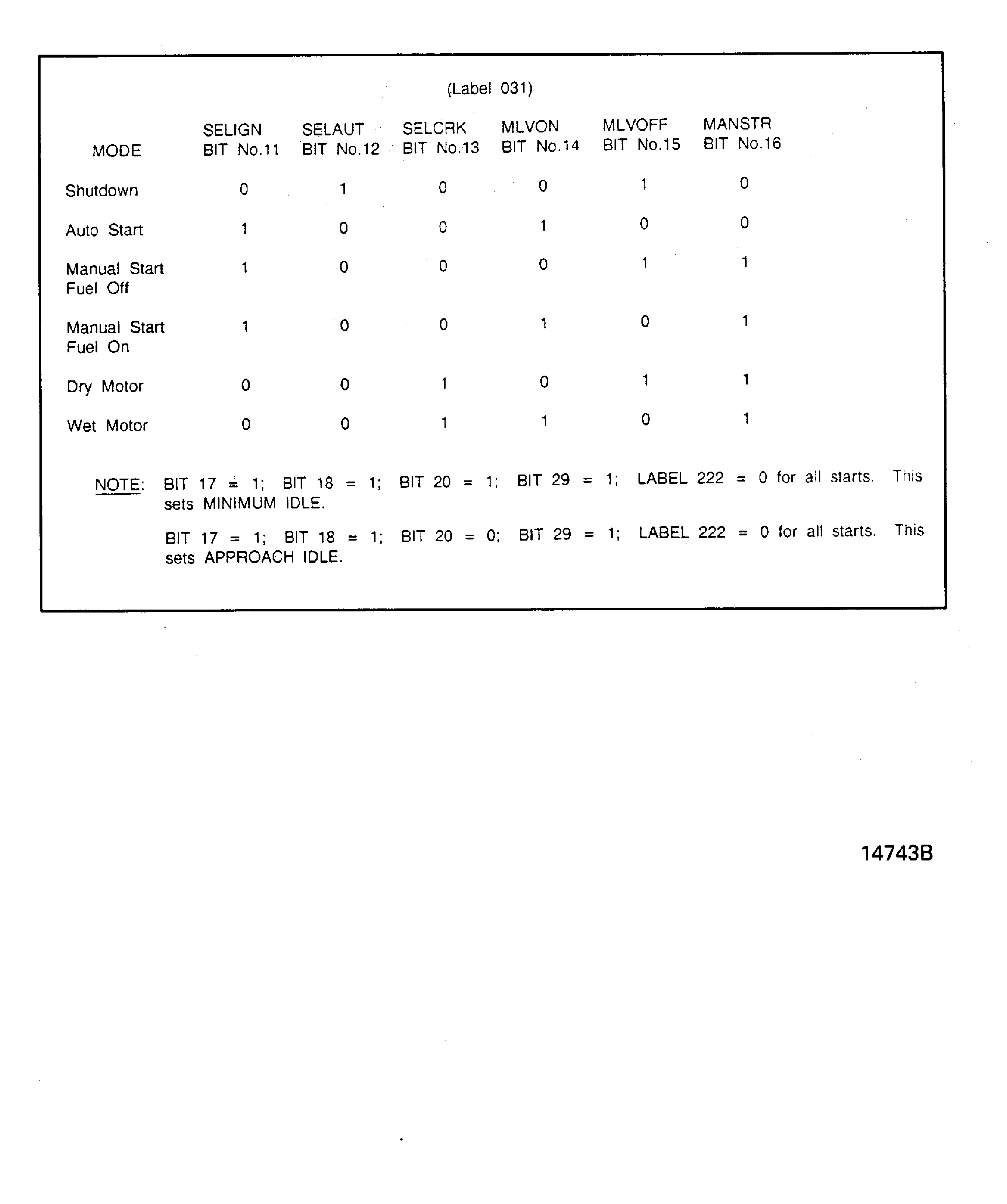

Set the Electronic Engine Control (EEC) in the SHUTDOWN mode. Refer to Figure.

Turn on the test stand starter air.

Turn on the EEC ground test power.

Turn on the 400 Hz igniter power.

Turn on the fuel supply system.

Set the thrust lever to the idle flat.

Set the necessary Engine Interface Unit (EIU) inputs to the MANUAL START/FUEL OFF as shown in Figure.

Make sure that N2 increases.

At 2500 RPM N2, set the EIU inputs to the MANUAL START/FUEL ON mode shown in Figure. The EEC automatically turns off the ignition. Test stand operation should manually cut starter out at 5500 NH RPM.

Monitor the EGT and N2 carefully during the start. If the EGT increases rapidly to 1175 deg F (635 deg C) and N2 is sluggish, abort the manual start. Refer to TASK 71-00-00-700-054-B00 (TESTING-000, CONFIG-002).

If the EGT is more than the start temperature limits, shut the engine down immediately. Write the length of time and the highest temperature during over temperature. Refer to the Fault Isolation TASK 71-00-00-810-017 (FAULT ISOLATION-017).

There is no N1 turn immediately after the EGT increases or when N2 is more than 5083 RPM.

More than 90 seconds is necessary to accelerate from FUEL ON to IDLE N2.

The EGT does not increase in less than 20 seconds after FUEL ON.

The fuel or ignition is accidentally stopped.

The oil pressure does not increase.

Abort the start if:

If you aborted the start, motor the engine for 60 seconds to remove caught fuel or gases, or until the EGT decreases below 482 deg F (250 deg C).

Do the manual start.

No minimum warm-up time is necessary after a usual engine shutdown, if the engine is started again in less than two hours.

If the engine was shut down for more than two hours, operate the engine at MIN IDLE for five minutes. This keeps thermal stresses to a minimum. The engine must be warmed-up until the oil temperature is a minimum of 14 deg F (-10 deg C) before you move the thrust lever forward.

Engine warm-up

Normal Engine Manual Start Procedure, Testing-000

Refer to Figure for Start Fault Diagnostics.

Start Fault Diagnostics

Figure: Engine interface unit (EIU) inputs

Engine interface unit (EIU) inputs

Figure: Start fault diagnostics

Start fault diagnostics